Environmental Effects of Beer Packaging

PACKAGING

This month’s column will examine the findings from a recent study on the environmental impact of various kinds of beer packaging. This study was sponsored by—and applied data directly from—the supplier and the brewer. Thus, by definition, it is biased toward the favored materials. It is intuitively obvious that these life-cycle analyses of beer packaging in four different containers would result in information tilted toward those who paid for the investigation.

A reason for believing the preceding statements is that the results do not concur with the widely publicized preconceived notions derived from the sustainers of sustainability. Human nature resists the acceptance of facts that do not support the cultural, intellectual, emotional, and psychological prejudices with which we are inculcated. Hardly any issues are more granulated with irrelevance than today’s currency of environmental protectionism.

“LCA (Life Cycle Analysis) of Beer Packaging Options,” published in November 2008 by RDC Environment in Brussels, Belgium, (www.rdcenvironment.be) was a study for Sidel (www.sidel.com), a maker of polyester bottle fabricating equipment. Major data inputs came directly from Martens, a medium-sized, independent Belgian brewer. Obviously, because of the sourcing, results are directly applicable only to beer in Belgium, but why might beer packaging in other venues not experience very similar results? In simple terms, this tightly controlled study is almost certainly indicative of the surprising ecological impacts of brewery packaging almost anywhere in the world.

Note, however, that despite the plethora of data, models, analyses, and interpretations by learned professionals, hardly a hint surfaced of the principal purpose of the packages being so minutely dissected: protection of the contents during distribution. Without judging the merits of beer as a food/ beverage (and the procedures cited are applicable to any packaging systems), the present focus on sustainability appears to totally omit the positive value of packaging—to reduce food/beverage loss and permit their safe delivery!

Summary of Results

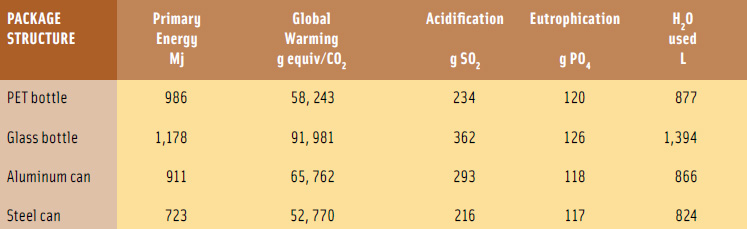

As expected, primary packaging, that in closest contact with the product and the brewing process, exerts the greatest environmental impacts. Distribution and secondary packaging contributions are relatively small. Steel cans (used in Europe) and barrier polyester (PET) bottles (not used much in either Europe or the United States) contribute least to global warming and so-called acid rain. The production of steel cans uses the least primary non-renewable energy and water, while glass bottles are the highest consumers. Where aluminum can recycling rates are high (e.g., in the U.S.), aluminum is a good choice for beer packaging (from an environmental perspective).

Methodology

Life-cycle assessment protocols were standardized by ISO 14040 and 14044 goals, inventory analysis, impact assessment, interpretation, and reporting.

Goals were to “obtain values of the main environmental indicators for each material” and “identify key factors which most influence environmental assessment in order to determine optimum actions to be implemented in a context of eco-conception…” of beer packaging.

The procedures allowed a comprehensive quantification of all matter, energy, consumption of water and mineral resources, emissions such as carbon dioxide, and environmental impact over the entire life cycle of four different types of beer packaging.

--- PAGE BREAK ---

Package structures studied were 0.5 L of beer in polyester bottles coated with ACTIS™ amorphous carbon to enhance oxygen and carbon dioxide barrier; nonreturnable, long-neck glass bottles; aluminum cans; and steel cans. The functional unit was 100 L of beer and “full life-cycle assessment of the associated packaging.”

Included in the research were beer production, primary package production, PET bottles, glass bottles, cans, secondary and tertiary packages— paperboard and polyethylene films, packaging operations, distribution, end-of-life packages, landfill, incineration, and recycling. Not included in this study were home activities such as retailer energy consumption, chilling of the beer in domestic refrigerators, cleaning operations, accidental pollution, and trivialities such as label glue.

Study Results

• Greenhouse effect. Recycling rate is critical to the effect on greenhouse gases. According to the report, steel cans are best for the least greenhouse gas effect, with aluminum cans and PET bottles nearly equal to steel and…“glass is the worst material for the environment.”

The greatest subtractors for glass packaging are primary packaging raw materials and production; secondary packaging (because of the greater amount of protection required to distribute glass bottles); and distribution (ditto—weight of glass bottles). Recycling of glass bottles in the UK is not nearly as great (similar rate as in U.S.) as is recycling of aluminum cans, thus adding to the emissions.

•Acidification effect. The hierarchy for beer packaging is the same for acidification as for greenhouse gases: glass is still the worst, steel is best, and PET is similar to steel—all because the major emissions are NOx and SOx during energy production.

• Eutrophication. This category of environmental impact embraces adverse effect on the water supply as measured by phosphate migration into the land. Eutrophication is dominated (85–90%) by beer production, with the impact stemming from fertilizers and pesticides applied during barley production. From a packaging perspective, the net impact is small relative to agriculture.

• Energy consumption. “Clearly, glass bottles are the worst packaging and steel is the best in terms of energy consumption,” according to the study report. Recycling aluminum can save much energy, and so the recycling rate is important to differentiate cans from polyester, which, realistically, is hardly recycled. If glass bottles were 100% recycled, glass would still be worse than all the other packaging systems. In absolute terms, glass bottles consume non-renewable 1,178 Mj (thousands of joules)/100 L, with primary packaging (the bottle itself) accounting for 62% of the total. Aluminum cans consume 911 Mj/100 L, with the primary package accounting for 89% of the total, but recycling provides a 36% credit, using a UK recycling rate of 44%. (In the U.S., the credit would be much greater due to higher recycling rates.)

• Mineral consumption. Aluminum and steel cans are computed to exert the most-negative impact relative to consuming the Earth’s resources, but, of course, the planet is not likely to run out of either of the base ores in any predictable future, and so this argument becomes meritless. Polyester uses natural gas raw material, which remains in ample supply in spite of the concern for petroleum, but both are “non-renewable.” The sand and other materials of glass are virtually ubiquitous, although aluminum ores are the most abundant on earth’s surface, and the planet is reportedly iron at the core.

--- PAGE BREAK ---

• Water Consumption. The glass option is again the largest consumer of water…,’’ according to the report, with the other three relatively similar in water consumption. The largest component is obviously beer production. The need for water in the production of soda for glassmaking constitutes a major portion of its production. In absolute numbers, 1,387 L of water are consumed packaging 100 L of beer in 0.5-L bottles, while about 820–860 L of water is used for cans and plastic bottles. Seventy-five percent of the water for glass bottle packaging is consumed in bottle production, including raw materials.

Final Waste

Final waste is that placed into sanitary landfills, and glass is still the worst offender due to its mass. All the materials are very stable and do not lead to significant air emissions or water migrants. The study results showed that 26 kg of glass/100 L of beer entered landfills compared with about 3 kg for PET and steel packaging, and 2 kg for aluminum.

Sanitary landfills of the 21st century are the standard in industrialized nations, and stable inputs such as glass, metal, and plastic that endure for “eternity” comprise the foundations for the ultimately resulting ski slopes, hiking trails, and parkland.

In case you have not been tracking the data, presented in much greater detail in the report itself, steel wins for greenhouse gases, energy from non-renewable resources, and water consumption. Polyester bottles place second (but not by much) for global warming, acidification, and eutrophication. And aluminum cans (thank goodness, since we in the U.S. use them rather than steel) place a close second for greenhouse gases and water consumption. The real loser, by large margins, in this “competition” is the non-returnable glass bottle.

After which some might reply, what can you expect from a study sponsored by a plastic bottle–converting machine-supply company? And the response might be, what results might you expect from research sponsored by an environmental-agenda group?

Public review of these findings on the environmental effects of various kinds of beer packaging appears to carry the validation of multiple sound inputs, but are the models true? Or might different, similarly valid algorithms deliver totally different outcomes: We suggest that the conclusions be scanned for sense, which would dictate to all but the most skewed minds, that they are the reality. The researchers have demonstrated that those who wish to offer beer to consumers have viable “environmental,” if not protective, options that allow the target market consumers to enjoy their brews while not upsetting the world.

Aaron L. Brody, Ph.D.,

Contributing Editor

President and CEO, Packaging/Brody Inc., Duluth, Ga.,

and Adjunct Professor, University of Georgia

[email protected]