Assuring Egg Quality

FOOD SAFETY & QUALITY

Eggs continue to be a highly desirable and nutritious food. According to the Economic Research Service of the U.S. Dept. of Agriculture (USDA), 6.66 million dozens of eggs will be produced in the United States in 2012. Americans consume 246 eggs per person per year: 30% in the form of pasteurized liquid egg and 10% in the form of specialty eggs, including organic, non-confined (cage-free), and enriched shell eggs. This article discusses the quality testing conducted by a major egg company as an example of the care taken by egg producers to provide the highest-quality and safest eggs and egg products to the consumer, at home or in foodservice situations.

High Quality Standards

Eggland’s Best LLC (EB LLC) (www.egglandsbest.com) is the largest marketer of nationally distributed branded specialty eggs in the United States. The company markets enriched white-shelled eggs from caged hens, brown-shelled eggs from cage-free hens, USDA-certified organic eggs, hard-cooked peeled eggs for retail and foodservice markets, liquid egg white for retail consumers, and liquid whole egg for the foodservice segment.

Structured as a producer-owned agricultural cooperative, the company obtains the eggs to be marketed under the Eggland’s Best brand from 35 approved and licensed producers (franchisees) on production complexes located throughout the United States. The producer sites are selected and approved on the basis of their ability to meet stringent quality standards with respect to structure, facilities, biosecurity, and procedures specified in the company’s operating standards manual. Each processing plant is monitored by the USDA and is certified as a Safe Quality Food (SQF) Level 3 facility incorporating HACCP and other procedures to ensure quality and safety.

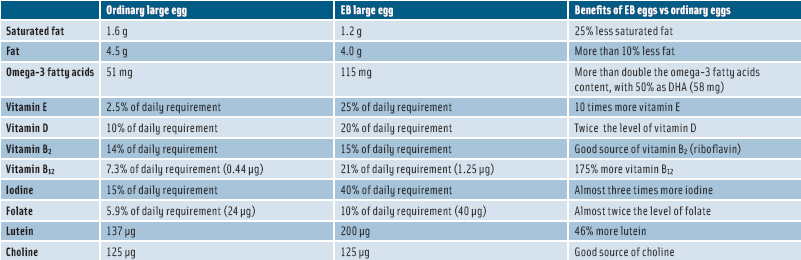

Charlie Lanktree, EB LLC’s President and CEO, said that the eggs marketed under the Eggland’s Best brand must be consistently fresh to meet consumer expectations, and having production sites throughout the United States enables franchisees to deliver fresh eggs to distribution centers and local supermarkets within 48 hr of egg-laying. It also reduces the amount of carbon generated in transport. The company prides itself on providing eggs that are much higher in quality and taste than conventional products. Label claims for Eggland’s Best eggs, backed by extensive analyses, are that the eggs have 25% less saturated fat, 10 times more vitamin E, 25% more lutein, and more than twice the level of omega-3 fatty acids (115 mg) than regular eggs. In addition, the eggs are an excellent source of vitamins D3 and B12 and a good source of riboflavin and folate.

The USDA specifies the characteristics for eggs to be classified into quality categories AA, A, or B. While only about 30% of regular commodity eggs in the United States are USDA-graded, all Eggland’s Best classic white-shelled eggs are packed under the supervision of the USDA and exceed the agency’s basic grading standards. Eggland’s Best Grade AA eggs must include at least 92% AA quality, whereas the USDA standard requires only at least 87% conformity. The company also has more stringent standards for cracked eggs, shell defects, stains, and blood spots.

A retail egg quality audit conducted by the USDA in 2010 showed that Eggland’s Best eggs had a lower prevalence of blood spots as well as fewer cracked and stained eggs, confirming findings from previous independent retail egg quality studies. A subsequent survey conducted for EB LLC by an independent quality evaluation firm compared 50 dozen Eggland’s Best eggs with 50 dozen store-brand large Grade A eggs collected from major supermarkets in the Chicago area. EB LLC’s eggs had statistically brighter yolk color and greater albumen height, especially at the end of the storage period, indicating that they stayed fresh for a longer period.

Ensuring Quality

Bart Slaugh, EB LLC’s Director of Quality Assurance, said that the company ensures the quality and safety of its products through a comprehensive program of production procedures that contribute to quality, laboratory assays to ensure compliance with standards, and field audits for confirmation. The company’s quality assurance efforts extend through all stages of production from farm through retail outlets.

Flocks. Correct housing and management of flocks is of vital importance to egg quality, Slaugh said. The hens are vaccinated against common poultry diseases and are maintained without administration of antibiotics or other medications. Immature flocks are vaccinated three times during the growing period to prevent Salmonella infection. Two consecutive doses of a USDA-approved live attenuated Salmonella vaccine are administered to protect young chicks. An inactivated Salmonella Enteritidis (SE) oil-emulsion vaccine is administered to each pullet before transfer to the laying house.

--- PAGE BREAK ---

Flocks are assayed five times during the cycle of rearing and egg production to confirm freedom from environmental contamination with SE. The company mandates a zero-tolerance policy for this infection. The efficacy of vaccination is monitored using an ELISA procedure to assay the antibody level in yolks derived from eggs produced by EB LLC’s flocks. The company’s program of vaccination, biosecurity, and monitoring for SE pre-dates the requirements of the U.S. Food and Drug Administration’s 2010 Egg Safety Rule by seven years and still exceeds the agency’s requirements. EB LLC’s laboratory is equipped to conduct assays for Group D1 Salmonella using immuno-based lateral-flow test kits.

The company requires annual audits of all farms and production locations. A panel of independent veterinarians board-certified in poultry medicine is responsible for evaluating and verifying vaccination programs, production records, biosecurity, and flock health and welfare. Feed-mixing plants, production barns, and packing facilities are visited and reviewed to ensure compliance with EB LLC’s operating standards. The strain, age, farm location, and SE test status of all flocks is maintained in a comprehensive database. Appropriate flags indicate any delay or failure to submit monthly flock production records or comply with mandated vaccination and environmental testing for SE.

Feed. Flocks producing Eggland’s Best eggs are fed an all-vegetarian diet with restrictions on nutrient composition and ingredient inclusion. Feeds must be formulated with predetermined levels of flaxseed and canola oil (rich sources of omega-3 fatty acids), and no animal byproducts, recycled or waste ingredients, or animal fat is allowed in the feed because peroxidation of fats in these ingredients can result in rancidity, which imparts an unnatural flavor to eggs and causes deterioration in the integrity of the vitelline membrane surrounding the yolk.

The feeds are fortified with a proprietary supplement, Biotene®, that contains sufficient vitamins and minerals to attain or exceed the label claims for nutrients in the eggs. Additives included beyond the requirements of the hen are vitamins D3 and E and organic forms of copper, manganese, zinc, and selenium. Natural plant pigments contribute lutein, which is necessary for healthy eye function in consumers, especially seniors. The stability and potency of supplementary nutrients is achieved by incorporation of antioxidants in Biotene.

Representative samples of EB LLC’s feeds from each flock are submitted each week to the EB LLC Quality Center in Jeffersonville, Pa., for analysis. Among other quality control procedures, Slaugh said, the feed is assayed for the presence of Microtracer™ particles to confirm that Biotene has been added to the diet, and an immuno-based kit from Neogen Corp. is used to verify that no animal byproducts have been added to the feed. As an added measure to ensure consumer safety, representative samples of feed are submitted to the University of Pennsylvania Toxicology Laboratory at regular intervals to confirm the absence of detectable heavy metal contamination. Franchisees are expected to maintain records relating to ingredient and feed quality, including moisture content, the possible presence of mycotoxins, and the efficiency of mixing.

Processing. Once laid, the eggs are collected on conveyor belts and moved promptly out of the hen houses to be processed in-line. Some cage-free and organic eggs produced on family farms are moved to a cold room and held at 45°F until transfer to the packing plant. The maximum length of time that the company allows for the eggs to equilibrate to the ambient temperature in a plant before packing is approximately 25% of the time allowed by the USDA.

Eggs are washed in warm water in a chlorine-detergent sanitizer to remove any adhering deposits and then rinsed in warm water. Grading equipment features electronic modules to detect and reject cracked or dirty eggs as well as internal defects such as blood spots. Eggs are graded and packed by USDA weight category (e.g., extra large, large, etc.). The plants are equipped with accessory drying fans to ensure that the surface of shells is dry at the time of packing. This reduces the risk of post-packing contamination with bacteria and fungi and eliminates possible spoilage or quality deterioration. A mechanical printer then stamps each egg with a red logo, EB, using food-safe ink, to indicate that the eggs meet the company’s standards for freshness and quality.

The company’s operating standards manual requires plant quality control personnel to monitor packing and quality of product through on-line inspection of a designated proportion of packs. In addition, USDA inspectors are responsible for ascertaining conformity with federal grading standards and EB LLC’s stricter requirements for shell integrity, cleanliness, weight, and grade, including internal quality.

--- PAGE BREAK ---

Eggs are maintained at or below 45°F from packing through the distribution chain. Rapid turnover of inventory is required to ensure freshness as perceived by the consumer. Prolonged storage or exposure to room temperature results in deterioration of the shell membranes surrounding the albumen and the vitelline membrane. The USDA allows eggs to be held for up to 21 days prior to processing and packing into cartons, but most Eggland’s Best eggs are packed within hours after being laid and are never stored in the cooler longer than seven days prior to processing. The company also strives to move eggs into distribution channels within 48 hr after processing.

Quality Testing. Eggland’s Best eggs are subjected to the most rigorous testing for physical, nutrient, and organoleptic attributes in the U.S. industry, Slaugh said. The Eggland’s Best Quality Center’s state-of-the-art laboratory conducts more than 35,000 analyses each year. The primary physical quality characteristics of eggs are shell cleanliness, shell strength, intensity of yolk pigment (yolk color), and Haugh values, which indicate albumen height and consistency. Haugh units are directly correlated to USDA grade criteria.

The laboratory uses the EggAnalyzer ® from Orka Food Technology (www.eggtester.com) to characterize the internal quality of eggs. A quality control technician places an egg on the instrument’s electronic scale to weigh it and cracks the egg onto the instrument’s plate. The instrument then automatically measures the intensity of the yolk color, according to a standard scale; provides noncontact measurement of albumen height, using ultrasound; calculates the Haugh value within 17 sec; and classifies each egg according to USDA grade criteria. Eggs with Haugh values of 72 or higher are considered to be of AA quality, as EB LLC requires. Orka Technology’s Egg Force Reader is used to measure the force required to crush a shell, a measure related to shell integrity and resistance to breakage.

To validate its claims for superior nutritional quality of its eggs, the company monitors representative samples of eggs from all its producing flocks. Laboratory personnel analyze freeze-dried egg contents for saturated fatty acids, omega-3 fatty acids, iodine, vitamin E, and cholesterol. Results are tabulated and reviewed before being entered into a database and circulated to franchisees with appropriate comments. Eggs are also submitted to reference laboratories quarterly for validation analyses.

Representative egg samples are sent to independent laboratories to analyze for lutein and vitamins D3, B2, B12, niacin, and folic acid. Slaugh said that nutrient assays can be correlated with organoleptic properties. The levels of vitamins D3 and E are regarded as indicators of possible oxidation in feed caused by rancidity of canola oil or other ingredients, he added, and levels of other nutrients can be directly correlated with egg quality. Vitamin E and organic selenium have been reported to improve the strength of the vitelline membrane of the yolk, and vitamin D3, zinc, and manganese contribute to improved shell strength. Sensory tests are also conducted in EB LLC’s laboratory. Depending on circumstances or events in the agriculture and livestock industries, feed or egg samples are also submitted to independent laboratories to detect possible contaminants.

An independent auditing firm, Ecosure, conducts twice-yearly point-of-sale audits in supermarkets throughout the United States to evaluate the quality of Eggland’s Best egg shells, stamped logos, cartons, and retail displays. The firm sends images and egg samples to the Eggland’s Best Quality Center for evaluation and nutrient analyses as part of the quality control process. Marketing and sales personnel and the panel of veterinarians also conduct occasional unannounced store audits and reviews to ensure that physical quality meets EB LLC’s standards.

Recognizing Quality Efforts

Producing and distributing a range of branded specialty shell eggs and derived products requires extensive planning and coordination, Slaugh said. All aspects of the business—from feed production through management of flocks, packaging, and distribution—require analysis and application of procedures to verify predetermined standards. EB LLC’s production and quality assurance programs have evolved over 20 years and represent a significant investment in personnel, equipment, and outside resources as well as the commitment of the company’s franchisees to meet the company’s standards. As a result of its production and quality assurance efforts, EB LLC has received awards from the American Masters of Taste organization for the taste, appearance, and freshness of its eggs and from magazines for their eggs’ health benefits.

Neil H. Mermelstein, a Fellow of IFT, is Editor Emeritus of Food Technology

[email protected]