Packaging Quenches Thirst for Beverages

PACKAGING

Beverage packaging has quenched the convenience needs for generations of consumers. The availability of single-serve, foodservice, and concentrated beverages meets the need for safe, quality, and enhanced hydration while lowering the environmental impact of beverage packaging.

Single-Serve Beverages

Single-Serve Beverages

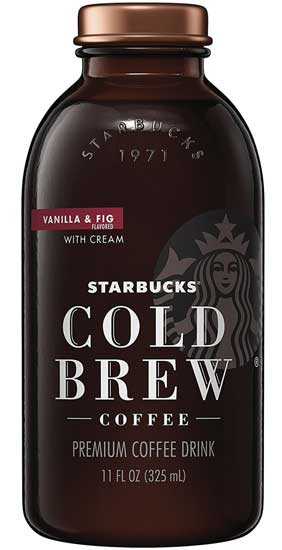

Hot and cold beverages commonly consumed in coffeehouses, tea shops, and restaurants are now available in ready-to-drink (RTD) single-serve cups purchased outside of these venues. This extends a brand’s image into the plethora of locations where portable beverages can be consumed. RTD foodservice-branded packaging seeks to provide an experience that strengthens the loyalty of consumers to the foodservice venue. For example, Starbucks and Caribou RTD beverages feature glass bottles with brand graphics on a shrink sleeve or pressure-sensitive label and steel cap with the logo. The images of these RTD products are maintained by high-quality branded graphics.

RTD coffee is increasingly available in aluminum cans. Aluminum cans offer a multitude of size options, high-quality printed graphics, optimal temperature ranges, high rates of recycling, and micro-copackaging operations. High-quality graphics printed using flexographic printing has improved to allow detailed explanation of can contents in high resolution. With certain products, this is a distinct advantage. Cans featuring a lot of text have a presence in the alternative beverage market. For example, to explain unique features, the high-resolution graphics appear on cans of Heineken Lagunitas Hi-Fi Hops hop-infused sparkling water and Two Roots nonalcoholic hop-infused beer. Aluminum also allows for beverages to be maintained at optimal drinking temperatures. HotShot beverages come in aluminum cans containing coffee extract and water in a 140°F HotBox for optimal temperature experience. The combined aluminum can package and HotBox unit allows for drop-in hot beverage solutions at convenience stores and at concessionaires. Such packaging also enables the sale of drop-in chilled beverages. Chill Can employs carbon dioxide to lower product temperature 30 degrees in 90 seconds. The 7-Eleven Fizzics brand of beverages comes in this self-chilling can that cools beverages when the plastic base of the can is twisted.

Aluminum cans have high recyclability because they are easy to collect and sort. Their high recyclability has fueled a circular economy for post-consumer use of recycled aluminum bottles and cans. In the United States, the rate of aluminum can recycling reached 64% in 2016, and because the aluminum cans have been light-weighted, the number of cans per pound has increased from 34 to 35 between 2006 and 2016. In Europe, recycling rates are at 70%. Production of cans made from recycled aluminum reduces greenhouse gases by 95% compared to production of cans made from virgin bauxite, which do not have recycled content. Rapid market entry is facilitated by an abundance of copackers that can package beverages for entrepreneurs. MetaBrand offers copacking for various beverage cans for rapid market entry.

Recyclable polyethylene terephthalate (PET) beverage bottles are common in single-use beverage packaging. However, their use is being reassessed due to environmental issues associated with poor recycling rates and the low use of recycled PET. New directions have taken the form of changing materials, considering reusable structures and design, and increasing the ease of recycling and use of recycled content to drive the economic value of recycled PET content. A focus on collection and sorting to enable cost-effective recycling and reuse is needed. Consumers recycled only half of the 480 billion plastic bottles purchased last year. The remaining bottles are in landfills or in oceans and on roadsides. If the level of plastic bottle recycling increased to that of aluminum cans, considerably less damage would be inflicted on the earth. Currently, 7% of PET bottles are recycled into new beverage bottles; this is expected to increase due to industry targets.

Evian is targeting 2025 as the year to achieve 100% recycled content plastic in its beverage packaging. By 2030, Coke PET bottles are slated to contain about 50% recycled content. Pepsi set a goal to have all packaging recyclable or reusable by 2025. Increased design for ease of recycling and reuse by facilitating the separation of packaging components is much needed. For example, a paperboard outer structure to provide product support can be designed for separation from an inner bag that provides a barrier. The Sustainable Packaging Coalition’s How2Recycle label directs the separation of packaging labels, caps, and tearaway rings and with clear instructions on how these package components can be recycled. More sustainable beverage packaging involves product considerations as well. As part of a sustainable solution, drinkable high-pressure processed fruit and vegetable juices reduce food waste associated with spoiled produce and provide convenient, healthful options to consumers. Packaging in the drinkable produce market focuses on transparency. The packaging for Evolution Fresh’s cold-pressed juices and smoothies features a clear 11-ounce PET bottle.

Foodservice Beverages

Even though waste from foodservice packaging represents less than 1% of packaging waste, it is more prone to being littered by consumers. This type of visible litter has prompted changes in beverage cups and drinking straws. Packaging for foodservice beverages, which has traditionally used polystyrene (PS) foam, polypropylene (PP), and coated paperboard, now also uses PET and polylactic acid (PLA) for beverage cups. Reusable cups are moving into the forefront as well with foodservice operations offering discounts on coffee when consumers bring reusable cups. This helps reduce the estimated 600 billion disposable cups generated each year. Increased use of PET is driven by its clarity and high rates of recycling. The use of PLA beverage cups has increased as composting interest and legislation have intensified despite the poor availability of industrial compost facilities. The Closed Loop Partners’ Center for the Circular Economy and Starbucks challenge to develop a compostable cup capable of resisting moisture while in contact with hot beverages is expected to move this field forward.

Until infrastructure for composting is more widespread, use of compostable beverage packaging is more viable only in defined environments and venues. For example, many university campuses and large sporting and music venues reduce food and packaging waste to zero, and collection and proper composting or recycling of packaging is tightly controlled to achieve this zero-waste goal. The use of paperboard with recycled content in contact with hot beverages has grown with tighter chains of custody for paperboard recycling and the use of low levels of functional barriers that can mix with paperboard recycling streams. Since paperboard that has been in contact with food cannot be sterilized, recycled paperboard is not suitable for most direct food contact. Ensuring a solid chain of custody in the use of recycled paperboard that has not had prior food contact is paramount to enable beverage cups made with recycled paperboard. This chain of custody is often not economically viable, and this reduces the availability of recycled paperboard that is not part of a contaminated waste stream. One option to increase the viability of using recycled paperboard for beverage cups is designing a functional barrier that can sustain its integrity between recycled content paperboard and beverages. Starbucks employs 10% recycled content cups for hot beverages by employing a polymer layer between the beverage and paperboard.

Maintaining the optimal temperature within packaging for foodservice beverages often requires air pockets for insulation. For example, PS foam or corrugated layers in the form of sleeves or integrated layers on the outside of cups provide insulation. PS cups are often used for large convenience store beverages to ensure they remain cold with minimal condensation outside the cup during hot months of the year. Consumers can purchase a 64-ounce fountain soda within a PS foam cup that maintains insulating capacity for two to three hours in 90-degree heat. But PS foam cups are not recyclable in most municipalities. Dunkin’ Donuts and other foodservice establishments have declared 2020 as their deadline for switching from PS to an alternative structure. Paperboard corrugated sleeves for beverage cups can be reused and recycled; they also protect hands from the heat emanating from hot beverages.

The littering associated with polyethylene (PE) and PP drinking straws has led to the reduced provision of drinking straws at foodservice establishments. The view of paperboard straws being more sustainable has prompted conversions from PE and PP straws to paperboard. These paperboard straws will face the same issues with recyclability as other food-contact paper-based packaging as well as the same collection and littering dilemmas. Information on degradation of the paper-based straws within ocean environments is not currently known. McDonald’s and other quick-service restaurants will begin converting to paperboard drinking straws in fall 2018.

Beverage Concentrates

Beverage Concentrates

Beverage concentrates provide consumers with the ability to personalize their beverages while being compatible with existing high-speed production lines at beverage packaging facilities. Concentrates in powdered or liquid form can add flavor or nutrients to various drinks. Packaging of these concentrates protects nutrients from degradation and the migration of flavors through packaging. The Nescafé foil-based single-serve tube contains coffee, creamer, and flavor in a powder. Coffee pods for Nespresso or Keurig machines are made of aluminum, PP, or compostable structures. Mio liquid water enhancers come inside high-density PE bottles with PP caps. In grocery outlets, powdered mixes containing coffee blend formulas into which consumers add hot water are available in paperboard cups. For example, Nescafe powdered drinks are sold in grocery stores within a sealed paperboard-based cup with a lid for drinking on the go.

Claire Koelsch Sand, PhD, Contributing Editor

Claire Koelsch Sand, PhD, Contributing Editor

CEO, Packaging Technology and Research

Adjunct Professor, Michigan State Univ. and

California Polytechnic State Univ.

[email protected]