Transforming Food Waste into Bandages

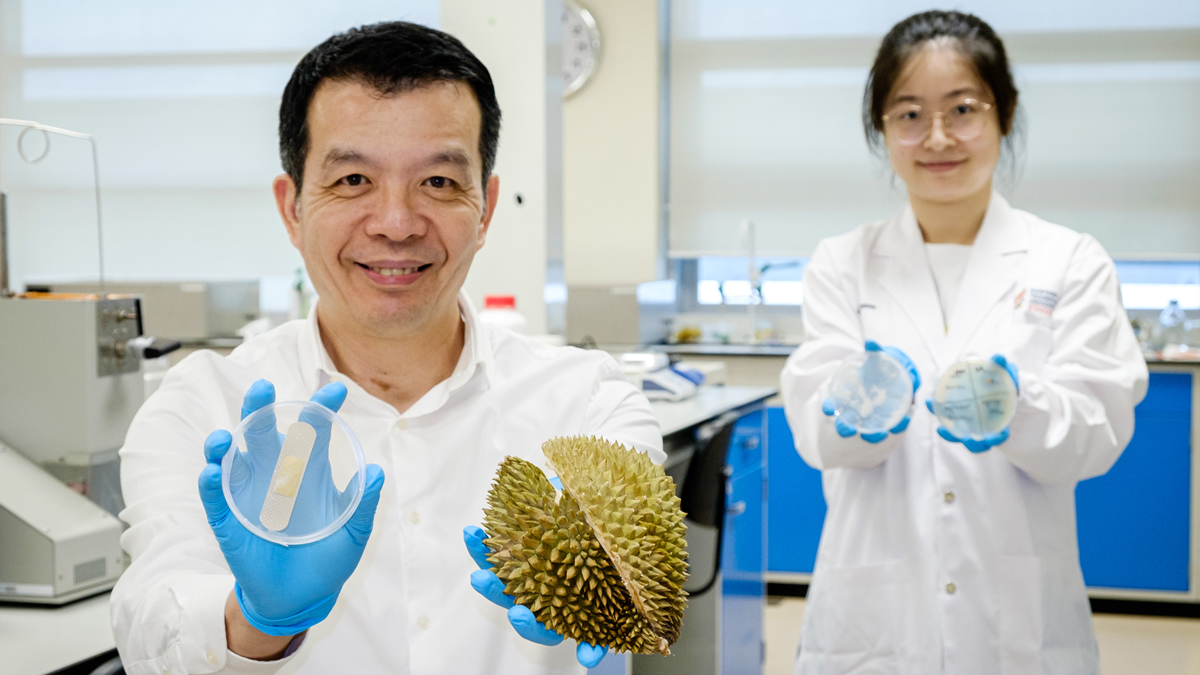

Researchers at Nanyang Technological University’s have developed technology to extract cellulose from durian husks to make hydrogel bandages and food packaging film.

Often described as sweet and custard-like, the pungent durian fruit (Durio Zibethinus Murr) is popular in Southeast Asian countries including Thailand, Indonesia, and Singapore. “We consume 12 million durian in Singapore every year,” says Professor William Chen, director of Nanyang Technological University’s (NTU) Food Science and Technology Program. The fruit’s hard, thorny husks make up 65%–70% of the entire weight of the fruit and are usually thrown out—contributing to environmental waste. Cellulose—an abundant renewable biopolymer—comprises 31.6% of the husks, which is “higher than other side-streams from food processing, such as soybean residues,” explains Chen.

Often described as sweet and custard-like, the pungent durian fruit (Durio Zibethinus Murr) is popular in Southeast Asian countries including Thailand, Indonesia, and Singapore. “We consume 12 million durian in Singapore every year,” says Professor William Chen, director of Nanyang Technological University’s (NTU) Food Science and Technology Program. The fruit’s hard, thorny husks make up 65%–70% of the entire weight of the fruit and are usually thrown out—contributing to environmental waste. Cellulose—an abundant renewable biopolymer—comprises 31.6% of the husks, which is “higher than other side-streams from food processing, such as soybean residues,” explains Chen.

Given the abundant supply of durian husks and their valuable cellulose content, Chen and his team at NTU set out to develop a method for extracting the cellulose and coming up with potential market uses for it. The proprietary process they developed involves chopping the husk into small pieces, then freeze drying and grinding them into a fine powder. From there, the researchers treat the powder with various solutions and rinses to remove the residual lignin and hemicellulose. “The cellulose extraction technology—and removal of other impurities—is green in nature and simple in process,” says Chen.

Mixing the extracted cellulose with glycerol resulted in soft, gel-like silicon sheets. As detailed in a recent study, the researchers then added organic molecules produced from baker’s yeast—known as yeast phenolics—to the hydrogel to give it antibacterial properties. The result? An antibacterial bandage that can be cut to various sizes and shapes. “As our cellulose-derived hydrogel has high water absorption ability and good antimicrobial activity, it can be used to absorb interstitial fluid on the wound and prevent infection at the same time,” says Chen. Conventional bandages are designed to simply protect the wounds, and their antibacterial properties come from metallic compounds like silver or copper ions, which are both expensive and inherently toxic. According to Chen, the hydrogel is “natural and sustainable; thus, its incorporation into bandages provides added function.”

The technology can be used on food waste materials besides durian husks. “Our cellulose extraction technology can be applied to soybean residues, thus showing its versatile nature to be a platform technology applicable to various raw materials of similar nature—those high in cellulose content,” says Chen. Additionally, the extracted cellulose has uses beyond healthcare. In 2019, the researchers published a study showing that the cellulose from durian husks could be used to make a film for food packaging that is comparable to commercial cellophane in its transparency, thermal properties, and structure, while also being biodegradable, sustainable, and low in cost.

Chen and his fellow NTU researchers have spent years developing ways to extract useful ingredients from what would otherwise end up in the landfills or incinerators. With less than 1% of land in Singapore used for farming, the country imports more than 90% of its food. According to Chen, Singapore also has a challenge in dealing with food waste, which amounted to 650,000 tons in 2020. “Food waste reduction not only helps us decrease environmental pollution, but also leads to lower levels of food import,” says Chen. “It’s all related to Singapore’s food security.”

Digital Exclusives

10 Food Trend Predictions for 2022

The editors at Food Technology magazine, published by the Institute of Food Technologists (IFT), have announced their predictions for the hottest food trends for 2022.

Food Technology Articles

How to Achieve EPR-Forward Packaging

In this two-part series, the author explores the history of Extended Producer Responsibility (EPR), what is needed to help EPR succeed, and how brands can best prepare for EPR.

Future Food-Tech 2024 Tackles Transformation, Underscores Collaboration

Mission-driven Future Food-Tech exhibitors and conference presenters showcased innovative, transformative ingredients and technologies and emphasized the importance of collaboration in addressing food system challenges.

Keeping the ESG Promise

An infographic describing food and beverage companies’ outlooks regarding ESG initiatives.

Ag-Tech’s Passionate Pragmatist

Agrologist and agricultural futurist Robert Saik wants to feed the world better and more sustainably. To make that happen, leveraging science and technology will be critical.

The State of Sensory Science

Three seasoned sensory scientists share their thoughts on the complexity of measuring consumer perceptions, the value of academic/industry collaboration, the evolution of the discipline, and why they love what they do.

Recent Brain Food

A New Day at the FDA

IFT weighs in on the agency’s future in the wake of the Reagan-Udall Report and FDA Commissioner Califf’s response.

Members Say IFT Offers Everything You Need to Prepare for an Uncertain Future

Learn how IFT boosts connections, efficiencies, and inspiration for its members.

More on the FDA's Food Traceability Final Rule

In a new white paper, our experts examine the FDA’s Food Traceability Final Rule implications—and its novel concepts first proposed by IFT.

Job Satisfaction in the Science of Food is High but Hindered by Pain Points

IFT’s 2022 Compensation and Career Path Report breaks it down.