Never Say Never: Emerging Technologies Solve Familiar Problems

INGREDIENTS

A popcorn kernel that does not pop. A steak that is on the tough side. A low-sodium soup that tastes a bit like dishwater. A strawberry-flavored beverage that does not quite capture the experience of eating fresh strawberries. These are some of the food situations that everyone has probably encountered at some time or another.

Some of these annoyances we take for granted, accepting them as part of life much like we accept the occasional flat tire. For example, if you like microwave popcorn, you try not to bite down on the unpopped kernels; otherwise you might have to make a trip to the dentist, which can be expensive. Or if your steak should not be as tender as desired, you might grumble a bit, douse it with some sauce, and eat an extra helping of vegetables (which is not necessarily bad for you).

Other problems, however, are more serious. If, for example, you suffer from food allergies caused by peanuts, you avoid eating dishes containing that food; otherwise you may become very ill. Or if you’re a diabetic, you modify your diet to not include foods that will trigger an undesirable reaction. Similar considerations also apply if you suffer from high blood pressure, obesity, and other health conditions which can have short- or long-term negative consequences.

Regardless of their severity, the food problems discussed in this article have one thing in common: they pose special challenges which food formulators through innovative technologies, ingredients, and new approaches are working to overcome. The resulting solutions reflect an imagination that thinks “beyond the box” and that stirs the cauldron of creativity. It is this kind of imagination that, for the past seven years, has been covered in Food Technology’s July Ingredients section on emerging technologies and ingredients.

These novel cutting-edge developments may shape parameters for future ingredients, helping us to rethink what they are, what technologies are used in their production, and what roles they play in health, functionality, and convenience.

This year, this section will take a different approach and will suggest how emerging technologies from a variety of disciplines are solving specific food challenges that many of us have taken for granted. These technologies are coming from such areas as agriculture, nutrigenomics, biochemistry, flavor chemistry and measurement techniques, nutrition, taste enhancement, and many others

Getting More Pop from Your Corn

Native American folklore tells of spirits who lived inside each kernel of popcorn. These spirits (perhaps part of the ancient Redenbacher tribe) were passive, living in quiet harmony until their homes were subjected to heat. As temperatures rose, so says the legend, they angrily shook the kernels, finally bursting out into the air as a disgruntled puff of steam.

--- PAGE BREAK ---

Scientists have since learned that each kernel does indeed contain a “spirit”—a small drop of water stored inside a circle of soft starch which is surrounded by the kernel’s hard outer surface. As the kernel heats up, the water expands, pressure builds, and …well, you know the rest of the story. However, what was never fully understood was why some of these kernels did not pop.

These “old maids,” as they’re sometimes called, present certain challenges, including a waste of popcorn, potential choking hazards, and expensive dental bills resulting from damaged teeth and fillings. And despite efforts by food manufacturers to reduce the number of unpopped kernels, the problem persisted, especially in microwave popcorn.

Recently, researchers from Purdue University’s Whistler Center for Carbohydrate Research, West Lafayette, Ind., found the answer to this problem. “Through this study, we now have a better understanding of the science behind why unpopped kernels occur and how we can use this knowledge to go about reducing their number,” said Bruce Hamaker, a food chemist at Purdue University and director of the center, which funded the project.

Hamaker and his associates analyzed 14 different genetic varieties of yellow popcorn and compared their microwave popping performance. Using the same experimental conditions, they determined that the number of unpopped kernels ranged from 4% to 47%, depending on the variety. They then analyzed the properties of the best-performing kernels to determine which factors contributed to their outcome.

The researchers found that the key factor that appears to influence popping quality is the chemical structure of the pericarp (outer hull) which is composed partly of cellulose, a polymer of glucose. Heating a kernel causes the cellulose molecules to align and assume a highly ordered crystalline structure. As a result of this change, the pericarp, during heating, acts like a pressure cooker that locks moisture inside the corn kernel. The heated moisture leads to a pressure buildup until the kernel eventually ruptures and pops, turning the kernel inside out and producing those white, irregularly shaped puffs that the consumer knows as popcorn.

Not too surprising, the researchers discovered that in the best popping kernels, the pericarp is composed of a stronger, more highly ordered crystalline arrangement of the cellulose molecules than the pericarp of the poorer-performing varieties. In laboratory studies, the researchers demonstrated that these stronger crystalline structures tend to maximize moisture retention, leading to a more complete rupture and fewer unpopped kernels. Or to put it another way, the duds were the result of hulls which leaked too much moisture, thus losing their ability to pop.

“We believe that the amount and location of the cellulose component of the kernel are critical for crystallinity and think that this property can be transferred to corn kernels to improve their popping performance,” noted Hamaker. “We’re not sure yet exactly how this will be achieved, but we’re optimistic that enterprising researchers will be able to do this in the near future.”

--- PAGE BREAK ---

Possible techniques include selective breeding of those kernel varieties that best exhibit this optimal crystalline structure, chemical modification of corn kernels to produce the desired structure, and even genetic engineering of the corn plant.

If researchers are successful, the new microwave popcorn could be available to consumers in three to five years, Hamaker predicts. Although the new popcorn will be slightly different chemically from conventional microwave popcorn, mainly because of the presence of more cellulose, it will look and taste like any other popcorn. Although this study focused on microwave popcorn, the modified kernels will likely show improvements in popping quality using hot-oil and hot-air popping techniques, he added.

Popcorn manufacturers have already expressed strong interest in this research, which was published in the online version of the American Chemical Society’s BioMacromolecules, a peer-reviewed journal. More than 17 billion qt of popcorn is reportedly sold each year in the United States, and the savory snack is becoming increasingly popular throughout the world. So, popcorn manufacturers and representatives of that industry will continue to look for ways to improve the product.

The Whistler Center for Carbohydrate Research, located within Purdue’s Dept. of Food Science, focuses on fundamental investigations of structure–function relationships of carbohydrates and other biopolymers as related to practical uses. For more information on the project, phone 765-494-6171 or contact www.whistlercenter.purdue.edu.

Staking Out a Better Beef

“It must have been an old cow,” is usually the disappointed response of a steak lover when he or she bites into a piece of meat and finds that it is tough.

Although the degree of tenderness of a steak is highly valued by the consumer, this quality is subject to a number of variables, including genetics, diet, stress, and meat handling throughout beef production. Consequently, even the place of purchase—a major supermarket, a fine restaurant, or the diner around the corner—does not necessarily guarantee the quality of the meat.

In the future, that scenario may change as USDA Agricultural Research Service scientists at the Roman L. Hrushka U.S. Meat Animal Research Center, Clay Center, Neb., study biochemical mechanisms to determine how to make steaks consistently more tender for the marketplace.

--- PAGE BREAK ---

The tenderness of meat actually goes through several steps. After slaughter, meat is tender, then it becomes tough because of rigor mortis, and then tender again. This tenderization is caused by the μ-calpain enzyme which degrades some muscle proteins. However, not all meat reaches the same level of tenderization, which prompted the researchers to find out why.

According to an article published in the February 2005 issue of USDA’s Agricultural Research magazine, chemist Timothy P.L. Smith and geneticist Eduardo Casas—led by animal physiologist Mohammad Koohmaraie—found that although calpain causes the protein degradation that improves tenderness, it’s actually the activity of a protein called calpastatin that determines how much calpain is active and consequently how tender the steak will be. Since calpain requires calcium for activity, the researchers developed a process for injecting calcium into meat to make it more tender.

The scientists are also applying what they have learned about these biochemical mechanisms to cattle genetics, in an attempt to breed bulls that will sire offspring that are likely to provide tender steaks. The ARS article noted that the researchers are using a large population of crossbred cattle to identify genes influencing tenderness. They discovered that variation in the gene that produces μ-calpain appears to affect tenderization.

“We’re using genetics to identify DNA markers that can track variation in the calpain gene,” Smith said, “and we’re looking for DNA tests that can predict the likelihood that a given animal will produce tender meat.” This will permit breeding cattle that ranchers will know are more likely to produce consistently tender offspring.

By sequencing the gene that produces μ-calpain in both tender and tough cattle, Smith and Casas identified differences that can be used as DNA markers. They have released a DNA test that was effective in identifying tough animals among a large herd of beef cattle representing the most popular beef breeds in the U.S. The researchers continue to develop additional markers for use in other breeds.

More information about this research can be obtained by contacting www.ars.gov.

Using your Noodle to Lower Calories, Blood Glucose Levels

A food processing technique, the CarboStar Method, makes possible the creation of pasta and other starch-containing foods that can help treat patients with type 2 diabetes by substantially reducing blood glucose levels while providing nutrition.

--- PAGE BREAK ---

“To help address the need for healthy foods that taste good, we have developed a method to make starch function like dietary fiber,” said Ajay Chawan, President of Saatwic Foods, Brentwood, Tenn. (phone 615-372-7462, www.saatwic.com). “Processed foods made with the method have 32% more fiber, 40% fewer calories from carbohydrates, and a lower glycemic response. These attributes are especially attractive to athletes, diabetics, and people looking to lose weight.”

Furthermore, the development achieves these results without any change in taste, texture, and safety of the food product. The method works by strengthening the protective wall of a starch cell, impeding release of its calorie-rich contents as it moves through the digestive system. In particular, the addition of propylene glycol alginate (PGA), an extract of seaweed, under the proper processing conditions during product manufacture strengthened the starch cell, helping to regulate its rupture and subsequent release of glucose from the cell.

The method can be applied to any product made from processed corn, wheat, potato, or rice. These foods include pasta, tortilla chips, pretzels, potato chips, pizza crusts, breads, cereals, and other starch-containing foods.

Products made from this technology can offer health benefits to a broad range of marketing segments. For example, based on current levels of complex carbohydrate consumption, the average U.S. consumer would be able to reduce caloric intake by approximately 400 kcal/day without reducing the quantity of food consumed. Furthermore, patients suffering from type 2 diabetes will be able to enjoy starch-based foods that they cannot eat today, and possibly may be able to reduce or eliminate their insulin treatments because foods made by the technology achieve the controlled starch hydrolysis for steady-state glucose release.

Removing Peanut Allergens in a Jiffy

A new study conducted by researchers from North Carolina A&T University found that a special processing method could significantly reduce the allergenicity of peanut products caused by the presence of specific types of proteins.

In the U.S., the most significant rise in food allergies has been attributed to peanuts and other nuts. Studies from the United Kingdom and the U.S. indicate that the prevalence of peanut allergy doubled in American children less than 5 years old during the past five years. Currently, the only therapy for peanut allergy is avoidance of food products containing peanuts

--- PAGE BREAK ---

“Due to the wide use of peanuts in food products such as cookies, snacks, and even soups, there is a need to inactivate peanut allergens to protect consumers from a potentially life-threatening allergic reaction,” said Jianmei Yu, a researcher involved in the study, which investigated the effects of heat treatment and fungal fermentation on the concentration of two major allergenic proteins, Ara h1 and Ara h2.

Yu and her colleagues discovered during the study that a fermentation method reduced the detectable level of major allergenic proteins by as much as 70% without causing any adverse effects on sensory quality of the final product.

It is important to note, however, that the data obtained suggest that some processing conditions tend to lessen allergenicity of peanut proteins while other conditions may enhance it. For example, while fermentation lowered the concentration of both allergens in roasted peanut flour and protein isolate, it increased the concentration of both allergens in raw peanut flour and protein isolate.

Therefore, processing conditions must be carefully selected to produce non-allergenic peanut products. “It is hoped that careful control of the process conditions may enable complete modification of allergenic proteins into non-allergenic and readily soluble proteins,” said Yu. “This finding is good news to individuals who are allergic to peanuts and important not only to the peanut industry but also to the food industry in general, where peanuts are used as an ingredient in food product development and food preparation.

The researchers reported their findings at the 105th General Meeting of the American Society for Microbiology, June 5–9, 2005, in Atlanta, Ga. More information about the study can be obtained at www.asm.org.

Bringing Experience to Salad Days

A new ingredient system helps manufacturers reformulate sauces, dressings, and marinades so that these products have fewer calories, less fat, and a higher quality with a cold process. Called Rebalance System™ Satin 50, the optimized combination of thickeners, texture-enhancing ingredients, and Splenda brand sucralose is the latest “ingredient solution set” from Tate & Lyle, Decatur, Ill. (phone 217-423-4411, www.tateandlyle.com).

In recent independent sensory tests, a reduced-fat ranch dressing containing the ingredient system was rated as good as many full-fat versions for key taste and texture attributes. The system is currently supplied as a co-processed mix ready for blending with oil and flavoring ingredients. It provides a functional stabilization system that provides a creamy, smooth mouthfeel without masking the special flavors and spices used in sauces and salad dressings. The ingredients system can be used in a variety of sweet and savory applications, in pourable and spoonable dressings and sauces, such as emulsified creamy dressings and vinaigrettes, and in cold-processed sauces and marinades.

--- PAGE BREAK ---

Over the coming months, Tate & Lyle will be introducing other ingredient solutions to help reformulate food products and beverages. These launches will further demonstrate the company’s evolving program to meet challenges in product development through use of its comprehensive ingredients portfolio which includes acidulants, gums, starches, polydextrose, sweeteners, and wheat proteins.

This program, which was introduced at the 2005 IFT Food Expo, is organized around four new services—Create™, Optimize™, Rebalance™, and Enrich™. Taken together, these services help create innovative new products, optimize costs, rebalance the health profile of brands, and enrich the nutritional benefits of a product portfolio, all without compromising on taste and at a low development cost.

Reaching a New Watershed in Flavor

In recent years, consumers have been looking for flavors that more closely resemble the profiles of the natural food, capturing the complexities of the eating experience and the rich variety that comes when different components interact with each other. To meet consumer demands, flavor manufacturers are increasingly changing their traditional approach to flavor development, adopting state-of-the-art technologies and measurement techniques to create these authentic flavors.

One such line of flavors is Commonsense, created by Danisco USA, Inc., New Century, Kans. (phone 913-764-8100, www.danisco.com). These emerging flavors are based on highly sensitive real-time and quantitative measurements of the release of volatiles responsible for human taste perceptions.

Real-time perception is the result of several sequential stages, including food in mouth, chewed and swallowed, volatiles released into mouth and transferred to the nasal cavity, aroma receptors stimulated by volatiles, multiple signals sent to brain, and brain interpreting information. When fresh fruit is being eaten, for example, various aroma chemicals and flavor components are released during the natural sequence of chewing, swallowing,and breathing. Some of these components are only temporarily present, but are critical in distinguishing a particular fruit or other food.

As can be guessed, the flavor chemistry of food is in constant change during consumption as enzymatic and other reactions influence the flavor molecules. But through the use of highly sensitive real-time measurement techniques, the flavor manufacturer can observe these processes, producing a real-time picture of the dynamics of key flavor chemicals during chewing, swallowing, and breathing. Measuring the release of volatiles that leads to the human perception of flavor, as it happens, is very different from the traditional approach, which measures static flavor components released at a single point in time.

The observed and recorded generation of flavor components can then be incorporated into new flavor creations. For example, the complexities of flavor release when eating a strawberry can be captured and recreated in a yogurt. This same approach can be used in other food and beverage applications.

--- PAGE BREAK ---

The scientific basis of Commonsense flavors was first conceived in the mid-1990s with the development of new techniques in analytical chemistry and advances in the study of olfactory mechanisms in humans. The result is technology that makes it possible to analyze air samples taken from the nasal cavity as food is chewed and swallowed. In addition to the actual flavor substances, the structure of a food or beverage is another key element in flavor perception. Danisco, with its knowledge of ingredient interaction, can ensure that these flavors have the desired impact in the finished product.

The new flavors, which were developed specifically for flavored waters, include peach, raspberry, apple, and strawberry. A prototype, True Waters demonstrates the effectiveness of these flavors. A no-sugar-added fruit-flavored version combines the discussed flavor technology with the benefit of polydextrose (Litesse from Danisco Sweeteners) to provide prebiotic fiber, improved mouthfeel, and a pleasant taste.

Providing Water Management with a Peel

A new fiber ingredient derived from citrus pulp, marketed under the name Citri-Fi, serves as an effective moisture-management tool. Because of its mechanism for binding water, it can incorporate into food products a significant amount of additional water in a tightly bound form without increasing the level of free water in the product.

As a result, the ingredient can be used as an alternative to shortening or oil, replacing up to 50% of the fat in food products without changing the taste, texture, or cost of the product to which it is added, says its manufacturer, Fiberstar, Inc., Willmar, Minn. (phone 320-231-1829).

The new ingredient has been tested in a number of bakery applications, including high-fiber breads, rolls, buns, muffins, cakes, donuts, pies, sweet doughs, and pizza crust. Its ability to attract, bind, and manage high levels of water, up to 12 times its weight, provides functionality benefits when used in formulating these products.

For example, it inhibits moisture migration, allowing a more uniform distribution of moisture in frozen doughs and fresh products; reduces staling and enhances freshness, taste, aroma, and eating qualities in conventional and high-fiber breads over an extended time; produces cakes, doughnuts, muffins, and other baked goods that are equal or better in volume, with a softer, moist texture; and offers a solution to reduce trans, saturated, and overall fat content in a wide variety of bakery applications.

Fiberstar, Inc., is a privately owned research and development company focused on improving food freshness and nutrition with enhanced natural fibers. Its technology can be used to open and expand the tightly bound cell structure of virtually any natural plant material.

--- PAGE BREAK ---

Proteins Provide Coating to Reduce Fat in Fried Foods

Foods prepared using frying techniques are generally believed to contain too much total fat. This problem may be underscored by the fact that consumption of these foods, especially by children, has risen steadily over time. Food developers, realizing this, are faced with the long-daunting challenge of creating deep-fat fried foods which have a reduction in fat.

As a response to this problem, an application process using extracted proteins provides a novel coating to reduce fat in deep-fat fried meat, poultry, fish, and other products by 25–50%, with a reduction in calories. The process, which increases both the moisture and protein content of the foods, was developed by Proteus Industries, Gloucester, Mass. (phone 978-675-9140; www.proteusindustries.com.

Proteins called NutraPure® are extracted from animal muscle and manipulated to effectively act as fat-blocking agents. They are produced by patented technologies licensed to manufacturers and function effectively with muscle from fish, seafood, beef, pork, and poultry.

The proteins are applied either as a batter/additive replacement or as a coating. Waterfall and spray applications are used to apply the proteins to the surface of the substrate prior to frying. In par-fried shrimp, fat percentage has been reduced 40% with an increase in moisture of 22% vs controls. Fully cooked, breaded 6-oz chicken patties treated with extracted proteins are found to contain 23–48% less fat than the leading national brands in similar product categories.

According to the manufacturer, the flavor has been rated clean and excellent by sensory panels, the substrate food is moist, and the final product undergoes little shrink and holds up well under heat lamps. The crumb has increased crunch with an attractive bronze color. In addition to decreasing fat absorption and improving the quality of the deep-fat products, the process extends the food’s shelf life and reduces bacteria.

The extracted proteins are Generally Recognized As Safe when mixed into or used as a coating in like-species foods. Label requirements list the proteins as “(species) protein.”

“At Proteus, we have made tremendous strides in our quest to improve the overall quality of meat, fish, and chicken,” said Stephen D. Kelleher, company founder and chief scientist. “We are discovering all-natural ways to make meat healthier and taste better.” Kelleher is giving a presentation on fat absorption and fat-blocking technology at a New Products & Technologies session at the 2005 IFT Annual Meeting + Food Expo.

--- PAGE BREAK ---

Developing Flavors Worth Their Salt

Food ingredient suppliers are taking different approaches when addressing the reduction of sodium in prepared foods. Over the past several months, an increasing number of these solutions ranging in complexity have been advanced.

For example, a blend of equal parts of sodium chloride and potassium chloride that provides a similar degree of saltiness when incorporated into food products while contributing half the sodium is available from Morton Salt (www.morton.com). A taste modifier, designed to mask the objectionable bitter aftertaste of potassium chloride is offered by Wixon Fontarome, Inc. (www.wixon.com). And taste enhancers that stimulate or amplify the effects of salt are being developed by Linguagen Corp. (www.linguagen.com) through an understanding of the sensory cells located in the taste buds of the tongue.

Flavors and flavor systems from Quest International, Hoffman Estates, Ill. (www.questintl.com), are said to dramatically reduce levels of sodium without compromising on taste. Marketed under the name ImpaQ Taste Technology, these flavors are specifically designed for use in low-sodium environments and can provide the flavor-enhancement properties traditionally performed by salt.

According to Harry Renes, Quest’s Executive Flavorist, the flavors have yielded excellent results in development work with food manufacturers: sodium reduction of 30–50% in soups and snacks can be achieved while maintaining the same eating quality. “Each flavor solution is tailored to the specific application to maximize taste performance, with a view to enhancing the brand taste characteristics and building further consumer loyalty by appealing to the intricacies of consumer preference,” said Renes.

A decade of research is said to lie behind the development of these flavors. “Our most significant step forward came with our fundamental research into meat bouillons and mature cheeses, aimed at identifying the key flavor components that make these important foodstuffs taste delicious,” observed Renes. “Since 1999, we have had more than 25 molecules approved for FEMA GRAS status and have submitted more than 35 flavor-related patents connected with this work. More important, this research gave us new insights into how we can use flavors to influence our perceptions of taste—that is the basis of our approach.”

Although the emphasis is currently on the reduction of sodium, flavors are also being developed to work well in low-sugar and low-fat environments without compromising the taste of the finished product.

In the ‘Quink’ of an Eye

This article has tried to show how a number of approaches are being used to solve familiar problems in food and beverage development. And as interesting as some these solutions are, my guess is that we are only seeing the tip of the iceberg, as different disciplines are getting involved that will have impact on the production of ingredients and their subsequent use in the final product.

--- PAGE BREAK ---

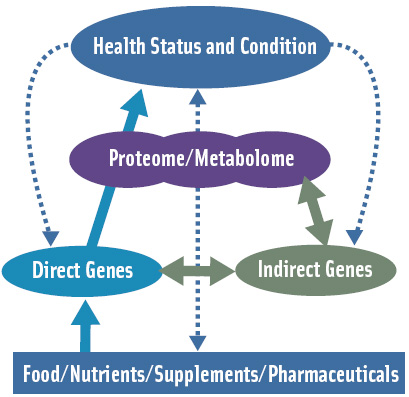

Take, for example, nutrigenomics, the bioscience that defines how the food you eat controls the work your genes are doing, which leads to health or disease. A company called AlphaGenics, Rockville, Md. (phone 240-314- 0563, www.alpha-genics.com), provides technologies to optimize a person’s genetic activity by matching the person’s diet against his or her genes—an advanced application of nutrigenomics science.

According to the company, what a person puts into his or her body in the form of foods, nutrients, supplements, and pharmaceuticals affects the person both directly and through the genome. Genes are turned on and off, and have varied activity levels, which can produce health or illness. Molecules or particles in the environment that can change gene expression—called quinks—include different proteins, minerals, fats, and carbohydrates, with each quink uniquely influencing how one or more genes operate. Different diets translate to different quink profiles, which in turn, change which genes are expressed and their level of expression. A person’s genome responds to changes in what a person eats, and these changes may be predicted and controlled.

According to the company, what a person puts into his or her body in the form of foods, nutrients, supplements, and pharmaceuticals affects the person both directly and through the genome. Genes are turned on and off, and have varied activity levels, which can produce health or illness. Molecules or particles in the environment that can change gene expression—called quinks—include different proteins, minerals, fats, and carbohydrates, with each quink uniquely influencing how one or more genes operate. Different diets translate to different quink profiles, which in turn, change which genes are expressed and their level of expression. A person’s genome responds to changes in what a person eats, and these changes may be predicted and controlled.

The fact that each person has his or her own genome profile provides the basis to define totally personalized diets that can improve health. The company’s strategy is to see what combination of foods works best for a given genotype. Consequently, its goal is to transform the adage “We are what we eat” into “We become what we eat.”

Or how about microbial DNA being used to accurately diagnose the health and vitality of any type of environment? Described as a milestone in genomics, this research, led by the U.S. Dept. of Energy Joint Genome Institute in collaboration with Diversa, makes it possible to create DNA-based metabolic profiles of rivers, lakes, streams, farmlands, and oceans to determine levels of pollution, monitor specific areas undergoing remediation, or assess animal and human health.

“Using this technology, it is now possible to sequence the biosphere in the same manner as a human, which can potentially lead to the development of new products for a range of applications, from animal health products to novel pharmaceuticals,” said Jay M. Short, Diversa’s President and Chief Executive Officer.

Such research can have impact on whether to grow certain foods which, in turn, can have an influence on the creation of certain ingredients. For example, noted Short, “we could take a sample of soil in the wine country of Northern California and tell you whether it is best for growing merlot or pinot noir grapes.”

And then there’s research exploring the science of taste buds, with Linguagen Corp. developing compounds that inhibit the bitter taste response. This company partnered with scientists at Rutgers University to explore the science of taste buds. Rutgers researchers are further studying the genetics of taste and the differences between how people receive different flavors and food preferences. “We are pleased to have this unique opportunity to work with Linguagen to evaluate the differences in bitter tastes and how a new ingredient could potentially affect the way taste is received by separate individuals,” said Beverly Tepper, Professor of Food Sciences at Rutgers.

And the list goes on . . . advances in flavor chemistry, new food processing techniques, varied approaches to sodium reduction, the development of novel ingredients that can address health issues such as obesity. All of these approaches suggest exciting times ahead for food formulation and the solving of familiar and not-so-familiar problems.

Of course, the evolution of these novel solutions may take some time. On the other hand, they may be accomplished in the “quink” of an eye.

Next month’s Ingredients section will look at advancements in emulsions and the diverse applications they offer.

--- PAGE BREAK ---

Global Symposium Explores New Ideas in Pectin

A global seminar explored the latest findings in pectin research and analyzed long-term marketed and demographic projections impacting future customer needs and related applications. The event, held May 8–11 in Soerup Herregaard, Denmark, was hosted by CP Kelco, Chicago, Ill. (phone 312-554-7800, www.cpkelco.com), a leading global producer of specialty hydrocolloids.

Participating in the conference were researchers from Wageningen University, The Netherlands; Institute of Food Research, Norwich, United Kingdom; and the Dept. of Pharmacognosy, University of Norway, Oslo. Industry participants represented leading innovators in food, nutrition, pharmacy, and personal care.

Kelco representatives noted that the first-ever pectin symposium generated a portfolio of high-potential ideas for new product development that the company will explore in the coming months. According to John Lapre, a pectin researcher for Kelco, “We anticipate numerous opportunities from new technology platforms, as well as the potential applications related to pectin’sdual functionalities such as improving both nutrition and texture.”

Pectin is a purified carbohydrate product obtained by aqueous extraction of appropriate edible plant material—usually citrus fruits or apples. It is used in a variety of applications, including food, beverages, and fat replacement.

Collaboration Focuses on Novel Enzymes

A collaboration to discover and develop novel enzymes for the production of proprietary ingredients has been formed between Cargill Health and Food Technologies, Wayzata, Minn. (phone 866-456-8872, www.cargillhft.com), and Diversa Corp., San Diego, Calif.

“Oil processing and nutrition products represent one of Diversa’s strategic focus areas, and we are pleased to be partnering with Cargill on this opportunity,” said Jay M. Short, Diversa’s President and Chief Executive Officer. “We are targeting the development of a novel, differentiated product through the combination of our industry-leading enzyme product-development platforms with Cargill’s bioprocessing and commercial expertise.”

Cargill Health and Food Technologies is a leading developer, processor, and marketer of science-based, health-promoting ingredients for food and dietary supplement industries worldwide, while Diversa is a leader in applying proprietary genomic technologies for the rapid discovery and optimization of novel protein-based products. Diversa is directing its integrated portfolio of technologies to the discovery, evolution, and production of commercially valuable molecules with agricultural, chemical, industrial, and pharmaceutical applications.

--- PAGE BREAK ---

Partnership Probes ‘Out-of-This-World’ Aromas

Ways to apply encapsulated aroma-release technologies to enhance space-food products’ flavor, aroma, and taste, are being explored through a partnership between ScentSational Technologies LLC, Jenkintown, Pa. (phone 215-886-7777, www.scentsationaltechnologies.com), and NASA’s Food Technology Commercial Space Center.

ScentSational’s CompelAroma technology encapsulates specially engineered FDA-approved food-grade flavor substances within the structure of plastic packaging components at the time of manufacturing. Aromas may be released at package opening, product preparation, and consumption, leading to more aromatic and better-tasting foods and beverages without the use of additional fats, sugars, calories, or carbohydrates.

The technology is expected to benefit the astronaut’s experience in space, since aroma plays a key role in eating and since food designed for ease of eating in space sometimes requires compromises in taste. According to Anthony Pometto, Director of NASA’s Food Technology Commercial Space Center, “this technology may hold the key to making many nutritional meals more pleasurable, thus encouraging good nutrition and enhancing the quality of life in space.”

by Donald E. Pszczola,

Senior Associate Editor

[email protected]