Life Cycle Assessments Guide Sustainability

PACKAGING

Life cycle assessments (LCAs) quantify environmental impact. For the food industry, packaging LCAs are commonly combined with food LCAs to provide a more complete picture of the impact that packaged food has on the environment. Packaging LCA determination methods differ and include forensic, comprehensive, and streamlined versions that can be combined with food LCAs and other data into system LCAs.

In the early 1970s, Harry Teasley at the Coca-Cola Company pioneered assessing various beverage containers to determine their impact on the environment. The assessments indicated that plastics and nonreturnable packaging had less impact on the environment than glass, steel, and aluminum packaging. Other pioneers, including Ian Boustead from the Open University in England, refined environmental assessments. Eventually, ISO standards were developed to enable more robust and commonly accepted assessment and to eliminate misuse and greenwashing. Now, LCAs demonstrate the comparative environmental impact of packaging alternatives, including reduced packaging, sustainable sourcing using bioderived and post-consumer recycled content material, and packaging disposal options such as recycling, composting, waste-to-energy incineration, landfills, and reuse. System LCAs assess the environmental impact of different packaging solutions to decrease product deterioration from oxidation, microbial growth, moisture loss and gain, and browning. These system LCAs compare nutrient and food waste, distribution damage, and shelf life and align with the United Nations Sustainable Development Goal 12, which focuses on the environmental impact of food and packaging waste. This facilitates decision-making that is essential to reducing the environmental impact of packaged food (Poore and Nemecek 2018). However, consumer and market research are needed to assess factors such as consumers’ opinions on foods with shorter shelf lives, anti-plastic measures, and convenience features (Robertson 2009).

LCA Determinations

Although LCA determinations vary, their framework is defined in two standards: ISO 14040 and ISO 14044. Within this framework, phases of an LCA are identifying a goal and scope, assessing inventory and impact, and interpreting results. The first step of an LCA defines the scope or the range that an LCA will cover. The LCA might not determine the full environmental impact if its scope is too narrow. This is especially relevant when comparing bioderived materials to fossil-derived materials. For example, if the scope of an LCA for bioderived polyethylene is set to assess only polymerization to recycling, then the environmental impact of bioderived versus fossil-derived polyethylene is not determined. Similarly, if a narrow scope does not include recycling, then the scope provides only an isolated view of the environmental impact of recyclable versus nonrecyclable packaging. A wide scope (i.e., from extraction of raw materials to disposal, such as recycling, composting, landfills, and waste-to-energy incineration) captures more of the total environmental impact while narrowly defined LCAs are inherently biased. LCAs with scopes that include processing can also capture more aspects of the food system. For example, DIL German Institute for Food Technology e.V. uses LCAs to choose environmentally conscious food ingredients, processing methods, and packaging materials and to assess the impact that switching these factors would have on the total food production chain. “We believe that processing defines the food ingredients, packaging, distribution, and food waste, so DIL harnesses its expertise in emerging and existing food processing to link packaging and processing LCAs,” explains Sergiy Smetana of DIL’s food data group.

Inventory assessment and environmental indicators quantify the environmental impact of food packaging within a defined scope. The impact can be measured in terms of fossil fuels and water, greenhouse gas emissions, ozone depletion, and other indicators. Consumers’ views of sustainable packaging differ from those of packaging LCAs (Boz et al. 2020). Large databases such as Ecoinvent are augmented with more specific databases. For example, a unique packaging material such as Genera Energy’s switchgrass-based molded pulp requires data specific to the environmental impact of growing switchgrass in Tennessee.

The final stage of an LCA is interpretation to identify significant issues, address data sensitivity and consistency, make recommendations, and conduct a critical review to assess the process and inherent bias. The specificity of the scope, reported data, and region of LCAs suggests that LCAs cannot be compared with each other and that results are not definitive. Careful review of the process, scope, and data is required to define comparative constraints in this review process. Due to comparison challenges for LCA studies conducted with different scopes, accuracy can vary by as much as 10%.

Types of LCAs

A forensic approach to LCAs determines the environmental impact of packaging that is not already documented or assessed, is a result of multiple converters, or is produced using a less common process or a unique additive. This is especially relevant when comparing material produced from different suppliers and processes or novel packaging materials. The LCA Centre in the Netherlands is forensic-focused and uses laboratory assessment, extensive spectra libraries, packaging technologists, and a vast library of inventory datasets to provide robust peer-reviewed LCAs on packaging structures and systems. The LCA Centre offers a wealth of knowledge that enables proactive action. “Our forensic LCA process identifies packaging materials composition for items in comparative product LCA studies for which there is no stakeholder information,” says Agnieszka van Batavia, packaging sustainability and regulatory advisor at the LCA Centre. “Information derived from this reverse engineering approach leads to a far more robust comparative LCA study, allowing us to enter the correct materials, associated processes, and country of origin to our study. Expanding on this information, we can pinpoint components that may pose pending regulatory compliance and toxicity issues and components that can be removed to reduce costs and suggest viable alternative components. We can confirm packaging specifications for clients who feel they are not getting the whole story from their packaging suppliers.” The results of a forensic LCA can differ by as much as 50% from other LCAs because forensic LCAs are far more robust.

Comprehensive LCA determinations include those that can be generated from SimaPro, GaBi, and Umberto LCA+. Simapro generates region-specific LCAs from actual data or by performing an estimated impact analysis. For example, paperboard produced in Finland and used in the United States generates a different LCA than paperboard produced and used in Finland. However, a high level of skill is required to accurately conduct comprehensive LCAs.

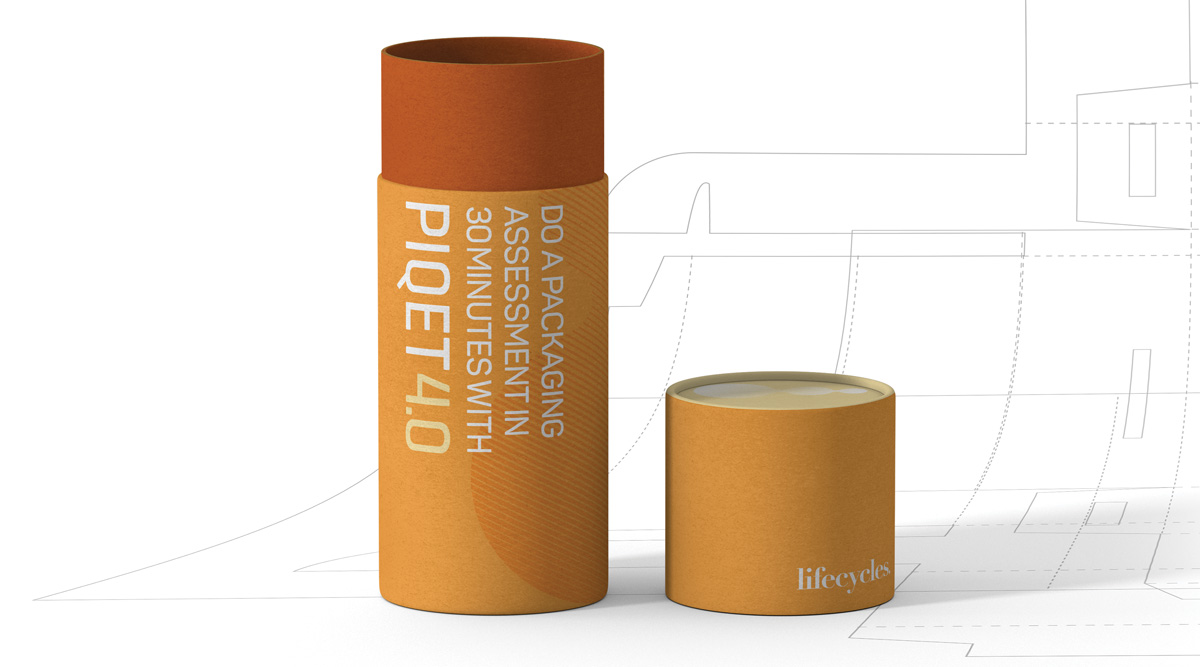

Streamlined LCAs save time and money and lower the complexity of required data by isolating the more impactful factors and making assumptions. When the scope is consistent and known, streamlined LCAs can assess the environmental impact of specific materials whether they are bioderived or post-consumer recycled content and assess disposal options. Streamlined LCA software tools such as PIQET by Piqet, COMPASS by Trayak, and the Economic Input-Output Life Cycle Assessment by Carnegie Mellon University are crucial because they vary in their ability to define scope and make different environmental impact assumptions. For example, when different streamlined LCA software is used to determine the LCA of the same package, the results can vary by more than 20%. This difference is due to the software itself and the scoping assumptions made by each analyst. For example, the LCA impact of a Tetra Pak multilayer carton composed of paperboard, metal, and polymers is lower when it is recycled than when the carton is not recycled. Likewise, when Sustana Fiber produces coffee cups made from recycled Tetra Pak cartons, the LCA impact of these coffee cups is less than when they are made from virgin fiber. However, if the software does not use data for recycling of TetraPak cartons into coffee cups, then the LCA impact is not properly assessed for either the TetraPak cartons or Sustana Fiber cups.

Material sourcing and recovery differences can be captured in PIQET because sourcing (bioderived, fossil-derived, and/or recycled content) and recovery (recycling, composting, landfills, etc.) can be differentiated in the tool according to regional defaults or specific user input. Recently added to PIQET was the ability to account for how a package protects its contents by assessing both the impact of making a product that is lost in the supply chain and the impact of disposing lost product. This captures the impact of food as well as that of package waste. The reuse, recycled content, and recovery are all assessed in PIQET in a material circularity index, which is based on the approach developed by the Ellen MacArthur Foundation. Primary, secondary, and tertiary packaging options can be screened in the early stages of package development before capital costs are committed. “Using industry-averaged data, package designers and sustainability professionals can rapidly and inexpensively screen multiple package design options in less than 20 minutes,” says Prashant Jagtap, president of Trayak.

REFERENCES

Poore, J. and T. Nemecek. 2018. Reducing food’s environmental impacts through producers and

consumers. Science 360(6392): 987–992.

Robertson, G. L. 2009. “Sustainable Food Packaging.” Chpt. 11 in Handbook of Waste Management and Co-Product Recovery in Food Processing, vol. 2, edited by K. W. Waldron, Cambridge, England: Woodhead Publishing.