Packaging Science Increases Food Access

PACKAGING

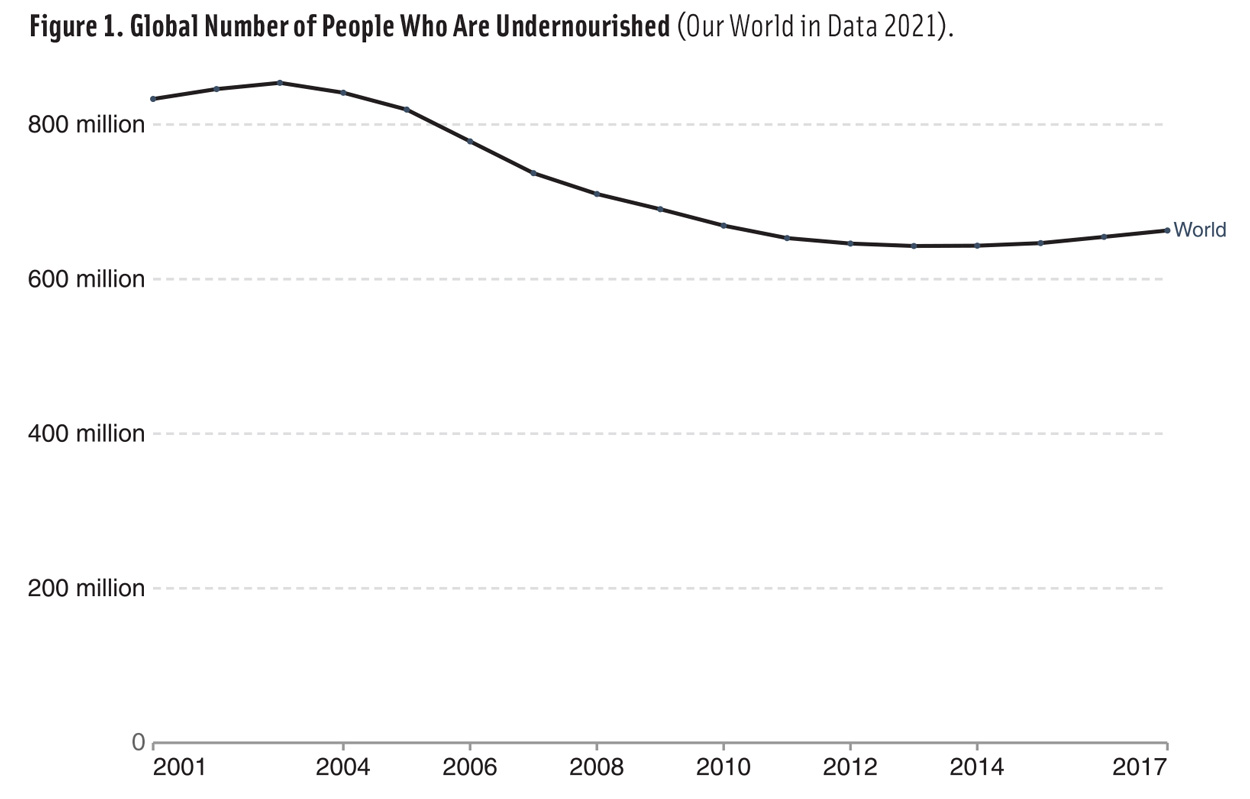

For 25 years, the International Covenant on Economic, Social and Cultural Rights (within the United Nations International Bill of Human Rights) has recognized adequate food as a human right. While undernourishment declined 4.3% from 2001 to 2019 as a percentage of the population, according to the Food and Agriculture Organization of the United Nations, it is now rising again. Between 2019 and 2020, the prevalence of undernourishment increased from 8.4% to around 9.9% (FAO 2021).

Historically, food access issues have involved mainly marginalized people. But the projected impact of climate change on the entire packaged food system means many people who are not part of that group will also be facing food access challenges at least intermittently.

The ability to grow food is being compromised by drought, wildfires, floods, and colder and warmer regional spikes resulting from climate change. Moving up the supply chain, relocation of food processing and packaging facilities is increasingly necessary when crops commonly grown near existing facilities cannot adapt to the changing climate. In addition, disasters such as tornadoes that destroy food processing and packaging facilities hinder food access. The consolidation of packaging and food manufacturing has only exacerbated this situation: Global food distribution demands infrastructure that can both produce and deliver food safely.

Fortunately, effective disaster management can help manage food access risk, along with an expanded array of solutions including food sovereignty, a larger degree of equity among different population groups, and social justice reform (Rosenberg and Cohen 2018). But these food access solutions all require safe packaged food made possible by innovative packaging science.

Intelligent Packaging Solutions

Many food packaging technologies can address food access by providing extended shelf life. Intelligent packaging that links foods from farm to fork, such as radio frequency identification (RFID) and near-field communication (NFC), is the cornerstone of improving food access. It can track where food is and what condition it’s in, and facilitate transferring food to those in need. The proposed Section 24 of the U.S. Food and Drug Administration’s Food Safety Modernization Act identifies specific foods to be tracked at critical tracking events, such as farms, manufacturers, retailers, and consumers along the supply chain (FDA 2021).

To aid in the multifaceted nature of food access and ensure food is authentic, existing tracking systems aligned with Global Standards 1 also can be linked with intelligent packaging technologies such as sensors, nutrition linked to the consumer’s health needs, fraud detection, and hyperautomation. Intelligent packaging that can monitor shelf life is advancing from current temperature integrators (such as Evigence sensors) programmed to mimic the growth kinetics of pathogens like E. coli, to rapid commercialization of H2S, CO2, and ethylene sensors integrated into packaging for red meat, chicken, and produce. Using this technology, consumers would know if food were safe or not safe to eat.

Still other intelligent packaging monitors food throughout a cold supply chain. Emerson internet-connected sensors, for example, allow access to real-time temperature data. Intelligent packaging equipped with decentralized identifiers can use cryptographic trust to verify food chain of custody, impeding food fraud and ensuring food arrives at the intended destination. In addition, hyperautomation links artificial intelligence, machine learning, and robotics to connect small- and large-scale farms, packaging and food manufacturing operations, and autonomous logistics to the arrival of food at food banks and disaster relief centers.

Fermentation Expansion

Many consumers do not always have access to a variety of nutrient-rich safe foods. Fermentation, retort and aseptic packaging, and high pressure processing (HPP) and package barriers all can help provide widespread food access; package requirements vary with the food and the type of processing.

Pickling and fermentation food packaging has a long history, and today packaging and refrigeration work in unison to stabilize bacteria promoted in the fermentation process. Although fermented foods represent only 1.4% of the food market, kimchi sales are growing at 90% and gochujang at 56%, according to The Fermentation Association.

Fermentation packaging requirements include acid resistance, pressure control, oxygen and moisture barrier, and temperature monitoring. For example, yogurt requires a low oxygen barrier to enable Bifidobacterium (facultative anaerobic) growth vs. lactic acid (aerobic) bacteria. In addition, yogurt packaging needs either temperature resistance to hot filling prefermented yogurt or temperature resistance to hot filling properties to promote fermentation. In both scenarios, the packaging needs to withstand UV-C/B, ebeam, or hydrogen peroxide sterilization before product filling.

Retort Packaging Evolution

Retort packaging has evolved from Nicolas Appert’s corked glass jars in the early 1800s, to glass jars equipped with metal closures, to steel and aluminum two- and three-piece cans, to multilayer retort pouches first used in the 1960s. Unsurprisingly, packaged retort foods are popular donations to food banks due to their long shelf life.

Reliable destruction of Clostridium botulinum is essential in retort processing, requiring packaging to be resistant to temperatures approaching 300°F for a variable time. Within retort temperatures, polymers move from a crystalline to an amorphous state. This transition causes oxygen permeability to increase and layers within a multilayer package to separate due to differential flexing. For example, during retort processing, the polymer flexes, but the glass within retort pouches made of glass-coated films does not flex, resulting in loss of seal and overall package integrity.

To protect metal cans, inner coatings provide abrasion and scratch resistance and also are resistant to acid and salts. Bisphenol A (BPA)-based epoxy coatings, used since the 1950s, have recently been replaced by non-BPA-derived epoxies.

Aseptic Requirements

Packaging food within aseptic pouches increases food access for people who do not have consistent refrigeration. Aseptic packaging connects packaging and food within a closed system in a sterile environment, which demands packaging that is resistant to sterilization methods such as H2O2 and ultraviolet light and high-temperature filling (Voicu et al. 2017). Sufficient mechanical strength also is needed for aseptic carton and pouch formats to enable high-speed production with optimized seals. For example, barley-based milk producer Take Two employs aseptic packaging within a polymer bottle and achieves a shelf life of 12 months.

HPP Packaging Advantages

HPP packaging allows for less thermal-intensive processing to extend the shelf life of refrigerated food, from sliced deli meats to juice, by more than 16 weeks. This additional shelf life is gained by destroying or depleting the microbial load within a packaged food. Because foods are less heat and time processed than with retort processing, more nutrients are retained, and fewer preservatives are required.

HPP consists of an initial heating (when necessary) of the confined fluid and packaged food, followed by application of adiabatic pressure ranging from 100 to 800 MPa for approximately 20 min. Because the air trapped inside the packaging presents greater compressibility than the food, headspace reduction is needed to ensure uniform processing. Without this reduction, nonuniform treatment and packaging deformation can occur, so HPP employs flexible packaging as the primary package vs. metal cans, glass, or paper-based packaging.

Due to the compression and decompression resulting from HPP, films with coatings such as metallization or inorganic matter can suffer damage, which may lead to loss of barrier and morphological changes in the packaging. HPP also affects crystallinity, so it alters sorption and migration and tensile strength. In addition, delamination can occur when processing at higher pressure (>600 MPa).

Product-Specific Package Barriers

Whether food has been minimally or fully processed, food packaging protects it from lipid oxidation, browning, moisture gain, and microbial growth. Active packaging technologies such as antimicrobial, modified atmosphere packaging, and oxygen absorbers also extend product shelf life.

The requirements for packaging barrier, however, depend on the product. Nuts and cured meat with a high degree of mono- and polyunsaturated fats require an oxygen barrier and often a nitrogen replacement of available oxygen within the package. Freeze-dried product demands an excellent moisture barrier—North Bay Trading, for example, packages its Thousand Lakes Food Company freeze-dried Dried Mixed Vegetables within a foil multilayer resealable standup pouch.

Regardless of the packaging method, centralized packaging has allowed food byproducts to be recovered and turned into upcycled food, which increases food access by reducing waste. The Upcycled Food Association estimates that more than 400 upcycled products are now available from centralized food packaging facilities.

REFERENCES

FAO. 2021. “Sustainable Development Goals.” http://www.fao.org/sustainable-development-goals/indicators/211/en/.

FDA. 2021. “FSMA Proposed Rule for Food Traceability.” https://www.fda.gov/food/food-safety-modernization-act-fsma/fsma-proposed-rule-food-traceability.

Our World in Data. 2021. “Global Number of People Who Are Undernourished.” https://ourworldindata.org/hunger-and-undernourishment.

Rosenberg, N. and N. Cohen. 2018. “Let Them Eat Kale: The Misplaced Narrative of Food Access.” Fordham Urban Law J. 45(4). https://ssrn.com/abstract=3189523.

Voicu, G., G. Constantin, S. Mădălina, et al. 2017. “Aspects Regarding the Aseptic Packaging of Food Products.” Presented at International Symposium ISB-INMA TEH 2017, Agricultural and Mechanical Engineering, Bucharest, Romania, Oct. 26-28.