Novel Ideas in Food Packaging

The Institute of Food Technologists has issued a Scientific Status Summary on recent innovations in food packaging materials. Here is a synopsis.

As the world continues to evolve, demand for portability and expediency increases. Today’s consumers want to access the Internet while ordering lattes, call their physicians while taking public transportation, send text messages while crossing intersections, and watch the latest film release on DVD while driving to grandma and grandpa’s house. As a consequence, modern society now consists of millions of impatient multitaskers—generations of individuals who want to maximize their time by engaging in two tasks or more simultaneously. This global trend of on-the-go access, convenience, and immediate gratification pervades not only the industries of technology, communications, and entertainment but the food industry as well. Today’s consumers expect to shop for clothing and interact with friends over the Web while dining on 7-minute Asian cuisine that tastes great and is safe for consumption.

Over the years, the food industry has answered the call for diverse choices of convenient food items, with food and beverage packaging paving the way. In the 19th century, pioneers such as Nicholas Appert, Louis Pasteur, Samuel C. Prescott, and William L. Underwood developed food packaging and preservation concepts that maintain relevancy today (Wilson, 2007). Twentieth-century inventions such as glass bottles, cellophane wrap, aluminum foil, and plastics shepherded greater utility and flexibility in food packaging (Lord, 2008).

Other 20th-century packaging developments such as packages incorporating antimicrobials and oxygen scavengers established new precedents for prolonging shelf life and protecting food from environmental influences. Nevertheless, omnipresent global trends such as increased industrial processing of food, greater importation and exportation of food products, and less time for preparation of fresh foods compel the food and beverage packaging industry to investigate newer, more advanced packaging solutions. Thus, while protecting and preserving food were once perceived as the principal roles of food packaging (Robertson, 2006), facilitating convenience has quickly emerged as equally important. Other elements of increasing importance in food packaging include traceability, tamper indication, and sustainability (Kotler and Keller, 2006; Marsh and Bugusu, 2007). Many new and exciting developments in food packaging fulfill these roles and more.

A new Scientific Status Summary issued by the Institute of Food Technologists discusses recent innovations in food packaging materials. Written by Aaron Brody, Betty Bugusu, Jung Hoon Han, Claire Koelsch Sand, and Tara H. McHugh, the Summary is titled “Innovative Food Packaging Solutions.” This article presents a synopsis of the Scientific Status Summary.

Active and Intelligent Food Packaging

Beyond passively delaying environmental elements from affecting food products, active and intelligent food packages use more dynamic techniques to contain and preserve food (Brody et al., 2001; Lopez-Rubio et al., 2004). For example, two common issues in maintaining the quality of packaged food are oxygen and moisture control. Oxygen in packages aids the growth of aerobic microbes and molds. Oxidative reactions in packaging also result in unintended odors and flavors and changes in color or nutritional quality. Similarly, moisture in food packages may cause powdered products to form lumps or crisp products to soften as well as supporting the growth of microbes. Conversely, too little moisture can result in dehydrated foods.

Active packaging incorporates components that address these issues. Oxygen scavengers remove oxygen from food packages, thereby impeding the growth of microbes and preserving the intended flavor and odor of foods. Carbon dioxide emitters suppress microbial growth in products such as meat, poultry, and cheese (Lopez-Rubio et al., 2004). Moisture-control agents suppress water activity, serving to remove fluids from meat products, prevent condensation from fresh produce, and curb the rate of lipid oxidation (Vermeiren et al., 1999). Lastly, maintaining humidity in packages is accomplished by humidity controllers, which can either diminish the loss of moisture from foods or reduce excess moisture in the interstices of package closures. Other tools in the array of active packaging components include antimicrobials and ethylene absorbers.

--- PAGE BREAK ---

While active packaging incorporates robust ways to control oxidation, microbial growth, and moisture, intelligent packaging designs facilitate the monitoring of food quality (Brody et al., 2001; Kerry et al., 2006). Time temperature indicators (TTIs), ripeness indicators, biosensors, and radio frequency identification (RFID) are all examples of intelligent packaging components. Most of these smart devices have not had widespread commercial application, but two are gaining more notoriety: TTIs and radio frequency identification.

TTIs can play a critical role in indicating the freshness and safety of a product. They monitor and communicate which food products are safe to eat, which becomes extremely important when food is stored in less than optimal conditions such as extreme heat or freezing. In the case of foods that should not be frozen, a TTI would indicate whether the food had been improperly exposed to cold temperatures. Conversely, a TTI could specify whether foods sensitive to heat had been exposed to unnaturally high temperatures and the duration of exposure.

Radio frequency identification provides wireless monitoring of food packages through tags, readers, and computer systems. Its uses within the food industry are numerous and range from facilitating the traceability of food to improving the efficiency of supply chains. But perhaps the ultimate benefits of RFID in food packaging are that it speeds stock rotation and improves tracking. RFID systems are beneficial for many food manufacturing operations and supply chains. Developing an intelligent food packaging application for food quality and safety would require RFID to become more established in the food industry and the integration of food science (Yam et al., 2005). Retail chains such as Wal-Mart and Home Depot already use RFID, so its prominence is likely to increase (Joseph and Morrison, 2006). Because RFID systems provide safety and security benefits by tracking the origin of food supplies, retailers are considering ways to integrate this technology into the management of their supply chains.

Controlling Volatile Flavors and Aromas

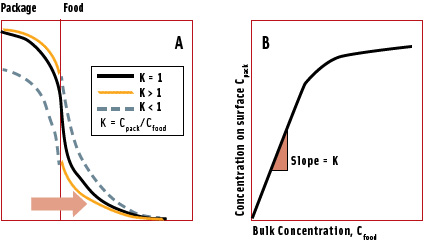

The loss of volatile flavors and aromas is a packaging issue that stems from the mass transfer of components between and within food and its packaging. For example, direct contact between the food and its packaging results in the migration of packaging components into food. And the unintended absorption of volatile food flavors by package materials is known as flavor scalping (Figure 1). Most incidences of migration occur in plastic packaging systems (Brown and Williams, 2003; Linssen et al., 2003), and polyethylene materials are responsible for most of the flavor scalping in foods (Sajilata et al., 2007). Both migration and flavor scalping are unfavorable because they deteriorate food quality and reduce consumer confidence in packaged food items. The solution to these issues is packaging components that incorporate absorption and barrier controls.

Flavor and odor absorbers usurp unwanted gaseous molecules such as volatile package ingredients, chemical and microbial metabolites, respiration products, or rancid flavors and odors (Rooney, 2005). Flavor and odor absorbers utilize the same transfer mechanism as flavor scalping to remove unintended characteristics in the forms of sulfurous compounds, amines from protein degradation, aldehydes and ketones, and bitter taste compounds.

--- PAGE BREAK ---

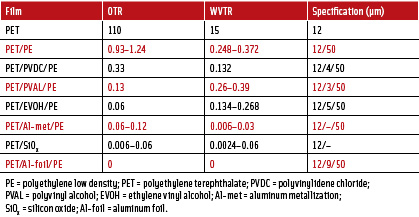

High-barrier packaging reduces absorption, desorption, and diffusion of gases and liquids to maintain food quality. It also assists in preventing oxygen and water vapor from penetrating packages. Polymer blending, lamination, and metallization are all ways to enhance the barrier properties of packaging materials (Table 1). Other innovative tools for improving the barrier property of packaging material include transparent vacuum-deposited or plasma-deposited coating of silica oxide PET films and composites of plastics with nanoparticles (Lange and Wyser, 2003; Lopez-Rubio et al., 2004).

Evolution of Foodservice Packaging

Other innovative trends in food packaging are occurring in foodservice. As consumers continue to spend heavily on foodservice products, the role of packaging in ensuring food safety and providing convenience can only increase. Packages designed for tracking and shelf-life extension reduce the risk of food-borne illness in the foodservice industry, but heating issues continue to be tricky. New packaging products, such as the CuliDish, are helping to address these issues. The CuliDish’s design allows simultaneous microwave heating of food that requires high heat and food that does not (such as salads) in the same tray. Such innovations in the area of heat and heat retention will reduce the safety risk associated with improper cooking.

Food consumers prepare and eat only 60% of meals at home (Packaged Facts, 2005), and 20% of consumers eat while in transit to another location. As a consequence, many of the innovations in foodservice packaging are to accommodate meals eaten in transit and multi-component meals—both of which are trends of convenience. The high demand for on-the-go meals has led to a significant increase in the variety of foods packaged for in-transit dining. Edible films and wraps have emerged on numerous foods, and package designs using modular folding cartons with flip-off lids or pouches with seatbelt flaps have been created for those who dine while driving.

Multi-component packaging accommodates the multi-unit meals that are available at quick-service restaurants. This type of packaging simplifies foodservice preparation, lessens waste, and makes consumption of multi-unit meals easy. Multi-component packaging is available in many forms: Les Petits Grande has reusable trays that clip together to form one larger serving tray, KFC uses triple-dip-strip cartons that allow consumers to dip chicken strips in three different sauces, and numerous coffee houses employ trays for holding more than one cup of coffee.

Green Packages

One of the key trends within food packaging is sustainable packaging. The Sustainable Packaging Coalition—an international consortium of more than 200 industry members—characterizes packaging as sustainable if it meets the following criteria:

• It is beneficial, safe, and healthy for individuals and communities throughout its life cycle;

• It meets market criteria for performance and cost;

• It is sourced, manufactured, transported, and recycled using renewable energy;

• It maximizes the use of renewable or recycled source materials;

• It is manufactured using clean production technologies and best practices;

• It is made from materials healthy in all probable end-of-life scenarios;

• It is designed to optimize materials and energy;

• It is recovered effectively and used in biological and/or industrial cradle-to-cradle cycles (SPC, 2007).

--- PAGE BREAK ---

A package’s sustainability is determined by the source of its packaging material. Consequently, corporations and environmental groups are working collaboratively to reduce the effect of packaging on global sources. In addition, global legislation, retailers, and corporations have guided initiatives for package sustainability that determine choice of materials and design. Examples of global legislation include the revised 1997 European Commission’s Packaging and Packaging Waste Directive, the 2007 Registration, Evaluation, and Authorization of Chemicals (REACH), and the BS EN 13432 standard (Warner, 2006).

Nanotechnology in Food Packaging

Some of the most exciting developments in food packaging involve nanotechnology; the science about very small materials is poised to have a big impact in food packaging materials. Nano-sized innovation could produce remarkable new packaging concepts for barrier and mechanical properties, pathogen detection, and active and intelligent packaging. At the forefront of nano-sized development in food packaging are nanocomposites.

Nanocomposites are materials that are made up of nanoparticle components. Toyota was the first company to commercialize nanocomposite materials, using nano-sized montmorillonite clay to increase mechanical and thermal properties of nylon (Weiss et al., 2006). In food packaging, montmorillonite clay is being explored as the nano-component in a variety of polymers: polyethylene, polyester, nylon, and starch. Nanocomposite plastic films block oxygen, carbon dioxide, and moisture from reaching food, so when used as packaging, the material extends the shelf life of food. Nanocomposite food packages are also light, strong, and heat resistant (ETC Group, 2004). In addition, research into the development of biodegradable nanocomposite packages is under way (Weiss et al., 2006).

While nanocomposites hold promise in food packaging through improved barrier properties, another type of nanomaterial shows great potential in managing microbial growth. Researchers have discovered that carbon nanotubes exert powerful antimicrobial effects: Direct contact with aggregates of carbon nanotubes proves to be fatal for Escherichia coli. The theory is that the long, thin nanotubes puncture E. coli cells, causing cellular damage (Kang et al., 2007).

Another nano-sized solution with positive indications for the future is nanosensors. When integrated with food packaging, nanosensors can detect chemicals, pathogens, and toxins in food. For example, biosensors have been developed that detect Staphylococcus enterotoxin B, E. coli, Salmonella spp., and Listeria moncytogenes (Joseph and Morrison, 2006; Liu et al., 2007). Nanosensors can also detect allergen proteins to prevent adverse reactions to foods such as peanuts, tree nuts, and gluten (Doyle, 2006). Nevertheless, progression in this area moves cautiously because the effects of nano-sized materials on humans are still under investigation.

The Bottom Line

Since its inception in the 18th century, food packaging has made great advances in active and intelligent packaging solutions. These advances have led to improved food quality and safety. While most packaging innovations have been the result of global trends and consumer preferences, some innovations have stemmed from unexpected sources, such as the emergence of nanoscience. Undoubtedly, new packaging solutions will focus more on food safety (controlling microbial growth, delaying oxidation, improving tamper visibility), product quality (managing volatile flavors and aromas), convenience, and sustainability. These are the most important factors in a fast-paced world where borders are rapidly diminishing and customer bases are increasingly global.

Scientific Status Summary Online

The IFT Scientific Status Summary, “Innovative Food Packaging Solutions,” appears in the October 2008 issue of Journal of Food Science. The Scientific Status Summary was written by Aaron Brody, Ph.D., a Professional Member of IFT, President and CEO, Packaging/Brody Inc., Duluth, Ga., and Adjunct Professor, University of Georgia ([email protected]); Betty Bugusu, Ph.D., Research Scientist, IFT, Washington, D.C. ([email protected].); Jung Hoon Han, Ph.D., a Professional Member of IFT and Senior Project Engineer, Frito-Lay, Plano, Texas ([email protected]); Claire Koelsch Sand, Ph.D., PTIS Associate/Ameripak, Stillwater, Minn., and Michigan State University Adjunct Professor ([email protected]); and Tara H. McHugh, Ph.D., Research Leader, Processed Foods Research Unit, U.S. Dept. of Agriculture, Agricultural Research Service, Western Regional Research Center, Albany, Calif. ([email protected]). The Summary can be viewed online at www.ift.org.

by Toni Tarver is Scientific and Technical Communications Manager, Institute of Food Technologists ([email protected]).

References

Brody, A., Strupinsky, E.R., and Kline, L.R. 2001. Odor removers. In “Active Packaging for Food Applications,” eds. A. Brody, E.R. Strupinsky, and L.R. Kline, pp. 107-117. Technomic Publishing Co. Inc., Lancaster, Pa.

Brown, H. and Williams, J. 2003. Packaged product quality and shelf life. In “Food Packaging Technology,” eds. R. Coles, R. D. McDowell, and M.J. Kirwan, pp. 65-94. Blackwell Publishing Ltd., Oxford, England.

Doyle, M.E. 2006. Nanotechnology: A brief literature review. Food Research Institute Briefings [Internet]. June 2006. Available from: http://www.wisc.edu/fri/briefs/FRIBrief_Nanotech_Lit_Rev.pdf. Accessed Aug. 4, 2008.

Joseph, T., and Morrison, M. 2006. Nanotechnology in agriculture and food. A Nanoforum report, May. pp. 1-14. Available from: http://www.nanowerk.com/nanotechnology/reports/reportpdf/report61.pdf. Accessed April 29, 2008.

Kang, S., Pinault, M., Pfefferle, L.D., and Elimelech, M. 2007. Single-walled carbon nanotubes exhibit strong antimicrobial activity. Langmuir 23: 8670-3.

Kerry, J.P., O’Grady, M.N., and Hogan, S.A. 2006. Past, current and potential utilization of active and intelligent packaging systems for meat and muscle-based products: a review. Meat Sci. 74: 113-30.

Kotler, P., and Keller, K. 2006. Marketing Management. 12th ed. Pearson, Upper Saddle River, N.J.

Lange, J. and Wyser, Y. 2003. Recent innovations in barrier technologies for plastic packaging–a review. Pack. Technol. Sci. 16: 149-158.

Linssen, J.P.H., van Willige, R.W.G., and Dekker, M. 2003. Packaging-flavor interactions. In “Novel Food Packaging Techniques,” ed. Ahvenainen, pp. 144-171. Woodhead Publishing Ltd., Cambridge, England.

Liu, Y., Chakrabartty, S., and Alocilja, E. 2007. Fundamental building blocks for molecular biowire based forward error-correcting biosensors. Nanotechnology 18: 1-6.

Lopez-Rubio, A., Almenar, E., Hernandez-Munoz, P., Lagaron, J.M., Catala, R., and Gavara, R. 2004. Overview of active polymer-based packaging technologies for food applications. Food Rev. Int. 20(4): 357-87.

Lord, J.B. 2008. The food industry in the United States. In “Developing New Food Products for a Changing Marketplace,” 2nd ed., eds. A.L. Brody and J. Lord, pp. 1-23. CRS Press, Boca Raton, Fla.

Marsh, K., and Bugusu, B. 2007. Food packaging: roles, materials, and environmental issues. J. Food Sci. 72(3): R39–55.

Packaged Facts. 2005. On the go eating and snacking: consumer mindsets, menu trends and product/packaging innovation. Available from: http://www.packagedfacts.com/Go-Eating-Snacking-1077422/. Accessed July 21, 2008.

Robertson, G. 2006. Food Packaging Principles and Practices, 2nd ed.Taylor & Francis, Boca Raton, Fla.

Rooney, M.L. 2005. Introduction to active food packaging technologies. In “Innovations in Food Packaging,” ed. J.H. Han, pp. 63-79. Elsevier Academic Press, Oxford, England.

Sajilata, M.G., Savitha, K., Singhal, R.S., and Kanetkar, V.R. 2007. Scalping of flavors in packaged foods. Comprehensive Rev. Food Sci. Food Safety 6: 17-35.

Sustainable Packaging Coalition. 2007. What is sustainable packaging? Available from: http://www.sustainablepackaging.org/about_sustainable_packaging.asp. Accessed April 24, 2008.

Vermeiren, L., Devlieghere, F., van Beest, M., de Kruijf, N., and Debevere, J. 1999. Developments in the active packaging of foods. Trends Food Sci. & Tech. 10(3): 77-86.

Warner, M. 2006. March 3. What Wal-Mart wants, Wal-Mart gets for its shelves. International Herald Tribune [Internet journal]. Available from: http://www.iht.com/articles/2006/03/03/business/walmart.php. Accessed Aug. 4, 2008.

Weiss, J., Takhistov, P., and McClements, J. 2006. Functional materials in food nanotechnology. J. Food Sci. 71(9): R107-116.

Wilson, C. 2007. Frontiers of Intelligent and Active Packaging for Fruits and Vegetables, CRC Press, Boca Raton, Fla.

Yam, K.L., Takhistov, P.T., and Miltz, J. 2005. Intelligent packaging: concepts and applications. J. Food Sci. 70(1): R1-10.