The Role of Metal in Food Packaging

PACKAGING

Packaging that employs metal as a barrier and structural layer plays a significant role in food preservation. Innovations in metal packaging optimize its use as a unique material. For example, innovations in forming cans and controlling metal deposition onto packaging materials allow more material-efficiency and unique antimicrobial and microwave susceptor properties.

Can Manufacture and Design

Cans are the most commonly used metal packaging and are made from steel or aluminum. Steel-containing cans are made from electrolytic tinplate or electrolytic chromium/chromium oxide-coated steel, also known as tin-free steel. Metal cans are classified by either the two-piece or three-piece manufacturing method. Two-piece cans undergo either a drawn-and-ironed process from a blank that is made into a successively same-diameter taller can or a drawn-and- redrawn process and made into a smaller diameter. Three-piece cans are made by first coating the steel and then rolling the can wall into a cylindrical shape. The seams are welded and the base is sealed to the cylinder by double folding of the cylinder and end lip and crimping—a process called double seaming.

Can forming innovations to reduce metal packaging materials and thereby reduce costs and weight continue. For example, Amcor’s CanSealPro and Crown’s Peelfit apply an aluminum membrane directly to the can cylinder, eliminating the need to double seam the can end to the cylinder and lightening container weight by 16%. Whipped cream, cheese spreads, and pan release sprays are packaged in aerosol cans with optimal metal use. A notable example is Ball Corp.’s ReAl aerosol can, which is 15% lighter than a standard can, offering less environmental impact. For both two- and three-piece cans, beading on the side walls adds strength, allows for an overall thinner sidewall, and provides a suitable surface for label adhesion. Other design elements such as laser engraved, printed, colored opening tabs, and can ends, which are used for beverage containers, allow brands to communicate with consumers when they drink the product.

Interior Linings

Can linings prevent steel corrosion and help maintain product quality (e.g., flavor). Linings inside cans have raised concerns over migration of substances from the linings into the food as well as loss of food flavor and aroma due to absorption by the lining.

More specifically, bisphenol A (BPA) and derivatives have been a concern; they are restricted in the EU (EC 1895/2005) and rejected by many U.S. consumers. Differences in the EU and U.S. regulations reflect the use of the precautionary principle in the EU and the use of risk assessment by the FDA. Concerning BPA alternatives, Can Manufacturers Institute President Robert Budway shared this: “Research on BPA alternatives started some 10 years ago and involved a depth of development in the prospective linings and a breadth of assessment on the prospective linings.” Further, “Prospective can linings were assessed under typical fabrication, processing conditions, and shelf life for compatibility and corrosion resistance,” he explained. “While Food Simulating Liquids (FSL) assisted with the initial screening of prospective linings, testing with the actual product was needed to assess the potential impact of the promising linings on product organoleptic properties. Further coating optimization was needed to ensure employee safety in the actual coating application process, minimize the environmental impacts of coating application, to ensure that unintentionally added substances are not generated during processing or shelf life, and to define sourcing parameters.”

Can linings continue to be product specific. For example, in an assessment of the aroma sorption by polyethylene terephthalate (PET) laminated steel (PET-LS) cans, the scalping of citral aroma was higher than hexanal, often associated with secondary by-products of oxidation. This level of scalping would prohibit the use of PET-LS cans for long-term storage of products containing citral-related compounds.

Barrier and Structure for Pouches

Aluminum is used in laminate and metalized pouches for its ductility and barrier properties. Pouch function and design is moving toward emulation of cans and jars. For example, AeroFlexx’s AeroFlexx Pak is a stand-up laminated package with an integrated spout for one-handed dispensing, and the Amcor pouch for a Predilecta Sacciali tomato-based product resembles a mason jar. Laminates are made of layers having distinct functions such as sealing, puncture resistance, and high-temperature resistance. Foods in need of high aroma or flavor barriers or long shelf life are commonly packaged within aluminum-containing laminate structures. Laminate pouches containing foil layers can be retort processed in a manner similar to metal cans. For advanced thermal processing technologies such as microwave assisted thermal sterilization, laminates containing an aluminum oxide layer can be used.

The high cost associated with a continuous layer of aluminum, as well as the cost and time associated with the lamination process has increased the use of metalized film for pouches. Plasma chemical vapor deposition of a 3–50 nm thin aluminum layer results in highly controllable barrier properties and opacity. For example, the Uflex metalized 4D flex-carton is a flexible structure that combines the barrier of an inner bag and the rigidity and shape of a folding carton. The metalized PET layer in the material and side seams creates structure and allows an integrated handle and reclose feature. While both metalizing on and laminating of metal substrates onto flexible packaging results in an extended shelf life with less metal than cans, the postconsumer use of these composite structures is limited because layers cannot always be economically separated and are not readily recyclable. These commingled materials, however, can be used as fillers within construction, appliance, and other heavy industries.

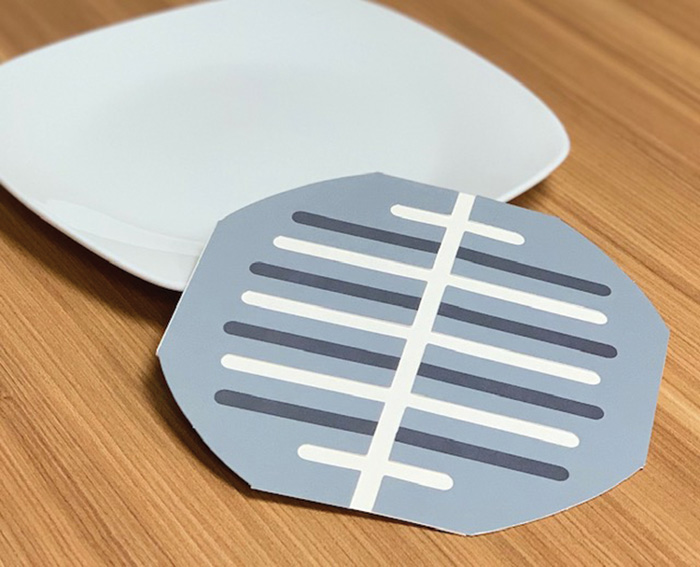

Further control of the deposition of aluminum onto a packaging substrate led to the development of microwave susceptor packaging. Deposition of small amounts (<10 nm in size) of aluminum in a pattern onto a heat-resistant surface such as PET results in spaces between the aluminum deposits. When the PET-based structure is exposed to microwave energy, an arc forms between the aluminum deposits and creates heat to warm, crisp, and cook food. Susceptor technology has evolved from its infancy in the early 1970s to a refined technology. Different types of susceptors in packaging include those in sleeves, wraps, cartons, trays, and pads for pizzas, egg rolls, sandwiches, and popcorn. For example, the Inline susceptor Micro-Grill pattern creates grill marks within a vented paperboard-based carton. Likewise, the Inline Superceptor focuses the heat in the center of the product to prevent overcooking on product edges. Graphic Packaging International also provides an array of susceptor packaging.

Beyond aluminum, other metals such as iron, silver, zinc oxides, magnesium oxide, and titanium oxide, are applied as nanoparticles to packaging surfaces to enhance mechanical strength and barrier properties and impart an antioxidant or antimicrobial effect (dos Santos et al. 2020). For example, titanium dioxide is an effective antimicrobial agent because it produces reactive oxygen species that destroy pathogenic microbes on the surface of the package or food. Recent EU regulations that consider nanoparticles a distinct entity require that their nano-specific risk be assessed. Refined attachment of silver nanoparticles that control antimicrobial activity is slated to increase the use of silver nanoparticles in the EU. Enabling the safe use of nanoparticles in direct food contact will extend the shelf life of foods.

Traceability

Track and trace from package origin throughout the food supply chain is becoming essential. The canning industry is uniquely positioned to add track and trace because codes can be printed on can bottoms which are not typically used for branding and because cans have established postconsumer value. For example, the inkjet or laser etched QR coding CrownSecure system by Crown is applied when the can is manufactured. This allows food manufacturers to add to the data used by retailers, consumers, and postconsumer packaging recyclers, aiding tracking of recycling by location.

Application of the codes by the can manufacturer improves production line efficiencies and eliminates the need for brands to apply additional codes. Using this system, consumers may assess food authenticity via web-based smart label applications, recyclers can more readily sort packaging containers, and can producers are allowed more understanding of the original metal source and prior use.

Sustainability

As we move toward a more sustainable food system, a life cycle sustainability assessment of the entire supply chain involving packaging, processing, and transporting food coupled with the environmental cost of food waste associated with canning, freezing, or fresh processing (chemical rinsing) is essential. The facts that canned foods do not require refrigeration and that steel is infinitely recyclable, reduce their environmental impact. Research has shown that canned spinach, tomatoes, and kidney beans result in less food and nutrient waste than when these foods are fresh processed (Boz and Sand 2020). Further, the 71% recycling rate of cans reduces the environmental impact of cans since every ton of recycled steel saves iron ore, limestone, and energy in the production of cans (Can Manufacturers Institute 2020).

REFERENCES

Boz, Z., and C. Sand. 2020. “A systematic analysis of the overall nutritional contribution of food loss and waste in tomatoes, spinach, and kidney beans as a function of processing. J. Food Process Eng. In press.

Can Manufacturers Institute. 2020. “Recycling Facts.” http://www.cancentral.com/recycling-sustainability/facts.

dos Santos, C. A., A. P. Ingle, M. Rai. 2020. “The emerging role of metallic nanoparticles in food. Appl. Microbiol. Biotechnol. 104(6): 2373–83.