Sustainability’s Fourth Wave

Peer to Peer | ISSUES & INSIGHTS

Sustainability may be an overused buzzword now, but its origins date to the transcendentalism of Ralph Waldo Emerson and Henry David Thoreau in the 1830s, considered the first wave of sustainability. In the 1970s, the second wave of sustainability was characterized by Rachel Carson’s groundbreaking book, Silent Spring, and Ohio’s burning Cuyahoga River, weather inversions, Earth Day, and the creation of the U.S. Environmental Protection Agency (EPA). The third wave of sustainability in the 1990s saw triple bottom line, corporate responsibility statements, and “people, profit, planet” become well-known mantras.

In the past five years, the fourth wave has resulted in more countries and regions learning to ride the currents of sustainability, driven by both negative and positive motivation. On the positive side are food waste awareness and corporate shared values, initiatives by global retailers, brands, and packaging suppliers, and the translation of the United Nations Strategic Development Goals (UNSDGs) into a business framework. On the negative side, however, are greenwashing, consumer confusion, lack of ethics in environmental claims, plastic bans, and competing life cycle analyses (LCAs).

Food Technology contributing editor Claire Sand recently sat down with Robert Lilienfeld, executive director of Sustainable Packaging Research, Information, and Networking Group (SPRING), to talk about how we can explore a new frontier of truly sustainable packaging. Both experienced the second wave of sustainability as young professionals and are deeply involved in the current fourth wave.

Lilienfeld works to achieve more sustainable packaging and to assist brands and packaging companies in deriving multipronged science-based solutions that address collection and sorting challenges, as well as material-based solutions to enable safe optimization, reuse, recycling, and degradation of packaging. Sand, who owns Packaging Technology and Research LLC and is also a SPRING advisory board member, focuses on preventing food waste with optimized packaging science and value chain–based solutions. Here’s what these two experts had to say about the timeliness of today’s sustainability wave, consumption trends, environmental scorecards, plastics, food waste, and more.

Sustainability in the Forefront

Sand: Why are we still having the “more sustainable packaging” conversation after all these years?

Lilienfeld: While you and I have been thinking about sustainability for 30-plus years, much of our society has not been doing so. It's hard for human beings to get concerned about something that doesn't affect them. We are concerned about issues that are close to us in several dimensions: physical distance, chronological immediacy, size and scope, and impact on family and friends. Up until now, there hasn't been a good reason for the average person to think about sustainability because it's such a big, vast problem, and it seemed so far away.

Well, it’s here. And everyone can participate in trying to do more with less and get involved and take responsibility. Most of the environmental issues that we face today are based upon what we as a species consume. If consumption is a human driver, then we need to make it easier for people to consume less and/or consume differently. There are three key ways to do this: financial incentives, emotional signaling, and legislative/regulatory controls.

Sand: That makes sense—linking these three issues is critical to driving meaningful change. In fact, we have seen this recently on the emotional front. As more people engage globally and learn how others interface with packaging and what solutions work, more will join the wave.

We also see tremendous achievement driven by economics. For example, in 2018, I saw the Yangtze—one of the 10 rivers where 90% of the ocean garbage is derived—littered with package and other waste. The same type of economic incentive used to build the stunning Three Gorges hydroelectric dam [on the Yangtze] can be applied to deter packaging waste being dumped in the river.

Economic incentives take many forms. For example, recently, a client of mine embarked on a more sustainable packaging initiative as a means of retaining employees, after a poll showed that employees wanted to be assured the packaging in use was as sustainable as possible. Fortunately, they employed a food system approach so that food waste was minimized, and packaging was optimized in tandem.

Source Reduction

Lilienfeld: Consumption is the primary driver of most of the environmental issues that we face today. If we're talking about the global climate, people say, well, our goal is to reduce carbon dioxide production. Well, that's not really our goal—that's a strategy. Our goal is to minimize the chance that we will make our climate uninhabitable for ourselves and other species.

And then you start looking at things like climate change. If we reduce the insatiable need to consume things, then the amount of CO2 that gets produced will decline, as opposed to having to figure out what to do with what we've already produced.

Sand: This is critical. Consuming less means optimizing packaging specifically to prevent food waste. When this is done, our environmental footprint will decline per capita.

If we just focus on the package sustainability and spend energy on this, we are missing the point and have misguided efforts in reducing the environmental impact of our whole food system. The focus should be on preserving and protecting resources. What I love about source reduction is that we use fewer chemicals of concern, and the EPA estimates that source reduction eliminated up to 15 billion pounds of chemicals being used from 1991 to 2016. You saw this many years ago, Bob, and highlighted it in your 1998 book, Use Less Stuff. Boy, I love that title because it addresses both using less stuff and useless stuff.

Lilienfeld: I became a proponent of the concept of source reduction because if less is used, there is less to collect, sort, recycle, reuse, degrade, landfill, incinerate, etc. So the late Bill Rathje from the University of Arizona, the world’s first garbologist, wrote the book with me to explain this.

Sand: The message is still true.

Lilienfeld: This ties back to what it is that we're trying to accomplish. Our goal is not to recycle more, reuse, or degrade more. It is to reduce the environmental impact, and we can do this best by using less stuff.

Environmental Scorecards

Sand: Environmental scorecards for packaging—such as the Walmart one developed in 2006—are increasing in popularity again. Ideally, scorecards can be used to guide industry decision-makers. Increasingly, we have seen packaging suppliers developing their own scorecards based on nonpeer-reviewed LCAs. But now I would say there is an overabundance of scorecards not entirely based on facts.

Lilienfeld: I was very involved in the Walmart scorecard process. But I was not a proponent—I was an opponent. I gave the keynote address at their sustainable packaging meeting where they introduced scorecards, and I said this is going to come back to haunt you. Leadership is about telling the truth!

The problem with that scorecard was that it focused on materials, recyclability, and recycled content and not actually more sustainable packaging. What I am a fan of is accuracy. For example, if you want to claim recyclability, you have to get the APR [Association of Plastic Recyclers] to approve your finished package for recycling. If you want to claim compostability in the European Union, you have to get Technischer Überwachungsverein certified in Germany. In the USA, the Biodegradable Products Institute certifies compostability.

Sand: Ah, the facts. That is what scorecards are supposed to assist with. One I do like is the section of the UP Scorecard that addresses an issue—chemicals of concern—that is ignored by other scorecards.

Recent legal action is clarifying the facts for consumers and brand owners too. For example, the plastic identification code developed in 1988 looks like a recycling symbol even though it is not, and California recently enacted a labeling law that mandates removal of the symbol. And there is also legal action against TerraCycle which alleges that they deceived consumers into thinking that packages are recycled when they are sent to TerraCycle facilities.

Lilienfeld: In many cases, using scorecards plants a seed. They can get people to realize that they may have to move in new directions or be open to new directions. It takes a while to actually grow the tree. For example, from Walmart, we now have Project Gigaton, designed to reduce carbon dioxide generation within the Walmart supply chain by 2.2 trillion pounds annually.

Disappearing Plastics

Sand: Many consumers have a strong wish for plastics to simply disappear.

Lilienfeld: I know. It is strange. If you start from the perspective of what is it that plastic material delivers, it is an amazing material. For example, polyethylene (PE) has one of the highest strength-to-weight ratios of any material in our universe. What this translates to in food packaging is that PE bags hold a lot of stuff. Plus, PE was a waste byproduct—an upcycled product from oil refining.

Sand: Material science advances in coatings, adhesives, inks in packaging are advancing the efficacy of what plastics can do. Bioderived PE from a renewable resource and recycling of flexible packaging has a lower LCA than fossil-derived PE. Making the distinction between bioderived and biodegradable is paramount.

Lilienfeld: Agreed! In theory, compostable or biodegradable packaging sounds great. But the reality is it doesn't just break down and go away. There are two types of composting—industrial composting and home composting—and the odds that a package is going to break down and go away in your home composter are almost nil. In order for the most popular biodegradable polymer, which is PLA [polylactic acid], to break down, it has to be in an environment where the temperature is at least 131°F, and that takes energy and is also not happening in your backyard in Minnesota anytime soon.

There are not a lot of facilities around that will accept biodegradable polymers. On top of that, even amongst those that do exist, a lot of them don't want PLA. They don't want it because frankly, it is a contaminant or contains contaminants, and the only reason they accept it is because it's the cost of getting the food waste and yard trimmings they do want.

Sand: Many people immediately assume that more sustainable packaging is compostable packaging. I find this very frustrating for many reasons. First, composting packaging is just above landfilling on the EPA pyramid and often not the most sustainable option. Second, compostable packaging is not compatible with municipal solid waste compost facilities that handle only food scraps, and we have limited capacity to handle compostable packaging. Third, the standards measure a limited amount of byproducts and allow certification if the particle size is 2 mm or less. And fourth, advocates for compostability cite packaging waste in oceans and on land, and they do not address that it is likely that compostable packaging will degrade in an uncontrolled manner and contaminate our water or soil. On this last point, PFAS [per- and polyfluoroalkyl substances] was not measured by compostability standards until two years ago.

Lilienfeld: Oddly, a lot of people who say they're in favor of a circular economy want composting of packaging, because [they mistakenly think] the packaging will somehow disappear into compost and will rejuvenate the soil. Compostable packaging was never part of the soil. For example, the result of composting plastic is not compost—it's greenhouse gases. It’s water vapor, it’s carbon dioxide, and if it's an anaerobic process like in a landfill, the third gas is methane. If it's an aerobic process such as in an industrial composter, the third gas is ammonia.

Sand: Those are greenhouse gases, so let me get this straight—a piece of plastic will be put in an environment where it breaks down. And in the best of circumstances, this creates greenhouse gases. In the worst of circumstances, it creates greenhouse gases and microplastics. It sounds as if composting often is not the most sustainable option.

Food Waste and Food Access

Sand: I became interested in food packaging in 1984 to use packaging to prevent food waste and improve food access. Awareness is increasing: We just had the second annual [virtual] FAO [Food and Agriculture Organization] International Day of Food Loss Waste Awareness in September. One point I made at the event was that we need to respect that many people have other things, such as feeding their children, to worry about rather than more sustainable packaging. The key is to provide good package choices for them that allow them to take care of their other nutrient needs and not really think about the packaging being the most sustainable or not. It just will be.

This is a tall order. But I do hope the conversation shifts to where more sustainable packaging is viewed as packaging that protects resources, and its disposal and sourcing can be taken for granted.

Lilienfeld: The whole underlying mechanism of food production, starting with corn and then corn being fed to cattle, significantly reduces the cost of getting that food on our plates. So we are spoiled. If we actually had to pay what it really costs to produce food, we would waste a lot less because it would be a significantly bigger portion of our disposable income.

Sand: We do see less food waste with high-value items such as meat and fish. The bottom line is reducing the total impact we have on the planet versus blindly following one solution. For example, for food with high greenhouse gas impacts, more sustainable packaging must focus on preventing that food waste. Smart brands and packaging companies are using packaging judiciously and respectfully to reduce food waste after retail, employing packaging that is more sustainable and linking the UNSDGs.

Springing Forward

Sand: Moving forward, we in the industry need to lead. Can you share details about the SPRING initiative and how it will make an impact?

Lilienfeld: SPRING stands for Sustainable Packaging, Research, Information, and Networking Group, and this is a concept that I started working on almost 10 years ago. SPRING provides transparent expertise and allows policymakers [and] business leaders, to make science-based and better decisions on more sustainable packaging. We have an advisory board—of which I am proud to say you are a member—with subject matter experts who have 25-plus years of expertise in a particular field and possess not just knowledge, but also compassion and facilitation skills. We have the ability to take a step back and instead of talking about which is the best bioderived polymer, we dig deep into the specifics of the best use of bioderived polymers to reduce greenhouse gas generation.

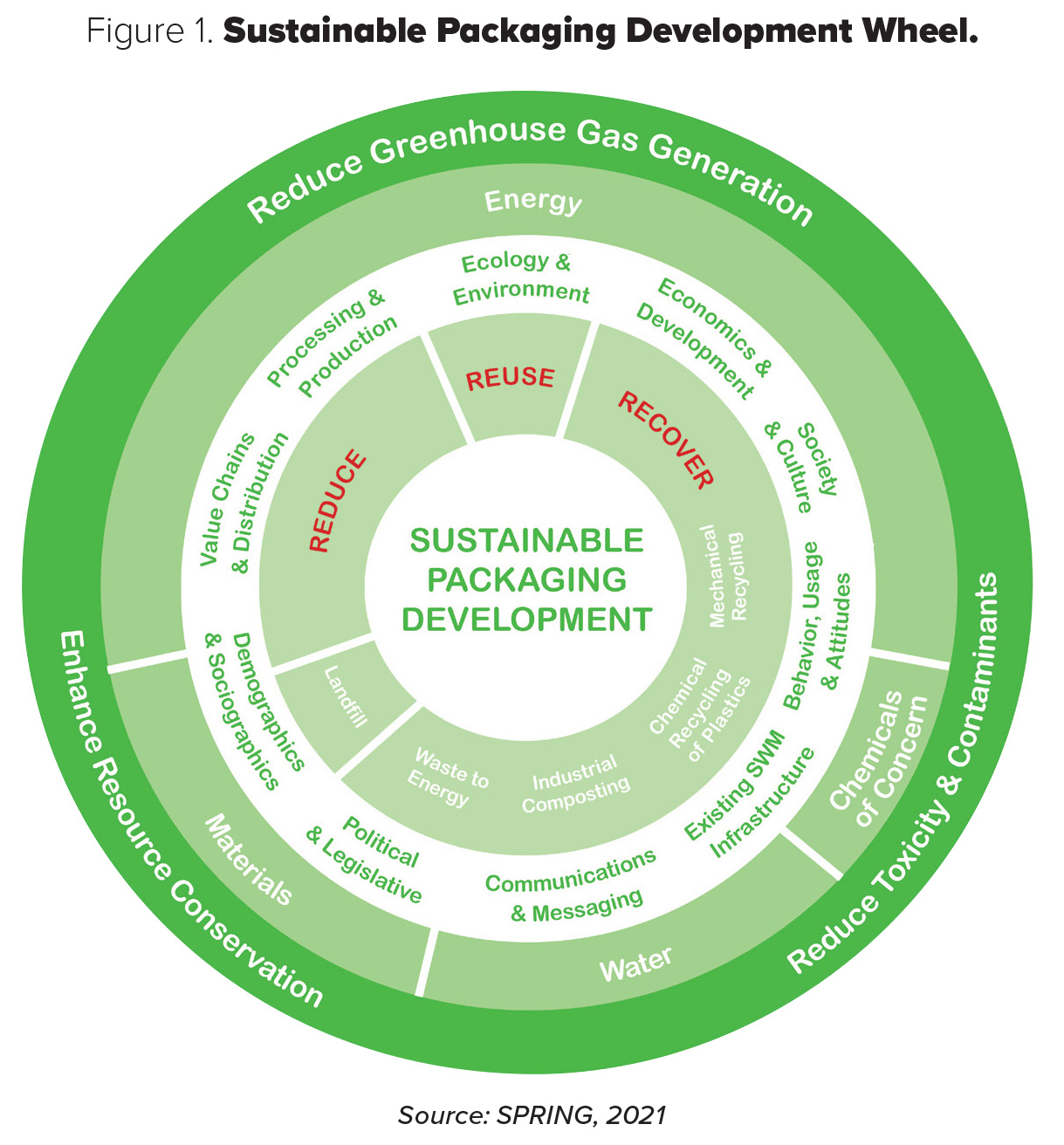

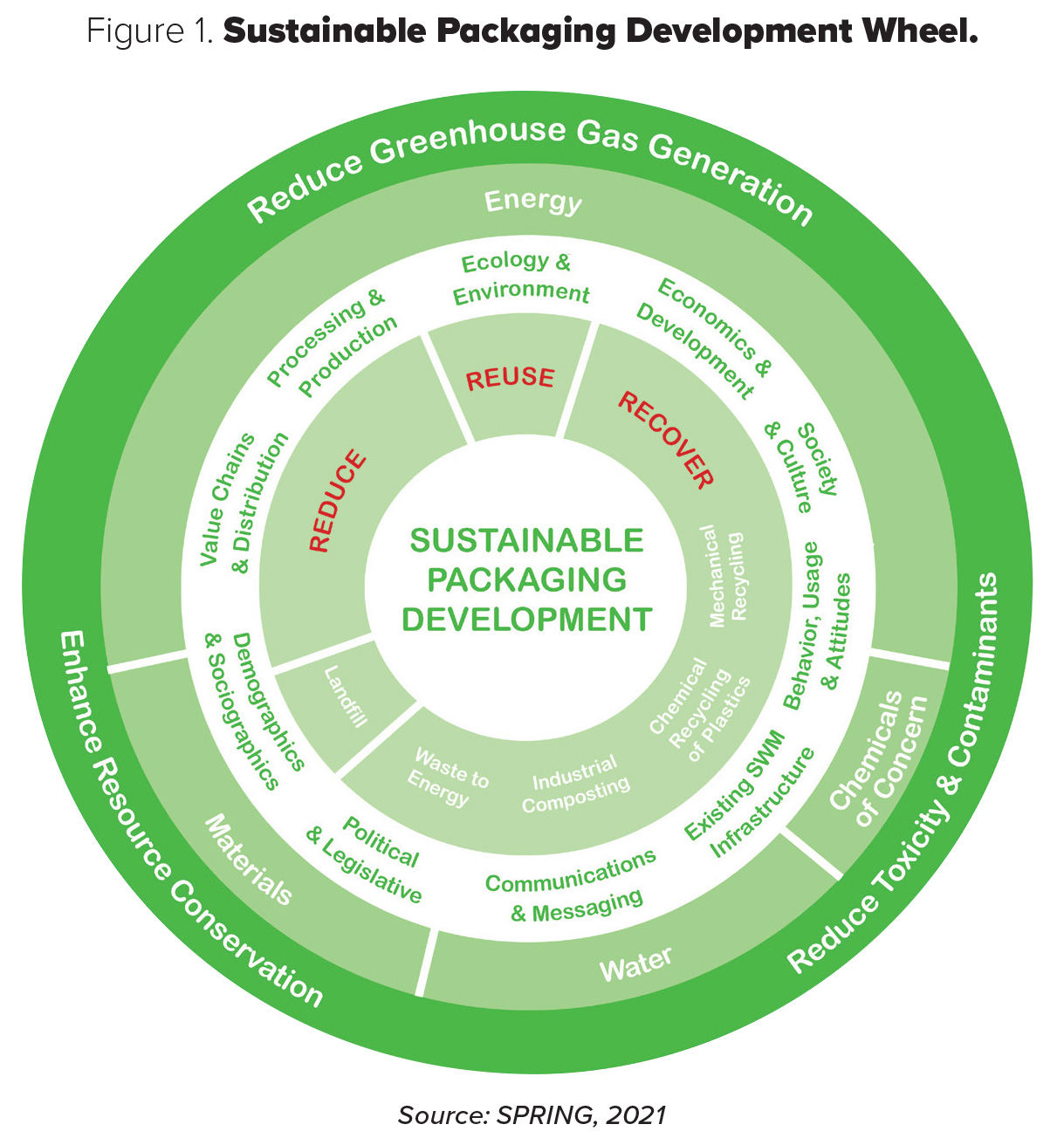

One of our goals is to help people understand the incredible complexity associated with the development of sustainable packaging. And many times, sustainability is defined by cultural and political considerations, not just scientific ones. To help people understand this complexity, SPRING has developed what I like to call the sustainable packaging development wheel (Figure 1

Sand: I think a lot of scientists, myself included, get so excited about a new material, and it's so important to take a step back and focus on the end goal—to achieve a more sustainable food system.

Lilienfeld: I agree. And we need to trust these scientists and our subject matter experts. Probably around 95% of consumers are never going to be in a position to make a smart decision about sustainable packaging, just as I am never going to be in a position to make a smart decision about what's the proper way to sustainably landscape my yard in eastern Colorado. That is what experts do. It's more important that we in industry get back to the understanding that expertise provides value that allows us to live our lives and feel reasonably comfortable that the big problems are being looked after by people who are capable of making those decisions. SPRING provides this expertise so that new materials, ideas, and processes can be assessed rationally.

Sand: A lot of young people are passionate about the environment. Right now we have a golden opportunity to harness the passion of the next generation and the experience of our generation. We just need to make the right decisions.

Lilienfeld: The packaging industry has a lot to be proud of. We do need to focus on the goal of truly reducing the environmental impact of packaging, and let expertise be our guide.