Sugar Reduction with Polyols

Polyols are in a unique position to assist with reduced-sugar or sugar-free reformulations since they can reduce calories and complement sugar’s functionality.

Sugar reduction will be an important goal over the next few years as consumers, government, and industry alike have expressed interest in lower-calorie and lower-sugar foods. The 2010 Dietary Guidelines for Americans put a strong emphasis on consuming fewer calories and reducing intake of added sugars. The Institute of Medicine (IOM) held a public workshop in November 2010 to discuss ways the food industry can use contemporary and innovative food processing technologies to reduce calorie intake in an effort to reduce and prevent obesity, and in October 2011 recommended front-of-package labeling that includes rating the product based on added sugars content. In January of 2011, Wal-Mart, along with First Lady Michelle Obama, outlined a new program to make food healthier. One of the key components of the initiative was a 10% reduction in added sugars in “thousands of everyday packaged food items” by 2015. Also in 2011, the Grocery Manufacturers Association (GMA), in conjunction with the Food Marketing Institute, announced the launch of Nutrition Keys, a voluntary front-of-pack nutrition labeling system designed to help consumers build a healthy diet. In the Nutrition Keys model, total sugar will be highlighted on the front of food packages. Reduced-sugar and sugar-free products can play an important role in helping Americans consume fewer calories and less added sugar.

Reduced-sugar products may be easier to formulate than sugar-free products since only a portion of the sugar needs to be replaced for “reduced-sugar” labeling. Many of the product’s original characteristics may still be maintained with the replacement of those sugars by polyols. In addition, excellent, good-tasting sugar-free products can be developed by using polyols. Polyols are in a unique position to assist with reduced-sugar or sugar-free reformulations; since they are only partially digested and absorbed, they can reduce calories and complement sugar’s functionality. Polyols provide the same bulk as sugars and other carbohydrates. Additionally, polyols have a clean, sweet taste, which is important since consumers are not likely to sacrifice taste for perceived health benefits. Polyols have a host of other functional properties that make them useful alternatives to sugars.

Digesting the Basics

Polyols are a group of reduced-calorie, low-digestible, low-glycemic carbohydrates. Their structure is similar to that of sugars, except for the substitution of a hydroxyl group in place of the aldehyde or ketone group found in sugars. This substitution is the reason polyols are commonly referred to as sugar alcohols, although they are neither sugars nor alcohols. Polyols still have many of the physical properties of sugar, which makes polyols well suited for replacement of some of the sugar and corn syrup in many food and beverage applications.

In food applications, polyols are considered bulk sweeteners because they can be used volume-for-volume in place of sucrose or corn syrups. This is why polyols serve as useful alternatives to sugars in a wide range of products, including chewing gums, candies, ice cream, baked goods, and fruit spreads. In addition, they function well in fillings and frostings, canned fruits, beverages, yogurt, and tabletop sweeteners. They are also used in toothpastes, mouthwashes, and pharmaceutical products such as cough syrups and throat lozenges.

--- PAGE BREAK ---

There are eight polyols available for use in the United States: erythritol, polyglycitols or hydrogenated starch hydrolysates (HSH), isomalt, lactitol, maltitol, mannitol, sorbitol, and xylitol. The term “polyglycitols” encompasses polyol mixtures, which are similar to corn syrups and maltodextrins. Xylitol is approved for use in special dietary foods, mannitol has interim food additive status, and sorbitol has been affirmed “generally recognized as safe” (GRAS) by the U.S. Food and Drug Administration (FDA). Erythritol, isomalt, lactitol, maltitol, and polyglycitols are self-affirmed GRAS.

Polyols may be listed in the Nutrition Facts Panel on food labels as sugar alcohols, or, if only one polyol is present in the product, by the specific name of the polyol. Listing in the Nutrition Facts Panel, however, is voluntary except when a claim is made about polyols or sugars when polyols are present in the product.

Absorbing the Message

Polyols as a whole are used by the body differently than sugar. Due to their unique structure, polyols are incompletely digested and/or absorbed by the body. Portions of the polyols that are absorbed are either metabolized or excreted via the urine. Most of the ingested polyol reaches the large intestine where this unabsorbed portion is metabolized to short-chain fatty acids and gases by bacteria in the large intestine.

As a result of incomplete absorption, some people may experience gastrointestinal effects similar to reactions to beans, cabbage, and other high-fiber foods. Such effects are dependent upon an individual’s sensitivity and the foods eaten along with the polyol-containing product. Gastrointestinal effects (such as a feeling of fullness or laxation) from consuming foods with polyols are usually mild and temporary, if they occur at all.

The statement “excess consumption may have a laxative effect” is required on the label of a food whose daily consumption may exceed 20 g of mannitol or 50 g of sorbitol. Since regulations have not been codified for the other polyols, any labeling statements regarding possible gastrointestinal (GI) effects are left to the discretion of the manufacturer. When polyols are used to replace only a portion of the sugar in a product, GI effects are less likely to occur.

Health Benefits of Polyols

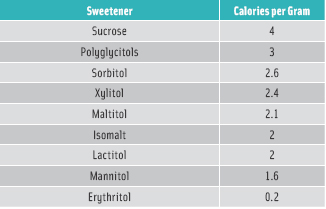

In addition to their clean, sweet taste and unique functional properties, polyols offer important health benefits. One key advantage is that they are reduced in calories and do not cause sudden increases in blood sugar levels. Due to their different metabolic fate, polyols provide significantly less than the traditional four calories per gram assigned to carbohydrates in general. The FDA allows the use of individual caloric values shown for the various polyols in Table 1, whereas a common value of 2.4 cal/g is laid down for all polyols except erythritol in the food legislation of the European Union for labeling purposes.

--- PAGE BREAK ---

There is a significant body of data suggesting that carbohydrates with mild effects on blood glucose levels may have health advantages over those that are rapidly digested and absorbed. Polyols, for example, elicit a reduced glycemic response and reduce the glycemic load of the diet. Polyols, therefore, can have a useful role in reducing the overall glycemic load of the diet and in so doing may help to reduce the risk of a variety of lifestyle-related diseases.

Furthermore, polyols are not readily converted to acids by bacteria in the mouth and, therefore, do not promote tooth decay. The FDA has authorized the use of the “does not promote tooth decay” health claim for sugar-free food products sweetened with polyols. This claim cannot be used, however, when polyols replace only a portion, not all, of the sugar.

Functional Benefits of Polyols

• Physical properties. Polyols and sugars have several physical properties that are important in food processing: solubility, sweetness, cooling effect, hygroscopicity, crystallization, viscosity, temperature stability, and browning. Despite their similarities, the polyols can differ greatly in characteristics, including level of sweetness, cooling effect, solubility, and molecular weight. Understanding the differences in physical and functional characteristics among polyols is vital for selecting the most suitable polyol for a food application.

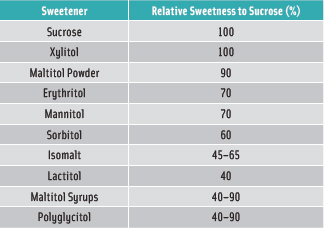

• Sweetness. The sweetness of sugars, intense sweeteners, and sugar replacers are usually measured in relation to the sweetness of sucrose or table sugar, which is given a sweetness reference value of 1 or 100%. The sweetness of polyols varies and is affected by other ingredients in products in which they are used. Generally, polyols vary in sweetness from about half as sweet as the same amount of sucrose to equally as sweet as sucrose (Table 2).

• Taste and cooling effect. Sweetness is one component of the gustatory perception. For polyols, flavor underpinning attributes and mouthfeel also become important factors. Polyols are non-reactive and easily combine with other sweeteners. Frequently, polyols are combined with intense or low-calorie sweeteners, such as acesulfame potassium, aspartame, saccharin, neotame, stevia sweeteners, and sucralose, in sugarfree chewing gums, candies, frozen desserts, and baked goods. The full-calorie versions of these products are sweetened with sugar or high fructose corn syrup, the amounts of which can be reduced by combining them with polyols. The polyol contributes mild sweetness as well as the bulk and texture of sugar.

Some crystalline polyols have a high heat of solution, resulting in a cooling effect in the mouth. The cooling effect of polyols varies. Erythritol has the strongest cooling effect, and isomalt the mildest. While this effect may be desirable for peppermint and menthol products, it is unsuitable for others—baked goods or chocolate, for example. Combining polyols with sugar may minimize any cooling effect.

--- PAGE BREAK ---

• Molecular weight. The molecular weight of polyols is very important when considering their applications because it can impact the viscosity, texture, freezing properties (e.g., cold and frozen products), crystallization, and osmolality of the polyol. Typically, as the molecular weight of a polyol decreases, osmolality increases, freezing point decreases, viscosity decreases, and boiling point increases. These changes can impact production by altering cookie spread, cake volume, ice cream texture, shelf life, and mouthfeel.

• Texture and appearance. Polyols may also exist in syrup form. They serve a number of functional roles, including use as bulk sweeteners and as sugar-free carriers for flavors, colors, and enzymes. They blend well with flavors and with sugars.

• Solubility. In general, the solubility of both sugars and polyols increases with temperature. Some of the polyols, such as sorbitol, xylitol, maltitol, or lactitol, are highly soluble in water. Others, like isomalt, erythritol, or mannitol, are somewhat soluble, but this does not often restrict their use in food applications.

• Hygroscopicity. Hygroscopicity is the ability of a substance to absorb water from the atmosphere. Polyols that are highly water-soluble also tend to be very hygroscopic. This behavior may assist in adding and retaining moisture in food products. Sorbitol, xylitol, and many polyglycitols have a high tendency to absorb moisture whereas mannitol, isomalt, and erythritol show very low hygroscopicity. These differences give each polyol unique attributes for applications in food processing.

In baked products like wafers and cookies, crispness and retention of crispness during storage are highly desirable characteristics. For example, the addition of low hygroscopic polyols to a recipe, in place of part of the sugar, will produce significant improvements in crispness of baked goods. Another advantage resulting from this property is that since the products do not absorb moisture, they have a longer shelf life.

• Crystallization. The ease of crystallization of a substance is also related to its solubility. The greater the solubility of the polyol, the lower will be the tendency to form crystals. Typically, the solubility of polyols increases substantially with rising temperature. With polyols, heat and super saturation followed by carefully controlled cooling may inhibit crystal formation similar to sugars. However, if temperature is not carefully controlled, super saturated solutions, commonly used in confectionery, are unstable and will crystallize rapidly.

--- PAGE BREAK ---

The addition of certain polyols can inhibit crystal formation, thus imparting smoothness and creaminess to the food product. In confections, sorbitol or polyglycitols can be used as interfering (doctoring) agents, ingredients that modify the crystal formation by influencing the rate of crystallization, crystal size, and crystal-syrup balance. Sorbitol often serves as a crystallization inhibitor for liquid sugar systems and is frequently used in syrups and jams to inhibit undesirable crystal formation.

However, certain applications, such as hard boiled candies and lozenges, require an amorphous state. These are high-temperature cooked, colored, and flavored sugar masses that are formed into sweets by stamping or molding. They have a non-crystalline, clear, and glossy appearance. This can be achieved with a low hygroscopic polyol with tight water binding in surrounding fine crystals, which shields the amorphous core from penetrating moisture. While hard boilings can be manufactured with various polyols, including sorbitol, maltitol, and lactitol syrups and mixtures thereof, isomalt has proved to be particularly good for this application. Isomalt hard boilings do not pick up moisture and can be packed for an extended time period without individual protection.

When crystallization is desired, polyols with lower solubility, such as mannitol, isomalt, erythritol, and lactitol, provide varying levels of crystal formation and crystal size, which impart desired ranges of texture from granular to crystalline.

Polyols such as sorbitol, maltitol, isomalt, and lactitol are all used to replace sucrose to manufacture sugar-reduced or sugar-free chocolate. The use of anhydrous crystalline forms of polyols such as isomalt, maltitol, and lactitol are much easier to work with from a process point of view.

Temperature, along with stirring, agitation, and other ingredients present in a solution, also influences the rate of crystallization and the size of crystals formed.

• Viscosity. Viscosity, a measure of the resistance to flow of a liquid when force is applied, varies depending on the type of polyol. Usually, the molecular weight impacts the viscosity. Higher molecular weights create more viscous solutions. For example, polyglycitols contain different amounts of sorbitol, maltitol, and higher hydrogenated saccharides (maltitriitol and others) and can provide a wide range of properties due to the varying average weight of molecular entities present in the polyglycitol formulation. The polyglycitol family can impart a wide range of sweetness, viscosity, and humectancy to foods.

Like sugar, all polyols act as bodying agents and thus eliminate any watery or thin organoleptic sensation and promote mouthfeel. Again, replacing some of the sugar also reduces the calories.

In beverages and liquid products, erythritol can be used to improve the mouthfeel of the finished product.

--- PAGE BREAK ---

• Heat stability. Polyols generally do not lose their sweetness when they are heated and can be applied to hot foods that are heated when processed or cooked. However, unlike sugar, they do not usually give a brown surface to baked foods as they do not undergo the Maillard reaction. The non-browning property is an advantage for products in which a change in color is not desired. Polyols are very heat stable over a wide range of pH (2–10). In baked goods, polyols can prevent product loss due to over-browning or off color. Also, polyols provide advantages in foods and ingredients that require preservation of lighter colors (cookies, marshmallows, custards) during exposure to high temperatures; this is true both when they are used alone and when they are used in combination with sugar.

Heat stability is one of the most important characteristics of polyols in sugar-reduced or sugar-free baked goods. They are able to withstand the processing conditions of pH and temperature without contributing off-flavors such as metallic or bitter notes. Of course, all technical properties play a role in this application; solubility and hygroscopicity, for example, result in slight modifications in formulations and processing.

Isomalt is a useful polyol in cookies because it absorbs a lower amount of water than sugar, leading to crispier products. Maltitol also can replace sugar 1:1 because its physical properties are similar to sugar. Lactitol, which is non-hygroscopic, benefits from the addition of humectants such as sorbitol in soft baked goods.

Maltitol’s heat stability, for example, enables it to be used extensively in chocolate-flavored coatings for frozen novelties (ice cream bars) and confections such as marshmallows and butter creams. The non-hygroscopic properties of maltitol make it very stable, even under conditions of high temperatures and humidity. In chocolate manufacture, maltitol can be used to decrease the amount of fat required to achieve the appropriate texture. Since fat is one of the most expensive ingredients in chocolate manufacturing, the addition of maltitol minimizes the amount of fat required in the chocolate coating and thus reduces cost and produces a superior sugar-free coating that extends shelf life of confections and maintains desirable sensory characteristics.

A unique application is the prevention of off colors that result from caramelization. Caramelization of polyols is retarded and attenuated compared with that of sugars. This property provides a benefit in products that are exposed to heat for long periods of time. For example, sausages/hot dogs found at sport stadiums and local convenience stores can spend extended periods of time on the rotary grill. This can lead to burning or charring of the sausage casing and diminishes the appearance and eye appeal of the product. Since sorbitol does not carmelize, it can be added to the formulation of sausages to preserve the color stability and prevent the formation of surface bacterial growth.

--- PAGE BREAK ---

• Stability in cold and frozen products. Ice formation (i.e., crystallization of water) is a major factor in how well or poorly a food product reacts to cold temperatures. Due to variety of crystallization properties within the polyol family and due to their molecular weight and solubility, they offer a wide range of applications in cold and frozen foods.

In frozen products such as frozen desserts, polyols provide body and texture, and they reduce the freezing point. This effect is inversely related to the molecular weight. Polyols such as maltitol, lactitol, and isomalt have similar molecular weights to sugar and therefore a similar effect on freezing point depression (FPD). Sorbitol and erythritol have even a higher effect on FPD and are therefore added to soften sugar-reduced ice cream and increase the scoopability. Polyglycitols and xylitol are also used in this application.

Cryopreservation of protein molecules is one application for polyols in diluted solutions. This desirable cryoprotective property protects protein fibers from damage (e.g., freezer burn). Thus, polyglycitols can be used as a protectant glaze in seafood and other products to increase the shelf life in frozen storage.

A Sweet Victory

As the demand for lower-calorie and reduced-sugar products grows, polyols can be a useful tool in the product developer’s toolbox. Replacing a portion or all of the sugar in a product with polyols can reduce calories and blood glucose response while maintaining many of the product’s desirable characteristics and functionality. Reformulating products is simplified since polyols provide bulk similar to that of sugar and other carbohydrates. The clean, sweet taste of polyols can satisfy consumers who desire health benefits but do not want to sacrifice taste.

The information in this article is based on chapters in Alternative Sweeteners, 3rd ed., published in 2011 by CRC Press, Boca Raton, Fla. , a book edited by Lyn Nabors.

Lyn Nabors, a Professional Member of IFT, is President Emeritus, Calorie Control Council, 1100 Johnson Ferry Road, Suite 300, Atlanta, GA 30342 ([email protected]).

Theresa Hedrick, a Member of IFT, is Nutrition Communications Specialist, Calorie Control Council

([email protected]).