Restructured sugar cuts usage in candy; Cold plasma hydrogenates soybean oil

CUTTING EDGE TECHNOLOGY

Restructured sugar enables 40% less usage in candy

Restructured sugar enables 40% less usage in candy

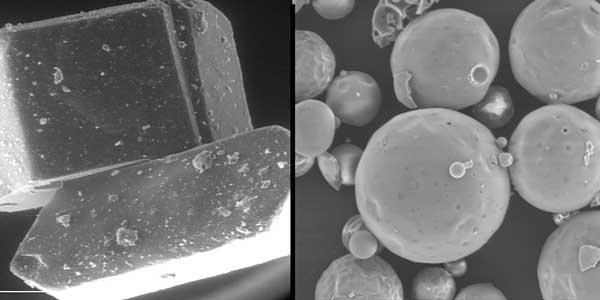

Nestlé scientists have discovered a method to restructure sugar, changing its shape from rectangular to hollow spheres. These spheres deliver sweetness on the tongue by maximizing their surface area relative to volume, which allows product formulators to use less sugar in candy products. “This truly groundbreaking research is inspired by nature and has the potential to reduce total sugar by up to 40% in our confectionery,” noted Stefan Catsicas, Nestlé chief technology officer. “Our scientists have discovered a completely new way to use a traditional, natural ingredient.”

Nestlé is patenting its findings and will begin to use the faster-dissolving sugar across a range of its confectionery products beginning in 2018. While the technology does present a breakthrough in confectionery products, it cannot be used in all food matrices. For example, the restructured sugar dissolves too quickly in liquids such as soft drinks.

The novel sugar is part of the company’s commitment to reducing sugar in its products. In 2016, Cereal Partners Worldwide (Nestlé’s joint venture with General Mills) reformulated its breakfast cereals to contain 9 g or less of sugar per serving. In 2015, Nestlé reduced its added-sugar content by 18,000 tons, which represents 4.1% towards its goal of a 10% reduction.

Cold plasma may yield trans fat-free soybean oil

Purdue Univ. researchers have developed a hydrogenation process utilizing cold plasma that could solidify soybean oil for food processing applications without creating trans fats, which have been linked to heart disease and stroke.

Former Purdue professor Kevin Keener, now at Iowa State Univ., and doctoral student Ximena Yépez developed a process known as high-voltage atmospheric cold plasma (HVACP) hydrogenation. The process occurs at room temperature, which avoids the high temperatures that cause trans fats to form.

Traditional hydrogenation processes use a catalyst, high pressure, and high temperatures to separate molecular hydrogen into atoms, Yépez said, but the HVACP process uses high-voltage electrical discharges to separate the molecules. Once the hydrogen molecule is split, each atom attaches to the double bonds between the molecules in the oil, giving them more structure. More structured molecules cause the oil to become more solid, or “saturated.”

Traditional hydrogenation processes use a catalyst, high pressure, and high temperatures to separate molecular hydrogen into atoms, Yépez said, but the HVACP process uses high-voltage electrical discharges to separate the molecules. Once the hydrogen molecule is split, each atom attaches to the double bonds between the molecules in the oil, giving them more structure. More structured molecules cause the oil to become more solid, or “saturated.”

“Cold plasma processes are being researched in many different fields,” Yépez said. “Dr. Keener developed this method in food science to eliminate pathogens. But as far as we know, no one has ever used this technology to hydrogenate oil before.”

The HVACP experimental design consists of a small amount of oil placed inside a plasma-filled container, which is then put inside a bag filled with a hydrogen-blend gas. As the gas fills the bag, two electrodes discharge up to 90 kW of electricity through the chamber, splitting the hydrogen molecules in the gas into ions. These ions bond with the double bonds in the fatty acid molecules on the surface of the oil.

Currently, a typical hydrogenation reaction might produce only a 3% increase in saturated fatty acids while increasing the formation of trans fats by up to 40%. But after a 12-hr HVACP treatment, the oil showed a 32.3% increase in saturated fatty acids and no trans fats. This ratio not only means that the finished product is safer for human consumption, Keener said, but also that the HVACP process is more efficient than traditional processes.

Two main obstacles still exist in adapting the process for commercial use. The first is that the HVACP procedure yields a small amount of byproduct that the researchers have not yet identified. This could be an alternate form of trans fat or a similar substance, said Yépez. The team will manipulate the parameters of the experiment to better understand where the substance comes from and its composition.

The second obstacle the researchers face is speed. While the process creates more product than heat-based hydrogenation, it is much slower. Yépez and Keener are trying several approaches to make the process faster, including increasing the amount of electricity discharged through the chamber and spraying the oil into the chamber as droplets.

Further details on this research, which was published in Innovative Food Science & Emerging Technologies, can be found here.

If you are working on or know of some cutting edge technology that you would like to be featured in this column, please send an email to [email protected].