Increasing Agility in the Packaging Value Chain

PACKAGING

Consumer interest in sustainability has fueled value chain initiatives. And the packaging value chain has matured with increased agility to implement sustainability initiatives. The use of value chain elements such as managing knowledge and shared value allows for innovative sustainability solutions by expanding beyond common materials and partners. This approach provides a fresh perspective on meeting consumer needs. As packaging suppliers expand global operations, partners are integral to translate the knowledge needed to ensure business success. Connections that have value vary from consumer to consumer. Packaging companies and food manufacturers need agility to enable product connections with fickle consumers. Agility in packing operations requires shorter time to market for sustainable products that meet consumers’ perception of sustainability. Expansion of the value chain to include new material partners ushers in new approaches to achieving shelf life. Increased levels of reducing, reusing, and recycling have been possible with a shared value approach to package sustainability by industry.

Connecting to Consumers

For many packaging companies and food manufacturers, connecting to shifting consumer needs is not viable if a high degree of agility is not inherent in food and package processes. Large high-speed manufacturing environments deliver cost-competitive products to consumers, often at the expense of allowing inherent agility to shift with consumer preferences. Co-packing has been historically used to allow agility, and its use is increasing. When co-packing is coupled with stock packaging, agility, tactics, and knowledge are gained. For example, co-packer expertise in processing technologies such as high-pressure processing, micro-wave-assisted thermal sterilization, and other common technologies can be employed to deliver a host of new products to consumers. The time to market can be reduced drastically with co-packing and the use of stock packaging by major food manufacturers.

From a value-chain perspective, co-packing enables meaningful value because products can be in consumers’ hands rapidly. Moreover, because 20%–50% of new food products fail within one year, co-packing provides a less risky market launch alternative. When co-packers are used to assess the market, less capital is required. The focus on meaningful value has led to new products that resonate on the trend toward sustainability. For example, Hampton Creek’s agile approach allows for approximately 50 sustainably focused new products in development. This requires flexibility in ingredient choice as well as the ability to act rapidly with proven packaging solutions from co-packers and with stock packaging.

From a value-chain perspective, co-packing enables meaningful value because products can be in consumers’ hands rapidly. Moreover, because 20%–50% of new food products fail within one year, co-packing provides a less risky market launch alternative. When co-packers are used to assess the market, less capital is required. The focus on meaningful value has led to new products that resonate on the trend toward sustainability. For example, Hampton Creek’s agile approach allows for approximately 50 sustainably focused new products in development. This requires flexibility in ingredient choice as well as the ability to act rapidly with proven packaging solutions from co-packers and with stock packaging.

Hampton Creek has also focused on expanding the value chain to drive sustainability in the food industry. This global outlook is based on the need to source sustainably and efficiently to feed the world. As a result, alternatives to animal-based food ingredients is the company’s focus. For sourcing, Hampton Creek relies on big data. An example of this is using big data to assess protein sources by pruning potential ingredients and determining where further exploration and refinements are needed. This approach allows for the efficient exploration of unique non-monoculture ingredients that drive a more diverse approach to meeting global food supply needs. To achieve this, agility in packaging is needed.

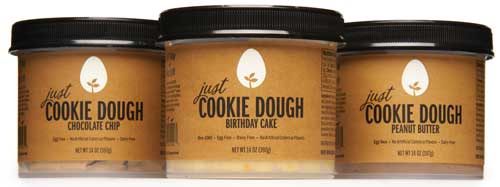

“In the packaging value chain we have considerable agility. We leverage contract manufacturing relationships and use stock containers so package design complies with contract packer machinery, easing production changes,” reveals Jamie Valenti-Jordan, a senior food process engineer at Hampton Creek. This agility allows for “a new product to be in national distribution six months after it was just a twinkle in a developer’s eye,” Valenti-Jordan says. “From an expanded value chain perspective, this leveraging of existing packaging relationships reduces the time, energy, [and] money required to get product out the door because a basic understanding of shelf-life requirements and solutions are already defined. This also allows us to focus our energy on making consistent, high-quality product because our partners already have an understanding of what is required in complex grocery distribution systems.” Since its debut in 2013, Hampton Creek has made waves with its popular Just Mayo product, packaged in a stock polyethylene terephthalate jar with a polypropylene lid. The use of an established value chain of co-packers allows the business to focus on increasing brand value, based on culinary attributes and ingredients.

“In the packaging value chain we have considerable agility. We leverage contract manufacturing relationships and use stock containers so package design complies with contract packer machinery, easing production changes,” reveals Jamie Valenti-Jordan, a senior food process engineer at Hampton Creek. This agility allows for “a new product to be in national distribution six months after it was just a twinkle in a developer’s eye,” Valenti-Jordan says. “From an expanded value chain perspective, this leveraging of existing packaging relationships reduces the time, energy, [and] money required to get product out the door because a basic understanding of shelf-life requirements and solutions are already defined. This also allows us to focus our energy on making consistent, high-quality product because our partners already have an understanding of what is required in complex grocery distribution systems.” Since its debut in 2013, Hampton Creek has made waves with its popular Just Mayo product, packaged in a stock polyethylene terephthalate jar with a polypropylene lid. The use of an established value chain of co-packers allows the business to focus on increasing brand value, based on culinary attributes and ingredients.

Engaging New Partners to Meet Needs

This same type of agility is driving material science innovations in fiber-based packaging for the food industry. Paper-making processes have improved efficiencies by extracting more value from raw materials with new technologies. To grasp opportunities associated with raw materials, energy prices, policies, and other uncertainties, expanding the paper value chain to form new partnerships is needed. A recent study identified molded-fiber packaging as a means of aligning with consumer needs. Limiting factors such as the expense of molds to form containers and the use of available material drove the molded-pulp industry to expand its value chain partnerships. New partners continue to breathe fresh air into an old technology.

This expansion has led to advances in the design of molded-pulp packaging and material use. Advances and agility in producing molds using polycarbonate and acrylonitrile butadiene styrene in fused deposition modeling has reduced mold cost from $30,000 to $500 and lead time from two weeks to two days. This agility has renewed interest in a molded-pulp packaging. Since consumers are requesting and European Standard regulations increasingly request biodegradable, compostable, and recycled content, ensuring a sustainable raw material source is paramount. Material innovation through an exploration of abundant available fibers has resulted in the GreeNest container by Huhtamaki, Espoo, Finland (huhtamaki.com), made with 50% grass fibers and the use of straw, bagasse, wheat stalk, reed, and bamboo by companies such as Roots Biopack, Hong Kong (rootsbiopack.com). These fibers are often the result of local food production waste such as bagasse fibers from sugar cane.

This expansion has led to advances in the design of molded-pulp packaging and material use. Advances and agility in producing molds using polycarbonate and acrylonitrile butadiene styrene in fused deposition modeling has reduced mold cost from $30,000 to $500 and lead time from two weeks to two days. This agility has renewed interest in a molded-pulp packaging. Since consumers are requesting and European Standard regulations increasingly request biodegradable, compostable, and recycled content, ensuring a sustainable raw material source is paramount. Material innovation through an exploration of abundant available fibers has resulted in the GreeNest container by Huhtamaki, Espoo, Finland (huhtamaki.com), made with 50% grass fibers and the use of straw, bagasse, wheat stalk, reed, and bamboo by companies such as Roots Biopack, Hong Kong (rootsbiopack.com). These fibers are often the result of local food production waste such as bagasse fibers from sugar cane.

Barrier technologies often alter the biodegradability of molded pulp. Polyethylene terephthalate and polyethylene barriers have traditionally been laminated onto preformed molded-pulp containers, making them neither degradable nor compostable. But the need for oxygen and water vapor barriers that are degradable or compostable when applied to molded pulp has led to considerable research and innovation in food packaging. More optimal technologies with nanobarriers and nanoporous networks that provide a barrier and reduce the need for a barrier through controlled release of active compounds such as antioxidants and antimicrobials are being tested. Cellulose fibers (also called crystallites, nanocrystals, whiskers, and nanofibrils) of nanometer size are a major area of research. Nanocrystal line celluloses are rod-like cellulose crystals that hold particular promise due to their inherent birefringence and mechanical strength. The connection between the molded-pulp industry and their partners within the nanotech world has created a strong bond between the packaging supplier, manufacturer, and researchers. This has reinvigorated a stagnant industry. Interestingly, this renewed interest in cellulose is juxtaposed to celluloid (developed in 1870) and was the first thermoplastic polymer. By expanding from traditional partners and focusing on value, the molded-pulp industry is able to meet the new needs of consumers.

Increasing the Use of Recycled Material

This year marks the 25th anniversary of green dot, the first comprehensive law requiring producer responsibility for packaging disposal costs. The law created a process in which manufacturers contribute to the cost of collection, sorting, and recycling methods for disposal of packaging materials. This value chain extension from post-consumer disposal needs to package selection determined new value chain partners in 1991 and continues to expand. For example, advances such as near-infrared separators, eddy flow separators, and metal separators have reduced the cost of recovering plastics by 95%.

Jochen Hertlein, manager of corporate packaging at Nestlé Germany, reflects on the need for further design for recycling and the commitment to the partnerships: “The industry connection to end-of-use [packaging] remains strong.” The industry connection has led to high recycling rates. Since 1991, glass weight has decreased 24%, and glass recycling rate has increased to 84%. In addition, plastic container weights have reduced 35% while plastic recycling increased to 54%. Beyond light-weighting containers, further innovations in materials, exploration into how packaging can enable higher recycling rates, and other means of disrupting the current rate of package disposal are needed.

Nestlé continues to reduce energy use through packaging supplier relationships, which prompted the producer of its water bottles, Sidel, Hünenberg, Switzerland (sidel.com), to reduce its energy use. Sidel modified the preform heating stage of its blow-molding operation. In this spirit of extending partnerships, Sidel shared the energy-saving process with competitors that also supply Nestlé. Together, the two companies have gained knowledge in the process. Responding to consumer interest in the complexities of sustainability requires agility in the packaging value chain approach.

Claire Koelsch Sand, PhD, Contributing Editor

Claire Koelsch Sand, PhD, Contributing Editor

President, Packaging Technology & Research

Adjunct Professor, Michigan State Univ.

[email protected]