Cross-Industry Technology Transfer

Borrowing technology from other industries may answer demands for innovation in the food industry.

New product introductions within the food industry were down in 2002 (Ostrowski, 2003), and the bulk of new food and beverage products were reformulations or line extensions rather than really new products (Gregerson, 2003). Food processors may dream of inventing the next green ketchup, but in the meantime they’ll settle for expanding flavor lines, redesigning packaging, and updating formulations to keep the supermarket aisles fresh.

For true new product inspiration, the answer may be to borrow techniques and innovations from other industries via cross-industry technology transfer.

Utilizing Technology from Other Industries

The term cross-industry technology transfer simply means utilizing intellectual property from other industries, such as the chemical, pharmaceutical, electronic, and biotechnology industries, for a purpose not originally intended by the developing industry.

The phenomenon of technology transfer is not new for universities. During the early 19th century, European companies developed new products around the expertise of its academic faculty. In the United States, the Massachusetts Institute of Technology has practiced the concept of using technology across multiple industries since the early 20th century.

The opportunities for the food industry are immense. Intellectual property can take the form of inventions (patents), trade secrets, business methods, industrial processes, chemical formulas, or any other product of the mind.

Isn’t there enough internal technology to keep the food industry happy? The answer is a resounding “No!” Private industry has abdicated its leadership in research and development to academia and government. No long-term (greater than one-year payback) research is conducted within food companies today, with all the downsizing, rightsizing, or whatever the latest management consulting term is for kicking out the researchers who look beyond a one-year payback.

Cross-industry technology transfer is not new to the food industry. The high-temperature and high-pressure extrusion of plastic resins was quickly adapted to the continuous manufacture of protein-based pet foods in the 1950s by General Foods Corp. Also, the desalination of wastewater by reverse osmosis was quickly applied to the dewatering of cheese and is being applied with a vengeance today.

Here are some other examples of technology transfer that are being applied or have potential to be applied in the food industry:

--- PAGE BREAK ---

• Nanotechnology. In terms of sheer potential, nanotechnology, invented by the Nobel Laureate physicist Richard Feynman, offers the food industry an impressive upside. He stated in 1959 that “The principles of physics, as far as I can see, do not speak against the possibility of maneuvering things atom by atom” (Feynman, 1959).

Carbon nanotubes have found applications in materials science and electronics. They can be blended with room-temperature ionic liquids to form “bucky gels” that can be used to make novel electronic devices, coating materials, and antistatic materials (Freemante, 2003). Since the bucky gels of ionic liquids are soft, and the carbon nanotubes are untangled, they can be readily processed into bucky cables, bucky films, bucky sheets, and even bucky inks. This gives technologists several unique forms of introducing ionic liquids into food products.

Could carbon nanotubes offer the food industry another way to protect volatile liquids, oxygen-sensitive materials, and other reactive food ingredients without spray drying or other means of conventional encapsulation? Why not?

All living things come from arrangements of atoms in protein molecules that make copies of themselves. Plants, animals, humans, and other forms of life in the food chain are built by nature from the atoms up. Since human hands are too big to handle atoms, we build down from giant chunks of atoms. Why can’t human beings imitate nature’s methodology? Instead of harvesting grain and cattle for carbohydrates and protein, nanomachines (nanobots) could assemble the desired steak or flour from carbon, hydrogen, and oxygen atoms present in the air as water and carbon dioxide. Nanobots present in foods could circulate through the blood system, cleaning out fat deposits and killing pathogens.

In May 2003, the U.S. House of Representatives passed the Nanotechnology R&D Act of 2002 (HR 766), approving $2.36 billion over three years for nanotechnology R&D. It establishes a formal structure for research across the agencies, emphasizes interdisciplinary research, addresses societal concerns raised by nanotechnology, requires outside reviews of the program, and promotes efforts to commercialize nanotechnology applications. The Act is currently awaiting passage in the Senate, where the Senate Commerce Committee will consider HR 766 and the 21st Century Nanotechnology R&D Act (S 189).

Massachusetts has received more funding from the National Science Foundation than any other, and Zymark Corp., Hopkinton, Mass., has developed a system that allows biotechnology and pharmaceutical companies to measure, dispense, and monitor compounds by the nanoliter, an invisible amount. This system, originating from the drug discovery industry, allows testing to be run at a low cost—one test in a test tube makes way for a million tests with the same amount of material.

--- PAGE BREAK ---

E.I. du Pont de Nemours and Co. (DuPont) recently acquired NanoSource Corp., established in 1999, which manufactures nanoparticles, notably TiO2, used for paint and paper applications. Heavily invested in particle size research and technology through its Particle Science and Technology group, DuPont is exploring the particle technology interface of chemistry, biology, electronics, and material sciences. Projects based on particle size are currently underway at the DuPont Experimental Station in Wilmington, Del., in the following areas: advanced drug delivery systems, food engineering, solids handling, nanoparticles, separations, product design and formulation, characterization and interfacial engineering, and particle formation.

What about all the relatively insoluble ingredients in the food industry that settle out of solution and require hydrocolloids for suspension, such as cocoa powder, various plant and animal proteins, fibers, and spices? If they could be nanosized, perhaps their solubility/dispersibility in liquid media would change dramatically. Particle research is the way to find the answers.

• Mixing. The behavior of flowing fluids—not only liquids and gases but also piles of skim milk powder or heaps of peanuts—has been under investigation by scientists and engineers since 1508 when Leonardo DaVinci made a detailed sketch of a jet of water plunging into a pool and carefully described his observations. The close observation of fluid flow had to wait until 1932, when Harold (Doc) Edgerton of MIT pioneered the field of high-speed photography using the strobe light.

The practical technology resulting from studies of liquid/solid/gaseous mixing has resulted in high-shear mixing equipment used in the chemical and pharmaceutical industries, but lately has surfaced in the food industry. Specifically, high-shear mixing using rotor-stator mixing technology is becoming quite useful in food applications.

Though no precise definition exists, a mixer is considered high shear if the rotor in the rotor/stator combination is moving at 15 m/sec. Units running at 40 m/sec and higher have been used. High-shear mixing has been shown to reduce particle size in on-line applications that were strictly batch operations. For example, tomato paste dilution to create soup and sauces is being done in-line using high-shear mixing. Chocolate conching, which normally takes 10 hr or longer has been performed in minutes commercially, according to Gregory R. Ziegler, Associate Professor of Food Science at Penn State University. Soy emulsions, gums, and other difficult-to-handle ingredients have also been emulsified using high-shear mixing in-line.

Richard Calabrese, Director of the High Shear Mixing Research Program at the University of Maryland, is studying the dynamics of mixing. He applies Laser Doppler Anemometry, computational fluid dynamics, and other analytical tools—all originating from the chemical industry—to better understand how powders, liquids, or combinations behave inside a rotor-stator mixing device.

This program isn’t strictly academic; it is funded and advised by a board that includes mixer manufacturers and industrial companies such as DuPont and Procter & Gamble. Du-Pont is using the knowledge to redesign equipment and better predict and control processing results.

--- PAGE BREAK ---

• Separation. From the separation of salt in prehistoric China from Lake Yuncheng in 6000 BC, through the modern separation of cream and skim milk, the history of food manufacturing parallels advances in separation technology. New centrifugal separating technologies borrowed from the pharmaceutical and chemical industries can separate psychotropic spores and other bacteria from pasteurized milk, enabling production of extended-shelf-life milk without excessive heat treatment, commonly the cause of off-flavor generation. Other new uses of centrifugation in foods include the elimination of filter media (kieselguhr, diatomaceous earth) for beer and juice clarification, greatly improving operating efficiencies and eliminating media disposal costs.

Membrane separation systems, common in treating the wastewater streams in industries such as food processing, pulp and paper, latex production, industrial laundries, textile processes, and the printing industry, are being used by the food industry, particularly in dairy and soymilk manufacturing, to separate higher-molecular-weight, value-added components from a feed stream and eliminate low-molecular-weight flavor impurities.

Chromatography, used in the pharmaceutical industry to separate and purify high-value-added pharmaceutical drug products through controlled, selective absorption of specific target molecules, is now being adopted by the nutraceutical industry to isolate active compounds from grape juice, wine, orange juice, and other antioxidant-laden natural products.

Finding Technology Transfer Opportunities

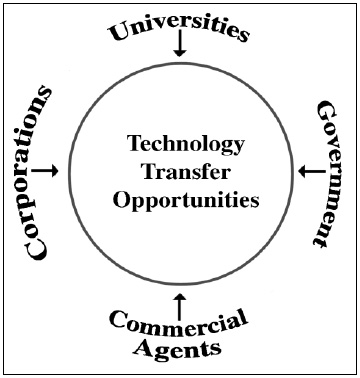

There are four key areas that food industry R&D personnel can access to find appropriate technologies for transfer: academic institutions, the federal government, commercial agents, and corporations.

What may surprise many is that patents alone are not necessarily ideal sources of technology transfer opportunities. Someone researching patents related to novel suspension agents for beverages, for example, may not realize that pigment suspension is an active area of research in the paint industry.

• Universities. Under the Bayh-Dole Act of 1980, universities can retain the rights to innovation developed with federal funding, and many of these innovations are turned into products. Universities, however, often do not know how to transfer knowledge to the commercial sector, and they sometimes have an unrealistic idea of what their intellectual property is worth. They also don’t have much discretionary money to file for patents, so they have to choose their opportunities to file carefully. Nevertheless, a cumulative total of licenses and options issued by universities since 1991 stands at around 20,000, and the percentage of licensing activity doubled between 1991 and 1998.

Practically every university has an Office of Technology Transfer (OTC); in fact, many have Web sites where the technology opportunities are described in detail. One example is the MIT Lincoln Laboratory technology transfer Web site: www.ll.mit.edu/about/techtrans.html.

--- PAGE BREAK ---

• Government. The Federal Technology Transfer Act of 1986 (Public Law 99-502) made technology transfer the responsibility of every federal laboratory scientist and engineer and mandated that technology transfer be considered part of employee performance evaluations. The law requires federal laboratories to actively seek opportunities to transfer technology to industry, universities, and state and local governments.

The Act also mandated that preference be given to industrial partners that agreed to manufacture within the U.S. In addition, it chartered the Federal Laboratory Consortium as an organization to promote technology transfer. The Act specified technology transfer activities, including technical assistance, patent licenses, cooperative research and development agreements (CRADAs), other cooperative agreements, educational partnerships, and grants.

Technical Assistance. A request for technical assistance to solve a technically challenging problem is usually made to a federal laboratory by a representative of a company, university, or state or local government. Once the technical request is made, the scientist or engineer at the laboratory who is best qualified to respond to the inquiry is identified. The two parties are then put in contact with each other.

Patent Licenses. The second transfer method provided by law is through the licensing of a patent held by the laboratory. The licensing agreement is negotiated by a local patent office.

Cooperative R&D Agreements. The purpose of a CRADA is to make government facilities, intellectual property, and expertise available for collaborative interactions with partners in industry, universities, or state or local governments to further the development of technology into useful, marketable products.

Under a CRADA, the federal laboratory may contribute people, equipment, and facilities, but not funds, to the joint R&D effort. The non-federal party may contribute the same, as well as funds, if required. The CRADA guarantees to the nonfederal party a non-exclusive, royalty-free license to any patents that are derived from the CRADA research. The non-federal party is granted an option to obtain an exclusive license. Company proprietary information is protected under the CRADA.

Other Cooperative Agreements. A federal laboratory may enter into a cooperative agreement with industry, universities, nonprofit organizations, and state or local governments.

--- PAGE BREAK ---

These agreements are formed when significant involvement between the government and the recipient during performance s expected. There are contractual arrangements in which the government provides money and/or property to a recipient to support research in areas of interest to federal laboratories. Cooperative agreements are usually awarded based on competitive bids and may require cost matching of resources.

Educational Partnerships. An educational partnership may be forged by the federal government with a university or a nonprofit local education agency. This does not involve commercial interests, however.

Grants. A Federal laboratory may provide educational institutions, non-profit institutions, and state or local governments with grants. Commercial entities are excluded from receiving grants.

Help on gaining access to federal technology information is available through the National Technology Transfer Center (www.nttc.edu), which provides access to federal technology information, knowledge management and digital learning services, technology assessment, technology marketing, assistance in finding strategic partners, and electronic-business development services.

• Commercial Technology Transfer Agents. There are many private international technology transfer agents that seek partners for joint ventures. Their intellectual property sources include governments, industry, universities, and consultants. Their Web sites, which are similar to university OTC Web sites, are virtual shopping malls for technology. In fact, most sites resemble virtual technology bazaars, with attractive graphics and enticing copy. As in any bazaar, however, the buyer should beware.

One example is www.GlobalTechnoScan.com, a weekly magazine focusing on new technology business opportunities regarding technology transfer, licensing, and research financing.

• Corporations. There are technology-rich companies looking to share their intellectual property with other entities, such as corporate R&D labs, government labs, startup companies, universities, and research hospitals. P&G, for example, developed calcium-ion control technology in its fabric care division, and later shared it with Tropicana for calcium-fortified orange juice.

P&G also regularly donates intellectual property to universities, such as termite control technology to the University of Florida and oral care technology to Boston University. Tiax LLC, formerly the technology and innovation group of Arthur D. Little, helps clients navigate the gap that exists between technology idea sources and the needs of the marketplace. Like P&G, DuPont also donates intellectual property to various universities nationally.

Offers Great Potential

Cross-industry technology transfer in the food industry is here to stay. It’s too attractive to ignore —just look at what other industries are doing, and adapt it for your use. The challenge is recognizing and isolating the technology that is useful. The food industry is rife with NIH (“not invented here”) syndrome. Most companies are too busy fighting the daily battle to look at industries with which they are not familiar. Yet, for those who do take advantage, technology transfer offers great potential.

The author, a Professional member of IFT, is Director, DuPont Food Industry Solutions, Chestnut Run Plaza, 708/205, 4417 Lancaster Pike, Wilmington, DE 19805, [email protected]

References

Feynman, R. 1959. There’s plenty of room at the bottom. Lecture given on Dec. 29, 1959 at the Annual Meeting of the American Physical Society at the California Institute of Technology; subsequently published in the February 1960 issue of Caltech’s Engineering & Science. Available at www.zyvex.com/nanotech/feynman.html.

Freemante, M. 2003. Ionic liquids go bucky. Chem. Eng. News, June 30, p. 7.

Gregerson, J. 2003. The 3rd annual top 100 R&D survey. Food Proc., May, pp. 44-48.

Ostrowski, A. 2003. Personal communication. Mintel’s Global New Products Database.