Hispanic Cheeses: The Quest for Queso

Hispanic cheeses, manufactured by modifications of European cheesemaking procedures to accommodate environmental and cultural influences, provide unique combinations of flavors, textures, and cooking properties.

Tacos, tamales, enchiladas, quesadillas, tostadas. Most American consumers recognize at least one of these foods. There is no denying that Hispanic, or Latino, cuisine is moving north and bringing an array of new ethnic culinary delights, including Hispanic cheeses.

Hispanic Cheeses

“Hispanic” is defined as pertaining to or affiliated with Spanish-speaking countries, and “Hispanic cheeses” refers to cheeses developed in the Spanish-speaking countries of Mexico and Central and South America. Although these cheeses are based on European cheese-making procedures, the manufacturing steps have been modified over the years to accommodate various environmental and cultural influences to produce cheeses that have unique combinations of flavors, textures, and cooking properties.

Queso, Spanish for cheese, is the star of the new expanding market for Hispanic dairy foods. In 1996, the U.S. Dept. of Agriculture’s National Agricultural Statistical Service began tracking Hispanic cheeses in a separate category. Production rose from 67.4 million lb in 1996 to more than 102.6 million lb in 2001 (NASS, 2002). This increase of 52% in 5 years has made Hispanic cheeses one of the fastest-growing cheese markets in the dairy industry.

Why is there such an increase in demand? A major factor is the growing population of Hispanics in the United States, currently estimated at 34.8 million. It is predicted that by 2005, Hispanics will constitute 13.3% of the U.S. population, making it the second largest ethnic group in the U.S. (U.S. Census Bureau, 2002). With the growing impact of Hispanics on American culture and cuisine, the growth of Hispanic flavors and foods (entrees, snacks, etc.) has been tremendous over the past few years. Sales of Mexican foods (Mexican/Tex Mex) reached $12.9 billion in 1997 (Promar International, 1998). Mexican foods represent one of the fastest growing ethnic food markets in the U.S., with projected annual sales of $32 billion by 2004 (Five Continents, 2001).

Cheese is at the heart of many Mexican/Latino dishes popular in the U.S. The quality, flavor, and functional properties of the Hispanic cheeses make Hispanic dishes culinary successes. Over the years, Hispanic cheese-makers have developed a wide variety of cheeses to match recipe requirements. Needless to say, defining the different cheeses can be very confusing because the names are not consistent from country to country and many cheeses are named after the specific region in which they were developed. In the U.S., there are no current Standards of Identity for Hispanic cheeses, and this creates its own problems in naming the cheeses. For the purposes of this article, the definitions and descriptions below are based on cheeses produced outside the U.S., mostly in Mexico.

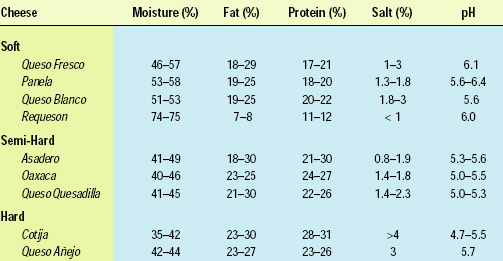

Hispanic cheeses can be grouped into the traditional classifications of soft, semi-hard, and hard cheeses (Table 1 on p. 34). These classifications are usually based on moisture content that gives an indication of the body and uniformity of the cheese, ranging from soft pliable cheeses to hard dry cheeses. According to Scott (1986), the moisture content of soft cheeses is approximately 55%, semi-hard cheeses 44–55%, and hard cheeses 20–42%.

Hispanic cheeses can be manufactured from whole milk, skim milk, or modified milk (containing added cream and/or solids, or formulated from milk components). Cheeses made from both raw milk and pasteurized milk (72°C for 15 sec) are manufactured around the world. Because most of the Hispanic cheeses are consumed within 60 days of manufacture, food safety concerns have prompted U.S. manufacturers to use pasteurized raw milk and ingredients in the cheese-making process. The Code of Federal Regulations requires that “if dairy ingredients used in the manufacture of cheeses are not pasteurized, the cheese must be cured at more than 1.7°C for at least 60 days.”

Some Hispanic cheeses utilize starter cultures, while many do not. Soft cheeses manufactured in Mexico traditionally are not made using starter cultures because the microflora in the raw milk supplies the needed lactic acid bacteria. In recent years, as pasteurization of the cheese milk has become more prevalent, cultures are added to the cheese milk to obtain targeted flavors. Semi-hard cheeses require lactic acid cultures (usually a mesophilic strain) in their cheese milk, supplied by either the microflora in raw milk or the addition of selected starter cultures. In hard cheeses, thermophilic starter cultures and exogenous lipases are added to obtain the desired flavors. All cheeses are coagulated with rennet, acid, or a combination of both ingredients.

--- PAGE BREAK ---

Soft Cheeses

Soft cheeses are probably the most recognized of the Hispanic cheeses. They are white cheeses that do not melt when heated (above pH 5.2 where cheese curd melts). Because they do not melt, they are ideal for cooked items that require fillings that hold their shape or position and do not flow. Some of the soft Hispanic cheeses crumble very well and are great for topping entrees, soups, or salads, while others slice very well. A few examples of Hispanic soft cheeses are described below.

• Queso Fresco translates as “fresh cheese” and is, by far, the most popular Hispanic cheese found in the U.S. and Mexico. It has a mild fresh-milk flavor that is slightly salty. The curd is usually finely milled before salting, making the cheese crumbly. The cheese contains about 46–57% moisture, 18–29% fat, 17–21% protein, and 1–3% salt and has a pH ≥ 6.1 (Hwang and Gunasekaran, 2001; Path, 1991).

It is a rennet-set cheese manufactured from whole or part skim milk. Manufacturers start with warming pasteurized milk to 30–32°C and adding rennet. The rennet-set curd is cut and cooked to a desired firmness, and the whey is drained. The curd is then finely milled with special grinding equipment, dry salted, and packed by stuffing into molds of different shapes and sizes. The cheese is packaged into round 12-oz consumer sizes for supermarket distribution or into 5- to 20-lb bulk sizes and sold to vendors who cut it on demand into smaller sizes. When packed and sold in the shape of bricks, it is called Adobera.

• Panela translates as “basket” because traditionally the cheese curd is placed in a basket to cool and drain, resulting in a basket-weave pattern on the finished surface of the cheese. It is usually made with whole milk to ensure a sweet fresh-milk flavor and is easily sliced and crumbled. It contains about 53–58% moisture, 19–25% fat, 18–20% protein, and 1.3–1.8% salt and has a pH of 5.6–6.4 (Guisa, 1999; Path, 1991).

It is a rennet-set cheese manufactured from whole milk. Cheese milk, supplemented with calcium chloride, is warmed to 30–40°C before rennet addition. After the milk is coagulated, the set curd is cut into large cubes (1 inch is traditional) and cooked to a desired firmness with gentle stirring. Half of the whey is drained before direct salting or a concentrated salt solution is added. After mixing for a few minutes, the wet curd is transferred into the basket-weave molds to drain overnight. Cheese is packaged for immediate sale. Queso crema is essentially similar to Panela except that it is made from milk fortified with cream to a high fat content.

• Queso Blanco translates as “white cheese” and is often confused with the generic “white” cheese (not all white Hispanic cheeses are Queso Blanco). It is an acid-set cheese, and care must be taken to look at manufacturing procedures when identifying this product. This cheese has a slightly acid flavor and will not melt when heated. The curd is not finely milled, giving the cheese a tougher texture than that of Queso Fresco. It contains 51–53% moisture, 19–25% fat, 20–22% protein, and 1.8–3% salt and has a pH ≤ 5.6 (Farkye et al., 1995).

As an acid-set cheese, Queso Blanco can be produced in a very short time frame. Cheese milk is heated to 85°C or higher, and an organic acid is added to bring the pH to about 5.3 (Farkye et al., 1995). This precipitates the protein and forms a curd (with entrapped fat) that settles out of the whey. After the whey is drained, the curd is salted, packed into hoops, and pressed to remove excess whey. The cheese is then packaged for immediate sale.

• Requeson is a soft, spreadable cheese that has a slightly salty flavor and grainy texture, similar to ricotta cheese. It is manufactured from pasteurized whey supplemented with whole milk or cream. The blended whey/milk mixture is heated to 85°C; vinegar is added to clot the milk, and salt is added for flavor. The wet curd is transferred to containers to drain overnight. The finished cheese contains about 75% moisture, with the fat content depending on the amount of milk/cream blended into the whey.

Semi-Hard Cheeses

The semi-hard cheeses usually rely on lactic acid cultures (either the indigenous cultures in raw milk or commercial starter cultures) to acidify the milk before rennet is added. After cutting, the curds are cooked before the whey is removed. This procedure results in cheeses with uniformly firm body and pH near 5.2. They have excellent slicing and melting properties, and are great in sandwiches, in cooked dishes were flow is important, and as a snacking cheese. A few examples of semi-hard cheeses are described below.

• Asadero is the most popular of the semi-hard cheeses. It has a firm, smooth texture and a slightly tangy, buttery flavor. It contains 41–49% moisture, 18–30% fat, 21–30% protein, and 0.8–1.9% salt and has a pH of 5.3–5.6 (De Alba et al., 1991; Path, 1991). Asadero is a rennet-set cheese manufactured from whole milk. Traditionally, milk is warmed to 30°C and, after the rennet is added but before coagulation occurs, dilute acid or pasteurized acid whey is stirred into the cheese milk to induce coagulation. The curd is then allowed to sit before the whey is drained. The freshly made curd is then transferred into a kettle, where it is heated to form a molten mass that is stretched, cooled, and molded into the desired shape—cylinder, ball, or ball of twine. Melting salts may be added during heating. The cylinder form is usually pre-sliced before packaging for immediate sale.

--- PAGE BREAK ---

• Oaxaca is named for the region in which it was developed, the state of Oaxaca in Mexico. It is a typical pasta filata style of cheese similar to mozzarella. This cheese has a sweet milk flavor and excellent melting properties. It contains 40–46% moisture, 23% fat, and 24% protein and has a pH of 5.0–5.5 (Guisa, 1999; Kosikowski, 1979). It is a rennet-set cheese manufactured from whole milk. The milk is warmed to 30–35°C, and cultures are added before coagulation with rennet. After the curd is cooked at 40–42°C, it is allowed to sit in the whey to reach the desired pH. Then the curd is immersed in hot water and kneaded like mozzarella. The molten cheese is pulled into a long, flat strand and cooled by placing it in cold water. The cheese is removed from the tank after it solidifies. Dry salt is rubbed on each side of the strand, then the strand is rolled into a ball of twine.

• Queso Quesadilla, Mennonita, or Chihuahua™ is essentially a high-moisture white Cheddar or Colby type of cheese. In Mexico, Mennonite settlers in the state of Chihuahua named their semi-hard cheeses after the region, but in the U.S., where the name Chihuahua has been trademarked by V&V Food Products, Inc., this style of cheese is also called Mennonita or Queso Quesadilla. It has a tangy flavor that sets it apart from Cheddar and is usually eaten within a month or two of manufacture (compared to Cheddar, which is aged a minimum of a few months to develop its distinctive flavor). It contains 41–45% moisture, 21–30% fat, 22–26% protein, and 1.4–.3% salt and has a pH of 5.0–5.3 (Diaz-Cinco et al., 1992; Path 1991; Solano-Lopez and Hernandez-Sanchez, 2000).

The cheese is a rennet-set cheese manufactured from whole milk. Milk is warmed to 30–37°C and coagulated with rennet. After cooking to 37–45°C and draining the whey, the curds are stacked and cheddared until the curd reaches the desired consistency. The curd is then milled, salted, packed in hoops, pressed, and dried for 1–5 days before packaging for sale.

Hard Cheeses

Although Hispanic cheeses are thought of as high-moisture cheeses, there are a few hard cheese varieties. What is interesting about these hard cheeses is that the hardness is not always due to aging. They have strong aromas and flavors, so a little can go a long way. Because of their hard texture, they are usually grated and sprinkled over cooked dishes, soups, and salads.

• Cotija is one the most popular of the hard Hispanic cheeses. It contains 35–42% moisture, 23–30% fat, 28–31% protein, and >4% salt (Guisa, 1999; Path 1991). With a pH of 4.7–5.5, it does not melt well but is ideal for grating. This cheese is very salty with a strong flavor and aroma and is usually thought of as the Hispanic version of Parmesan.

It is manufactured from whole or part-skim milk by rennet coagulation using thermophilic starters because of the high cooking temperatures used. Also, exogenous lipases may be added to increase lipolysis in the cheese, thereby enhancing flavor. Following coagulation, cooking, and whey drainage, the curd is milled by grinding it into small particles and then heavily salted. Traditionally, the salted curd is packed into cheesecloth and hung to drain and dry for several days. Alternately, the salted curd is hooped and pressed for several days before packaging for sale.

• Queso Añejo literally means “aged” cheese. It can be either aged Cotija or aged Queso Fresco. It contains 43% moisture, 23–27% fat, and 3% salt and has a pH of 5.7 (Path, 1991).

Research on Safety and Properties

Since the early 1990s, studies have examined consumer awareness (Geilman and Herfurth-Kennedy, 1992), composition (De Alba et al., 1991; Genigeorgis et al., 1991; Path, 1991; Saltijeral et al., 1999), manufacturing processes (Farkye et al. 1995; Path 1991), textural properties (Aigster et al., 2000; Farkye et al. 1995), and flavor (Aigster et al., 2000; Farkye et al. 1995) of specific Hispanic cheeses, but there are gaps in our knowledge.

In addition, much of the research addresses detecting pathogens (Listeria monocytogenes) in commercial soft Hispanic cheeses produced in the U.S. (Genigeorgis et al., 1991) and commercial soft and semi-hard cheeses in Mexico (Saltijeral et al., 1999). Challenge studies have also examined the survival of pathogens in cheeses made with inoculated pasteurized milk; L. monocytogenes (Glass et al., 1995; Mendoza-Yepes et al., 1997; Solano-Lopez and Hernandez-Sanchez, 2000), and Escherichia coli O157:H7 (Kasrazadeh and Genigeorgis, 1995; Mendoza-Yepes et al., 1997), and Salmonella (Kasrazadeh and Genigeorgis, 1994).

After conducting a risk assessment of L. monocytogenes in the food supply, the Food and Drug Administration issued a health warning about consuming “soft Mexican-style cheeses, such as Queso Blanco Fresco” (FDA, 2001). Confusion in defining Hispanic cheeses is cause for concern in the dairy industry and supports the need to continue research to better identify these cheeses and to standardize names and production practices. Licensed Hispanic cheese manufacturers in the U.S. follow Good Manufacturing Practices (GMPs) and Sanitation Standard Operating Procedures (SSOPs) to improve the safety and image of Hispanic cheeses.

--- PAGE BREAK ---

Current research efforts are directed at examining the functional and textural properties of Hispanic cheeses (Aigster et al., 2000; Hwang and Gunasekaran, 2001; Tunick et al., 2002). Establishing quantitative definitions for the functional and textural properties of Hispanic cheeses allows for comparisons and evaluations of the cheeses’ manufacturing procedures and utilization.

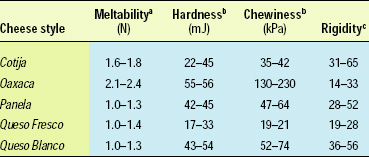

At USDA’s Dairy Processing and Products Research Unit at the Eastern Regional Research Center, relationships between chemical, functional, and textural properties of Hispanic cheeses are being determined, as well as the impact of manufacturing parameters on these properties. A few of the functional (melt) and textural properties of Cotija, Panela, Queso Blanco, Queso Fresco, and Oaxaca cheeses are shown in Table 2 (see p. 38). Melting values have also been obtained to determine how soft, hard, and semi-hard cheeses compare in their ability to melt and flow.

The textural properties, as expected, relate back to the manufacturing practices. For example, when using the Texture Profile Analysis compression method to determine chewiness of cheeses—a measurement of work required to masticate the sample—the cheeses were ranked as follows Queso Fresco < Cotija < Panela ≤ Blanco << Oaxaca. This ranking was expected, since the finely milled cheeses (Queso Fresco and Cotija) fell apart when compressed and the cheese with the pasta filata processing step (Oaxaca) was very elastic and flexible.

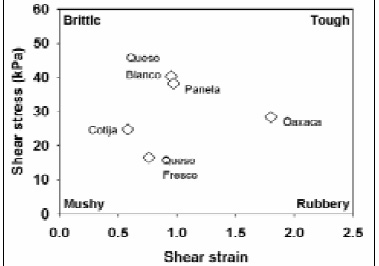

The rheology results illustrate the difficulty in using traditional rheological testing methods to evaluate Hispanic cheeses. Hardness values (amount of force required to compress the sample by 75%) rank the cheeses as Queso Fresco ≤ Cotija Panela = Queso Blanco < Oaxaca. By classification, Queso Fresco is a soft cheese and Cotija is a hard cheese, yet they have similar low hardness values. This is due to the milling step used during the manufacture of both cheeses, resulting in both cheeses being very crumbly when compressed, although other factors, such as moisture content, also influence texture.

When comparing Oaxaca and Queso Fresco for chewiness, the cheeses are dissimilar, but when comparing them for rigidity, they have similar low values. For Queso Fresco, the curd is finely milled and falls apart when minimal force is applied. For Oaxaca, the curd is very elastic and will tolerate a large degree of deformation before failure. If the ratios of shear stress to shear strain are compared, the cheeses are similar, but if the same data are graphed as shown below, the textures are separated. Establishing compositional, functional, and rheological properties is another tool to help in the manufacture of cheeses with uniform texture and quality.

A Bright Future

The growth of the Hispanic population in the U.S. and in the consumption and sale of specialty Hispanic foods will continue to drive the growth in Hispanic cheeses. The unique flavors, textures, and cooking properties of Hispanic cheeses offer American consumers nutritious dairy foods with diverse characteristics.

As researchers learn more about Hispanic cheeses, improvements can be made in cheese quality, production, and utilization. Hispanic cheeses will have an impact on the U.S. dairy industry, as the potential growth for this market is tremendous. The quest for queso has found a home in the U.S., and its future is bright.

by Diane L. Van Hekken and Nana Y. Farkye

Author Van Hekken is Research Chemist, Dairy Processing and Products Research Unit, Eastern Regional Research Center, U.S. Dept. of Agriculture, Agricultural Research Service, 600 E. Mermaid Ln., Wyndmoor, PA 19038. Author Farkye is Professor, Dairy Products Technology Center, California Polytechnic State University, San Luis Obispo, CA 93407. The authors are Professional Members of IFT. Send reprint requests to author Van Hekken.

References

Aigster, A., Sims, C., Staples, C., Schmidt, R., and O’Keefe, S.E. 2000. Comparison of cheeses made from milk having normal and high oleic fatty acid compositions. J. Food Sci. 65: 920-924.

De Alba, L.A., Staff, C., Richter, R.L., and Dill, C.W. 1991. Mexican Asadero cheese: A survey of its composition. Cultured Dairy Products J. 26: 11-12.

Diaz-Cinco, M.E., Fraijo, O., Grajeda, P., Lozano-Taylor, J., and De Mejia, E.G. 1992. Microbial and chemical analysis of Chihuahua cheese and relationship to histamine and tyramine. J. Food Sci. 57: 355-356, 365.

Farkye, N.Y., Prasad, B.B., Rossi, R., and Noyes, O.R. 1995. Sensory and textural properties of Queso Blanco-type cheese influenced by acid type. J. Dairy Sci. 78:1649.

FDA. 2001. HHS and USDA release Listeria risk assessment and Listeria action plan. Food and Drug Admin., Washington, D.C., www.fda.gov/news/releases/2001/01/0020.htm.

Five Continents. 2001. Market facts. Authentic ethnic foods. www.fivecontinents.com/market_facts.html.

Geilman, W.G. and Herfurth-Kennedy. C. 1992. Non-Hispanic consumers awareness of Hispanic cheese in California. Cultured Dairy Products J. 27: 4-5.

Genigeorgis, C., Toledo, J.H., and Garayzabal, J. 1991. Selected microbiological and chemical characteristics of illegally produced and marketed soft Hispanic-style cheeses in California. J. Food Protect. 54: 598-601.

Glass, K.A., Prasad, B.B., Schlyter, J.H., Uljas, H.E., Farkye, N.Y., and Luchansky, J.B.1995. Effects of acid type and Alts 2341 on Listeria monocytogenes in Queso Blanco type of cheese. J. Food Protect. 58: 737-741.

Guisa, F.L. 1999. Types of Mexican cheeses. Exploring cheeses of Mexico and Latin America. Artisan course. Univ. of Wisconsin, Madison.

Hwang, C.H. and Gunasekaran, S. 2001. Measuring crumbliness of some commercial Queso Fresco-type Latin American cheeses. Milchwissenschaft 56: 446-450.

Kasrazadeh, M. and Genigeorgis, C. 1994. Potential growth and control of Salmonella in Hispanic type soft cheeses. Intl. J. Food Microbiol. 22: 127-140.

Kasrazadeh, M. and Genigeorgis, C. 1995. Potential growth and control of Escherichia coli O157:H7 in soft Hispanic type cheese. Intl. J. Food Microbiol. 25: 289-300.

Kosikowski, F.V. 1979. Manufacture of Queso Blanco and other Latin American cheeses.Marschall Italian & Specialty Cheese Seminars 69: 1-10.

Kosikowski, F.V. and Mistry, V.V. 1997. “Cheese and Fermented Foods,” 3rd ed. Kosikowski FV, LLC, Westport, Conn.

Mendoza-Yepes, M.J., Sanchez-Hidalgo, L.E., Maertens, G., and Marin-Iniesta, F. 1997. Inhibition of Listeria monocytogenes and other bacteria by plant essential oil (DMC) in Spanish soft cheese. J. Food Safety 17: 47-55.

NASS. 2002. Dairy products—annual summary, 04.25.02. Natl. Agric. Statistical Service, U.S. Dept. of Agriculture, Washington, D.C., http://usda.mannlib.cornell.edu/reports/nassr/dairy/pdp-bban/.

Path, J. 1991. Hispanic cheeses: A promising new market for the specialty cheesemaker. UW Dairy Pipeline 3(4): 1-4.

Promar International. 1998. Riding the U.S. ethnic food tide: Strategies for food manufacturers into the new millennium. Promar International, Alexandria, Va.

Saltijeral, J.A., Alvarez, V.B., and Garcia, B. 1999. Presence of Listeria in Mexican cheeses. J. Food Safety 19: 241-247.

Solano-Lopez, C. and Hernandez-Sanchez, H. 2000. Behavior of Listeria monocytogenes during the manufacture and ripening of Manchego and Chihuahua Mexican cheeses. Intl. J. Food Microbiol. 62: 149-153.

Scott, R. 1986. Cheese varieties. Chpt. 4 in “Cheesemaking Practice,” ed. R. Scott, pp.24-36. Elsevier Applied Science Publishers, New York.

Tunick, M.H., Van Hekken, D.L., Smith, P.W., Malin, E.L., and Holsinger, V.H. 2000.Characteristics of Mozzarella cheeses made from fortified milk or nonfat dry milk. Milchwissenschaft 55: 450-453.

Tunick, M.H., Van Hekken, D.L., Molina-Corral, F.J., and Gardea, A.A. 2002. Influence of commercial manufacturing parameters on the composition and rheology of fresh Hispanic cheese made in Chihuahua, Mexico. Abstract AGFD-97, presented at 224th Natl. Mtg., Am. Chem. Soc., Boston, Mass., Aug. 18-22.

U.S. Census Bureau. 2000. Projection of the resident populations by race, Hispanic origin, and nativity: Middle series 2001 to 2003. U.S. Census Bureau, Washington, D.C., http://landview.census.gov/populations/projections/nation/summary/np-t5-b.pdf.