Flavor Scalping in Plastic Packaging

PACKAGING

Flavor scalping is slowly being recognized as playing a major role in food quality loss during ambient-temperature and even long-life chilled distribution. So little research has been performed on this topic that we barely understand the mechanisms, much less can quantify them.

Five years ago, this column focused on flavor scalping driven by package materials, summarized papers and lore on the topic, and offered some perspectives on the problem (Brody, 2002). Recently, four researchers from the University of Mumbai in India published an extensive review article on the topic in Comprehensive Reviews in Food Science and Food Safety (Sajilata et al., 2007). Because the topic is increasingly important to food packagers and because in-depth articles on food packaging are so infrequent in peer-reviewed food journals, the new information is examined here.

Flavor Scalping

Flavor Scalping

Flavor scalping describes the loss of quality of a packaged food due to flavors being absorbed into plastic package material. A key variable here is "plastic" increasingly employed to contain and protect foods and beverages.

Food packagers estimate that about 70% of food and beverages come into intimate contact with plastics at some time during their distribution cycle. All food and beverage cans are lined with plastic, and large volumes of bulk components and ingredients are held in containers lined with polyethylene film. A second influencing variable is that foods are being held in contact with plastics for far longer periods than ever before.

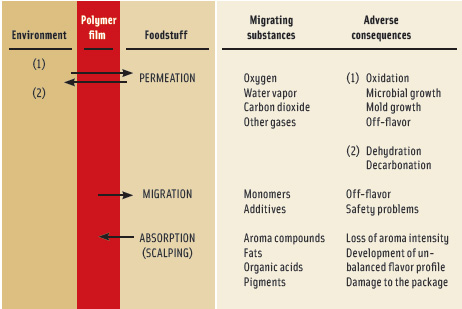

Some would argue that the passage of undesirable odors into the food from the external environment through the plastic constitutes a variation on flavor scalping. Others have taken this addition as migration of chemicals adverse to health. Regardless, the issue of the role of package materials in flavor management is growing.

Since flavors are such delicate blends of so many different constituents and retention of flavors is so vital to the quality of foods, any external driver that upsets these balances can have profound effects on consumer acceptability.

Consider the most prominent manifestation of flavor scalping: removal of limonene from orange juice by polyethylene heat sealants, leading to loss of desirable top notes. Because of the volatility of the compound, the contents do not even have to be in contact with the package material to exert their effect. Juice packagers have been able to retard the losses by complementing the interior with ethylene vinyl alcohol, nylon, polyester, or some combination of them.

The common polyolefins are lipophilic, capable of retention of nonpolar compounds. Absorption, permeation of volatiles through the plastic, and reaction with polymers to alter properties individually or in concert can result in imbalance of the flavor profile.

Sorption of flavors in polymers involves both partitioning and diffusion through the plastic. absorption is influenced by polymer properties such as chain stiffness, morphology, polarity, and crystallinity; by flavor properties such as chemistry, concentration, and polarity; and by environmental variables such as temperature and the proximity of other compounds.

Flavor Characteristics

Chain length is related to boiling point and therefore to solubility in polymer films. absorption and solubility coefficient increase with increasing chain length of the flavor compounds. Distribution ratio is the ratio of the amount sorbed into the polymer to the amount remaining in solution, increasing with chain length.

Various studies have quantified the absorption of esters, ketones, and aldehydes into polypropylene, whose absorption increases with chain length. In some studies, longer-chain compounds were absorbed, while shorter compounds were retained in the product. Highly branched compounds were absorbed more than linear molecules. Esters and aldehydes were absorbed more than alcohols.

Chain length and saturation level of the lipophilic portion of the molecule affects absorption. The longer the chain, the lower the polarity and thus easier absorption by nonpolar polyolefins.

The effect of functional groups on distribution ratio of flavor compounds is greater in liquid because of proximity. The effect of molecular weight is higher in the vapor phase. Linear relationships have been measured between solubility coefficients and boiling points of flavor compounds such as limonene.

Solute polarity is a major factor: flavors are more easily absorbed in polymers of similar polarity. The absorption of many citrus flavors by low-density polyethylene is almost instantaneous, the partitioning depending on the polarity of the compounds.

Effect of Polymer Characteristics

Variables in the plastic affect absorption:

• Polarity. Because of different polarities, each polymer has a different affinity for flavor compounds. Similar polarities lead to easier absorption. Polyolefins are lipophilic and so are not good for packaging nonpolar food compounds such as lipids and aromatics such as limonene. More-polar polymers such as polyester demonstrate less affinity for nonpolar compounds.

• Glass Transition Temperature (Tg). This is a measure of the stiffness of the polymer. Below Tg, the polymer is in the glassy state and tends to be stiff, so that the probability of an opening for the sorbed molecule is low. Above Tg, polymers are more flexible and so have higher propensity to absorb compounds. Rubbery polymers, such as polyethylene and polypropylene, which have Tg below ambient temperature have a high diffusion coefficient for flavors, with steady state being established quickly. Stiff-chain polymers such as polyester have a high Tg above ambient temperature and a low diffusion coefficient for aroma molecules.

• Crystallinity. The more ordered the polymer structure, the lower the absorptivity; crystalline regions act as impermeable barriers for diffusion through the plastic. Furthermore, they restrain polymer mobility, affecting solute permeation to the amorphous regions.

• Density. Aroma absorption decreases with increase in polymer density.

• Free Volume. This is the void space in the solid state. The greater the void, the more open the pathways for the flavor compounds to pass through. Asymmetrical polymers and polymers with many side chains exhibit high free volume and hence high permeability to flavor compounds.

• Other Variables. These include surface area, surface polymer hydrolysis, and presence of recycled plastics.

Effect of External Factors

External variables also influence flavor absorption:

• Food. Interactions of various food constituents with flavor constituents affect the mobility of the free flavors through the food to reach the package material and be absorbed. Because so many flavors are lipophilic, foods with high lipid content tend to lose flavor to polyethylene relatively easily. Food constituents that increase food viscosity help to reduce flavor mobility and thus reduce loss to adjacent plastic packaging.

As indicated above, polyethylenes have a high affinity for nonpolar compounds. Flavor constituents more miscible in polyethylene are absorbed. By lowering the solution polarity or creating nonpolar regions (emulsified oil droplets), the equilibrium partition coefficient could be reduced, thereby increasing flavor retention.

Research results to date suggest that food formulation affects flavor scalping so much that consideration might be given to altering the food’s flavor system to accommodate to the scalping plastic, a route that contradicts fundamental food science and technology. Such inverted priorities are not, however, unknown in food packaging technology.

• Relative Humidity. Water vapor accelerates gas diffusion in polymers that have an affinity for water, the water diffusing into the structure to function as a plasticizer, thus increasing affinity for flavors.

• Temperature. Increased flavor absorption at higher temperatures is attributed to increased molecular mobility, plastic swelling, crystallinity decreases, or changes in volatile solubility. In general, flavor absorption follows the general Arrhenius model of increasing activity as temperature increases.

Avoiding Flavor Scalping

Although it is not easy to describe the problem of flavor loss from foods into or through plastic package materials, overcoming the problem has been even more difficult. Obviously, packaging food in materials other than plastics might prevent most of the many losses and might even in part satisfy those who advocate elimination of plastic packaging as a basis for sustainability. However, the benefits of plastic packaging far outweigh any serious consideration of discarding one of history’s great advances in food distribution enhancement.

Another approach might be flavor encapsulation, reasonable for added flavors but obviously not feasible for all the flavor systems inherent in the food product itself. Some tests have demonstrated that adding natural flavors to plastic package materials establishes a zero concentration gradient and thus might markedly reduce volatile losses.

Most research has been aimed at the selection of the plastic materials, based on the premise that all plastics have different properties and we marry them to achieve the desired final results. The application of ethylene vinyl alcohol and polyvinylidene chloride, both excellent flavor barriers, illustrates the effectiveness of this direction. Neither is a good heat sealant, so one-to-one replacement of polyolefin sealants is not always feasible. Polyester is a good flavor barrier, but its ability to substitute for polyolefin sealants is very limited. An intriguing possibility is bio-based polylactic acid, which has been demonstrated to have relatively high resistance to scalping.

Even more interesting is the possibility that incorporation of nanocomposites into the interior polyolefin sealants might not only enhance barrier and mechanical properties but also function as flavor barriers. Considering the magnitude of the flavor scalping issue, and the hints of nanocomposites being potential flavor blockers, perhaps the real value of nanotechnologies for food packaging might be realized.

By employing empirical approaches, some flavor scalping problems have been reduced, but most remain mysteries to food and food packaging technologists. It should be evident by now that scalping is an enemy of flavor quality retention and that comprehensive research on overcoming scalping should be a food packaging priority.

by Aaron L. Brody, Ph.D.,

Contributing Editor ,

President and CEO, Packaging/Brody, Inc., Duluth, Ga.

[email protected]

References

Brody, A.L. 2002. Flavor scalping: Quality loss due to packaging. Food Technol. 56(6): 124-125.

Sajilata, M.G., Savitha, K., Singhal, R.S., and Kanetkar, V.R. 2007. Scalping of flavors in packaged foods. Comp. Rev. Food Sci. Food Safety 6: 17–35. www.blackwell-synergy.com/ doi/pdf/10.1111/j.1541-4337.2007.00014.x.

Nielsen, T.J. and Jagerstad, I.M. 1994. Flavor scalping by food packaging. Trends Food Sci. Technol. 5: 353–356.