Orchestrating More Sustainable Reusable Food Packaging

PACKAGING

All packaging has an environmental impact, and so does reusable packaging, which has been in use and reuse for many years. Reusable packaging represents a decoupling of the single-use packaging economy of “produce–use–dispose” and can reduce—but does not eliminate—the need for new packaging materials.

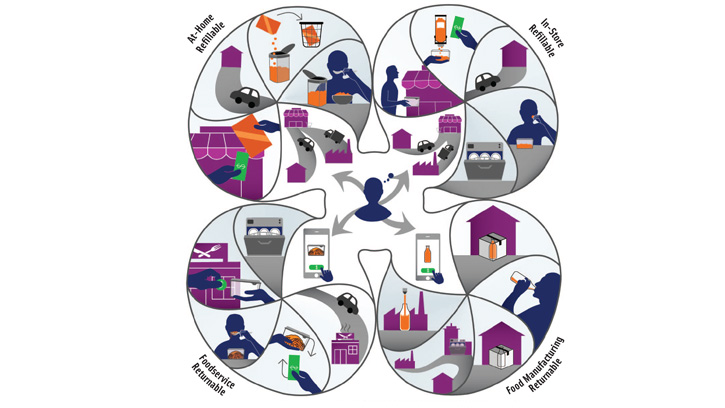

The environmental impact of reusable packaging is multifaceted, and the reuse of packaging fits into the middle range in terms of its ability to reduce the environmental impact of packaging. While reuse is important, package design and minimization have a much higher environmental impact (Potting et al. 2017). The environmental impact of reusable packaging is nuanced because it depends so much on the type of reusable packaging: food manufacturer reusable packaging, foodservice reusable packaging, at-home refillable packaging, or in-store refillable packaging (Coelho et al. 2020).

Food Manufacturer Reusable Packaging

The environmental impact of reusable packaging can be minimized to create a more sustainable alternative to single-use packaging. The hub Towards a Circular Economy and Society at Utrecht University in The Netherlands is a value chain–inclusive platform for scientists and stakeholders to jointly contribute to the transition to a more sustainable circular economy.

“There are four key factors to employ to make reusable packaging more sustainable,” says Patricia Coelho, a researcher on packaging reuse and circular economy and co-coordinator of the hub. She breaks them out in this way:

• decrease transport distances between steps in the supply chain, such as package supplier, food manufacturer, retailer and washing facility, and refilling site;

• ensure an increased number of reuse cycles, so the packaging is reused as many times as possible;

• reduce packaging production impacts by choosing a material with lower production emission and/or increasing the percentage of recycled content; and

• ensure that the packaging is recyclable and that it is recycled at the end of life instead of being incinerated or landfilled.

“Beer bottles are a great example of successful reuse,” says Coelho, explaining that in the Netherlands, beer bottles are produced with recycled glass and more than 90% of them are reused. “Deposit return schemes are a decisive ally, ensuring that the packaging is returned to the producer, reducing littering and increasing reuse and recycling rates,” she says. “The environmental impact of deposit return schemes can be lowered with package standardization, pooling in decentralized supply chains, and decreasing overall transport distances. This leads to a lower environmental impact of returnable packaging.” In the United States, the use of deposit schemes in 20% of states triples plastic bottle collection rates.

While returnable pallet and crate systems have been in place for many years for business-to-business transactions, their use has increased in the food industry. For example, to limit handling, strawberries are often packed in consumer-ready containers and placed within returnable plastic crates while in the field. The plastic resists deterioration associated with corrugated cases in wet environments. And repacking for retail-ready displays is not needed. Crates are well ventilated to facilitate rapid cooling and provide a high degree of protection during distribution. Notably, crates are returned in the same trucks that pick up new product and are washed prior to reuse. The Reusable Packaging Association guides the reusable transport packaging industry.

On the other hand, for some returnable food packaging, the environmental impact can be high due to a long distance between manufacturer and consumer if the three factors mentioned earlier are not addressed. For example, in Loop’s reusable packaging subscription system, trials show a higher environmental impact than single-use food packaging. This environmental impact is high because the four factors are not well addressed in the process, in which: 1) trucks deliver the product with additional packaging to withstand distribution directly to consumers, 2) the empty containers are picked up at the consumer’s home and sent to a centralized site at which they are washed and sorted, and 3) the containers are then are sent back to manufacturers for refilling. However, when guided by the four factors and optimization models, returnable packaging systems can be designed to reduce the environmental impact and be convenient for consumers.

Foodservice Reusable Packaging

For standardized reusable foodservice containers that are returned by consumers for on-site foodservice washing and reuse, the environmental impact can be low. Foodservice containers in closed-loop systems are increasingly returnable. In these systems, dispensing, collection, and on-site cleaning are eased through simplification of required package configurations. In response to increased ordering of meals-to-go rather than eating in restaurants during the COVID-19 pandemic, the increase in use along with the cost of single-use packaging has renewed interest in returnable foodservice packaging.

For example, the OZZI system features reusable polypropylene containers that can be washed up to 1,000 times, and offers collection, cleaning, and storage fixtures to facilitate reuse. Specifically, the patented OZZI system encompasses the use and subsequent collection of digitally marked containers in internet-aligned machines that provide tokens for consumers when containers are returned and alerts when near capacity along with washing, drying, and storage racks. Using this system, OZZI estimates it has averted the use of five million single-use containers since its inception in 2013 and incorporated 30% of recycled polypropylene from the OZZI containers into new containers. OZZI containers are washed on-site and are designed for optimal washer space. This eliminates the environmental impact of transporting returnable packaging as well as minimizes water use and drying time.

OZZI Chief Executive Officer Tom Wright expands: “We provide a more sustainable system to single-use packaging, and although the OZZI system provides more sustainable packaging, our Savings Calculator provides an initial assessment so organizations can assess if the system is financially prudent.”

Wright says universities such as the University of California, San Diego, where users receive deposits onto their campus ID card, municipalities such as Los Angeles and Ashton, Ore.; U.S. military bases in Belgium, Hawaii, and Alaska; the corporate headquarters of Exxon Mobile, Merck, BP Texas, and Freddie Mac, as well as a number of food retailers, foodservice providers, and hospitals, are employing OZZI reusable container systems to cut costs and lower the environmental impact of foodservice packaging.

Importantly, OZZI is certified by the National Safety Foundation International, matching single-use food packaging in food safety. These food safety codes require washing and sanitizing at high heat to meet the hygiene and disinfection level required by the Food and Drug Administration and Centers for Disease Control and Prevention. Notably, dishwashing of reusable foodservice packaging inhibits viral transfer; thus single-use foodservice packaging and reusable packaging do not differ in terms of viral transfer from consumer to consumer (Coelho et al. 2020).

Other successes are seen in foodservice salads, with Just Salad reusing polypropylene packaging at 40 locations and Fresh Bowl reusing glass salad bowls available from vending machines with a high degree of efficiency and positive environmental impact. Using a similar concept, Burger King is assessing reusable foodservice packaging in three locations.

At-Home Refillable Packaging

Consumers can purchase flour, sugar, and cereals in bags and pour them into rigid packaging for ease of storage, dispensing, and increased shelf life. This refillable package is rigid to withstand multiple uses and can be supplied by the food manufacturer. Although the bag is discarded as single-use packaging when food is poured into a rigid package, the overall package material use is less when rigid packaging is refilled with product from minimalist packaging. Concentrates, such as powdered drinks, capsules, and infusions sold in small packages without water, are diluted when being transferred to a refillable package. This requires less overall packaging and reduces the environmental cost of transporting high-water-based foods.

In-Store Refillable Packaging

Refilling packaging in stores allows consumers to select the exact quantity of food needed, thus reducing food waste and making product selections more affordable. Refillable packaging can be provided by stores or by consumers. The potential for cross-contamination is an issue, however, which requires careful monitoring of bulk containers and innovative bulk-container design. Many bulk dispensing systems and foodservice refillable offerings have been halted to limit virus transmission via handling of dispensers and containers. For example, Starbucks incentivized consumers to bring their mugs for filling by store personnel, but the company has moved away from this offering.

To ensure that we move toward more sustainable packaging, reusable packaging must be orchestrated to lower the environmental impact of the complete value chain.

REFERENCES

Coelho, P. M., B. Corona, and R. ten Klooster, et al. 2020. Sustainability of Reusable Packaging–Current Situation and Trends. Resour., Conserv. Recycl. 6: 100037.

Potting, J., M. Hekkert, and E. Worrell, et al. 2017. Circular Economy: Measuring Innovation in the Product Chain. Policy Report. PBL Netherlands Environmental Assessment Agency, The Hague.