Mycoprotein—A Meat Alternative New to the U.S.

Production and Properties of Mycoprotein as a Meat Alternative

Although thousands of new food products are launched every year into the retail food market, very few of the ingredients used in their manufacture are really new in the sense that they have never been used before. The subject of this article is one of those few: a new ingredient, mycoprotein, about to be introduced into the market in the United States, which has both physical and clinical functional properties.

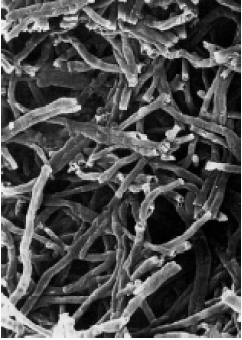

Mycoprotein is the generic name given to the ribonucleic acid–reduced biomass comprising the hyphae (cells) of the organism culture PTA 2684 grown under axenic conditions (i.e., without adventitious microbial growth) in a continuous fermentation process.

Development of Mycoprotein

The development of mycoprotein had its roots back in the early 1960s, when there was a concern that the world was on the brink of a severe food protein shortage. This stimulated a great deal of activity to find alternative sources of protein, not just by traditional food companies, but also by the chemical and petrochemical industries. The intention was to use by-products of these industries as nutrients for the growing of single-cell systems (bacteria/yeast/fungi) which would be harvested and used as a new source of protein, principally for animal feeds but also in human foods where appropriate.

During the development of these processes, it was realized that the projected protein shortages were probably not going to materialize as expected and that the competitive prices of traditional protein sources generally meant that single-cell systems as animal feeds were not economically viable. However, it became apparent that one raw material—mycoprotein—had exciting physical and nutritional properties which enabled very attractive development of it as a human food to be followed.

Although mycoprotein is obtained from a naturally occurring source, the lack of history of application in human foods meant that safety evaluation and regulatory approval were necessary. Approval for general food use was granted in the UK in 1985 and in the rest of Europe in succeeding years, and Food and Drug Administration approval for use of mycoprotein, under food additive legislation, as a food ingredient is expected this summer. A panel of U.S. experts reviewed all the relevant data in 1998 and declared that in its view, “The process has been demonstrated to a reasonable certainty to produce a consistent product that is free of contaminants that might pose a risk to human health” (see “Evaluating the Safety and Nutritional Value of Mycoprotein” beginning on p. 42 of this issue).

Production of Mycoprotein

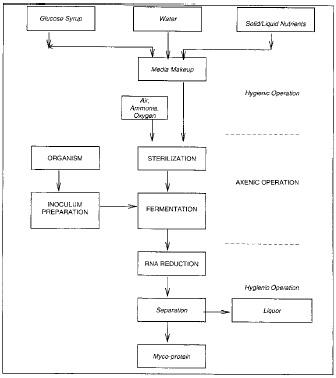

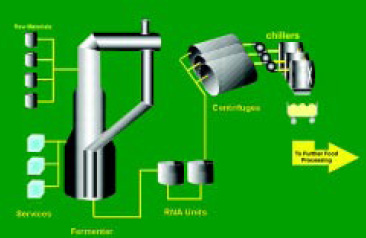

Mycoprotein is produced by the process outlined in Figs. 1–3. All raw materials used in the process are of food-grade quality and purity. These materials, which are components of the liquid feeds to the fermenter, are combined together in ways which optimize process operation. The liquid and gaseous feeds are sterilized prior to addition to the fermenter. The inoculum is prepared by a patented process starting from stock cultures which are available in lyophilized form from the American Type Culture Collection, Washington, D.C., as PTA-2684.

Following initial filling of the fermentation vessel, which has been sterilized, an inoculum of pure culture is introduced. After a period of batch growth of the organism, a continuous feed of nutrients and simultaneous removal of fermenter broth are established. In the continuous fermentation process, constant environmental conditions are maintained by continuous automatic control.

The plant is designed and the process operated so as to avoid contamination. Temperature and pH are controlled, and the flow of nutrients is adjusted to maintain an excess in the supernatant. Flows of other medium components are set to maintain the specified supernatant conditions. The process is aerobic, so the supply of air and any supplementary oxygen is adjusted in response to measured dissolved oxygen levels. Biomass concentration is controlled by adjustment of the total flow of medium into the fermenter, and is inferred from the carbon dioxide evolution rate and checked by on-line analysis; the fluid level in the fermenter is maintained by control of exit flow.

--- PAGE BREAK ---

Since the purine bases in nucleic acids are metabolized to uric acid, foodstuffs should be treated, if possible, to reduce their RNA content to minimize any increases in serum uric acid. Therefore in the production of mycoprotein, its RNA content is reduced from 10% to less than 2% (dry weight) by rapidly heating the fermenter “broth,” a process which causes complete loss of viability and loss of most of the cell RNA into the supernatant. Following RNA reduction, the suspension is recovered by a centrifugation dewatering process in the form of paste. At this point, the paste which is collected has a water content of approximately 75%, and is denoted by the name mycoprotein.

Physical Functionality and Applications

Mycoprotein’s physical characteristics make it suitable for use in various applications:

• As a Muscle Fiber Replacer (for use in meat-alternative products). The functionality of mycoprotein derives from the shape and size of the hyphae. It is not via any solution properties, since mycoprotein is not soluble nor does it give rise to any soluble components. This is the result of the heat treatment experienced during the RNA reduction process, which renders the protein component insoluble.

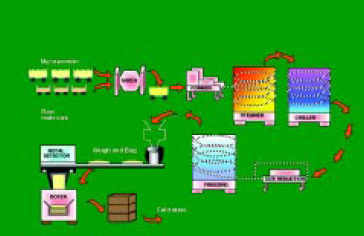

The hyphae are typically 400–700 μ long and 3–5 μ in diameter, and the branch frequency is 1 per 250–300 μ . Because the harvested hyphae have a similar morphology to animal muscle cells—i.e., they are filamentous with a high length/ diameter ratio—one product application seeks to reproduce the structural organization which exists in natural meats. In meats, muscle cells are “held together” by connective tissue; to establish a similar product texture with mycoprotein, the hyphae are mixed with binders, flavorings, and other ingredients depending on final product format, formed into the required shape and size by the appropriate processing equipment, and then heated, which causes the protein binder to gel and thereby “bind” the hyphae together.

The resulting structures are similar to those in meat products, and they also break down in the mouth during chewing in a manner similar to meat products, which accounts for their similar textural properties. The meat-alternative products contain a high level of mycoprotein (up to 90% of product weight), and are expected to have retail sales in excess of $150 million in 2001.

• As a Fat Replacer. Although the properties of the hyphae constituting mycoprotein are such that they are not sensed as individual particles in the mouth, they do exert a rheological effect which can be used in products where they exist in a dispersed state. These rheological properties can also be influenced by modifying the length of the hyphae and their relative phase volume in the formulation, and a range of products, including yogurt and ice cream, where the mycoprotein acts as an effective fat replacer, are under development.

• As a Cereal Replacer. The properties of mycoprotein also allow it to be used in extruded formats similar to breakfast cereals or puffed snacks. The resultant products compare favorably with commercial products in parallel taste testing.

--- PAGE BREAK ---

Nutritional and Clinical Functionality

In addition to physical functionality, mycoprotein also has nutritional and clinical functionality. It has been described as a functional food by Turnbull (1998).

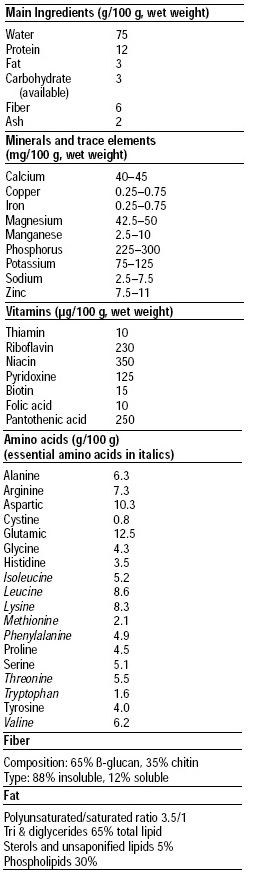

• Nutritional Analysis. A typical analysis of mycoprotein as “harvested” is shown in Table 1. The amino acid composition of mycoprotein shows the presence of all the essential amino acids. The fat content of the harvested material is typically 2–.5%, and the fatty acid composition is much more like vegetable than animal fat. The cell wall components of the harvested mycelia contribute approximately 6.25 g of dietary fiber/100 g of cells (wet weight), giving mycoprotein the unusual combination of being a good source of protein and being rich in fiber. The composition of the fiber is about one-third chitin and two-thirds β-1,3 and -1,6 glucans.

• Effect on Blood Lipids. The consumption of mycoprotein under both controlled and free-living studies has been shown to significantly reduce total and LDL serum cholesterol levels, and occasionally raise HDL levels. These effects have been reported in various studies by Udall et al. (1984), Turnbull et al. (1990, 1992); Nakamura et al. (1994); Homma et al. (1995); and Ishikawa et al. (1995), and all included the consumption of realistic amounts of mycoprotein. The general consensus was that mycoprotein consumption advantageously altered serum lipid variables.

• Effect on Diabetic Diet. A study by Turnbull and Ward (1995) to investigate the effect of mycoprotein consumption on acute glycemia and insulinemia in normal healthy individuals showed that glycemia was reduced post-meal compared to the control and was statistically significant at 60 min (13% reduction). Insulinemia was also reduced post-meal compared to the control and was statistically significant at 30 min (19% reduction) and 60 min (36% reduction). The authors concluded that mycoprotein could be of benefit in the dietary treatment of diabetes.

• Effect on Satiety. Three studies (Turnbull et al., 1991, 1993; Burley et al., 1993) showed that a mycoprotein lunch has a clear effect on “late satiety”—i.e., the amount of food consumed in the evening was less after a lunch containing mycoprotein than after a control lunch. This and further analysis of the data generated led one author to declare that “these data have clear implications for the use of mycoprotein for the control of appetite and body weight.”

• Other Potential Effects. There are early indications that the fiber component of mycoprotein may function as a prebiotic in the lower gut. The presence of chitin may influence fat uptake from the gut. There is a very large literature in the Far East extolling the value of fungi as food. Of course, many of the claims are unsubstantiated, but several pre-eminent U.S. centers are investigating their putative effects. Mycoprotein is fungal in origin and may also have as-yet-undiscovered benefits.

Organoleptic Properties

One of the quotes used most by food commentators is that “the consuming public will not buy food products on the basis of their nutritional profile/clinical benefits—taste is the key.” In this respect, mycoprotein compares very favorably with soy, for example—it is basically taste free, and in meat-alternative products constituting up to 90% of the product weight on a dry weight basis, there is no aftertaste introduced by the mycoprotein. This is also key to its application in dairy systems, where blandness of ingredients is essential.

Quality of Mycoprotein Products

Mycoprotein is a very versatile ingredient for use in the food industry. It can be used at variable inclusion levels in a range of products. In addition, by virtue of its composition, there are strong nutritional benefits. In contrast, other food ingredients which have clinical effects, such as phytosterols and stanols, have no physical function in the product at all but are present only as a component to affect the physiology of the body.

A range of food products based on mycoprotein have been manufactured and sold in Europe under the brand name Quorn™. These products meet consumer expectations in four areas:

--- PAGE BREAK ---

• Sensory Quality. Because the hyphae in harvested mycoprotein have a similar morphology to that of animal muscle cells, the product assembly process seeks to reproduce in the mycoprotein products the structural organization which exists in natural meats by mimicking the myofibril-connective tissue arrangement which exists in muscle foods.

Of course, not all meat products have identical textures, and neither does the range of mycoprotein products. There are several ways of controlling product textures: varying the amount of the mycoprotein and/or the binder (egg albumen), which are the major influencers of the firmness/chewiness/and fibrosity of the products, and varying the amount of vegetable fat added to control juiciness.

Flavor is also key, and only after thorough evaluation of the performance of a particular flavor in a product is it adopted. This evaluation includes process and storage stability tests, but also, most important, determination of whether it tastes good.

It might be believed that if texture and flavor are satisfactory, then the battle is over. However, appearance is an often underestimated quality parameter. For example, one of the products developed for home cooking (product pieces) was originally cut into dice, but the consumers did not like the “regular” cube shapes. As a result, a process was developed to fracture the parent blocks under tension to create ragged surfaces which looked natural and were much more acceptable. In addition, consumers are often disappointed when cooking meat products—the degree of water and fat loss and product shrinkage can be extreme, and what is seen on the plate may not be representative of what is actually in the package prior to cooking. In contrast, mycoprotein products do not shrink during cooking, and there is no weight loss.

The mycoprotein products (Fig. 5) are considered high in sensory quality, and the line of products is the biggest seller in the UK and is growing very quickly in the rest of Europe, in competition with soy-based products. Consumer research consistently reports that mycoprotein products have none of the disadvantages of poor flavor profiles and spongy textures often associated with the competition.

Does it follow that these products are automatically suitable for the U.S. palate? It doesn’t—market research has shown that there are national and even regional differences in product acceptability, and several European products have required slight alterations to the flavor profile to maximize acceptance.

• Nutritional Quality. Mycoprotein’s nutritional benefits arise from its chemical composition. The cell walls of the hyphae are the source of dietary fiber (chitin and β-1,3- and 1,6-glucan); the cell membranes are the source of the polyunsaturated fat; and the cytoplasm is the source of the high-quality protein.

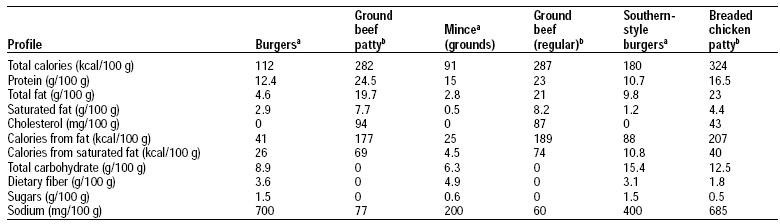

Table 2 compares some of the mycoprotein products and their meat equivalents. The mycoprotein products have a lower total fat content, a lower saturated fat content; and no cholesterol. They also contain intrinsic fiber (there is no fiber in a meat product unless it is introduced as an ingredient), and the fiber does not interfere with mineral absorption, since no phytate is present.

They also have a lower energy density than their meat equivalents. This latter point is significant with regard to obesity in the U.S. Weight management, not weight loss, is the key to maintaining a healthy weight; most individuals can lose weight, but keeping it off without feeling hungry is where the difficulty lies. Mycoprotein products, by virtue of lower energy densities than their meat equivalents and the satiating effects conferred by their mycoprotein content, may therefore play an important role, helping the consumer feel full on fewer calories.

--- PAGE BREAK ---

No less important are the beneficial reductions in total serum cholesterol levels which occur as a consequence of consuming mycoprotein products. New guidelines recommend a revision in the optimal standards for good and bad cholesterol (Anonymous, 2001). Under the new guidelines, which (1) recommend a total cholesterol level of 200 mg/deciliter as a target, (2) raise the “too low” reading for HDL cholesterol to 40 mg/dL (up from 35 ), and (3) indicate that the optimal LDL cholesterol level is 100 mg/dL, the number of Americans using prescribed cholesterol drugs could jump from about 13 million to 36 million. In addition, the number of people prescribed a restricted diet to lower cholesterol would also grow sharply.

• Safety. BSE, foot-and-mouth disease, swine fever, Escherichia coli—these are all issues which have had considerable influence on consumers’ perception of the food industry on both sides of the Atlantic. These “food scares” have also helped the development of the meat-free market, helping drive sales of both mycoprotein-based and soy-based products. Yet, even soy has not been immune from external pressures—the furor in Europe and the increasing awareness of U.S. consumers about the use of genetically modified soy ingredients support the contention that what is real in the food industry is what the consumer thinks is real.

Mycoprotein has a strong pedigree of safety. First of all, as a raw material, it has been subjected to intense safety assessment by both the UK Ministry of Agriculture, Fisheries and Food and FDA. It has been cleared for unrestricted use in food products by the former, and approval by the latter is imminent. Second, every production batch of mycoprotein products is checked to ensure its microbiological safety and sensory quality prior to distribution from the factory, and there are obviously none of the potential dangers associated with meat processing. In addition, it can be guaranteed that mycoprotein is from a non-GMO source. All this helps establish trust and belief in the brand.

• Convenience. The line of mycoprotein products includes ingredients for home cooking, such as grounds and tenders; convenience products, such as burgers, fillets, and nuggets; deli slices; and ready meals—in chilled and/or frozen formats. The initial launch into the U.S. will focus only on frozen products and will be limited to some ingredients for home cooking and ready-meals types of products.

One great benefit to the consumer is the ease of preparing mycoprotein products. They are all “cooked” during the manufacturing process and need only to be heated to an internal temperature which effects product pasteurization (72°C for 10 sec), which can be achieved using any of the usual heating techniques.

A Promising New Market

The mycoprotein products have been extremely successful in the UK and Western Europe because they deliver pleasant eating experiences, an appeal without which no product would be successful in the long term. Whether this success will be repeated in the U.S. will soon become apparent as products go into test market.

The potential of the products as a dietary tool in the management of some health issues has not yet been fully explored, but they promise to open up new markets as the consuming public slowly but surely awakens to the concept that health in life, especially later life, is governed very much by overall lifestyle and diet.

DEVELOPINGFOODS.COM is a quarterly section covering the interaction of Research & Development and Marketing in the development of food products. This special report is also available on the Internet at www.developingfoods.com.

by Graham Rodge

The author is Research & Development Manager, Marlow Foods Ltd., Station Rd., Stokesley, Cleveland TS9 7AB, U.K.

Edited by Neil H. Mermelstein,

Editor

References

Anonymous. 2001. Executive summary of the 3rd report of the National Cholesterol Education Program (NCEP) expert panel on detection, evaluation, and treatment of high blood cholesterol in adults (adult treatment panel III–special communication). J. Am. Med. Assn. 285: 2486-2496.

Burley, V.J., Paul, A.W., and Blundell J.E. 1993. Influence of high fibre food (myco-protein) on appetite: Effects on satiation (within meals) and satiety (following meals). Eur. J. Clin. Nutr. 47: 409-418.

Homma, Y., Nakamura, H., Kumagai, Y., Ryuzo, A., Saito, Y., Ishikawa, T., Takada, K., Yamagami, H., Kikuchi, H., and Inadera, H. 1995. Effects of 8 week ingestion of myco-protein on plasma levels of lipids and apo(lipo)proteins. Prog. Med 15: 183-195.

Ishikawa, T., Ohsuzu, F., Yoshida, H., Yamashita, T., Miyajima, E., and Nakamura, H. 1995. The effect of mycoprotein intake (12 and 24 g per day) over 4 weeks on serum cholesterol levels (in Japanese). Prog. Med. 15: 61-74.

Nakamura, H., Isshikawa, T., Akanuma, M., Nishiwaki, M., Yamashita, T., and Tomiyasu, K. 1994. Effect of mycoprotein intake on serum lipids of healthy subjects. Prog. Med.14: 1972-1976.

Turnbull, W.H. 1998. Myco-protein as a functional food: Effects on lipemia, glycemia, and appetite variables. In proc. of 16th Intl. Cong. of Nutrition.

Turnbull, W.H. and Ward, T. 1995. Myco protein reduces glycemia and insulinemia when taken with an oral glucose tolerance test. Am. J. Clin. Nutr. 61: 135 140. Turnbull, W.H., Leeds, A.R., and Edwards, D.G. 1990. Effect of myco-protein on blood lipids. Am.J.Clin.Nutr. 52: 646-650.

Turnbull, W.H., Bessy D., Walton J., and Leeds A.R. 1991. The Effect of myco-protein on hunger, satiety and subsequent food consumption. In “Obesity in Europe 91,” ed. G. Ailhaud et al., pp. 67-70.

Turnbull, W.H., Leeds A.R., and Edwards, D.G. 1992. Myco-protein reduces blood lipids in free living subjects. Am. J. Clin. Nutr. 55: 415-419.

Turnbull, W.H., Walton, J., and Leeds A.R. 1993. Acute Effects of myco-protein on subsequent energy intake and appetite variables. Am. J. Clin. Nutr. 58: 507-512.

Udall, J.N., Lo, C.W., Young, V.R., and Scrimshaw N.S. 1984. The tolerance and nutritional value of two microfungal foods in human subjects. Am. J. Clin. Nutr. 40: 285-292.