A Brief Look at Grain and Seed Analysis

FOOD SAFETY & QUALITY

A variety of test methods are used to analyze grains and seeds as well as their products such as flours and oils. Here’s a brief discussion of some of the most-used methodologies.

Near-Infrared Spectroscopy

Near-infrared (NIR) spectroscopy was first used to measure moisture content in grain in 1964, and the first use of a commercial NIR grain analyzer for the examination of cereal products was reported in 1973. It has since become an important analytical technique for the analysis of food and feed.

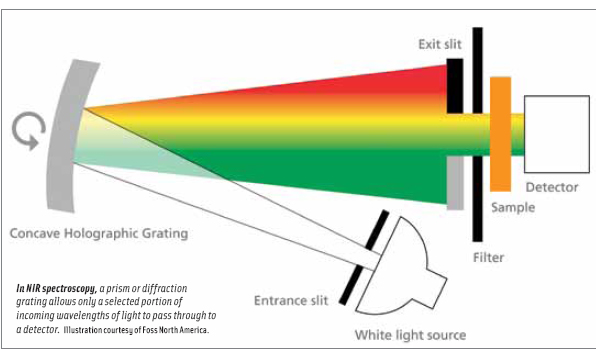

NIR spectroscopy measures the wave-length and intensity of the absorption of light in the near-infrared region of the electromagnetic spectrum (800 nm – 2,500 nm). A typical instrument consists of a sample holder, a light source (usually a tungsten lamp), a prism or diffraction grating to select specific wavelengths, and a detector, generally solid-state. Depending on the sample, the spectrum can be measured in either reflection or transmission mode. NIR spectroscopy is said to provide qualitative and quantitative information not available from any other technique. It can determine the content of protein, fat, moisture, fiber, sugars, fatty acids, etc.

According to Carl Hoseney, Emeritus Professor of Cereal Chemistry at Kansas State University, things don’t change very fast in the grain and seed industry, and analytical techniques haven’t really changed much. NIR continues to make inroads but not tremendous ones. It is used quite a lot, particularly in milling, where fast answers are needed and not necessarily with a high degree of accuracy. The technology is slowly evolving, he says, getting better at analyzing for different things. It’s not an absolute analysis but a correlation, and instrument suppliers are developing more algorithms for fiber, damaged starch, etc.

NIR works, he says, if the sample source is constant, but if the source of the sample changes, it becomes a problem. The analysis is no better than the samples used to calibrate the instrument. If the calibration is based on one set of standards but next year the hardness of the grain or something else changes, the analysis becomes suspect in a hurry. Consistency throughout the industry is important, he adds. As long as the sample is consistent, there is usually no problem. Wheat, for example, is a biological material that varies from year to year because the water is different, the soil is different, and the temperature is different. In addition, grain is not totally static when it is harvested. After-ripening occurs after harvesting. Biological changes occur over time in the grain and also in the products after grinding.

Suppliers of NIR Instruments

Several companies manufacture and market NIR instruments geared to the grain and seed industry.

• Foss North America (www.foss.us) is one of the largest manufacturers of NIR instruments for analysis of food and agricultural products. The company offers NIR transmittance and reflectance instruments, reference wet chemistry, X-ray, and digital imaging for analysis of wheat, barley, durum, malt, green malt, rye, triticale, oats, canola/rapeseed, corn, soybean, rice, flour, plant tissues, and plant-breeding samples.

• Foss North America (www.foss.us) is one of the largest manufacturers of NIR instruments for analysis of food and agricultural products. The company offers NIR transmittance and reflectance instruments, reference wet chemistry, X-ray, and digital imaging for analysis of wheat, barley, durum, malt, green malt, rye, triticale, oats, canola/rapeseed, corn, soybean, rice, flour, plant tissues, and plant-breeding samples.

--- PAGE BREAK ---

Mark Host, Vice President of Sales, says that one of the biggest challenges is standardizing the analysis of agricultural and food products. One of the approaches the company has taken is to incorporate artificial neural networks into its NIR instruments. This simplifies the calibration process, Host says, making the instrument essentially plug-and-play. In the past, every customer had to calibrate each instrument and create unique calibrations for each product and parameter. Using artificial neural networks, the company takes data from around the world and compiles them into one massive global database consisting of more than 100,000 data points. Most of the world’s wheat, for example, is traded on one single calibration, Host says, making buying and selling of wheat almost routine.

Artificial neural networks are mathematical models based on the way the human brain works. Although they are not new per se, they have really taken off in the past 10 years and are being applied on a larger scale, Host says. In developing an artificial neural network, data are fed into nodes, and the outputs of the nodes are interconnected to predict a value, which is then fed back into the network until a minimum error is obtained. Like the brain, the model can handle very complex nonlinear relationships and can be trained to improve its ability to analyze future unknown samples correctly.

The database is continuously updated with information on samples collected each season, representing variations in varieties, climate, geography, temperature, concentration ranges, etc. The samples are chemically and spectrally analyzed, and the data are added to the database to calculate a new mathematical calibration model.

Foss offers NIR instruments for use throughout the grain industry, ranging from small portable instruments for use on the farm to laboratory instruments for routine quality control and in-line analyzers for real-time analysis in production. The most widely used instrument Foss offers for the grain and seed industry is the Infratec™1241 Grain Analyzer, which comes with ready-to-use calibrations for protein, moisture, starch, and oil for all grains and rice. It can analyze products ranging from incoming grain to finished flour. It analyzes both whole-grain and tempered wheat, allowing for correct analysis of incoming raw material, correct blending, and moisture assessment when tempered wheat is ready for milling. The automated instrument is said to provide reliability and uniformity, regardless of location and operating conditions. It can be used alone or networked, with each networked unit giving nearly identical measurements.

Foss offers NIR instruments for use throughout the grain industry, ranging from small portable instruments for use on the farm to laboratory instruments for routine quality control and in-line analyzers for real-time analysis in production. The most widely used instrument Foss offers for the grain and seed industry is the Infratec™1241 Grain Analyzer, which comes with ready-to-use calibrations for protein, moisture, starch, and oil for all grains and rice. It can analyze products ranging from incoming grain to finished flour. It analyzes both whole-grain and tempered wheat, allowing for correct analysis of incoming raw material, correct blending, and moisture assessment when tempered wheat is ready for milling. The automated instrument is said to provide reliability and uniformity, regardless of location and operating conditions. It can be used alone or networked, with each networked unit giving nearly identical measurements.

First introduced more than 20 years ago, the instrument has been continuously improved, Host says. The newest version offers increased speed of analysis so that sample throughput is 25% faster; simplified communication with external computers using Foss DataLogger™ and DataLink™ software; a simpler user interface/menu system; new design of the sample drawer, making it easy to transfer the sample back into the sample container after analysis is finished; and increased wavelength range of 570 nm – 1,100 nm, making it possible to accurately measure factors such as carotene levels in durum wheat (yellowness), chlorophyll in rapeseed (maturity), tannin in wheat (redness), whiteness in polished rice (milling degree), and carotene levels in corn (whiteness/yellowness).

--- PAGE BREAK ---

Foss also offers other NIR instruments and systems. The InfraXact NIR Analysis System includes automatic sample identification, no need for chemicals, ready-to-use calibrations, quick start-up, user-friendly interface, and ability to customize reports and integrate NIR results into LIMS, process system, or other software. The Infratec SOFIA portable whole-grain analyzer is based on the same NIR technology and calibrations as the Infratec 1241 and offers protein, moisture, and oil analysis of wheat, barley, and canola on the farm. The ProFoss™ provides continuous in-line analysis of key components of whole grain and flour, such as moisture, protein, and ash; it can be used to validate the flour quality and allow for adjustment of grain mixing, milling conditions, or final flour quality by addition of moisture or gluten before product release.

• ASD Inc. (www.asdi.com) offers portable and online NIR instruments and systems for measurement of components such as oil, protein, and moisture in feed, grain, and seed products. The company says that the wide spectral wavelength range of its visible/NIR technology more thoroughly analyzes samples for various constituents and their concentrations in whole grain and seed, including oil, protein, fatty acids such as oleic and linoleic acids, and amino acids such as lysine and methionine. Because of the variance that occurs in an uncontrolled environment, larger data sets obtained through the added visible and third overtone regions are said to be key in making the calibration model more robust.

The company’s LabSpec® 5000/5100 Portable Vis/NIR Spectrometer is a post-dispersive NIR spectrometer designed for the field, laboratory, and manufacturing environments. It provides Ethernet and optional wireless functionality and can be used on a wide selection of materials, including solids, powders, slurries, and liquids.

• Perten Instruments (www.perten.com) offers its DA 7200 NIR Analyzer, which it calls the most accurate, rapid, and easy-to-use NIR instrument available. It is used by many companies to test their raw materials and ingredients, monitor and optimize production processes, and verify end-product compliance to specifications. It can analyze many types of samples in only six seconds and provide highly accurate results for moisture, protein, and fat in such products as whole grains, flour, food, and feed. It can measure moisture, protein, ash, starch damage, water absorption, and other parameters with little or no grinding or other sample preparation. The company recently released a calibration package for the analyzer that enables flour millers to accurately analyze wheat, flour, ingredients, and by-products in one instrument.

The company also offers other NIR instruments. The Inframatic 9140 Flour Analyzer is a low-cost NIR analyzer for laboratory and at-line determination of moisture, protein, ash content, and other content in flour and meal. The Inframatic 9200 Grain Analyzer provides 40-second analysis of moisture, protein, and other parameters in whole grains and is suitable for use at grain intake and at-line placement for temper control. The Aquamatic Grain Moisture Meter is a low-cost moisture analyzer for grain, suitable for testing both incoming grain and grain after tempering. And the DA 7300 On-line NIR Analyzer determines moisture, protein, ash, and other parameters in real time and automatically feeds the information back to the process control system for instant optimization.

--- PAGE BREAK ---

Other Technologies

Several other technologies are also being used in the grain and seed industry. Here are brief descriptions of some instruments and applications.

• Nuclear Magnetic Resonance. Oxford Instruments Magnetic Resonance (www.oxford-instruments.com) says that its low-field benchtop nuclear magnetic resonance (NMR) technology is a rapid and accurate technique for the measurement of oil content and a viable alternative to traditional wet chemical techniques, which are time-consuming, use hazardous chemicals, and require skilled laboratory personnel. The company says that NMR is easier to calibrate than NIR because it is not dependent on the product matrix. As a result, it is often possible to calibrate against 100% oil for oil determination. In addition, the company says, NMR has better sampling than NIR because signal is acquired from the whole sample, not just the surface. For some applications, such as seeds, it is possible to simultaneously measure moisture content below 10%.

The company’s MQC analyzer is said to be ideal for determining the oil content of seeds, nuts, and grains as well as a wide variety of processed foods, snack foods, and animal feed. Since NMR acquires a signal from the whole sample and not just from the surface, it provides better accuracy and precision than alternative secondary techniques, according to the company. For some applications, as in analyzing oilseeds, it is possible to measure both the moisture and oil concentrations simultaneously. The instrument’s internal computer runs the company’s EasyCal software, and a 17-inch LCD flat-screen monitor mounted on the instrument provides a clear view of results and operational instructions.

Bruker Optics (www.brukeroptics.com) offers its mini-Spec TD-NMR for determination of oil and moisture content in seeds and nuts, including sunflower kernels, soybeans, and canola/rapeseeds. The mini-spec line of time-domain NMR instruments includes the mq-one Seed Analyzer; the mq-one Seed XL Analyzer for sunflower seeds; the mq7.5 Large Seed Analyzer for sunflower seeds; the mq10 Seed Analyzer; and the mq20, mq40, and mq60 for analysis of small amounts down to single seeds. The instruments offer preparation-free and grinding-free sampling, direct transfer of the seeds to the sample tube, weighing of the sample, and automatic transfer of mass to the minispec software, placement in the instrument, automatic start, and display of results within seconds.

• Atomic Absorption Spectrometry. Thermo Fisher Scientific Inc. (www.thermo.com/ice) offers, among other instruments, its Thermo Scientific iCE 3000 Series atomic absorption spectrometers, which are said to allow quick and easy optimization for precise analyses of nutritional and toxic elements in rice products at parts-per-million and parts-per-billion levels. An application note titled “Food Safety Series—Determination of Trace Elements in Rice Products by Flame and Graphite Furnace Atomic Absorption Spectrometry” provides a detailed overview of sample and standard preparation with optimized methods for the analysis of copper, zinc, manganese, cadmium, and lead in rice products, using flame and furnace atomic absorption.

Neil H. Mermelstein,

a Fellow of IFT, is Editor Emeritus of Food Technology

[email protected]