Total Utilization of Fish

Pork producers say they use everything but the “oink,” but because fish are quiet, the fish industry can do better! The industry is far from its goal of total utilization of fish, but significant progress is being made.

Fish is a very popular food, but, as with other foods, not all of it is consumed, specifically those parts of the fish that are not sold directly to consumers.

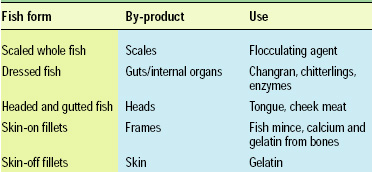

Although some customers take the whole fish, many take it dressed, and many Americans use only steaks and fillets. Steaks and fillets generate the greatest waste, since as little as 20% and rarely more than 40% of the original fish is in those forms. The major other parts of the fish are the heads, skin and scales, guts/internal organs, frames (bone rack with adhering meat), and trim (pieces cut from the fillets during processing). These parts are either discarded as waste or converted into by-products (Table 1).

Although some customers take the whole fish, many take it dressed, and many Americans use only steaks and fillets. Steaks and fillets generate the greatest waste, since as little as 20% and rarely more than 40% of the original fish is in those forms. The major other parts of the fish are the heads, skin and scales, guts/internal organs, frames (bone rack with adhering meat), and trim (pieces cut from the fillets during processing). These parts are either discarded as waste or converted into by-products (Table 1).

With regard to these parts, we need to think of different alternative uses that might be viable, as most will depend on the circumstances of the fishery and its location as well as the needs/acceptance by the customers. The season and other agriculture/aquaculture/industrial activity occurring locally also will affect what is possible. Transportation costs are often a major factor to consider with by-products.

Another potential source of raw material is the flesh of underutilized species, such as a species that is caught when other fish are being sought. Most offer challenges for food processing, which is another reason they are underutilized. For example, red hake has a soft texture and develops gadoid texture (see below) on frozen storage. Arrowtooth flounder undergoes proteolysis, which seems to be pretty widespread and may be due to an indigenous enzyme.

Fish Mince

Like red meat and poultry, fish mince (ground fish, fish hamburger) can be prepared using mechanical deboners. For many of the most heavily processed species—gadoid species such as cod, haddock, hake, pollock, and whiting—mincing accelerates negative frozen storage texture changes. These species contain trimethylamine oxide (TMAO), which is believed to help fish “osmoregulate,” i.e., deal with their salt-water environment. During chilled storage (refrigeration), this compound is easily broken down by bacteria to trimethylamine (TMA), which is associated with the “odor” of spoiling fish. However, when fish are frozen, even at temperatures as low as –30°C, there is a biochemical pathway (with debate as to whether it is enzymatic or not) that breaks down TMAO to dimethylamine (DMA) and formaldehyde. DMA is less volatile than TMA and is not an odor problem. But formaldehyde is an active compound that is responsible for cross-linking of protein leading, to the undesirable texture—the cross-linking leads to weaker water binding, so that too much moisture is released on the first bite and what is left is a “cottony” dry mass.

Dealing with this problem has been difficult. First, there is a measurement problem. DMA, because it is easier to measure, is used to follow the reaction. But what if one blocks the highly reactive formaldehyde from reacting with protein? The DMA level will not change, but the texture may change dramatically. If one uses a sensory “touch” panel to evaluate the texture, then various compounds that might prevent the reaction can be screened. Ironically, one of the best compounds to use is starch—regular corn starch works fine in preventing mince gadoid texture formation. Starch often can be incorporated into the finished formulation, sometimes quite beneficially, but unfortunately this process has not been commercialized yet. The industry seems to prefer to prepare mince blocks with a very limited list of ingredients so that it can sell the product to all markets, rather than develop a closer customer relationship.

With respect to deboning, there are different pieces of equipment that can use “headed and gutted fish,” “trim,” or “frame mince” to produce “fish hamburger” with various amounts of texture. The equipment can also use fillets, as is done for surimi, but why use beautiful fillets to make mince and then compound the issue by extensively washing this mince to create liquid effluents with a high biological oxygen demand?

--- PAGE BREAK ---

High-quality whole fish and trim minces are being used in products like fish sticks, which kids often prefer to be made with mince. Some is used in fish blocks, as the addition of a small amount of mince makes it easier to pack a box of fish fillets without any voids. Frame mince is made from the flesh attached to the bones and will therefore contain blood. This is a challenge for food scientists, but it is also an advantage—it is much redder, looking more like the “real” hamburger, it has a much higher iron content, and the blood gives the product some meaty flavor notes. Frame mince can be used to make many “fish” products, to demonstrate that it is a tasty, quality material, but it can also be used to make healthier (fewer calories, and omega-3 fatty acids) “meat products,” like taco filling, sausages, “meat loaf,” and chili filling.

With the current concern about obesity, hopefully fish mince will become more acceptable. Also, since the United States incorporates great ethnic diversity, many excellent meat products can be developed using fish mince. Of course, the challenge is to use these materials while maintaining product quality during frozen storage, avoiding problems like gadoid texture and oxidative rancidity.

Other parts of the fish can be eaten. A few are “special foods” in other societies. Examples are fish tongues from Newfoundland (a very acquired taste) and fish cheeks, a lovely “chunk” of meat from fish heads. Equipment to remove this chunk of meat is commercially available but has not been widely adopted.

Arrowtooth flounder is the largest fish biomass in Alaska, greater than Alaskan pollock. When the fillet is cooked, it disintegrates into a mass of small particles. The use of acids, such as vinegar and citric, will reduce the severity of the reaction, apparently by limiting the activity of the proteolytic enzyme. The product is still soft, but by using injection equipment to uniformly inject the appropriate acid solution it is possible to get a fillet that with gentle handling will remain intact. Fish products that take advantage of the vinegar/citric acid present need to be developed.

Because of the importance of enzymes in modern food processing and other industrial processes, it is sometimes significant that fish, which come from a variety of temperature environments, often have enzymes with “temperature” profiles different for each species and different from those of terrestrial animals. This may permit the enzyme to be “denatured” at lower temperatures that are detrimental to the process being undertaken. Most work to date has focused on proteolytic enzymes. However, with the development of biotechnology, some of these special applications may eventually be incorporated into bacterial fermentation systems. So the window of opportunity may be limited.

Thus, if the fishing industry is to compete with other center-of-the-plate foods (the turkey industry sells more turkey per capita than the entire seafood industry!) and garner the environmental benefits of fish, more creativity in the use of seafood will be needed. Note that this article focuses on finfish, as the handling of shellfish waste is a very different process. The total amount of “wild-caught fish” is probably limited, although the species mix will be constantly changing as sustainable fisheries management policies are developed. Therefore, the concept of optimizing the utilization of the entire fish is a goal that the industry must continually strive to reach.

By-Product Use

Now let’s look at some of the more unusual parts. The skin, bones, and maws (swim bladders) are a source of gelatin. Fish gelatin will gel, and it may have less off-flavor than beef or pork gelatin. It has unique properties:

• It can be produced as both kosher (for the Jewish market) and halal (for the Muslim market) much more easily than beef gelatin.

--- PAGE BREAK ---

• Markets that are concerned about mad cow disease (bovine spongiform encephalitis, BSE) find fish gelatin attractive.

• By mixing gelatins from different fish species, materials that have a wide range of melting points can be prepared, thus presenting the food product developer new technological options. For example, initial work has shown that a lower melting point leads to a faster and more intense flavor release. Thus, gelatin melting point becomes a variable that can be manipulated over a wide range of temperatures. The greatest limitation to date has been the higher cost of fish skin gelatin.

The limited work on fish bone gelatin suggests that the bloom strength and yields are lower than for the equivalent skin gelatin. However, as a substitute for traditional beef and pork gelatin, fish bone gelatin may have numerous benefits. With more effort to develop an easily digestible calcium from fish bones, fish bone use may become viable. Canned fish bones are already well recognized as an excellent source of calcium, especially for those with allergies or intolerances to dairy products.

Another potential source of gelatin is the swim bladders, which provide fish with “buoyancy” that permits them to easily move up and down in the water column. These bladders are removed when fish are properly gutted, but they are not captured for use at this time as a gelatin source. For some species this is easy, but for others more effort is needed. Certainly in Asian cuisine, bladders are often a recognized soup ingredient.

Interestingly, there are products using the “guts” for edible purposes. The Koreans eat a product called changran that represents the stomach of the fish. In some fish processing plants, this has become an economically viable operation. There has also been work on making a fish chitterling!

Many of these less-eaten organs may contain valuable nutraceuticals, which could offer excellent economic opportunities for the fishing industry. The use of condroitin sulfate from shark and other fish is one very successful example. A recent report suggests that a very powerful painkiller can be made from the poison of puffer fish. In general, these are excellent applications for by-products, but they also often still generate a lot of waste. And, unfortunately, when such highly valued materials are extracted, the incentive to do something with the much-lower-cost by-products is minimal. This is a major impediment to all by-product use—those involved in high-value food products treat by-products as an afterthought, and even if they become a profit center, rarely do they receive the corporate focus that they need to flourish.

Both whole fish that are too old, too small to process, or not desirable as a food fish and by-products for which no other uses are found generally go into production of fishmeal and fish oil. This is an important industry whose products serve the needs of both the poultry and aquaculture industries. Fishmeal is a great feed ingredient, and fish oil can often also be used for both food and pharmaceutical uses. But in isolated areas, processing plants are finding that despite the marvelous omega-3 fatty acids of fish oil, the economics of bringing petrochemical diesel fuel in and of shipping fish oil out to market make the economics favor bio-diesel applications, i.e., burning the fish oil as a fuel. This is certainly a technological accomplishment, but is this the long-term best use of fish oil? Could more fishmeal be used for human food?

Fish protein concentrate (FPC) was seen to be the answer to feeding the poor worldwide, but whether guts can be used to make this solvent-extracted dry protein became a political issue that tainted the product for many. The solvent extraction processes in this application also raised various issues. And does the world need an expensive substitute for soy and whey proteins? So at this time FPC remains an unused technology.

--- PAGE BREAK ---

Another way to make human food mince from the small, difficult-to-gut species without using classical gutting equipment has been the “flotation” processes in which the fish is cut into small pieces and the different parts are collected by their density differences—a sound idea, but one that has not caught on commercially.

The scales of fish at one time were used to produce pearl essence, which was used to put the sparkle in women’s nail polish. Unfortunately, synthetic alternatives have destroyed this market, a not-uncommon occurrence in the real world as byproduct uses ebb and flow. Work some years ago showed that scales may be able to assist in flocculating waste waters, particularly those from food plant waste streams. The beauty of this approach (along with the use of chitosan from shellfish waste) is that unlike the traditional chemical flocculants, these seafood flocculants are edible and can therefore be used to turn food processing wastes into animal feed.

Waste Management

At times, all of the above “great” ideas are not feasible and we are left with a situation that really is “waste” management. Many places have banned fish wastes from either the landfill or discharge into the ocean. This is where composting, done right, can at least be a beneficial use when all else fails. It has the benefit that it can even take spoiled fish. Composting can take a waste with a high disposal cost (e.g., hauling and tipping fees) and turn it into a soil amendment, providing the soil with more organic matter, that may return a small profit, break even, or at least cost less than the hauling/landfill option.

But composting, like any industrial process, requires attention to detail. Fish will smell (TMA again) if not handled properly. Although turned-pile composting will speed up the rate of composting, each time the pile is turned the “odiferous” materials will come to the surface. The bigger the operation, the more challenging odor control becomes.

The alternative is to use static piles. These are piles having the fish “buried” in the “center,” often layered lasagna-style. The surfaces are covered with materials like previous compost, wood chips, or other wastes such as paper sludge that serve as biofilters and provide for pile aeration. These piles compost much slower, but also are much more neighbor-friendly. In New York State, this system is being used to deal with salmon waste from the intensive sports fishery along Lake Ontario in the fall. Piles are made and left for almost a year, and large quantities can be successfully composted.

An Incentive

Thus, we are far from our goal of total utilization of fish waste, but significant progress has been made. Much remains to be done, both technically and, more important, economically—the costs of more of our by-product handling will be internalized within the individual companies, providing the incentive for adoption of these or similar beneficial uses.

Based on the IFT Aquatic Food Products Division Lecture presented at the Annual Meeting of the Institute of Food Technologists, Chicago, Ill., July 12–16, 2003.

The author thanks his colleagues Susan Goldhor, Robert C. Baker, Chuck Crapo, and Don Graves; and a great group of students he’s had the opportunity to work with over the years.

by Joe M. Regenstein

The author is Professor, Dept. of Food Science,

Cornell University, Ithaca, NY 14853-7201,

[email protected].