Shelf Life Enhancement of Milk Products

PROCESSING

International dairy markets can be categorized into two major types: milk products that are distributed predominantly in a cold chain, such as the United States, Canada, and the United Kingdom; and those markets, like Argentina, Brazil, Spain, and France, where milk is distributed predominantly at ambient temperature.

Milk products are generally required by law to be processed by various thermal methods, such as pasteurization, to ensure a product free from pathogens, or by Ultra High Temperature (also called Ultra Heat Treatment) (UHT) or sterilization to ensure commercial sterility. Pasteurized products require chilled distribution, while UHT and sterilized products can be distributed under ambient conditions.

Demands for longer shelf life and wider distribution of chilled milk products have resulted in the concept of extended shelf life or ESL milk. ESL milk has begun to play an important role in the dynamics of dairy markets along with the rapid development of new processing and packaging concepts.

While thermal processes such as pasteurization, UHT, and sterilization have a long history of use and are well defined by regulators, there is no similar definition of ESL milk products, and the methods that can be used in ESL milk processing operations. This article will focus on various treatments for chilled distribution and the way in which new nonthermal UV (ultraviolet) treatment can improve the microbiological quality of both raw and pasteurized milk. (A related article on UV and pulsed light processing techniques appears on page 65.)

Thermal Processing of Milk

Various types of thermal processing are available for treatment of milk products to extend storage life of raw and pasteurized milk.

Pasteurization is defined as a heating process of not less than 63°C for 30 min (batch method) or 72°C for 15 sec (HTST or high temperature short time) in approved equipment. According to the U.S. FDA Pasteurized Milk Ordinance and the International Dairy Federation (IDF), this heat treatment is considered to be adequate exposure for the destruction of Coxiella burnetii and Mycobacterium tuberculosis/M. bovis, the main milk-borne pathogens of concern.

The IDF’s definition of pasteurized milk also includes requirements that the product is cooled and packaged without delay after heat treatment to minimize contamination, and that the product gives a negative phosphatase test result immediately after the heat treatment process. The phosphatase test has been used in quality control and food safety programs as an indicator of the efficiency of the milk pasteurization process.

The shelf life and quality of pasteurized milk can be affected by quality of raw milk, pasteurization conditions, contamination from the food contact surfaces and the environment, and particularly distribution temperature. Bacillus spp. (Bacillus cereus, Bacillus subtilis, Bacillus licheniformis, and Bacillus pumilus) has been shown to be a frequent contaminant of raw and pasteurized milk and dairy products in recent decades.

--- PAGE BREAK ---

The shelf life of pasteurized milk varies greatly in different countries and regions. Pasteurized milk can have a shelf life from only a couple of days in some countries to over 20 days in the U.S. due to a well-established cold chain at 4°C.

Thermisation (also known as thermization) is defined as sub-pasteurization heat treatment applied to raw milk, typically in the range 62–65°C for 10–20 sec that is not intended to destroy any pathogens of concern. Thermisation is applied to raw milk to extend its storage life prior to normal pasteurization by controlling the psychrotrophic bacteria at an early stage. In this case, the milk is cooled to refrigerated storage temperatures immediately following the thermisation treatment, pending pasteurization at a later date (i.e., it is not intended to be a replacement for pasteurization). Thermisation can allow cheese making to proceed with the positive bacteriological effect of pasteurization, but without its disadvantages for cheese ripening and whey protein manufacture. In this case, the milk is not subjected to later pasteurization and would usually be cooled directly to the cheese making temperature only.

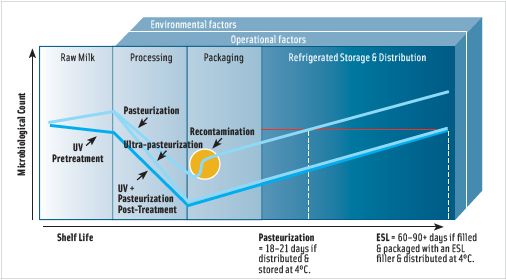

Extended shelf life treatments may be defined based on the particular market need and system capability for various regions around the world. The definition of ESL products can be described as the milk having been treated in a manner to reduce the microbial count beyond normal pasteurization, packaged under extreme hygienic conditions, and which has a defined prolonged shelf life under refrigerated conditions in a specific market.

In the case of European milks, the market expectation for ESL milk would be circa 21 days compared with the standard achievable by pasteurization alone of 12 days at a distribution temperature around 10°C. In the U.S., as a result of the lower distribution temperature of 4°C, a shelf life of 30–60 days or even up to 90 days can be achieved, depending on the nature of the product.

Nonthermal Processing Technologies

With the growing new segments of processing and distribution of milk products in the developed and developing countries, there are opportunities for involving innovative processing technologies such as bactofugation, microfiltration, and UV processing as adjunct treatments before and after pasteurization.

Microfiltration removes bacterial cells and spores from the milk mechanically using membrane technology. The shelf life potential is dependent on membrane type, configuration, and operations. In Argentina, Canada, and the U.K., microfiltration is an ESL processing technology used to achieve longer lasting, premium quality white milk. Shelf life can be expected to be about 21–35 days if filled and packaged on an ESL filler and distributed and stored at 7–10°C.

Bactofugation uses centrifugal force to remove bacteria and spores and is a simple and cost-effective complement to regular pasteurization. Bactofugation is recommended when only a few days extra shelf life is required. The added shelf life potential is 4–5 days at a distribution temperature of 7-10°C and is dependent very much on raw material quality and distribution conditions.

Ultraviolet or UV photosterilization via turbulent UV technology is one of the promising novel nonthermal adjunct processes that could provide milk processors with a safe, energy-efficient, and cost-effective process to gain an added measure of quality and extended shelf life as compared to pasteurization.

--- PAGE BREAK ---

Studies from commercially available turbulent UV photosterilization systems, such as SurePure, have found that UV processing of raw milk can reliably achieve a 3–4 log 10 reduction of initial microbial load measured as standard plate, psychrotrophic, coliform, and thermoduric counts, and extend shelf life up to 14 days.

Additionally, UV treatment has been found effective against pathogenic bacteria commonly found in milk. A reduction in Escherichia coli O157:H7, Listeria monocytogenes, Salmonella senftenberg, Yersinia enterocolitica, and Staphylococcus aureus can be achieved and help to ensure the safety of milk.

Amylase, catalase, lactase, lactoferrin, lipase, phosphatase, protein, and vitamin A that are easily destroyed by heat remain intact after UV processing and maintain the essential healthy properties of natural milk.

Furthermore, the trace amounts of fat-soluble vitamin D found naturally in milk can be enhanced by UV processing. The vitamin D3 levels in whole and skimmed milk that underwent UV treatment was greater than 200 IU/kg compared to standard pasteurized milk, which only contained trace amounts of vitamin D3.

Applications & Benefits of UV Processing

The application of UV technology for pretreatment of raw milk can control microorganisms and allow the storage of milk for prolonged periods, and due to its “cold” nature, can improve milk quality and reduce losses in the parts of the world where lack of a reliable energy supply and high cost make on-farm refrigeration prohibitive.

In developing countries with warm climates (e.g., India, Brazil, African countries), milk processing is often more problematic than in temperate climates with a well-developed cold chain infrastructure, owing to higher temperatures and humidity. Consequently, milk spoils at a faster rate, cheese ripens too quickly, and it is often difficult to ensure adequate cooling conditions. UV treatment can be successfully employed as an alternative thermisation method and can be related to raw milk processing as shown in Figure 1 for pretreatment of raw milk on the farms and collection centers for microbial control and extend shelf life during transportation to milk processing centers.

UV processing of raw milk can lower the risk of consumption of non-pasteurized cheeses in North American dairy markets. According to a joint risk assessment drafted by the U.S. Food and Drug Administration and Health Canada, consumers are up to 160 times more likely to contract a Listeria infection from soft-ripened cheese made from raw milk compared to the same cheese made with pasteurized milk.

When UV processing is used in conjunction with pasteurization as a post-treatment method, the shelf life of milk can be increased by at least 30%. UV technology has been used for production of ESL product in the U.K. to reduce any post-pasteurization contamination and residual bacteria surviving pasteurization, thereby extending shelf life from the current 12 days to 21 days as shown in Figure 1. The milk products intended to be processed utilizing UV processing include pasteurized skimmed, semi-skimmed, and whole milk variants. As part of the action of the UV light, vitamin D3 levels in milks containing fat are elevated. This rise in vitamin D3 is both beneficial and is not at a level that constitutes a risk to human health.

UV processing can offer advantages in both developing and established dairy markets through extending milk shelf life in the supply chain without destroying essential nutrients and while enhancing functional properties. Any consumer wastage due to the limited shelf life of milk can be considered a waste of the embedded resources (i.e., the materials and energy used to produce the milk). Additional benefits of the application of UV processing on dairy products may include energy savings due to the nonthermal nature of the technology. Sustainability and the environmental considerations become increasingly important to consumers who expect the products they buy to be produced in an environmentally responsible way.

Tatiana Koutchma, Ph.D., is a Research Scientist at Agriculture and Agri-Food Canada, Guelph, Ontario, Canada ([email protected]).

Gail Barnes, Ph.D., a member of IFT, is a Partner at Personify LLC, Hoffman Estates, IL ([email protected]; @DrGailB).