Bacteriophages: Not So Alien

FOOD SAFETY & QUALITY

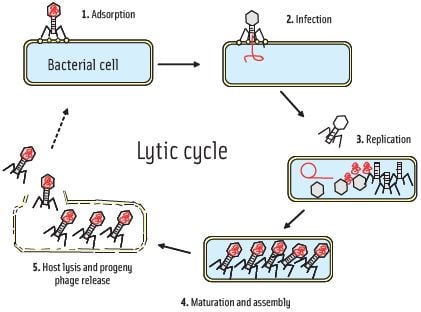

Fans of the 1979 movie Alien may remember the shocking scene in which the alien creature erupts from a spaceship crew member’s chest. That scene epitomizes what bacteriophages do. They infect a target bacterial cell, replicate within the cell, and then cause the cell to rupture, releasing additional progeny bacteriophages that infect other target bacterial cells. The difference between the movie scenario and reality is that bacteriophages—phages, for short—attack only their specific bacterial target, not humans, animals, or plants, and they are not alien but rather are found naturally in food and the environment in high numbers (more than 1030 are estimated to be present in water, soil, and foods) as well as in the human gastrointestinal system.

Fans of the 1979 movie Alien may remember the shocking scene in which the alien creature erupts from a spaceship crew member’s chest. That scene epitomizes what bacteriophages do. They infect a target bacterial cell, replicate within the cell, and then cause the cell to rupture, releasing additional progeny bacteriophages that infect other target bacterial cells. The difference between the movie scenario and reality is that bacteriophages—phages, for short—attack only their specific bacterial target, not humans, animals, or plants, and they are not alien but rather are found naturally in food and the environment in high numbers (more than 1030 are estimated to be present in water, soil, and foods) as well as in the human gastrointestinal system.

They play a key role in controlling bacterial populations in nature and can be a natural alternative to the chemical antimicrobials and antibiotics being used in the food industry. Phages have been used for various purposes, including therapeutic uses, for nearly 100 years, but the number of new phage applications for food safety has increased in the past decade, along with acknowledgment by the U.S. Food and Drug Administration (FDA) of phage products as generally recognized as safe (GRAS) processing aids.

Mechanism and Products

A phage is a virus consisting of a body called a capsid, which contains DNA, and tail fibers. The phage kills (lyses) its specific bacterial host by attaching via its tail fibers to the bacterium, injecting its DNA into the bacterial cell, and causing it to produce new progeny phages. As the number of progeny phages increases, the cell bursts, releasing progeny phages to seek additional target bacteria to infect.

Studies have shown that phages are effective in reducing populations of pathogenic bacteria such as Escherichia coli O157:H7, Salmonella, and Listeria monocytogenes on foods such as produce, beef, poultry, cheese, and fish. Regulatory agencies in the United States have issued various approvals for the use of phages for food safety, indicating that their use in foods poses a minimal risk to human health. Phages have been shown not to affect the taste, appearance, or smell of foods.

Many phage products are provided in highly concentrated liquid form for dilution by the user while others are provided in dehydrated form for reconstitution. Among the companies actively developing and marketing phage products for use by the food industry are Intralytix Inc., Micreos Food Safety, OmniLytics, and Elanco.

Important Developments

Alexander Sulakvelidze, Vice President, Intralytix Inc., said that he considers the most important development regarding phages to be the FDA’s 2006 approval of ListShield, the first phage preparation for food applications. He added that another important development was the scaling-up of phage production, a critical step for his company’s commercialization of the technology. He said that in addition to phage cocktails that are optimal for specific applications, work is being done to develop phage products that are lytic against additional bacterial pathogens and strains of particular concern in specific geographic locations or specific food processing or clinical settings.

Manan Sharma, Research Microbiologist, U.S. Dept. of Agriculture, Agricultural Research Service, said that the increasing number of U.S. and international research groups examining phages for food safety use has led to more focused and applied research on the topic. The innovative nature of these experiments and the high quality of data they are yielding, he said, is giving the scientific community a much better understanding of the capability of lytic phages to reduce pathogens on foodborne commodities and is giving the food industry a much better understanding of potential uses for phages.

--- PAGE BREAK ---

Andre G. Senecal, Science Advisor, Food Protection Team, Combat Feeding Directorate, U.S. Army Natick Soldier Research, Development, and Engineering Center, said that a recent technical development was his group’s work showing that phages produce an additive effect when combined with a commercial produce wash for reducing pathogens on fresh fruit and vegetables. Of particular interest, he said that phages were found to increase the effectiveness of the commercial wash when there was an increase of organic material present in the wash solution. These additive effects were found for phage cocktails against E. coli O157:H7, Salmonella, and Shigella.

Dirk de Meester, Business Development Manager, Micreos Food Safety, said that he considers the FDA’s acceptance of phage products against Listeria and Salmonella as GRAS a quantum leap. He added that the World Health Organization is putting a lot of pressure on companies to replace antibiotics in the food chain while consumers are calling for green solutions. In this light, he said, the fact that several phage products have been considered suitable for use as processing aids for organic products helps position phages as a very elegant solution. He said that more and more companies are prioritizing on developing sustainable solutions to problems. He added that the acceptance in Canada, Australia, and Europe of phage technology as a green alternative to the use of antibiotics and chemicals has led to enormous increase in the demand for phage solutions.

Mansel Griffiths, Director, Canadian Research Institute for Food Safety, University of Guelph, Canada, said that the regulatory approval of the use of phages as processing aids has triggered more interest in their use and research on their applications. He added that research that his group and collaborators have been doing on phage immobilization yields new opportunities for the use of phages in the food industry.

Challenges Ahead

Some experts consider consumer acceptance one of the challenges ahead, but there was a difference of opinion about this. Sulakvelidze said that phages may face a special challenge regarding consumer acceptance. Senecal said that the biggest challenge would be public acceptance since most people have no idea what a phage is. Calling a virus that kills bacteria may give a negative connotation, he said, because the public perceives viruses as microorganisms that make them sick. Griffiths said that more work needs to be done on consumer perception. Although humans ingest probably millions of phages each day without any ill effects, he added, consumer fears may be allayed by the adoption of phage immobilization techniques to create packaging materials that ensure that phages are only transferred to the food if a target organism is present. In contrast, De Meester said that consumers are among the strongest supporters of phage technology, citing the approval of his company’s phage product, Listex, by Food Safety Authority Australia & New Zealand.

With respect to technical challenges, Sulakvelidze said that complete eradication of a targeted bacterium is not always achievable, so how effective is effective enough? Exact identities of bacterial contaminants must be known for application of the proper phage. He said that application equipment would not be a major challenge since most existing spray equipment could be used to apply phages, but he cautioned that some phage products require refrigerated storage and that commonly used disinfectants may inactivate phages.

De Meester said that while a lot of people know that phages can be used to kill certain bacteria, understanding the nuts and bolts of phage application at a food processing plant is necessary for phages to become a new industry standard for food safety. Sharma said that it is very important to understand what the application of phages can do (reduce pathogenic bacterial populations under specific circumstances) and cannot do (serve as a single step that will eliminate all risk associated with a product), so identifying how lytic bacteriophages should be used in a specific process or on a commodity becomes really important. Senecal said that one challenge is to make phages more acceptable for commercial use, such as by improving the stability and shelf life of phage cocktails that are provided in a dehydrated state.

Griffiths said that there is a need to develop better ways of stabilizing phage to deliver a longer shelf life and a need to develop commercial-scale methods for production of immobilized phage. He added that his group has been working on developing phages with a variety of tail fibers capable of recognizing more than one bacterial genus and on developing a pathogen-detection method using immobilized phage in a manner similar to immunomagnetic separation. He said that arguably the most-effective use of phages will be as adjuncts to other processing techniques to provide an extra layer of protection to the food supply and that as the industry understands more and more about phage biology and as the number of phages that are isolated increases, opportunities for their use to control and detect pathogens will increase.

--- PAGE BREAK ---

Bacteriophage Research

Several presentations on bacteriophages occurred at the Institute of Food Technologists’ 2013 IFT Annual Meeting & Food Expo. Manan Sharma of the U.S. Dept. of Agriculture discussed opportunities that proposed safety regulations provide for the use of phages as intervention strategies for the produce industry. He said that the amount of phage initially present must be sufficient to suppress populations of target pathogens in a food commodity or on a food-contact surface and keep them low during shelf life at appropriate storage temperature. He said that phages used in combination with refrigeration temperature can provide sufficient preventive control or mitigation, but he cautioned that phages, like other antimicrobial treatments, have strengths and limitations that must be considered when used in foods, produce harvesting, or food processing environments.

Alexander Sulakvelidze of Intralytix Inc. discussed various food safety-related applications of phages, corresponding regulatory strategies, pitfalls in commercialization, labeling requirements, and issues regarding kosher, halal, and organic certification.

Andy Senecal of the U.S. Army Natick Soldier RD&E Center described results of a study investigating the use of lytic phage cocktails and a levulinic acid produce wash for their effectiveness against pathogens on broccoli, cantaloupe, and strawberries. Inoculated samples were treated with a phage cocktail prior to storage, a levulinic acid produce wash after storage, or a combination before or after storage and compared to a chlorine wash of 200 ppm of free available chlorine. He found that the combination of phage cocktails with commercial produce wash was very effective for treating produce contaminated with E. coli O157:H7, Shigella spp., and Salmonella spp. even in the presence of elevated organic loads.

Mansel W. Griffiths of the University of Guelph, Canada, discussed the use of immobilized phage for biocontrol of E. coli O157:H7 on raw meat, L. monocytogenes in ready-to-eat meat and cantaloupes, E. coli O104 in alfalfa seeds/sprouts, and Vibrio spp. in mussels and concluded that phages represent a specific, effective, and environmentally friendly way to control and detect foodborne bacterial pathogens to produce safer food.

Nitin Nitin of the University of California, Davis, discussed integration of nanoscale phages with food packaging materials to develop highly specific antimicrobial packaging solutions.

Erica Vonasek of the University of California, Davis, described results of a study to develop food-grade formulations for encapsulation and controlled release of phages on fresh fruit and vegetables. Films and dip coatings using whey protein were used to form a bacterial pathogen-specific antimicrobial packaging material, and the results showed that encapsulated phages can be released upon contact with food material and maintain activity for an extended period of time.

Koji Yamazaki of Hokkaido University in Japan described the isolation and preliminary characterization of a phage active against Morganella morganii, which is one of the most important histamine producers and is responsible for histamine accumulation during storage of fish products.

Nadeeka Bandara of Chonbuk National University in South Korea said that rice straw, a well-known niche for microorganisms used to produce traditionally fermented soybean foods in Korea, contains harmful microorganisms such as Bacillus cereus and described the development of a B. cereus-specific phage that could be used to prepare a rice straw-based B. cereus-free starter culture without destroying its naturally existing bacterial community and properties.

Neil H. Mermelstein, a Fellow of IFT, is Editor

Neil H. Mermelstein, a Fellow of IFT, is Editor

Emeritus of Food Technology

[email protected]