Removing Alcohol from Wine

PROCESSING

Many people want to enjoy the taste of wine but do not want the alcohol, for any of a number of reasons, such as pregnancy, illness, alcoholism, abstention, or dieting. The wine industry has responded by producing and marketing nonalcoholic products. This month’s column will focus on methods for removing alcohol from traditionally fermented wine rather than formulating products without alcohol.

Nonalcoholic wines represent a niche market, accounting for about 0.5% of the total United States wine market, according to Stan Hock (phone 707-963-3104), Director of Communications at Sutter Home, St. Helena, Calif., the largest producer of nonalcoholic wines in the U.S. About 500,000 cases of nonalcoholic wine—one case equaling 9 liters, regardless of bottle size—are produced in the U.S. per year, primarily by three wineries: Sutter Home, Ariel Vineyards, and Canandaigua Wine Co., Inc.

Four methods are approved by the Bureau of Alcohol, Tobacco and Firearms for removing alcohol from wines to produce nonalcoholic wine (containing less than 0.5% alcohol) or reduced-alcohol wine (7–8% alcohol), according to Richard M. Gahagan (phone 559-251-1759), ATF’s Wine Technical Advisor. They are thin-film evaporation under reduced pressure (also called vacuum distillation), reverse osmosis, spinning cone column, and thermal gradient processing. Of these, only reverse osmosis and the spinning cone column are being used by the major producers of nonalcoholic wine.

• Thin-Film Evaporation. Canandaigua Wine Co., Gonzales, Calif., produced the first nonalcoholic wine, Inglenook St. Regis, in the U.S. in 1975. The company initially used centrifugal thin-film evaporation under vacuum. In this method—described in U.S. patent 4,405,652 issued in 1983 to Armand R. Boucher at Canandaigua’s parent company, Joseph E. Seagram & Sons, Inc., New York, N.Y.—wine is fed to a centrifugal evaporator consisting of several hollow cones. A thin film of product travels across the inner surface of the cone, which is in turn heated by steam flowing through the hollow chamber within the cone. Exposure of the thin film to elevated temperatures for a relatively short period of time under vacuum allows the alcohol to be removed as vapor. The company switched to a reverse osmosis process in 1989.

• Reverse Osmosis. Ariel Vineyards, Napa, Calif., which produces only nonalcoholic wines, also uses reverse osmosis. It has been marketing its Ariel nonalcoholic wine since 1985, currently selling about 110,000 cases/year, for a 22% market share, according to Ariel’s Winemaker Jeff Meier (phone 408-288-5057). The company’s nonalcoholic wines have won eight medals in professional judging against wines with alcohol.

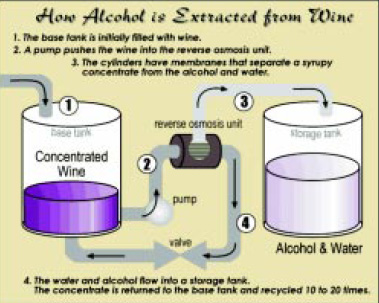

If a solution, such as wine, is placed on one side of a semipermeable membrane, and water is placed on the other side, water will diffuse through the membrane to the solute side until the concentration is the same on both sides of the membrane. This phenomenon is called osmosis. In reverse osmosis, wine is pumped against the membrane at a pressure greater than the osmotic pressure, causing smaller-molecular-weight compounds such as ethanol and water to diffuse selectively through the membrane, thereby removing the alcohol from the wine. The membrane rejects or passes compounds based on their molecular weight and the membrane pore size. Since ethanol and water are small relative to the wine matrix, the larger compounds, such as organic acids and phenolics, are retained in the wine and are concentrated. Water is added back to the concentrated wine to restore the initial balance of these materials and produce a pleasing nonalcoholic or reduced-alcohol wine.

Meier said that they are using reverse osmosis because they feel that this cold filtration method is a superior technology, since there is no heating of the product and the wine therefore retains all of the natural flavor of the grapes. The alcohol removal is conducted under high pressure (450 psi), with the temperature controlled to 45–55°F. Very small membrane pore sizes are used so that only alcohol and water pass through. Meier said that there is no water on the other side of the membrane at the start; the pressure of the filtration moves liquid through the membrane. If desired, the alcohol can be recovered from the alcohol-and-water permeate by standard steam distillation. Although to be called nonalcoholic, the wine must contain less than 0.5% alcohol, he said, the resulting wine generally has one-tenth that level.

According to Barry Gnekow (phone 415-929-8136)—formerly Ariel’s President and Winemaker and now an independent winemaking consultant—reverse osmosis was a breakthrough technology. Prior to it, all other methods for removal of alcohol from wine required application of heat, which destroyed the flavors. De-alcoholized .wine was first made and marketed by Carl Jung in Germany in 1920, he said, but the product reportedly wasn’t very good. It was made by distillation, which removed not only the alcohol but also the flavor volatiles. In contrast, reverse osmosis maintains the same flavor after the process as before. The process is described in his U.S. patents 4,888,189 (1989) and 4,999,209 (1991), assigned to Ariel.

• Spinning Cone Column. Sutter Home, which has a 60–65% share of the nonalcoholic wine market, was the first winery in the U.S. to use the spinning cone column (SCC) to produce nonalcoholic wine, introducing its Fre™ line of alcohol-free wines in 1992. According to Hock, the company chose the SCC because it does a better job of preserving essential wine aromas and flavors.

The SCC, developed in Australia, has been marketed in the U.S. since 1991 by Flavourtech Americas Inc., Graton, Calif. Company president Tony Dann (phone 707-829-6200) said that the SCC process is superior to other alcohol-removal systems, since both steam distillation and reverse osmosis degrade wine aromas and flavors through exposure to either the heat or high pressures used to remove the alcohol, and reverse osmosis concentrates the residual base liquid to the extent that it must be diluted with water.

The SCC is a thin-film multistage stripping column that uses centrifugal force to enhance distillation. The 40-in-diameter, 13-ft-high column contains a series of alternating stationary and rotary truncated cones. Wine is fed into the top of the column, flows down the upper surface of the first stationary cone and onto the surface of the first spinning cone, where centrifugal force spreads it into a turbulent thin film that flows off the cone and drops onto the next stationary cone, and so on. The stripping gas—generally low-pressure steam—enters the column at the bottom and flows upward, stripping out the flavor volatiles from the thin film. The volatiles are then condensed and collected. The wine without the volatiles is then run through the column again, at a slightly higher temperature, to reduce the alcohol content to the desired level. The volatiles are then added back to the alcohol–reduced wine to produce a low-alcohol wine which retains its original flavor. The alcohol can be recovered as a by-product.

Scott Burr (phone 707-829-6218), Flavourtech’s Vice President of Operations, said that the SCC differs from the falling-film centrifugal evaporator described in the Seagram patent, in that the Seagram system removed the alcohol from wine at 40–50°C in a single step, taking the flavor volatiles with it. In contrast, the SCC accomplishes alcohol removal from wine at high degrees of vacuum (29.5 in Hg) in two steps. It removes all flavor volatiles in the first pass at 26–28°C, removes the alcohol in a second pass at a slightly higher temperature (33–35°C), then adds the flavor volatiles back to the alcohol-reduced wine.

Although its use in the wine industry was initially met with skepticism by winemakers, Dann said, the SCC is now a standard tool, used by 300 wineries. Although it is being used to produce nonalcoholic wine, he said, by far the most common use of the SCC is to make minor adjustments in the alcohol content of wine to account for variations in sugar content of the grapes and consequently the alcohol content. Wine with a high alcohol content (14–15%) doesn’t produce the proper flavor nuances on the palate, he said, so the SCC can be used to adjust the alcohol level in the wine.

• Thermal Gradient Processing. In this method, wine is cooled to form ice crystals, which float to the top of the tank, increasing the alcohol concentration in the liquid. About half of the contents is then drained from the bottom of the tank. Then the tank is heated to melt the ice crystals, essentially diluting the liquid in the tank and thereby producing wine with reduced alcohol concentration. ATF’s Gahagan said this energy-intensive method is not currently being used commercially.

• Osmotic Distillation. Another method of dealcoholizing wine is osmotic distillation. Christian E. Butzke (phone 530-752-9312), Professor and Enologist at the University of California–Davis, said that in osmotic distillation, wine is passed through a hydrophobic hollow-fiber membrane and degassed water is passed along the other side. The difference in vapor pressure results in some of the alcohol in the wine evaporating into the water. This is done at room temperature without elevated pressures (except enough pressure to gently pump the wine), whereas reverse osmosis uses high pressure and vacuum distillation uses elevated temperature, both of which conditions may be detrimental to wine quality.

Gahagan said that osmotic distillation is not yet approved for commercial use but is being tested in some wineries. The companies are not authorized to market the product but are authorized to blend small trial lots back into commercial wine after ATF examines the samples. So far, he said, the process looks very favorable. However, it generates a lot of stripping water containing alcohol, a consideration for a company that wants to use the process. The alcohol can be recovered by traditional distillation.

Butzke added that small alcohol adjustments (1–2%) are currently the most popular and widespread application of both SCC and reverse osmosis, and potentially osmotic distillation, in the California wine industry. This allows the winemaker to harvest grapes at optimum flavor ripeness, even when the sugar content—and therefore the resulting alcohol concentration in the wine—is very high. Alcohol, he said, has a strong impact on the balance of a wine, affecting acidity, astringency, and volatility of aroma components, and he is experimenting with replacing the sensory characteristics of alcohol with other ingredients.

PATENTS

Removal of undesirable components from a liquid or gas with proteinaceous oat material. U.S. patent 6,113,964, filed 3/16/1998, issued 9/5/2000 to R.C. Potter et al., assigned to Nurture, Inc. Describes a system for removing bitter or otherwise undesirable compounds, such as caffeine and tannins, from beverages such as tea, coffee, or wine by using a natural proteinaceous milled seed material derived from oats. The liquid or gas is contacted with the material, resulting in the sequestration of the undesirable compounds within the pores of the proteinaceous material.

Method for removing cholesterol from milk and cream. U.S. patent 6,110,517, filed 7/29/1998, issued 8/29/2000 to H.S. Kwak et al., assigned to Se Jong University. Describes a method for removing cholesterol from milk and cream at a high efficiency without deleteriously affecting the product quality. After homogenization, beta-cyclodextrin is added to milk at 0.5–5% (w/v) to form a complex. The milk is stirred at 4–30ºC and 200–2,000 rpm for 5–30 min, followed by centrifugation at 22–555 x g for 5–30 min to isolate the complex. Similarly, beta-cyclodextrin is added to cream at 1–20% (w/v) and then treated by stirring at 20–60ºC and 400–4,000 rpm for 5–60 min and centrifuging at 222–444 x g.

Products & Literature

NONCONTACT INFRARED THERMOMETER for the foodservice industry is calibrated to meet 1% accuracy (+/-1ºC/2ºF) in the 0–65ºC/32–150ºF food safey zone. The MiniTemp Food Safety (FS) model can quickly and accurately identify potential problem areas, which can then be confirmed using a traditional probe thermometer to take internal temperatures. It also has a laser sighting system that helps pinpoint the measurement area on the cooking, processing, or preparation surface. For more information, contact Raytek Corp., P.O. Box 1820, Santa Cruz, CA 95061-1820 (phone 800-866-5478 or 831-458-1175 ext 353, fax 831-425-4561, www.raytek.com) —or circle 306.

CRYOGENIC FREEZER, the AGA Freeze SC, uses a disposable plastic film belting system to handle delicate, wet, sticky, and hard-to-handle products efficiently and hygienically. Product travels on a disposable plastic film that is in contact with the cold plates as it moves through the SuperContact freezer. The plates are chilled to –196ºC with vaporized liquid nitrogen. High-speed fans circulate the cold generated by the plates to quickly freeze the upper surface of the product and ensure efficient use of the cold air. The single-use plastic film enables processors to quickly and efficiently clean the freezer at the end of each production run. For more information, contact AGA AB, S-181 811 Lidingo, Sweden (phone +46 8 731-10 00, fax +46 8 765 2487, www.ga.com) —or circle 307.

METRIC CONVERTER/CALCULATOR provides answers for 126 types of conversions. Users simply enter a number, press an arrow, and read the metric or U.S. answer with decimal point in place. The solar-powered converter converts length, area, volume, weight, liquid measures, energy, and temperature. It also performs English conversions and has all routine calculator functions. The lightweight unit measures 2.5 in x 4.25 in x 0.25 in and weighs only 2 oz. For more information or a 6-p catalog of other types of calculators, contact Control Co., 308 W. Edgewood, Friendswood, TX 77546 (phone 281-482-714, fax 281-482-9448, www.control3.com) —or circle 308.

MICROWAVE HEATING LITERATURE DATABASE is available for on-line searching. Spanning more than 25 years of publications by the International Microwave Power Institute (IMPI) and almost 3,000 literature citations, the database offers researchers, educators, and product developers a quick, easy method of browsing through the microwave heating literature by author, keyword, or subject title. Search results provide information on source, publication date, order availability, and cost. For more information, contact IMPI, 10210 Leatherleaf Ct., Manassas, VA 20111 (phone 703-257-1415, fax 703-257-0213, www.impi.org) —or circle 309.

PROCESS DESIGN SOFTWARE helps food technologists identify, through a system of comprehensive checklists, the safety issues associated with specific unit operations, raw materials, and ingredients. The safefood Process Design System also contains a library of about 1,000 articles, providing background information on hazards, controls, and related issues. The system covers such processes as washing, baking, pasteurization, and sterilization and such products as meat, fish, dairy, fats and oils, cereals, fruits, and vegetables, including combination products. The emphasis is on microbiological food safety, with additional guidance regarding physical and chemical contaminants. For more information or a demonstration copy, contact CCFRA Technology Ltd., Chipping Camden, Glos., GL55 6LD, UK (phone +44 (0) 1386 842225, fax +44 (0) 1386 842100, www.campden.co.uk) —or circle 310.

by NEIL H. MERMELSTEIN

Senior Editor