Measuring Food and Beverage Color

FOOD SAFETY & QUALITY

Color is one of the most important aspects of foods and beverages. Although color does not generally indicate whether a food is safe, a food or beverage whose color is unappealing will likely not be purchased or consumed. Accordingly, food and beverage manufacturers try to control the color of their products and use various instruments to measure product color, both in the laboratory and online.

Why Color Measurement Is Important

Consumers associate food and beverage color with product quality and expect their products to be consistent in color from purchase to purchase, according to Gordon Leggett ([email protected]), Senior Applications Specialist at HunterAssociates Laboratory Inc. Products may change in color over time because of changes in ingredient source, changes over the growing season, and storage conditions, he said, and the primary application of color measurement is to verify color consistency from lot to lot.

Food safety is not usually a color measurement application, he added, since by the time that a fresh food has degraded to a point that it is bordering on a safety issue, the color change is obvious and there are other attributes, such as odor, that indicate that the food may be unsafe to eat.

There are other food applications beyond color consistency where color is measured, he said. Many food products are “freshness dated,” and color is often measured in a shelf-life study to see the degree of product degradation up to the date when the product is to be removed from the shelf. The task would be to verify that the color, indicative of quality, has not changed significantly over the freshness period. Sometimes it is used to check product that has been returned to the food company to see if it is out of the expected normal color range of the product over the shelf life.

Colorants are sometimes added to some food products to enhance or stabilize the color over the freshness period, he said. For example, annatto, a natural food colorant, is often added to cheese to enhance and support more consistent coloration of the product, and color measurement is used to determine how close the color is to the target color.

Color measurement can also be used for monitoring and optimizing production, he added. For example, if a manufacturer is making thousand-gallon batches of a sauce that is to be cooked to an optimum endpoint, color measurement could be used to quantify how close the process is to that endpoint.

How Instruments Measure Color

“Color measurement” ranges from subjective visual comparisons involving color chips or liquids to objective analytical tests based on physical reflectance or transmittance measurement.

Two types of instrument are used for objective measurements—colorimeters and spectrophotometers. Both provide the same CIE L*, a*, b* or Hunter L, a, b color values that represent the three primary color components of light that the human eye sees—red, green, and blue—but they do so by slightly different methods. Colorimeters measure the light reflected from or transmitted through a sample and convert the measurement into colorimetric values using filtered detectors. Spectrophotometers measure the reflectance or transmittance of an object at each wavelength in the visible spectrum, 400-700 nm, and convert the results into the same colorimetric values using software to perform the calculations.

--- PAGE BREAK ---

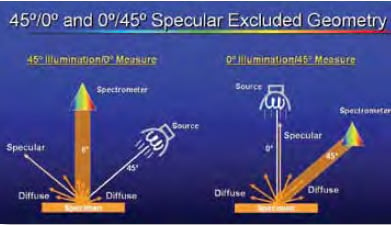

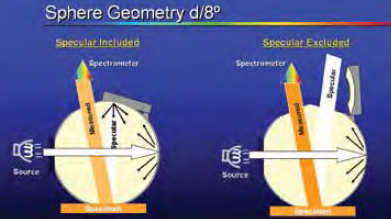

The measurement geometry of the instruments is important. Leggett—who authored “Color Measurement Techniques for Food Products,” Chapter 2 in the ACS Symposium Series 983 book, Color Quality of Fresh and Processed Foods—said that the International Commission on Illumination (CIE), the governing body for color and light measurement, recommends the use of bidirectional geometry for color-measuring instruments: 45°/0° or 0°/45°, and diffuse/8°.

In the 45°/0° geometry, a white light source illuminates the sample at 45°, and the reflected or transmitted light is viewed at 0°. In the 0°/45° geometry, the positions are reversed. In the diffuse/8° geometry, abbreviated as d/8, the illumination is diffused by a sphere and viewing is at 8º.

Each geometry has its purpose, Leggett said, and the best geometry to use depends on the sample being measured. His company’s long experience in providing color-measuring solutions for every type of food product has proven that both types of geometries are needed by the food industry, he said.

Each geometry has its purpose, Leggett said, and the best geometry to use depends on the sample being measured. His company’s long experience in providing color-measuring solutions for every type of food product has proven that both types of geometries are needed by the food industry, he said.

For solid foods, 45°/0° and 0°/45° reflectance measurements are preferred for their superior correlation with visual evaluation of product appearance and robust performance in a food environment. Color and translucency contribute to the way a food product appears to the consumer. The 45°/0° or 0°/45°geometry measures closest to the way a consumer would visually compare two food samples, Leggett said. For that reason, it is the most popular geometry for quality control uses.

Since many food products take the form of pastes, sauces, powders, gels, and small particles and pieces, he added, the measurement of these samples is best performed in a glass container with measurement typically through the bottom. The 45°/0° or 0°/45° geometry is best suited for measuring the reflectance through glass, as it negates the specular shine of the bottom of the glass container in the measurement, he said. Another benefit of 45°/0° geometry instruments is their ability to average a large measurement area of the food product; this is especially important for color analysis of nonhomogeneous samples. For transparent liquids, a d/8 sphere geometry is preferred for measuring transmitted color or haze.

For on-line measurement, a different approach to instrument geometry is required, Leggett said. The instrument must measure products on a production line using a noncontact method. To measure color at a distance from the product, be insensitive to ambient light conditions, and give the best correlation with bench instruments, an online instrument with a directional geometry is used.

Software is available for color formulation and color matching in the laboratory and for use in quality control.

What Instrument Companies Offer

I contacted two of the most prominent companies manufacturing color-measuring instruments for foods and beverages and asked about their newest instruments. Here’s what they told me.

• HunterLab. Hunter Associates Laboratory Inc. (www.hunterlab.com) has been manufacturing color-measurement instruments for more than 50 years, and its portable, benchtop, and on-line instruments have been used to measure the color of thousands of different food products all over the world.

Its most popular instrument is the ColorFlex, a compact mini-bench visible spectrophotometer, first introduced in 1998. A new version, the ColorFlex EZ, will be introduced at the 2010 IFT Annual Meeting & Food Expo this July. It will feature a large, colorful, brightly backlit LCD screen, three USB 2.0 ports for connecting to a computer, a printer, a keyboard, a barcode scanner, and a USB hub for full-speed devices. The ColorFlex provides both 45º/0º and d/8 geometries; the ColorFlex EZ provides 45°/0° geometry.

--- PAGE BREAK ---

Another of the company’s most popular instruments is the LabScan XE bench spectrophotometer, first introduced in 1998. It measures the reflected color of opaque, translucent, powder, and granular samples using 0°/45° geometry.

HunterLab has also introduced other instruments within the past three years: the UltraScan VIS bench spectrophotometer, with d/8 geometry, for the beverage market; the MiniScan EZ portable instrument, with 45°/0° and d/8 geometries for portable color measurement; and the D25LT bench instrument featuring 45°/0° geometry and a large area of view suitable for snack foods, chips, crackers, and cookies

Also to be introduced at the IFT Annual Meeting & Food Expo® is the SpectraTrend HT on-line spectrophotometer, which uses 0°/30° geometry. Designed for use in production environments, it uses LED sample illumination technology to measure and monitor product color on the production line. Like a bench spectrophotometer, the instrument can output both colorimetric and spectral values for the visible spectrum, along with a measurement of product height.

HunterLab also offers color-measurement software called EZMatch® QC, which displays numerical and graphical data on the instruments.

• Konica Minolta. Konica Minolta Sensing Americas Inc. (konicaminolta.com/sensingusa) has been manufacturing color-measurement instruments for more than 20 years. Norm Demers ([email protected]), Senior Applications Engineer, said that its next-generation top-loading spectrophotometer, the CM-5, introduced in January 2010, is the company’s first stand-alone, “all-in-one,” benchtop instrument. It can be used for both reflectance and transmittance measurements and features d/8 geometry. With this geometry, he said, the user can take measurements with the gloss of the sample included in the measurement (specular component included, SCI) or with gloss excluded (specular component excluded, SCE).

The biggest advantage the CM-5 has over the company’s previous instruments, he said, is that it can be used without the need to connect to a computer. It can also be interfaced with the company’s SpectraMagic NX software, which allows the user to store and plot measurement data in multiple ways. Data can be stored on the instrument or downloaded to a USB flash drive.

The user can enter specific indices for a wide variety of food applications, Demers said. A user index, usually a single number, is an objective way to determine if food products correspond to a specific visual color standard or a range of reference tiles or color chips. It makes the color evaluation process more consistent and not reliant on the subjective opinions of an observer.

For example, peanut butter has been traditionally graded for color by an observer looking at a product and comparing the sample of peanut butter to a standard set of colored plastic chips, Demers said. Konica Minolta worked with a peanut butter manufacturer to develop an index the manufacturer can use to grade its batches of peanut butter, using a CR-410 colorimeter. The proprietary color index formula can be entered into a custom SpectraMagic NX template. After the measurement, the colorimetric values will be displayed along with the specific index value for comparison. The company has also developed indexes for other products, such as coffee and tomatoes.

The company also offers a variety of other instruments for the food industry:

--- PAGE BREAK ---

The CR-10 and CR-14 Color Readers are portable colorimeters for quick color quality control. The user simply measures the standard (the target) and then the sample, and the LCD screen displays the color difference in L, a, b or other values.

The BC-10 colorimeter is designed for measuring the color of baked, fried, and processed foods, as well as ingredients, in various environments to ensure consistency in appearance.

The CR-400 series of Chroma Meters feature a large backlit display for numerical or graphic display of data and can be used with a data processor with a built-in thermal high-speed printer. It can store up to 100 target colors and 1,000 measurements.

The CR-410C, a handheld unit designed specifically for measuring the color of roasted whole-bean coffee, displays an index value, calculated to correlate to industry standard measurements.

The CM-3220d is a compact benchtop spectrophotometer with d/8 geometry for color matching and quality control in the laboratory.

Although Konica Minolta does not offer an on-line instrument for measuring the color of foods and beverages during production, Demers said that the CR-400 or CR-410 instrument could be configured for mounting in such a way that it could measure the color of a product online.

Color Seminars Available

Both companies mentioned above offer a variety of educational opportunities, ranging from application notes to seminars, both in-person and Web-based.

HunterLab offers two-day Color and Appearance Seminars on “Basics of Color Measurement” and “EasyMatch QC Operations.” The most recent seminars were held earlier this month, and the next seminars will be held on October 9–10, 2010. The company also offers Web Seminars, 1-hr live presentations by an applications specialist over the Internet, as well as a wide variety of educational materials on its Web site. Details are available at www.hunterlab.com/coloreducation/seminarstraining.

Konica Minolta offers On-Demand Webinars on topics such as “The Fundamentals of Color Science,” “Color Measurement in the Food Industry,” and others. Users can proceed through the Webinars at their own pace at any time and can play, rewind, pause, or fast forward as desired. Details are available at www.konicaminolta.com/sensingusa/events/index.html.

Both companies have a wide variety of application notes on their Web sites.

by Neil H. Mermelstein, a Fellow of IFT, is Editor Emeritus of Food Technology [email protected]