Making Packaging Tradeoffs for Commercialization

Packaging | APPLIED SCIENCE

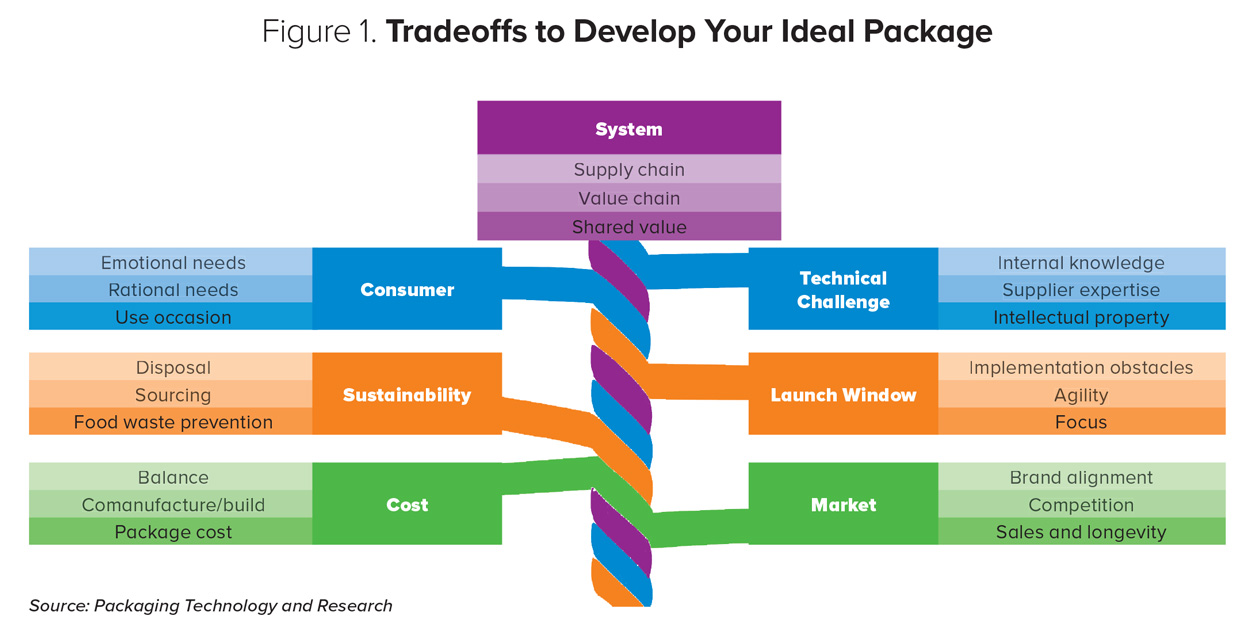

Package design is a thought-intensive process with necessary tradeoffs based on cost, consumer needs and market opportunity, system capabilities, technical challenges, sustainability, and the desired launch window.

Food safety, however, is not one of those tradeoffs. With more than 14 multistate pathogen outbreaks in the United States in 2021, according to the Centers for Disease Control and Prevention, food safety is always the overriding criterion in food package selection, often dictated by the processing required. For example, “all three components—hydrogen peroxide sterilized packaging, UHT [ultra high temperature] processing, and an aseptic environment—need to be approved for nonrefrigerated milk to be safe,” says food safety professional Snehee Chaplot, CEO of The Food Shop.

Since 1957, the U.S. Food and Drug Administration has considered packaging to be an indirect food additive, and it must be approved for use with the process and also conform to direct food contact regulations. Global food safety regulations stipulate testing with specific food-simulating liquids, as well as with approved additives specific to foods and packaging materials at the time and temperature conditions of contact.

Consumer Needs and Market Opportunity

Consumer needs are both rational and emotional, and the package design choices that match these needs will be different. A single-serve yogurt package with easy peel lidding meets a consumer’s rational portion control needs, for instance, while the emotional need for a “treat” can be satisfied with a product using more involved packaging that requires time for unwrapping, such as the Lindt Excellence 99% cocoa chocolate bar. To get to the chocolate, the consumer has to open the top flat of a solid bleached sulfate folding carton, slide the carton out, and peel off the lidding on an aluminum foil sealed tray. Facial analysis software can measure the comparative emotional connections of packaging.

For brands with frequent and intermittent consumer use, counter-friendly package design makes kitchen counter placement intuitive. The retractable pour spout on Kirkland Signature Organic Balsamic Vinegar, for example, eliminates the need to transfer vinegar from the bottle into another metered-use container. The aluminum crown screw closure addresses consumer concerns about contamination in an open bottle in a way that other metered-use containers do not.

Packaging suppliers also may be able to work with fresh ideas from students to develop innovative package design. For one recent project, “Esko partnered with our students to design more sustainable and accessible food and beverage packaging,” says Donna Razik, a lecturer at the School of Graphic Communications Management at Ryerson University.

System Capabilities

The supply chain focuses on delivery dynamics, and the value chain focuses on the value of what is being transferred, but both are essential for product success.

Disaster management is a critical aspect of package selection to ensure the chosen package will be available as needed when supply chain issues are encountered. Natural disasters (drought, fires, floods, typhoons, hurricanes, tornados), human struggles (virus, famine, political upheaval), and power unreliability (outages, internet, production) all can affect the packaging supply chain.

The availability of packaging materials also needs to align with volume projections. While more rigid supply chains were standard in the past, today companies must build in the ability to make rapid shifts in package materials as a proactive way to prevent unforeseen supply chain stress. For example, “recent EVOH [ethylene vinyl alcohol] supply shortages prompted brands to rapidly decide between reverting to PVC [polyvinyl chloride] as the barrier layer, reducing product shelf life, and/or adjusting production parameters to eliminate the need for a barrier layer,” says Kate Barry, packaging optimization manager at Chainalytics. Removing the barrier layer enabled single material recycle-ready films, accelerating sustainability efforts.

Value chain linkages are formed when shared values are aligned among manufacturers and suppliers. When a brand has a company culture of making rapid artwork changes in response to sales data, seasonal and regional promotions, and recent events, for example, conflicts could arise with a packaging supplier that has long lead times, long runs, and a cumbersome artwork approval process.

The shared value of food safety is paramount within the value chain from manufacturer to consumer. Intelligent packaging, such as intelligent barcodes, increasingly conveys confidence in food safety when a cold chain is in doubt or unknown. Intelligent barcodes can be disabled when temperature abuse has occurred or can act as visual cues when microbial growth is sensed via package pH sensors (Hakola et al. 2021, Anonymous 2021).

Cold chain uncertainty can be predicted using systematic kinetic modeling (Giannakourou and Taoukis 2020). However, in the case of a very unreliable, inflexible cold chain in which food safety risks and unsaleables are excessive, an alternate package that does not require a cold chain is needed. As a result, cost-effective e-commerce often leads to the redesign of packaging so that a cold chain is not required.

Cost Considerations

Package selection cost considerations often focus on the cost of the package itself, but other associated fixed and variable costs can vary based on different packaging options. Using a package format that is not specialized, for example, enables lower comanufacturer or capital equipment dollar costs. Delegating production to a comanufacturer also involves costs for shipping, lag times, distribution, and issues for which it’s hard to calculate a price, such as confidence, confidentiality, and risk management. In addition, working with a comanufacturer requires investing in processes to minimize risk, qualifying multiple package sources and materials, and defining processes for a food safety inspection.

Technical Challenges

Almost all packaging development processes entail technical challenges of varying degrees, and rarely does an organization already possess the precise knowledge base to embark upon a new initiative. The organization might need intellectual property of varying types to help address the challenge.

Joint development agreements may define the exact intellectual property exchanged, but the tacit knowledge transfer governs what actually gets done. Tacit knowledge arising from optimal relationships among internal organizational operations, suppliers, and external expertise can help organizations address technical challenges more efficiently.

An expanded array of expertise, including expert decision-making systems, contingency plans, and extended reality, ensures efficient tacit knowledge transfer. However, an organization’s ability to access tacit knowledge can be limited, and it may shift away from a challenging package because of its inherent inability to transfer and gain knowledge.

Sustainability Tradeoffs

The most sustainable packaging makes the least impact on the environment while minimizing the environmental impact of food waste, processing, and food distribution.

Package material selection often is dictated by the degradative reactions that the packaging is required to stall or inhibit within food, as well as the required shelf life. But the environmental tradeoff among packaging, preservatives, and energy expended during the product’s entire shelf life is complex. For instance, baked goods lacking preservatives are prone to mold, and a modified atmosphere plus an excellent oxygen and carbon dioxide barrier can extend the shelf life. Baked goods with preservatives, however, or those that use a high greenhouse gas-intensive frozen environment do not need modified atmosphere packaging to attain an extended shelf life.

To maintain package sustainability, clear communication to consumers on specifics relating to package disposal—such as reusing, recycling, landfilling, and composting—is essential.

“When materials are food contaminated, they may be suitable for composting. Some state laws require compostable products to be certified by a third party as meeting internationally recognized standard specifications. Certified compostable packaging should be clearly distinguishable from noncompostable packaging,” says Jeanette Hanna, biopolymers market development manager, North America at BASF.

“Brands must also consider [that] market access to facilities composting these products is limited. As a result, they are responsible for ensuring compostable products are sold only where they can be recovered in organic systems without causing contamination from lookalike materials,” says Hanna.

Using a package material sourcing location closer to where food manufacturers will utilize the packaging significantly lowers the environmental impact. Material switching also can result in more environmentally friendly disposal of packaging (Bauer et al. 2021, Tyagi et al. 2021).

“Brands appreciate the stiffness, gloss, print protection, and heat resistance for sealing that PET [polyethylene terephthalate] brings to the standup pouch format. However, a laminated multimaterial package cannot always be recycled like a monomaterial flexible film,” says plastics engineer Laura Martin, a personal contributor at SPRING, The Sustainable Packaging Research, Information, and Networking Group.

“One solution gaining traction is to replace the PET layer with oriented polyethylene [OPE],” says Martin. “However, since the OPE can’t quite achieve the thermal resistance of PET, the improved sustainability of these recycle-ready pouches must be weighed against the cost of modifying production sealing equipment and potentially running at slower line speeds.”

Shorter Launch Windows

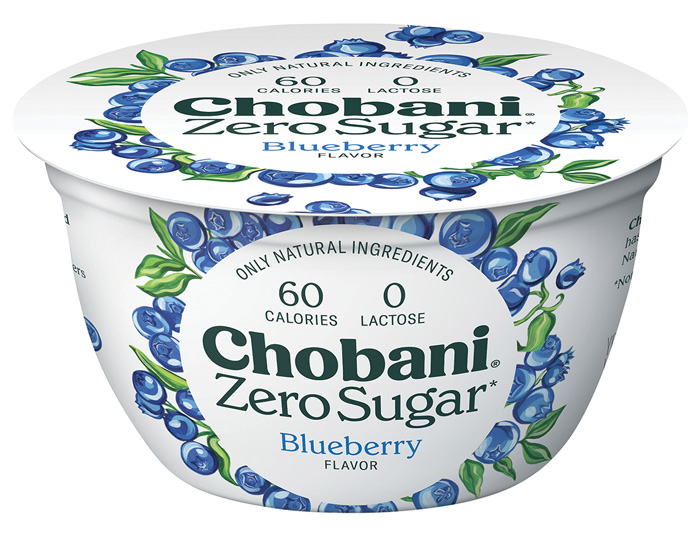

The time from idea to launch of food products has shortened within the past few years. The 2017 launch of Oui brand yogurt within a glass container consumed three years of development time, while the 2021 rollout of Chobani with Zero Sugar within a platformed thermoformed polypropylene cup took only a year.

Implementation obstacles can result in shifting package design away from being optimal in order to meet tighter timetables. For example, one brand launching a premixed snack shifted to a more expensive and less consumer-preferred package when it found that the required equipment lead time for the ideal package exceeded 16 weeks.

The necessary tradeoffs for commercializing a package are product, brand, and company specific and based on relative priorities. These priorities can shift as new products gain competition and require packaging that adds more value to the consumer experience.

Learning Objectives

- Understand the relationship between food safety and package development.

- Define tradeoffs and factors used in the package development process.

- Assess tradeoffs required for a specific food package.

Food Technology Articles

How to Achieve EPR-Forward Packaging

In this two-part series, the author explores the history of Extended Producer Responsibility (EPR), what is needed to help EPR succeed, and how brands can best prepare for EPR.

Battling Biofilms

In this column, the author describes the stages of biofilm development in food processing plants, methods of removal, and best practices for prevention.

Keeping the ESG Promise

An infographic describing food and beverage companies’ outlooks regarding ESG initiatives.

Ag-Tech’s Passionate Pragmatist

Agrologist and agricultural futurist Robert Saik wants to feed the world better and more sustainably. To make that happen, leveraging science and technology will be critical.

Smart Steps to Peak Traceability

Creating an effective road map to advance your food traceability program is key to overcoming data, process, and stakeholder challenges.

IFT Podcasts

EP 11: The Challenge of Water

Water is a critical resource for growing and processing food. This episode discusses the challenges we face regarding water, and present and future solutions to resolve them.

Episode 29: All About Food Safety Culture

In this podcast, we discuss food safety culture, including how food safety culture is established, measured, and how they are expected to change in light of ongoing advancements in food science and policy. Our guests include Hugo Gutierrez, Global Food Safety and Quality Officer for Kerry, and Bob Gravani, Professor Emeritus of Food Science and Director Emeritus of the National Good Agricultural Practices (GAPs) Program at Cornell University.