Exploring Extrusion

PROCESSING

Extrusion as a food process technology is still relatively young, but also mature in the sense that it is well established in a number of areas. Years ago, when Quaker Oats was trying to catch up in ready-to-eat breakfast cereals by using extrusion to replace several traditional unit operations, the company could not find extruders designed for the sanitation requirements of foods. Instead, according to Elwood Caldwell, author of Breakfast Cereals and How They Are Made, 2nd ed. (American Association of Cereal Chemists, 2000), the company had to use extruders designed for polymers. Today there are extruders specifically designed for use in pet foods and human foods including breakfast cereals, snacks, and ingredients.

Extrusion as a food process technology is still relatively young, but also mature in the sense that it is well established in a number of areas. Years ago, when Quaker Oats was trying to catch up in ready-to-eat breakfast cereals by using extrusion to replace several traditional unit operations, the company could not find extruders designed for the sanitation requirements of foods. Instead, according to Elwood Caldwell, author of Breakfast Cereals and How They Are Made, 2nd ed. (American Association of Cereal Chemists, 2000), the company had to use extruders designed for polymers. Today there are extruders specifically designed for use in pet foods and human foods including breakfast cereals, snacks, and ingredients.

What Is an Extruder?

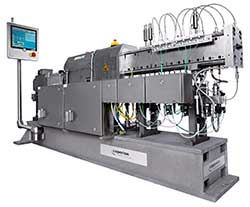

There are two main types of screw extruders and then some other equipment that may also be called an extruder. A screw extruder has a helical shaft inside a cylindrical barrel that is closed at one end by a die plate with holes of various shapes drilled through it. The shaft or screw is rotated by an electric motor. The barrel may be jacketed or not, and sections may be heated or cooled. At least one model is heated electrically.

If there is one shaft in one barrel, the machine is called a single-screw extruder. A more complex device has two shafts inside a double barrel that looks like a figure eight when seen end on. The two screws may intermesh or not and may rotate in the same direction or not. These are called twin-screw extruders.

Both types have a feed hopper, which may include some type of metering device to control feed rate. Either type of extruder may have a preconditioner, which is another cylinder with a conveying screw in which feed material may be partially cooked and hydrated before being fed to the extruder proper.

The die plate typically has inserts with the precise cross-sectional shape desired machined into the inserts. With such inserts, the same plate can be used for various shapes.

In operation, the extruder acts as a mixer, heat exchanger, pump, and former, replacing separate operations and equipment with one unit. Typical feed materials include cereal grits, flour, protein meals, and whole grains. In the presence of heat and moisture, carbohydrates, such as cereal starches, gelatinize and swell to form doughs or pastes. Protein materials may denature and solubilize.

Material Properties in Extrusion

Describing quantitatively the flow of material in an extruder is challenging for many reasons. The rheological properties of food materials are rarely well known, and they are typically non-Newtonian fluids. Further, the temperature, shear rates, and pressures within the extruder barrel are changing in complex ways. It is somewhat easier to describe qualitatively what seems to be occurring.

In polymer processing, some materials are thermoplastic, meaning they get softer and thinner as temperature increases. They may also become less viscous as shear or force is applied. Other materials, known as thermosetting, behave exactly opposite: they become thicker and less fluid as temperature increases, often because they are reacting. Polyolefins, such as polyethylene and polypropylene, are thermoplastics. Polyesters and polystyrene are thermosetting, though polyesters may soften on heating.

Common foods that are extruded may be considered somewhat analogous to some polymers. For instance, carbohydrates, such as moistened corn grits, act a little like thermoplastics and “melt” when they are heated, becoming a little less viscous. Proteins, such as moistened soy meal, act more like thermosetting polymers, becoming thicker and more viscous as they are heated. Now what happens when one mixes the two? Good luck predicting that.Mixtures are fairly common in extrusion, especially for such products as pet foods and fortified porridges. Many snacks and breakfast cereals are based on a single major ingredient, such as corn or rice.

As these strangely behaving doughs or pastes are transported through the barrel by the screw’s rotation, they are heated by friction, at least, but may also be heated by direct steam injection and by heat transfer through the barrel wall and through a hollow screw in some cases. To control temperature, cooling may be applied through the barrel and screw.

Often, the objective is to thoroughly cook the mixture to make it soluble, digestible, and safe from pathogens. Temperatures may exceed the boiling point of water at atmospheric pressure because of pressure increase in the barrel. Shear forces may increase temperature and contribute in their own way to modifying properties of the material.

To increase shear, there can be sections of the screw that simply knead the material without attempting to transport it. To allow for such sections, many screws are modular, composed of short sections that can have different screw profiles, including reverse sections that contribute to back mixing. Screws typically are deeper and have a wider pitch—the distance between flights—at the feed end of the barrel because the bulk density of the feed material is typically lower than it is after it has been heated and compressed. Screw design is an empirical art. Any given machine usually has a selection of screw modules that can be assembled in various configurations to achieve the desired effects.

--- PAGE BREAK ---

Pumping Characteristics of Extruders

Pumping Characteristics of Extruders

Screw extruders can be compared to conventional pumps in their performance. A single-screw extruder behaves like a centrifugal pump while a twin-screw extruder behaves more like a positive displacement pump. What does that mean?

A centrifugal pump has a characteristic performance curve for a given design that generally shows output pressure decreasing as flow rate increases. A centrifugal pump can operate against a closed output line or dead head. The pressure generated under this condition is the maximum it can provide. When a centrifugal pump is delivering against no resistance—nothing connected to it—it delivers the maximum flow rate. Between these two extreme points, there is a unique set of points characteristic of the pump’s specific design.

In contrast, a positive displacement pump is not sensitive to the pressure against which it delivers, so its characteristic curve is a horizontal line of pressure against flow rate. For any flow rate, it will deliver whatever pressure is required up to some limit that is typically set by some other feature, such as pressure limits of seals, gaskets, or piping connections. For this reason, positive displacement pumps must be protected against a dead head, usually by having a relief valve or bypass loop.

Continuing the analogy, the resistance against which extruders are pumping is the die plate. The pressure required to move a fluid through a small hole is proportional to the apparent viscosity of the fluid, the length of the hole (thickness of the plate), the flow rate, and the cross-sectional area of the hole. On a plot of pressure against flow rate, this produces a generally straight line with a positive slope—the line rises as the flow rate increases, all other factors being equal. This line corresponds to the pressure drop against flow rate curve of a piping valve system to which a pump may be connected.

When the single-screw performance curve and the die plate line are plotted on the same graph, the lines intersect at one point, which is the operating point for a single-screw extruder. Any change that causes deviation from this point may cause an upset in operation. One of the most sensitive such changes is to the apparent viscosity, which, as mentioned, is difficult to define. However, for foods, it is sensitive to moisture content, so one key to stable operation of an extruder is to control the moisture content of the feed. That is one function of the preconditioner.

Single-screw extruders are typically flood fed, meaning they are kept full. Flow rate may be controlled by adjusting rotational speed. The most reliable scale-up parameter is specific mechanical energy, so long as geometric similarity is maintained. That means, for instance, that length divided by diameter is constant when diameter is increased, and that screw design is kept constant.

Twin-screw extruders were developed in polymer processing to handle slippery polymers such as polyvinyl chloride. Intermeshing screws can grip elusive feed materials whereas a single-screw relies somewhat on a sticky feed. (Twin screws that are not intermeshing behave more like two single screws that just happen to share a barrel.) Twin-screw extruders do not operate full, but rather flow rate is determined by controlling feed rate. Whatever pressure is needed to flow through a given die plate will be developed, within the limits of gaskets and fittings.

An attribute of twin-screw extruders that is not always used is the potential ability to handle drier feeds, reducing the water removal requirements that typically follow extruders.

Most cooking extruders cause expansion of the material upon exiting the die as pressure is released and superheated water flashes into steam. This can make die design challenging because the non-Newtonian fluids may relieve strain in ways that distort shape in addition to the expansion.

J. Peter Clark, Ph.D., CFS,

J. Peter Clark, Ph.D., CFS,

Contributing Editor, Consultant to the Process Industries, Oak Park, Ill.

[email protected]