HPP Gains Ground as Batch and Bulk Capabilities Advance

PROCESSING

Nonthermal high pressure processing (HPP) technology is not new, but its application has expanded in recent years thanks to its ability to extend shelf life and kill pathogens without affecting organoleptic and nutritional attributes in a variety of food and beverage products. In fact, HPP is now the most widely implemented nonthermal preservation method in the food and beverage industry. For processors, HPP is relatively easy to use, validate, and scale up. Consumers appreciate its ability to deliver minimally processed products.

The initial investment required has been the main factor limiting HPP adoption; a processing chamber or vessel is the costliest part of the system. Also, until recently, products had to be individually packaged and sealed and processed one batch at a time, adding production costs. In addition, industrial HPP installations have historically been batch systems and maintenance intensive, which reduces production throughput.

The Batch ‘In-Pack’ Process

Traditionally, HPP has been characterized by processing prepacked products using a so-called in-pack process. Although there are variations in the process, in the typical approach, a product is vacuum packed and then pressurized by direct and indirect methods, utilizing a pressure-transmitting medium (normally water). The pressure is isostatic and thereby acts homogenously throughout the chamber and product, independent of product size, shape, or dimensions.

The HPP operation starts with loading prepacked food products in perforated baskets, which are transported into the vessel. Then the vessel is sealed and filled with water that is pressurized by the use of intensifiers that inject additional quantities of water, consequently compressing the water by almost 15%. After the product has been held for the desired time at the process pressure, releasing the pressure-transmitting fluid decompresses the vessel. For most applications, products are held for 3–5 min at 600 MPa, which allows for approximately 6 to 8 cycles per hr, including time for compression, holding, decompression, loading, and unloading.

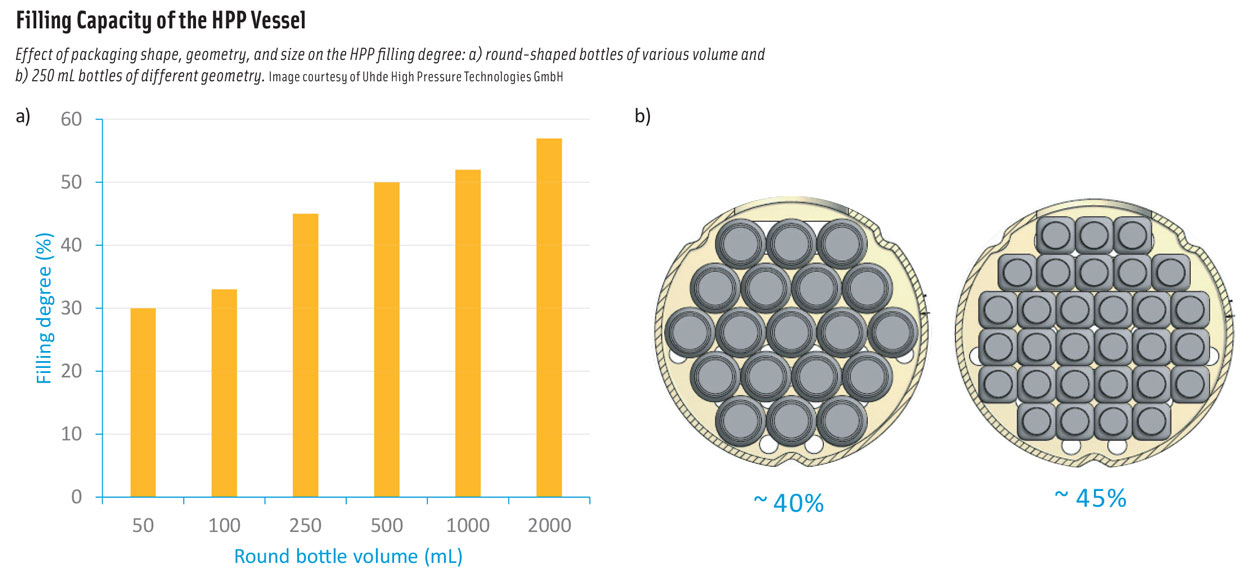

Two key improvements—increased vessel size and reduced cycle time—allow for the intensification of batch HPP production capacity. Considering HPP equipment that can operate at 600 MPa, in 1998 the largest industrial vessel had a volume of 215 L. In 2009, the vessel capacity doubled and reached 420 L, and 2014 marked the commercial introduction of Hiperbaric’s largest vessel, which has a capacity of 525 L. However, due to the size and shape of the bottles, vessel filling efficiency is often restricted to 40%–55%.

Uhde High Pressure Technology (UHPT), an HPP technology provider for more than 90 years, established a partnership with Multivac, a provider of high-quality packaging machines, to supply the food market with specialized HPP packaging solutions. Since 2010, UHPT has manufactured batch HPP machines with a portfolio of 2 L to 350 L and special solutions. UHPT built the first pressure-assisted thermal sterilization unit up to a size of 150 L for 700 MPa and a temperature range up to 135°C.

To optimize HPP machine filling efficiency, it is important to reduce the amount of air inside the packaging, preferably using optimally designed vacuum packaging. With a smart approach, it is possible to create a honeycomb structure inside the vessel and fill all the space in the basket with products. Vacuum packages and pouches normally achieve filling efficiency of 50% to 60%. This value is reduced when it comes to bottles and is increased when it comes to process pouches.

Semi-Continuous HPP for Beverages

HPP has commercial applications for a broad range of product categories, including beverages, meat, poultry, seafood, dairy, fruit, vegetables, and ready-to-eat meals. The use of HPP for beverages and juices is the fastest-growing segment with 25%–30% market share. Processing beverages in-bulk in a semi-continuous system before bottling without any limitations for use of glass or metal packaging is of interest to the industry as an alternative to in-pack configuration.

The early semi-continuous HPP machines were built as single vertical vessels (up to 210 L) or medium or small vessels (up to 3 x 20 L) connected in a series with a free or floating piston that could move up and down within the vessel. After the vessel was filled with a product to 85%–90%, the pressurizing fluid was pumped and compressed into the vessel on the opposite side of the free piston, displacing it and consequently compressing the product. However, because of corrosion and sanitation issues caused by direct contact of the product with the piston, vessel, plugs, and seals, semi-continuous HPP systems had limited use and no commercial success.

Continuous ‘In-Bulk’ HPP

Hiperbaric recently introduced an innovative “bulk” approach that avoids the use of a free piston and the direct product contact with the vessel and plugs, and delivers filling efficiency of at least 90%. The continuous HPP system contains a large, watertight flexible plastic bag or container located in the vessel where the liquid is processed. The bag is filled through a clean, pressure-resistant valve in the high-pressure plug. Depending on required productivity, the system can have one or two vessels of 525 L together with a system of tanks to store a beverage before and after pressurization.

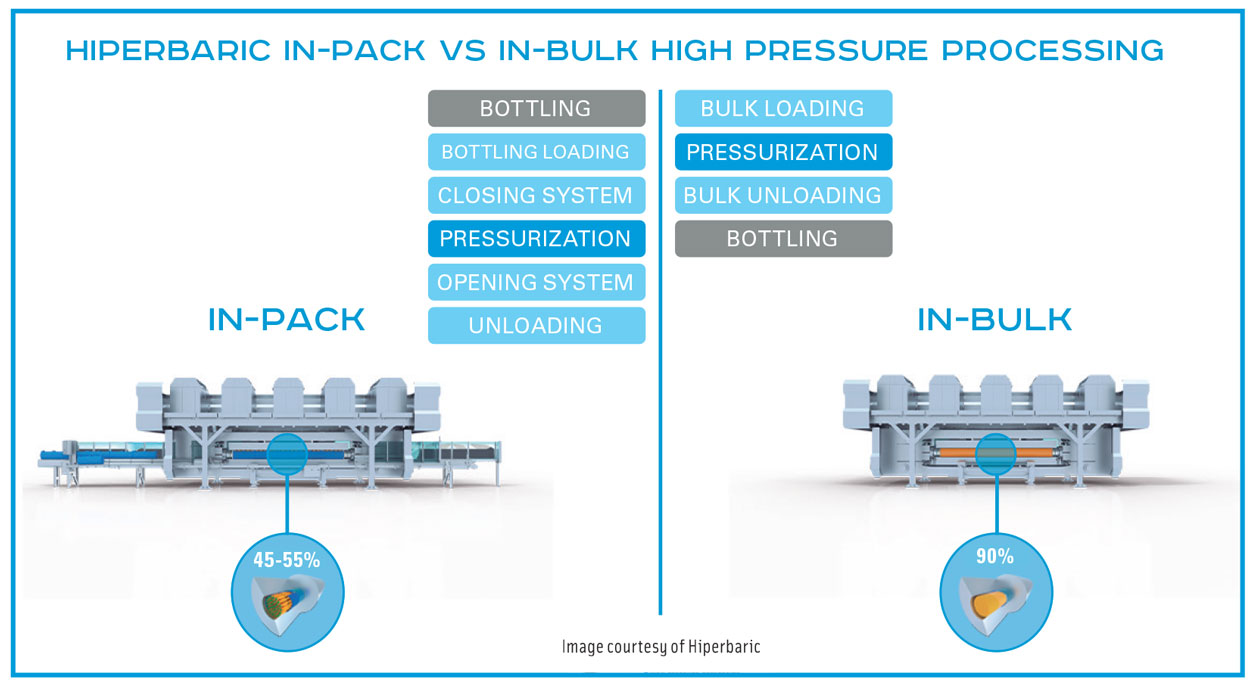

The HPP pressurization cycle of the in-bulk process is similar to a conventional in-pack cycle. However, prior to liquid pressurization, three operations must be carried out: 1) pre-rinsing of the complete circuit with water as part of a clean-in-place protocol, followed by the circulation of a cleaning agent at a high temperature and final rinse step with hot water; 2) steam sterilization of pipes and outlet tank; and 3) mounting a bag in the vessel and attaching it to the hygienic pressure valve in the plug through which the beverage will be filled. By overcoming in-pack processing limitations, an in-bulk system reduces processing and packaging steps from six to four, increases filling efficiency from 45%–55% up to 90%, and increases productivity from 3,000 L/hr to 5,000 L/hr.

Although the cost of a Hiperbaric 525 Bulk machine is 20% higher than a similar in-pack unit, advantages of the in-bulk process include reduction in operational cost, labor, and energy consumption, as well as added packaging versatility. French processor Ateliers Hermes Boissons is the first company to put Hiperbaric’s 525 Bulk machine to use commercially.

HPP-Enabled Product Innovation

With the COVID-19 pandemic prompting consumers to seek out a variety of more healthful products—some of them highly perishable and prone to contamination by foodborne pathogens, HPP is a good fit for the times.

Beverages processed using HPP help satisfy increased demand for juices and beverages rich in vitamins, functional compounds, and probiotics to strengthen the immune system. Numerous scientific reports support the fact that HPP doesn’t change nutritional profiles, antioxidant content, or flavors.

Plant-based dips and spreads produced using HPP are also consumer favorites; Uhde has demonstrated HPP’s ability to extend the shelf life of pea protein–based dips and spreads. In addition, Uhde’s HPP technology has been employed for ready-to-eat vegan fitness meals such as a cereal porridge with mango puree and spinach-banana puree; the company reports that the treated products have a shelf life that is 35 times longer than untreated products.

HPP treatment at 600 MPa and 3 min extended the shelf life of pasta and pizza doughs from Colucci Innovative Food for more than 3 mo compared with only 3 days without treatment. The microbial counts of total aerobic bacteria, Enterobacteriaceae spp., and other bacteria remained under critical values in the company’s Pasta Quark or buckwheat chia dough treated with HPP even after 6 mo of storage.

A Healthy Future for HPP

The use of HPP is growing; more than 500 units have been installed worldwide. Though the investment cost in HPP technology has not changed substantially, improvements in the machines’ configurations and components have translated to higher productivity and lower production costs. In addition, HPP foods and beverages serve nutritionists’ recommendations to choose raw or minimally processed foods and allow for safe, tasty, and convenient products with extended shelf life. For these reasons, demand for HPP equipment is expected to increase for the next few years.