Principles of Refrigeration

PROCESSING

The food industry relies heavily on refrigeration in manufacturing, distribution, and retail sales. In spite of this reliance, refrigeration has often been taken for granted as a usually reliable utility or service. In some segments of the food industry, refrigeration may be a major consumer of energy, and more recently, it has become a target of regulation because of its potential impact on the environment. To understand these developments, we will briefly review some refrigeration basics.

Refrigeration Cycles

Mechanical refrigeration, as distinct from cryogenic refrigeration, which relies on cold, liquefied gases, uses compression of various chemicals or working fluids to transfer energy from a low temperature to a higher temperature in just the opposite direction from that in which energy flows naturally. This transfer is accomplished by changing the conditions under which the working fluids can be condensed and evaporated. Condensation requires the removal of heat from a substance, while vaporization or evaporation requires the addition of heat to a substance. Refrigeration involves the removal of heat from an environment or material at one temperature and the discharge of that heat at a higher temperature, typically to the outside air at a temperature of around 100°F.

According to thermodynamics, and confirmed by common experience, heat normally flows from a high temperature region or material to a lower temperature region or material. The rate of energy transfer is proportional to the temperature difference.

Working fluids are chosen on the basis of their thermodynamic properties, including their vapor pressure as a function of temperature, their heat of vaporization (which is about the same as their heat of condensation), and their critical temperature and pressure. Desirable working fluids can be condensed around 100°F at reasonable pressures and can be evaporated at low temperatures and modest pressures. In addition, good working fluids have heats of vaporization (and condensation) that are large enough to minimize the quantities required to transfer the needed amount of energy. Finally, their critical temperatures and pressures allow for phase changes to occur in the desired temperature and pressure ranges. (Critical points define temperature and pressures above which gases cannot be condensed into liquids.)

The simplest refrigeration cycle works as follows: the working fluid is compressed to a pressure high enough that it can be condensed by exposure to ambient air in a condenser, usually made of finned tubes with a fan to improve heat transfer. The condensed fluid is expanded through a valve to create a mixture of lower temperature liquid and vapor. Normally, the vapor is separated and returned to the compressor. The liquid is provided to a heat exchanger, the evaporator, in the region to be cooled. Heat from the volume or material to be cooled causes the liquid to vaporize. The evaporator may also use finned tubes and have a circulating fan. It is common for frost to form on the evaporator coils from water vapor in the atmosphere. The vapor is returned to the compressor, and the cycle repeats. There are various, subtle refinements in commercial practice to improve the efficiency of this simple cycle, but the underlying principle remains the same.

--- PAGE BREAK ---

Preferred working fluids for refrigeration are nontoxic and noncorrosive. Common refrigerants often require some compromises among the desired properties. For instance, ammonia, commonly used in large refrigeration systems, is toxic. Sulfur dioxide, once used in home refrigerators, is corrosive and toxic. Carbon dioxide requires relatively high pressures. Propane is explosive.

A wide variety of synthetic refrigerants have been developed; they are known chemically as chlorofluorocarbons(CFC), hydrochlorofluorocarbons (HCFC), and hydrofluorocarbons (HFC). (See Food Technology 56 (7): 76-78.) CFCs contribute to the depletion of ozone in the atmosphere. HCFCs are less harmful, but are still being phased out by international agreement. HFCs are not ozone-depleting substances (ODS), but, sadly, many are greenhouse gases (GHG), contributing to global warming.

Synthetic refrigerants are expensive so refrigeration systems are closed, but many still leak, releasing chemicals to the atmosphere and requiring replacement. The desire to reduce environmental impacts, along with the cost of synthetics and the deficiencies of natural refrigerants, motivates designers and operators of refrigeration systems to reduce the quantity of primary refrigerants in a system, often by using secondary refrigerants.

Secondary Refrigerants

A secondary refrigerant is a material used to deliver cold (remove heat) from regions or materials by discharging heat to a primary refrigeration system that uses one of the working fluids previously discussed— HFCs, ammonia, propane, or some other chemical. Secondary refrigerants may be single phase, such as liquid water, or solutions, or they may be multi-phase, such as a slurry of ice in water or a solution.

Solutions of various substances in water are used to depress the freezing point of pure water to allow operation below 32°F. Examples include sodium chloride (salt), calcium chloride, propylene glycol, and ethanol, all of which are tolerable with foods. (Ethylene glycol, commonly used in automotive antifreeze coolants, is not acceptable because it is toxic.) Water may be used for cooling above 32°F.

Single phase secondary refrigerants transport energy as sensible heat, reflecting a temperature change in the fluid. The amount of energy per unit mass of fluid is equal to the temperature change times the specific heat. The specific heat (or heat capacity) of water is 1 BTU/lb F. That for solutions is generally slightly less, depending on the concentration. This means that the secondary refrigerant flow rate, for a given heat load, is proportional to the temperature change, typically a few degrees F. The larger the allowed temperature increase, the less efficient are the heat exchangers. On the other hand, the more fluid that must circulate, the larger the required pumps and piping, and the more energy spent in driving the pumps.

Phase change secondary refrigerants have significantly larger heat carrying ability than do single phase fluids. For instance, a 30% ice slurry in water has a theoretical heat capacity of about 39 BTU/lb compared with 4 BTU/lb for water using a 4 degree temperature change. Further, the ice slurry does not change temperature so long as ice is present.

--- PAGE BREAK ---

In addition to ice in water, other phase change heat transfer fluids include suspensions of wax in water or oil and of other solids capable of melting. Ice slurries are appealing because they are inexpensive, have no environmental impact, and have desirable thermodynamic properties.

Carbon dioxide is a secondary refrigerant that is finding some acceptance. As a primary refrigerant, carbon dioxide has disadvantages because it requires very high pressure to be condensed at ambient temperatures. However, in a cascade system, carbon dioxide can be condensed against an ammonia system and then used in a distributed system.

Refrigeration at Retail

Supermarkets have numerous refrigerated spaces—storage freezers, walk-in coolers, frozen display cases, and refrigerated display cases. One approach is to provide each such unit with its own refrigeration system. Refrigeration systems enjoy an economy of scale, meaning that large systems are more cost effective and energy efficient than smaller ones (in general). Also, distributed systems discharge energy to the store environment, increasing the load on the air conditioning system—another refrigeration system, of course.

Large supermarkets often install a central, multi-level refrigeration system, distributing cold liquid refrigerant to the various use points. The distribution piping has many joints, fittings, and valves, which are potential sources of leaks. Some systems lose 30% of their refrigerants annually. A secondary system, in which the synthetic refrigerants are confined to the central system, greatly reduces the risk of leaks.

A secondary system using carbon dioxide can be labeled natural, reduces the GHG and ODS risk, and reduces risk to customers as compared with a distributed ammonia system. On the other hand, the carbon dioxide system requires its own compressor and the piping system must contain relatively high pressures. This increases capital cost.

Ice Slurries

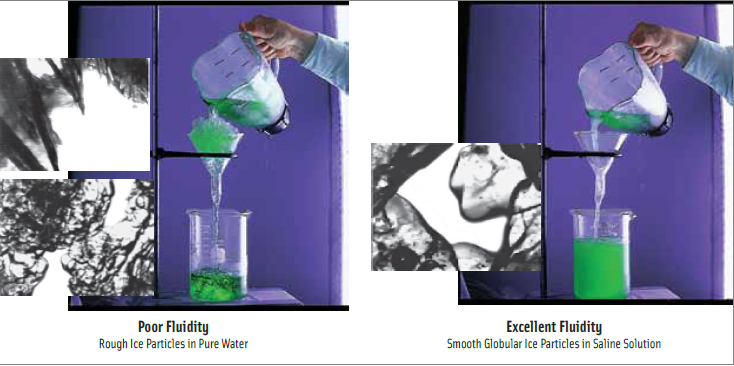

As previously described, ice slurries have high energy carrying capacity, use smaller piping, require smaller pumps, and use less energy to circulate. Typical issues with ice slurries have been a tendency to plug circulating lines and difficulties with storing the slurry. Fine particles of ice have a tendency to agglomerate and to float. To capture capital cost savings, smaller heat exchangers can be installed, but in a retrofit, this may not be possible.

--- PAGE BREAK ---

To address some of the recognized issues with ice slurries, Argonne National Laboratory developed a technique for producing very fine, rounded ice crystals that have good flow properties such that a slurry can actually flow through a capillary tube. (See Figure 1.) Funding to demonstrate Argonne’s ice slurry in a district cooling application ran out, so the focus shifted to one-time use, specifically for cooling patients following cardiac arrest or during invasive surgery. (Other onetime uses of ice slurries include cooling fresh fish and fruits and vegetables.)

To address some of the recognized issues with ice slurries, Argonne National Laboratory developed a technique for producing very fine, rounded ice crystals that have good flow properties such that a slurry can actually flow through a capillary tube. (See Figure 1.) Funding to demonstrate Argonne’s ice slurry in a district cooling application ran out, so the focus shifted to one-time use, specifically for cooling patients following cardiac arrest or during invasive surgery. (Other onetime uses of ice slurries include cooling fresh fish and fruits and vegetables.)

The full benefits of the Argonne ice slurry in closed systems remain to be demonstrated. Preliminary discussions with potential users of ice slurry secondary refrigeration confirm that the benefits are substantial.

J. Peter Clark , Contributing Editor,

Consultant to the Process Industries, Oak Park, Ill.

[email protected]