Measuring Moisture Content & Water Activity

LABORATORY

Both moisture content and water activity—the ratio of the water vapor pressure of a substance such as food to the water vapor pressure of pure water under the same conditions—are important in formulating products for safety and stability.

In his Processing column in the October 2009 issue of Food Technology , J. Peter Clark discussed the basics of water activity, so in this month’s Laboratory column I will not go into depth on the concept. Instead, I will focus on the methods and instruments available to measure moisture content and water activity of foods.

In his Processing column in the October 2009 issue of Food Technology , J. Peter Clark discussed the basics of water activity, so in this month’s Laboratory column I will not go into depth on the concept. Instead, I will focus on the methods and instruments available to measure moisture content and water activity of foods.

Moisture Content vs Water Activity

Moisture content is, simply, how much water is in a product. It influences the physical properties of a substance, including weight, density, viscosity, conductivity, and others. It is generally determined by weight loss upon drying.

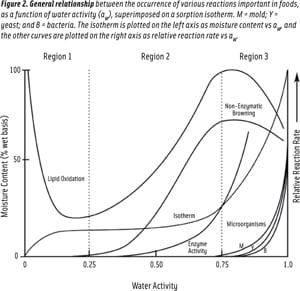

Water activity, aW, is a measure of how much of that water is free, i.e., unbound, and thus available to microorganisms to use for growth. It is therefore important with regard to food safety. Microorganisms will not grow below a certain water activity level—aW 0.90 for most pathogenic bacteria, 0.70 for spoilage molds, and 0.60 for all microorganisms. While temperature, pH, oxygen availability, and several other factors can influence whether an organism will grow in a product and at what rate, water activity is often the most important factor. Water activity also plays a role with regard to chemical and physical properties.

Brady Carter ([email protected]), Applications Engineer, Decagon Devices Inc., Pullman, Wash., said that product stability has traditionally been determined by the “cook-and-look” method but we now have instruments that can measure water activity of a laboratory or pilot plant formulation and indicate whether the product will work prior to production. And once the product is in actual production, he added, we can use the measurement essentially as a form of process control—we can determine whether we need to dry the product more, cook it longer, control the belt speed or oven time, and so on. Moisture content is generally used as the end measurement in production, he said, but water activity gives tighter control and will find increased use at line, if not online.

Measuring Moisture Content

There are many methods for determination of moisture content. The primary methods used are loss on drying and Karl Fischer titration.

-

Loss on Drying. In this method, a wet sample is weighed on a balance, placed in an oven, and heated until the end of the drying period, i.e., until the sample reaches equilibrium. The weight loss is the moisture content of the sample. In moisture balances, this process is sped up by superheating the sample by a variety of means, including infrared, halogen, and microwaves.

- Karl Fischer. In this method, the amount of water in a sample is determined directly by titration with Karl Fischer reagent, which consists of iodide, sulfur dioxide, a base, and a solvent system. There are two titration approaches: coulometric titration for samples with very low moisture content (<0.03%) and volumetric titration for samples with moisture contents ≥0.03%. In coulometric titration, the sample is added to the reagent, and electrolytic oxidation causes the production of iodine. The amount of iodine produced is proportional to the electricity (number of coulombs) used, which in turn is proportional to the amount of water in the sample. In volumetric titration, a sample is added to a moisture-free solvent and titrated with the reagent, whose titer (mg of water/mL of reagent) is known. The titration endpoint, determined by a constant-current polarization voltage method, represents the moisture content of the sample.

Whereas the loss-on-drying method will detect the loss of any volatile substance, the Karl Fischer method is specific for water.

A list of suppliers of moisture content analysis instruments includes: Arizona Instruments LLC (www.azic.com); Denver Instrument USA (www.denverinstrumentusa.com); Metrohm USA Inc. (www.metrohmusa.com); Mettler Toledo Inc. (http://us.mt.com); and TEWS-Elektronik (www.tews-elektronik.com).

--- PAGE BREAK ---

Measuring Water Activity

We can’t insert a probe into a sample to directly measure its water activity. Instead, water activity is measured by placing the sample into a closed chamber and equilibrating the liquid-phase water in the sample with the vapor-phase water in the headspace and measuring the relative humidity of the headspace. Since water activity is the ratio of the water vapor pressure of the sample to the water vapor pressure of pure water under the same conditions, it is also equal to the equilibrium relative humidity, ERH (expressed in %), divided by 100.

Two types of instruments are used to measure water activity. Each type has advantages and disadvantages, Carter said, and the methods vary in accuracy, repeatability, speed of measurement, stability in calibration, linearity, and convenience of use.

-

Capacitance Sensors. These sensors, also called capacitance or electric hygrometers, consist of two charged plates separated by a hygroscopic polymer membrane. As the membrane adsorbs water, its ability to hold a charge increases. The resulting capacitance change is approximately proportional to the water activity as determined by a sensor calibrated against known saturated salt standards. The sensor gives a signal relative to the ERH and thus the water activity (as ERH/100). Commercially available instruments measure over the entire water activity range with an accuracy of ±0.015 aw.

-

Chilled-Mirror Dewpoint System. As air is passed over a chilled surface whose temperature is gradually reduced, the temperature at which the water vapor begins to condense on the surface is the dewpoint temperature, which is directly related to the vapor pressure of the air. The system, provided only by Decagon, consists of a sensor block containing a dewpoint sensor, an infrared thermometer, and a fan. A sample is placed in a sample cup which is sealed against the sensor block. The dewpoint sensor measures the dewpoint temperature of the air, and the infrared thermometer measures the sample temperature. The relative humidity of the headspace is calculated as the ratio of dewpoint temperature saturation vapor pressure to saturation vapor pressure at the sample temperature. When the water activity of the sample and the relative humidity of the air are in equilibrium, measurement of the headspace humidity gives the water activity of the sample. Chilled-mirror instruments make accurate (±0.003 aw) measurements in less than 5 min, without the need for calibration.

Suppliers of water activity analysis instruments include: Decagon (www.decagon.com); Novasina AG (www.novasina.com); and Rotronic Instrument Corp. (www.rotronic-usa.com).

Determining Moisture Sorption Isotherms

The relationship between moisture content and water activity of a product is described by its moisture sorption isotherms—curves relating them to each other at specific temperatures. Moisture sorption isotherms are unique to each product and temperature. There are several methods for determining the moisture isotherms.

-

Traditional Static Method.

A sample of food is exposed to various constant-humidity atmospheres produced by means of saturated salt solutions in a series of sealed chambers, all maintained at the same temperature. After equilibrium is reached, the moisture content is generally determined gravimetrically (by weight loss or gain). Saturated salt solutions have the advantage of maintaining a constant humidity as long as the amount of salt present is at the saturation level.--- PAGE BREAK ---

-

Dynamic Vapor Sorption (DVS) method. In this method, the traditional static method is automated by instrumentation. A sample is subjected to varying conditions of humidity and temperature set by the user and controlled by the instrument. The response of the sample is measured gravimetrically. The instruments use mass flow controllers, one for dry air and the other for air saturated with water to generate the ratio of wet to dry air. They can provide nearly any relative humidity from 0 to 98%. They are programmed to automatically cycle between different humidity levels, holding the humidity constant at each level until equilibrium is achieved.

-

Dynamic Dewpoint Isotherm (DVI) method.

This method, used only by Decagon, directly measures water activity while gravimetrically tracking weight, so there is no dependence on equilibration to preset water activities, making it fundamentally different from all other isotherm methods, Carter said. Adsorption occurs as saturated wet air is passed over the sample, and desorption is accomplished as desiccated air is passed over the sample. After roughly a change of 0.015 in water activity, airflow is stopped and a snapshot of the sorption process is taken by directly measuring the water activity and the weight. It is faster than the DVS method, according to Carter.

Once an isotherm has been generated, it can be used to indirectly determine moisture content from a water activity measurement by developing an equation that describes the curve. After we have obtained the isotherm data, Carter said, we need to express the data in terms of an isotherm model that spans a large range of water activity values and isotherm shapes. The most commonly used models are the Guggenheim–Anderson–deBoer (GAB) model and the Brunauer, Emmett, and Teller (BET) model. Carter said that Decagon has developed another model, the Double Log Polynomial (DLP), that it considers superior to the others since it consistently provides a better fit to the data across the entire water activity range. The models are determined empirically using the data collected during isotherm generation, and the resulting equation can be used to calculate moisture content using water activity.

Some software programs, such as Decagon’s SorpTrac software, can model the isotherm and generate the equation coefficients automatically, Carter said, and most DVS instruments have software to also do data analysis.

A list of suppliers of automated isotherm generators in addition to Decagon includes: Surface Measurement Systems Ltd. (www.thesorptionsolution.com); Hiden Analytical (www.hideninc.com/gravimetric-analysis.html); TA Instruments (www.tainstruments.com/main.aspx?id=239&n=1&siteid=11); CI Electronics Ltd. (www.cielec.com/lab/laboratory_instruments.html); ProjektMesstechnik (www.projekt-messtechnik.de/sps_sorption_e.html); and Quantachrome Instruments (www.quantachrome.com/technologies/hydrosorb.html).

Two Measurements in One Instrument

Since moisture content and water activity are currently measured using separate techniques or instruments, conducting both analyses in one instrument would save time and labor, Carter said. That was the idea behind Decagon’s introduction in February 2009 of its AquaLab Series 4TE Duo.

The instrument uses a chilled mirror to determine the water activity. Once the moisture sorption isotherm model for a particular product is loaded into the instrument, it converts water activity into moisture content and shows both aw and moisture content on the screen. The user of the instrument can select from a library of isotherm models.

Since the moisture sorption isotherm is complex and unique to each product type, it must be determined experimentally by measuring water content at several water activity values. Decagon offers a separate instrument, the AquaSorp, that can rapidly generate isotherms, which can subsequently be loaded into the AquaLab Duo.

--- PAGE BREAK ---

Advances and Challenges

Carter said that there really haven’t been any major advances in water activity determination other than using it to predict moisture content automatically. There have been advances in instruments to measure water activity, he said, but the methods are the same.

With regard to moisture content determination, Shelly Schmidt ([email protected]), Professor of Food Chemistry at the University of Illinois-Urbana, said that Karl Fisher titration is still the best method overall for determining the moisture content of intermediate-moisture and low-moisture foods, but it takes a lot of effort and time. It takes 5–10 min to conduct if it’s set up for routine, regular use, such as in a quality assurance setting, she said, but if it’s not for routine use, it can take a good deal of time to set up, since for each formulation the user must decide which solvent system works best.

Schmidt said that there have been advances in the development of rapid methods and instrumentation for measuring both moisture content and moisture sorption isotherms. They are not necessarily brand new, she said, but they are now faster and more reliable. Halogen drying, for example, has an advantage over other forms of infrared heating, she said, allowing the temperature to climb faster and thus shorten the analysis time.

Automated humidity generators can obtain sorption isotherms much faster—in days instead of weeks or months—than the traditional static saturated salt solution method, she said. Research on new formulations involves changing ingredients, she explained, so it’s necessary to determine a moisture sorption isotherm for each. The traditional method uses saturated salt solutions, which requires weeks to months to come to equilibrium. Quite a few companies, she said, now offer instruments that generate relative humidities by means other than saturated salt solutions, thus reducing the time required to hours or days.

Several companies make automated isotherm generators, Schmidt said, but they are relatively expensive. They have done well in reducing the time to generate isotherms and allow the user to obtain other sorption-related information, such as kinetic data, amorphous content, and heat of sorption, but they require more care than saturated salt solutions. Another advantage is that the user can obtain isotherms over a wide temperature range, whereas before a user needed to buy an incubator for temperature control.

Among other advances, Schmidt added, is the ability to watch a sample in the sample chamber as it absorbs water.

The DVS Advantage System from Surface Measurement System, for example, offers both a video microscope and a Raman port (for insertion of a Raman spectroscopy probe), so one can observe and capture visual and structural information from the sample during the sorption experiment.

One of the challenges ahead, Schmidt said, is determining the moisture content of samples that are high in simple and/or complex carbohydrates and/or fat. Intermediate-moisture foods are the most challenging. High carbohydrate content, for example, leads to thermal degradation and an overestimation of the moisture content.

Another challenge, Carter said, is how to get a true water activity value if the product has volatiles other than water, such as propylene glycol or ethanol. All current instruments are affected by volatiles in one way or another. An additional challenge is to develop a way to measure water activity online. We can measure water activity at line but not online, with the exception of some near-infrared systems, he said, but the challenge is to get repeatable results. With production lines, the material is in constant motion. Some dryer and extruder manufacturers have systems that do measure moisture content online, but it would be preferable to measure water activity. However, measurement of water activity is an equilibrium test, so it is impossible to do it on something on a moving belt because it’s not in equilibrium. Decagon continues to investigate new technologies to address these challenges, Carter said.

--- PAGE BREAK ---

Moisture content is, simply, how much water is in a product. It influences the physical properties of a substance, including weight, density, viscosity, conductivity, and others. It is generally determined by weight loss upon drying. There are many methods for determination of moisture content. The primary methods used are loss on drying and Karl Fischer titration. There are many methods for determination of moisture content. The primary methods used are loss on drying and Karl Fischer titration.

There are many methods for determination of moisture content. The primary methods used are loss on drying and Karl Fischer titration.

Conference to Address Water in Food

The EuroFoodWater Association is soliciting abstracts for papers to be presented at its EuroFoodWater Conference on Water in Food, to be held in Reims, France, on arch 21–23, 2010. This will be the sixth annual conference for engineers and scientists working in the fields of water determination, water activity, and water interactions in food. Previous conferences were held in Italy, France, Switzerland, Belgium, and Germany.

The conference will feature three sessions: “Water Structure and Interactions in Food,” “Water Determination and Food Quality,” and “Water Activity and Food Stability.” Deadline for abstracts is January 15, 2010. For more information, visit www.efw2010.eurofoodwater.eu or contact Barbara Rogé at [email protected] or M. Mathlouthi at [email protected].

Water Activity Software Aids in Formulation

Adria Developpement (www.adria.tm.fr) has created a computer program that calculates water activity as a function of the composition of a product.

AwDesigner is said to determine water activity with the same precision as classical measurement methods and predict the shelf life of new food products. It features a database of 160 ingredients—such as starches, protein concentrates, fibers, gums, flours, fat, egg products, spices, meat, cereals, fruits, and vegetables—and 70 food additives, including preservatives, antioxidants, emulsifiers, stabilizers, and gelling agents.

The software includes mathematical models for calculating the water activity of any formulation on the basis of the hygroscopic properties of the liquid and solid phases that constitute the food. The calculations are based on published models—Guggenheim–Anderson–de Boer (GAB) and Ferro–Fontan for the solid phase and Teng and Roa for the liquid phase.

The software can be used in conjunction with Adria’s

Sym’Previus software (www.symprevius.org) to predict which spoilage and pathogenic microorganisms will grow in a particular formulation.

by Neil H. Mermelstein

a Fellow of IFT, is Editor Emeritus of Food Technology

[email protected]