All Sorts of Options for Food Product Sorting

PROCESSING

Most food products undergo significant processing before arrival at the grocery store or local market. A major component of this processing includes sorting the product according to quality attributes such as size, color, sweetness, and ripeness. In addition, removal of defects or contaminants is a major factor in protecting the quality of agricultural products. Thus, sorting of agricultural commodities maximizes quality for the consumer as well as return on investment for producers and processors. It is therefore not surprising that many types of sorting devices are commercially available and routinely used in processing plants.

In order to be practical, a sorting instrument must satisfy a number of conditions. It must be economical in the sense that it does not significantly increase the price of the product. It must operate at commercial processing line speeds, which generally requires sorting dozens of samples per second. It must be nondestructive to the product, meaning that it must not affect the quality in any way. Finally, it must be highly accurate so as to maintain the quality of the overall product stream while not unnecessarily rejecting good product. In other words, it must be highly accurate in avoiding both false negative results (bad product that is allowed to pass) as well as false positive results (good product rejected as bad).

Unfortunately, given the high level of difficulty in simultaneously satisfying all of the preceding requirements, many conditions in the food supply remain undetectable in real time and cannot be sorted out. Fortunately, however, the sophistication of available technologies for addressing such sorting issues continues to increase at a rapid pace. The result is a constantly replenished field of research dedicated to applying cutting-edge technologies to improve the quality and safety of the nation’s food supply. This field is, and has been, a high priority for the Agricultural Research Service (ARS), the official research agency for the U.S. Dept. of Agriculture (USDA).

It is my privilege to co-author this month’s column with Ron Haff, a pioneer in the development and application of economical, nondestructive, high-speed sorting devices for agricultural products. He is a research agricultural engineer at the ARS Western Regional Research Center, Healthy Processed Foods Research Unit in Albany, Calif. His research demonstrates the critical role government research can play in providing innovative solutions to problems and concerns that affect consumers and the food industry.

Principles of Food Sorting

Commercial food sorting devices employ a multitude of technologies to address the wide variety of sorting requirements that arise in processing the nation’s food supply. While to even briefly describe them all would require vast amounts of time and space, the general principles of most approaches can be understood in the context of sensor technology. Ever more sophisticated physical sensors allow qualitative analysis based on high-quality digital images and/or analysis of light absorption characteristics of materials across most electromagnetic wavelengths, response to mechanical stress, acoustics, and scattering of light, to name just a few. Recent advances in biological sensors hold promise for real-time detection of toxins and bacterial contaminants.

In Haff’s research, the basis for detection and sorting can be any of a number of physical or chemical techniques, including x-ray imaging, color imaging, acoustics, visible light transmission or reflection, near infrared (NIR) spectroscopy, and laser light transmission. Image and/or signal analysis and processing, classification algorithm programming, and material handling are key elements in the development of these sorting devices. Some of the technologies that are key to the sorting devices and their applications are highlighted in this month’s column.

In Haff’s research, the basis for detection and sorting can be any of a number of physical or chemical techniques, including x-ray imaging, color imaging, acoustics, visible light transmission or reflection, near infrared (NIR) spectroscopy, and laser light transmission. Image and/or signal analysis and processing, classification algorithm programming, and material handling are key elements in the development of these sorting devices. Some of the technologies that are key to the sorting devices and their applications are highlighted in this month’s column.

X-Ray Imaging

X-ray inspection has a distinct advantage over most other detection technologies because it allows nondestructive imaging of interior features of a sample to detect hidden defects or contaminants. However, it also has a number of disadvantages, including a relatively high cost, the need for radiation shielding and the dangers inherent in using radiation, and the need for high-voltage power supplies to generate the x-rays. For these reasons, x-ray inspection is generally considered the option of last resort. In spite of this, its use continues to expand in the food industry because it is often the only viable option.

In recent years, x-ray inspection has become increasingly common in certain segments of the food industry. This is particularly true for processed foods, including product that is packaged in cans, bottles, or jars, due to the ever-increasing emphasis on food safety. It is now an accepted fact that x-ray inspection is superior to traditional metal detection technology for the detection of metallic contaminants and adds the potential to eliminate other foreign nonmetallic material such as bone, glass, wood, plastic, and rocks. Technological advances in the areas of high-voltage power supplies, solid-state detectors, and computation power and speed have made x-ray systems more affordable, reliable, and easier to use while improving image quality and detection capabilities. A variety of improvements in sensor technology, including cesium iodide crystals and improved charged-couple device arrays, have improved resolution.

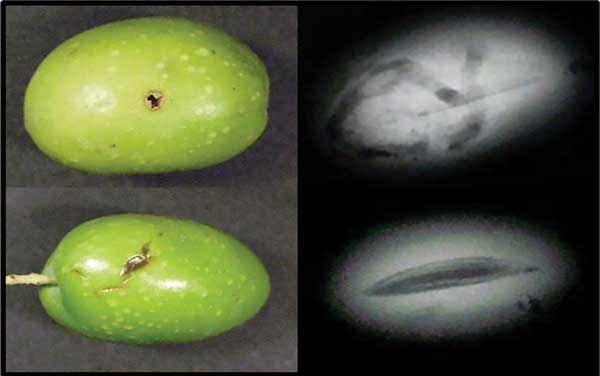

Haff has been involved in the application and adaptation of x-ray imaging technology for the detection of defects and contaminants in foods for more than 20 years. During that time, he has developed the means to detect and sort for a number of food quality issues, including particulates in processed meat products; defects in apples; insects in wheat, fruit, olives, and sunflower seeds; translucency in pineapple; and pits in fresh cherries.

--- PAGE BREAK ---

Spectroscopy

Spectroscopy is a tool for the study of how light, which includes all wavelengths of the electromagnetic spectrum, interacts with matter. In the context of food inspection, spectroscopic data is generally represented by absorption spectra, which are plots of the amount of light absorbed by the sample as a function of wavelength or frequency. NIR spectroscopy, covering the wavelengths from 700 nm to 2,500 nm, is ideally suited for food analysis because those wavelengths are on the same order as the size of molecules found in food. Haff has collaborated with experts around the world to develop applications for sorting food products that are based on NIR and visible light spectroscopy. These efforts have led to the development of sorting technology for a variety of food quality issues, including pistachio nut defects and shell pieces, fruit fly larvae in fruit, defective hazelnut kernels, minced meat adulteration, mold-damaged chestnuts, as well as insect infestation in mangoes, chestnuts, and olives.

Impact Acoustics

Impact Acoustics

Consumers of pistachio nuts understand the frustration caused by those few nuts in each batch that have no split in the shell. Processors are highly motivated to sort out these closed-shell nuts. It turns out that when a closed-shell nut strikes a hard surface, it makes a different sound than nuts that have a split shell. By recording these sounds with a microphone, it is possible to separate these two classes of nuts at high speed. This type of sorting, known as impact acoustics, was originally developed in Haff’s laboratory and is now a basis for sorting a variety of products, including pistachios, pinto beans, red beans, and wheat kernels. While impact acoustics is not appropriate for most food products, which are highly sensitive to impacts and bruise easily, for those products that don’t mind being banged up a bit, it can be highly efficient.

Mechanical Sensing

For some food quality or safety issues, mechanical sensors that mimic human fingers are just the right tool for the job. This is exemplified by technology developed in Haff’s laboratory designed to detect pits or pit fragments in prunes or other dried fruit. Human inspectors detect these pits by squeezing the fruit between their fingers, the old-fashioned way. This action is replicated by squeezing the fruit between a roller and a force transducer mounted under a conveyor belt, which produces an electrical signal when the roller pushes down on a hard pit. Again, this technology only works for specific problems in specific agricultural products.

Other Technologies

Other technologies routinely employed for food sorting include transmission of laser light, high-speed color imaging, machine vision, hyperspectral imaging, Raman scattering, and the list goes on. Developing a sorting device for a particular situation requires determining which of these many technologies is most appropriate for the task at hand. As more and more new technologies become available and as existing technologies are improved, researchers like Haff are standing by to put these new capabilities to work to improve the quality and safety of the food we eat.

Tara McHugh, PhD, Contributing Editor

Tara McHugh, PhD, Contributing Editor

Research Leader, USDA

Agricultural Research Service,

Albany, Calif.

[email protected]

Ron Haff, PhD, is a research agricultural engineer,

Agricultural Research Service,

Healthy Processed Foods Research Unit,

Albany, Calif. ([email protected])