Nanotechnology: A New Frontier in Food Science

Understanding the special properties of materials of nanometer size will allow food scientists to design new, healthier, tastier, and safer foods.

Nanotechnology—the science and technology that focuses on special properties of a material which emerge from nanometer size—is becoming one of the most promising scientific fields of research in decades. It is enabling scientists to better understand the relationships between macroscopic properties and molecular structure, degree of order, and intermolecular forces in synthetic materials and biological materials of plant and animal origin.

Understanding the nanoscale colloidal properties of materials, particularly macromolecules, makes it possible to envision the manipulation of molecular conformation to deliver active compounds precisely to the sites needed in the human body, thus leading to more-efficient delivery systems. Minuscule nanomachines able to circulate through the bloodstream, kill microbes, undo tissue damage, and reverse cancer could be delivered to the human body through food macromolecules. Such discoveries have the potential to give the health-promotion role of foods a new dimension.

Nanotechnology-based strategies have resulted in progress in the development of sensors for rapid detection of pathogens in foods or the environment. This article will review some of the current nanotechnology research that is applicable to food science and technology and project what the future will bring to the newly emerging field of food nanotechnology.

Nanotechnology

Nanotechnology has captured the imagination of researchers, manufacturers, and even the general population in recent years. It received a big boost in the United States after the National Nanotechnology Initiative in 2000 identified it as an emerging area of national interest. Recognizing its importance and huge potential, many federal agencies declared nanotechnology research a top priority.

The term “nano” refers to dimensions on the order of magnitude of 10–9; thus, one nanometer is 10–9 m. Using approaches inspired by nature, scientists are now able to self-assemble atoms into structures with controlled properties. Two building strategies are currently used in nanotechnology: (1) the “top down” approach, in which nano-level structures are generated by breaking up bulk materials, using milling, nanolithography, or precision engineering, and (2) the newer “bottom up” approach, which allows nanostructures to be built from individual atoms or molecules that are capable of self-assembling.

Today, using the “bottom up” strategy in particular, remarkably strong construction materials with precisely controlled structure and properties, particles with high surface area, materials that encapsulate active compounds, and smart coatings that are self-cleaning or can change color depending on environmental factors are being developed.

--- PAGE BREAK ---

Nanotechnology has opened up new ways for studying individual molecules and the specific intra-and inter-molecular interactions in which they participate. Current research objectives include understanding the mechanisms of catalysis and enzymatic reactions, muscular contraction, cellular transport, DNA replication and transcription, DNA unknotting and unwinding, and protein folding and unfolding. Nanotechnology is opening windows to understand and replicate or improve the complexity and functionality of biological materials, enabling the type of control of such materials that nature has.

The potential of nanotechnology in food science cannot be fully appreciated yet because of lack of sufficient knowledge. If nanotechnology continues to advance at its current pace, we could expect that soon we will be able to build self-replicating nano-robots powered by light energy that are able to move, sense their environment, and handle atoms. Such nano-robots could be circulated into the bloodstream and programmed to repair or change DNA, fix damaged cells, and eliminate infections, cancers, or aged cells, enabling humans to live longer, healthier lives. Conservation and creation of new sources of energy will become possible, waste will be minimized by use of “clean” production methods and revolutionary recycling techniques, minuscule supercomputers will be built, human-class artificial intelligence might become a reality sooner than we expect, and aerospace advances will make space travel trivial. Nanomachines could create unlimited amounts of food by synthesis at the atomic level, which would eradicate hunger.

Food Nanotechnology

Most of the current applications of nanotechnology are in electronics, automation, super-materials, or life sciences such as pharmaceuticals and medicine. However, the experience gained by humankind over decades of scientific discoveries clearly points to the fact that such a groundbreaking science will not be contained within a limited number of applications, and will heavily impact human life in its totality. It is possible that it is only a matter of time until we see the products of nanotechnology “on our plate.”

Nanotechnology has the potential to revolutionize the global food system. Novel agricultural and food security systems, disease-treatment delivery methods, tools for molecular and cellular biology, sensors for pathogen detection, environmental protection, and education of the public and future workforce are examples of the important impact that nanotechnology could have on the science and engineering of agriculture and food systems. The following are some examples:

• Nanosensors for detection of pathogens and contaminants could make manufacturing, processing, and shipment of food products more secure.

• Specific nano-devices could enable accurate tracking and recording of the environmental conditions and shipment history of a particular product.

--- PAGE BREAK ---

• “Smart” systems capable of providing integrated sensing, localization, reporting, and remote control of food products could increase the efficacy and security of food processing and transportation.

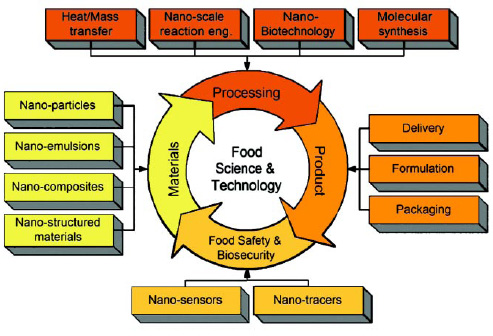

The four major areas in food industry that will probably be significantly enhanced by nanotechnology are development of new functional materials; micro- and nanoscale processing; product development; and design of methods and instrumentation for food safety and biosecurity. The potential applications of nanotechnology in the food industry, grouped by target area, are depicted in Fig. 1.

Some of the benefits of nanotechnology will be conveyed to the food sector through agriculture and agricultural research. The development of new tools in molecular and cellular biology will result in significant advances in reproductive science and technology; conversion of agricultural and food wastes into energy and useful by-products through enzymatic nano-bioprocessing; and disease prevention and treatment in plants and animals. New materials with special characteristics at the nanoscale level, such as self-assembly and self-healing properties, or abilities for pathogen and contaminant detection, could be breakthroughs in the agriculture and food industry of the near future.

Protection of the environment through the nanoconversion of agricultural materials into valuable products is another exciting area of advancement. The design and development of new nanocatalysts for the conversion of vegetable oils into biobased fuels and biodegradable solvents is already under scientific examination, and could be greatly enhanced with the help of nanotechnological abilities.

Management of local and environmental conditions is another critical area that could benefit from nanotechnology. Before reaching the dinner table, the lettuce, baked potato, broccoli, and oven-fresh bread will have survived a formidable number of environmental challenges. Agricultural crops must be protected against the invasion of weeds, insects, plant pathogens, and hostile weather. Close daily scrutiny, or “scouting,” of crops for potential problems is critical for food producers. Preventive monitoring and treatment of crops or animals with nanoscale sensors and “smart” delivery systems can improve the quality of the food raw materials of both vegetable and animal origin.

The tools of nanotechnology will allow food scientists to understand better how food components are structured and interact with each other. As a consequence, they will be able to precisely manipulate food molecules and design new, healthier, tastier, and safer foods. Nonpolluting, cheaper, and more efficient processes will be developed; lighter and more precise food manufacturing equipment will be built; and lighter, more functional, and stronger packaging materials will be used to package wholesome, nutraceutical-loaded foods. Safety of the food supply could be improved significantly by creating “bacteria-repellent” surfaces or packaging materials that change color in the presence of harmful microorganisms or toxins.

--- PAGE BREAK ---

Nanocomposites

Nanostructured materials exhibit unique properties that open windows of opportunity for the creation of new, high-performance materials, which will have a critical impact on food manufacturing, packaging, and storage. Nanostructuring adds value to traditional materials by enhancing their mechanical strength, superconductivity, and ability to incorporate and efficiently deliver active substances into biological systems, at low costs and with limited environmental impact.

A promising class of new materials is represented by nanocomposites made of nanoscale structures with morphology and interfacial properties that give them unique characteristics. The fabrication of the first nanocomposites was inspired by biomineralization, the process in which an organic substance (protein, peptide, or lipid) interacts with an inorganic substance (e.g., calcium carbonate) and forms materials with increased toughness. An example is a packaging material composed of potato starch and calcium carbonate. This foam has good thermal insulation properties, is lightweight and biodegradable, and has been developed to replace the polystyrene “clam-shell” used for fast food (Stucky, 1997).

Nanocomposites are regarded as the potentially ideal solution for plastic beer bottles, since previous attempts to use plastic for this application have resulted in spoilage and flavor problems. A Japanese company, Nano Material Inc., developed a microgravure process for coating plastic films such as PET with a nanocomposite barrier material, which is a better-performing, transparent alternative to silica and alumina–coated food packaging films (Moore, 1999).

Nanostructures can be also built from natural materials. Natural smectite clays, particularly montmorillonite, a volcanic material that consists of nanometer-thick platelets, are a popular source for producing nanoclays (Quarmley and Rossi, 2001). Some companies in the U.S., such as Nanocor Inc. and Southern Clay Products, are using montmorillonite as an additive in nanocomposite production. Addition of only 3–5% montmorillonite makes plastics lighter, stronger, and more heat-resistant and provides improved barrier properties against oxygen, carbon dioxide, moisture, and volatiles. These characteristics are extremely useful for food packaging applications, and their use could enhance considerably the shelf life of foods such as processed meats, cheese, confectionery, cereals, and boil-in-bag foods. They can also be used in the extrusion manufacturing of fruit juice and dairy foods packaging, or beer and carbonated drink bottles.

Nanotubes and Membranes

A newer generation of nanomaterials is represented by carbon nanotubes. Discovered in 1991 by the Japanese electron microscopist Sumio Iijima at NEC Corp., Tokyo, Japan, nanotubes are made by “winding” single sheets of graphite with honeycomb structures into very long and thin tubes that have stable, strong, and flexible structures.

--- PAGE BREAK ---

Nanotubes are the strongest fibers known—10–100 times stronger than steel per unit weight—and researchers are using them to make nanotube-reinforced composites with high fracture and thermal resistance to replace conventional ceramics, alumina, and even metals in building aircraft, gears, bearings, car parts, medical devices, sports equipment, and industrial food-processing equipment.

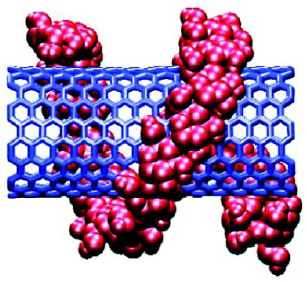

Recent studies have suggested the use of carbon nanotubes for biological purposes, such as crystallization of proteins and building of bioreactors and biosensors (Huang et al., 2002). For biological applications, the insolubility of carbon nanotubes in aqueous media needs to be overcome. Dagani (2002) has solubilized single-wall carbon nanotubes in aqueous iodine–starch solutions (Fig. 2), and Bandyopadhyaya et al. (2002) have obtained a similar result using aqueous solutions of gum arabic. Other solutions for solubilization of single-wall carbon nanotubes consist of functionalizing the tubes with glucosamine (Pompeo and Resasco, 2002) or bovine serum albumin (Huang et al., 2002).

Grafting functional groups onto carbon nanotubes can be extremely useful in health-related applications. For example, linking a nanotube to a DNA sequence that can bind specifically to a protein in a cancer cell and grafting a cell toxin to another part of the same nanotube may provide a “guided missile” that can target the tumor cells and destroy them (Huang et al., 2002). Another example consists of nanotubes formed by self-assembly of phospholipid bilayers capable of entrapping active compounds; because of their biocompatibility, such tubules are ideal for delivery in biological systems (Jelinski, 1999). Carbon nanotubes, particularly multiwall nanotubes with well-defined nanostructures, can be used to build sensors.

Manufacturing of nanotube membranes has significant potential for use in food systems. Highly selective nanotube membranes can be used both for analytical purposes as part of sensors for molecular recognition of enzymes, antibodies, various proteins, and DNA and for membrane separation of biomolecules, such as proteins (Lee and Martin, 2002; Rouhi, 2002). The selectivity and yield of the membranes currently used in the food industry are not fully satisfactory, mainly because of the limited control of their structure and chemical affinity. By functionalizing nanotubes in a desired manner, nanotube membranes can be tailored to efficiently separate molecules on the basis of both their molecular size and shape and their chemical affinity. For example, Lee and Martin (2002) have developed membranes that contain monodisperse gold nanotubes with inside diameters of <1 nm, which can be used either for separation of molecules or for the transport of ions between solutions placed on either side of the membrane. They were able to make the interior of the nanotubes hydrophobic, so the nanotube membrane preferentially extracts and transports neutral hydrophobic molecules. While such technologies are still too expensive for industrial food applications, they could be applied in the future for the separation of food biomolecules with functional value (e.g., proteins, peptides, vitamins, or minerals), which would be used for food fortification or the manufacturing of dietary supplements or drugs.

Another area of carbon nanotube–based applications is the development of electrically conductive membranes. The high length-to-diameter ratio of carbon nanotubes can be used to turn ordinary synthetic polymers, which are typically electrical insulators, into conducting polymers. In addition to their uses in the electronics and automobile industries, these polymers can also be utilized to develop novel membranes that will enhance separation and energy efficiency in the separation of flavor and nutraceutical molecules.

--- PAGE BREAK ---

The basic idea of this development is to incorporate minuscule carbon nanotubes uniformly into polymer substrates that can be then developed into membranes. These electrically conductive membranes can be resistance-heated to provide the thermal energy needed for some membrane separation processes that involve phase change. This could minimize the energy losses that occur when the feedstock is heated, enhance the heat transfer, and limit the detrimental effects of prolonged heating on the nutritional and sensory properties of the food/bioactive feedstock. Membrane pervaporation of food flavors, dehydration of alcohols by pervaporation or membrane distillation, and temperature-swing absorption of volatile liquids are just some examples of possible applications of such conducting membranes in the food and associated industries.

High-performance nanoporous membranes can also be manufactured using high-surface-area nanoscale materials, such as clusters and nanocrystalline materials. Nanotechniques can be used to functionalize supported microfiltration or ultrafiltration polymeric membranes by filling their pores with polymeric or oligomeric liquids that have affinity for the compound of interest (Jelinski, 1999). A nanoparticle-enhanced membrane that combines organic polymers with inorganic silica nanoparticles and enables large molecules to pass through more readily than small molecules was developed by Kingsley (2002). The addition of the silica resulted in >200% improvement in the flux and increased the permeability of the membrane, which challenges the common knowledge about membrane separation. The increased permeability was due to the nanoparticles, which, according to the author, pushed the polymer chains apart, creating larger openings in the membrane’s structure. The reported use of these membranes is to purify fuel (ethanol and methanol) inexpensively, but food-related applications could also become possible.

High-surface-area materials also have a great potential for the manufacturing of thin films for electronic and optical devices, nanoporous thermal barrier coatings, or adsorbents selective for amino acids and other biological molecules (Cox, 1999). The latter is achieved using the molecular imprinting technique, which allows making artificial “locks” for “molecular keys” (Ramström, 1996). Such ideas can be useful in food systems for building biosensors or creating efficient delivery systems.

Revolutionary Delivery Vehicles

For delivery systems to be effective, the encapsulated active compounds must be delivered to the appropriate sites, their concentration maintained at suitable levels for long periods of time, and their premature degradation prevented (Jelinski, 1999). Nanoparticles and nanospheres allow better encapsulation and release efficiency than traditional encapsulation systems, and are particularly attractive, since they are small enough to even be injected directly into the circulatory system (Bodmeier et al., 1989; Roy et al., 1999).

--- PAGE BREAK ---

Roy et al. (1999) showed that complex coacervates of DNA and chitosan could be used as delivery vehicles in gene therapy and vaccine design. Their work resulted in immunization of mice against peanut allergen gene, which indicates that oral immunization using DNA-functionalized nanoparticles could become an effective treatment of food allergies, a very serious problem affecting a large number of consumers all over the world.

The efficiency of delivery systems can be enhanced using dendrimer-coated particles. Dendrimers, macromolecules with a regular, highly branched 3-dimensional structure, have a large number of functionalities due to the high local density of active groups. This characteristic makes them usable in a wide range of applications, such as sensors, catalysts, or agents for controlled release and site-specific delivery.

A very stable and precise delivery system is represented by “cochleates,” stable phospholipid–divalent cation precipitates composed of naturally occurring materials, developed and patented by BioDelivery Sciences International Inc., Newark, N.J. They have a multilayered structure consisting of a large, continuous, solid lipid bilayer sheet rolled up into a spiral; they deliver their contents to target cells through the fusion of the outer layer of the cochleate to the cell membrane (Gould-Fogerite et al., 2003). Cochleates resist environmental attack, and their solid layered structure provides protection from degradation for the “encochleated” molecules, even when exposed to harsh environmental conditions or enzymes, including protection from digestion in the stomach. They can be used for the encapsulation and delivery of many bioactive materials, including compounds with poor water solubility, protein and peptide drugs, and large hydrophilic molecules. It is possible to envision that such systems could be used in the not-too-distant future for the encapsulation and targeted delivery/release of functional food biomolecules.

Manipulation of matter at the nanolevel also opens up possibilities for improving the functionality of food molecules, to the benefit of product quality. Dziechciarek et al. (1998) have developed starch-based nanoparticles that behave like colloids in aqueous solution, and can be used in food applications such as mixing, emulsification, and imparting specific rheology to foods, or in nonfood applications such as manufacturing of paints, inks, and coatings.

Nanotools for Biosafety

Another window of opportunity for nanoparticles is represented by food safety applications. Latour et al. (2003) are investigating the ability of synthesized adhesin-specific nanoparticles to irreversibly bind to targeted types of bacteria, inhibiting them from binding to and infecting their host. This research is aimed at reducing the infective capability of human foodborne enteropathogens in poultry products, using two types of nanoparticles. One type is based on the self-assembly of organic polymers (e.g., polystyrene), and the other on inorganic nanoparticles functionalized with polysaccharides and polypeptides that promote the adhesion of the targeted bacterial cells.

The biosecurity of the food and water supply is a serious concern, and novel solutions are required for the development of fast, reliable, and highly sensitive biosensors for the detection of biological agents in food or water. Fellman (2001) has developed a method to produce nanoparticles with a triangular prismatic shape that can be used in detecting biological threats such as anthrax, smallpox, and tuberculosis, and a wide range of genetic and pathogenic diseases.

--- PAGE BREAK ---

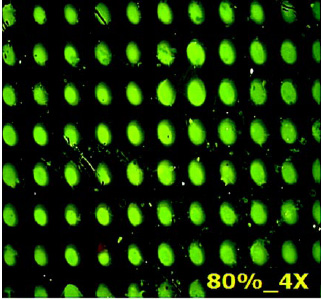

Chip-based sensing for rapid detection of biological pathogens is another new area with tremendous potential for application in food handling and processing, and in early warning regarding exposure to air- and water-borne bacteria, viruses, and other antigens. A novel method of making simple, linker-free, high-capacity DNA microarrays based on highly porous organosilicate supports is being developed in Huang’s laboratory at Rutgers University. DNA microarrays, which consist of short strands of DNA sequences patterned on solid supports, are the primary choice for such systems. The “target” DNA extracted from pathogens can be analyzed by sequence-specific binding (hybridization) to the microarrays to obtain detailed DNA sequence information. Fluorescence microscopy is usually used to detect the hybridization of fluorescent-labeled target DNA to the microarrays (Fig. 3).

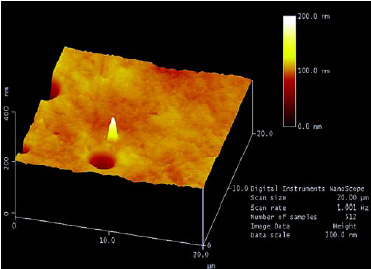

Many of the microbial safety problems encountered in the food industry are related to the contamination of food processing equipment and surfaces with microorganisms and microbial spores. One of the most important properties related to the contamination of surfaces is adhesion, which has been identified as one of the principal virulence factors in microorganisms like Bacillus. The quantification of spore adhesiveness, which is a particularly significant problem in the food industry, has been facilitated by the development of tools capable of analyzing single-molecule mechanics. Bowen et al. (2000) used Atomic Force Microscopy (AFM) to study the adhesive properties of Aspergillus niger and to obtain structural information about bacterial polysaccharides that form biofouling layers on food processing equipment. Camesano and Logan (2000) developed an AFM method to probe the effects of pH, ionic strength, and bacterial surface polymers on the electrosteric repulsion between negatively charged bacteria and AFM silicon nitride tips, and found that bacterial surface polymers were the dominating factor.

Understanding the interaction between contaminated surfaces and microorganisms allowed the design of materials that are resistant to bacterial adhesion. Researchers are already making efforts to develop a new generation of “self-cleaning” materials loaded with antimicrobial compounds that can be released under certain environmental conditions and kill the contaminant microflora.

Such solutions would be extremely useful to the food industry, although they seem rather long-term. Therefore, disinfection of surfaces remains one of the most important “weapons” in fighting harmful microorganisms. However, the corrosive nature of the commonly used disinfectants and biocides makes their use unsuitable for the decontamination of sensitive equipment. Baker and coworkers have used high-shear mixing of a lipid-oil discontinuous phase with an aqueous continuous phase to develop nanoemulsions, which represent an effective solution for disinfecting sensitive equipment safely (Lerner, 2000). Nanoemulsions consist of oil droplets of 400–800 µm in diameter that are able to fuse with and subsequently disrupt the membrane of a variety of different pathogens, such as bacteria, spores, enveloped viruses, and fungal spores.

--- PAGE BREAK ---

Characterization and Manipulation of Biomolecules

The development of techniques able to characterize materials and single-polymer molecules at the nano-level resulted in significant progress in the science and technology during the past decade.

The development of force microscopy allowed the characterization of biopolymers’ structures and the quantification of the intra- and intermolecular forces that stabilize such structures. AFM and Friction Force Microscopy (FFM) can be used for making local glass-transition, nanorheological, and nanotribological measurements of biopolymers. Rheological properties of single chains of proteins, polysaccharides, or DNA have been investigated using AFM. As a result, scientists have made important advances in understanding how motor proteins work, how drugs interact with the target molecules in the human body, and which are the mechanisms involved in DNA transcription and protein folding.

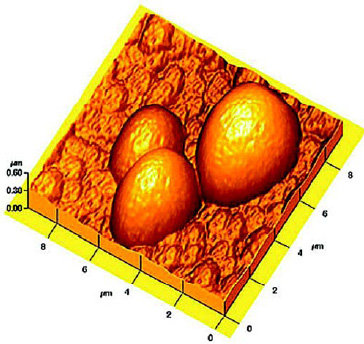

AFM has been used for the structural characterization of starch (Fig. 4) and proteins, and has helped to better understand the mechanism of gel formation for biopolymers like hylan, xanthan gum, kappa-carageenan, gellan, and collagen, or the interfacial distribution and interaction of surfactants in emulsions and microemulsions. Such studies have significant value for controlling the functionality, quality, and shelf stability of foods and food ingredients.

One of the most popular applications of AFM is the nondestructive topographical analysis of delicate biomaterials. Kokini’s group at Rutgers University is using AFM for characterizing the nanoscale properties of edible biopolymer films and coatings. AFM analysis of zein films yielded nanometer-scale topographic details of surface roughness, which provided an insight into the barrier potential of these films (Fig. 5). Nanoscale force measurements allowed quantifying the influence of environmental factors on the hardness, elasticity, and adhesiveness of the film surface, which is extremely useful for the design of high-performance edible food packaging.

--- PAGE BREAK ---

AFM can also be instrumental in probing the local mechanical properties and phase behavior in multi-phase foods, or for evaluating the compatibility of food ingredients. These are just a few examples of how nanotechnology and its tools can benefit the food industry and food research. A myriad of new applications will probably be developed in the next few years, or may have already been developed by the time this article appears.

Potential for Huge Contributions

It is very difficult to predict the long-term impact of any technology, nanotechnology in particular. As in the case of almost every nonconventional technology, e.g., genetic engineering, some fear that nanotechnology can give people too much control. We believe that this control can be wisely used, and that the huge contributions that nanotechnology can make are very strong arguments in favor of using this revolutionary science to its fullest potential. Food science and technology should take advantage of the powerful tools of nanotechnology, for the benefit of humankind.

Publication D-10544-1-04 of the New Jersey Agricultural Experiment Station, supported by State Funds and the Center for Advanced Food Technology, a New Jersey Commission on Science and Technology Center.

The authors are, respectively, Assistant Professor, Graduate Student, Assistant Professor, Associate Professor, Assistant Professor, and Professor II at the Center for Advanced Food Technology and Dept. of Food Science, Rutgers University, New Brunswick, NJ 08901. Author Moraru is currently Assistant Professor, Dept. of Food Science, Cornell University, Ithaca, NY 14850. Authors Moraru, Liu, and Kokini are Professional Members of IFT. Author Kokini is a Fellow of IFT. Send reprint requests to author Kokini.

References

Bandyopadhyaya, R., Nativ-Roth, E., Regev, O., and Yerushalmi-Rozen, R. 2002. Stabilization of individual carbon nanotubes in aqueous solutions. Nano Letters 2: 25-28.

Bodmeier, R., Chen, H.G., and Paeratakul, O. 1989. A novel approach to the oral delivery of micro- or nanoparticles. Pharmaceut. Res. 6: 413-417.

Bowen, R., Lovitt , R., and Wright, C. 2000. Direct quantification of Aspergillus niger spore adhesion in liquid using an atomic force microscope. J. Colloid Interface Sci. 228: 428-433.

Camesano, T.A. and Logan, B.E. 2000. Probing bacterial electrosteric interactions using atomic force microscopy. Environ. Sci. Technol. 34: 3354-3362.

Cox, D.M. 1999. High surface area materials. In “Nanostructure Science and Technology. A Worldwide Study,” prepared under the guidance of the National Science and Technology Council and The Interagency Working Group on NanoScience, Engineering and Technology, ed. R.W. Siegel, E. Hu, and M.C. Roco. Available online at www.wtec.org/loyola/nano/toc.htm (accessed May 2002).

Dagani, R. 2002. Sugary ways to make nanotubes dissolve. Chem. Eng. News 80(28): 38-39

Dziechciarek, Y., van Schijndel, R.J.G., Gotlieb, K.F., Feil, H., van Soest, J.J.G. 1998. Development of starch-based nanoparticles: Structure, colloidal and rheological properties. Presented at Meeting of Dutch Society of Rheology, Oct. 22. Abstract available online at: www.mate.tue.nl/nrv/ede/dziechciarek.html (accessed June 2003).

Fellman, M. 2001. Nanoparticle prism could serve as bioterror detector. Available online at http://unisci.com/stories/20014/1204011.htm (accessed May 28, 2002).

Gould-Fogerite, S., Mannino, R.J., and Margolis, D. 2003. Cochleate delivery vehicles: Applications to gene therapy. Drug Delivery Technol. 3(2): 40-47

Huang W., Taylor, S., Fu, K., Lin, Y., Zhang, D., Hanks, T.W., Rao, A.M., and Sun, Y.P. 2002. Attaching proteins to carbon nanotubes via diimide-activated amidation. Nano Letters 2: 311-314.

Jelinski, L.1999. Biologically related aspects of nanoparticles, nanostructured materials and nanodevices. In “Nanostructure Science and Technology. A Worldwide Study,” prepared under the guidance of the National Science and Technology Council and The Interagency Working Group on NanoScience, Engineering and Technology, ed. R.W. Siegel, E. Hu, and M.C. Roco. Available online at www.wtec.org/loyola/nano/toc.htm (accessed May 2002).

Juszczak, L. 2003. Surface of triticale starch granules B NC-AFM observations. Electronic Journal of Polish Agricultural Universities, Food Science and Technology, Volume 6, Issue 1. Available online at http://www.ejpau.media.pl/series/volume6/issue1/food/art-08.html (accessed November 2003)

Kingsley, D. 2002. Membranes show pure promise. ABC Science Online, May 1. Available online at www.abc.net.au (accessed August 2003).

Latour, R.A., Stutzenberger, F.J., Sun, Y.P., Rodgers, J., and Tzeng, T.R. Adhesion-specific nanoparticles for removal of Campylobacter jejuni from poultry. CSREES Grant (2000-2003), Clemson Univ., S.C. www.clemson.edu (accessed June 2003).

Lee, S.B. and Martin, C.R. 2002. Electromodulated molecular transport in gold-nanotube membranes. J. Am. Chem. Soc. 124: 11850-11851.

Lerner, E.J. 2000. Nano is now at Michigan. Medicine at Michigan, Summer issue, pp. 14-21. Available at www.medicineatmichigan.org. (accessed June 2002).

Moore, S. 1999. Nanocomposite achieves exceptional barrier in films. Modern Plastics 76(2): 31-32.

Pompeo, F. and Resasco, D.E. 2002. Water solubilization of single-walled carbon nanotubes by functionalization with glucosamine. Nano Letters 2: 369-373.

Quarmley, J. and Rossi, A. 2001. Nanoclays. Opportunities in polymer compounds. Ind. Minerals 400: 47-49, 52-53.

Ramström, O. 1996. Molecular imprinting technology. A way to make artificial locks for molecular keys. Homepage of Olof Ramström, Center for Chemistry and Chemical Engineering, Lund University, Sweden. Available online at www.smi.tu-berlin.de. (accessed June 2003).

Rouhi, M. 2002. Novel chiral separation tool. Chem. Eng. News 80(25): 13

Roy, K., Mao, H.Q., Huang, S.K., and Leong, K.W. 1999. Oral gene delivery with chitosanBDNA nanoparticles generates immunologic protection in a murine model of peanut allergy. Nature Med. 5: 387-391.

Stucky, G.D. 1997. High surface area materials. Proceedings of the WTEC Workshop on R&D Status and Trends in Nanoparticles, Nanostructured Materials, and Nanodevices in the United States. Available online at http://www.wtec.org/loyola/nano/US.Review/07_03.htm (accessed September 2003).