A Classic Resurges: Glass

PACKAGING

Within the food and beverage industry, 75% of glass packaging is for beverages, and glass packaging for food is undergoing a resurgence. The inherent safety of glass, design innovations, and recyclability and refilling of glass are reasons why food companies are taking a fresh look at glass as a packaging option.

Glass Is GRAS

Although packaging is considered an indirect food additive, glass packaging is generally recognized as safe (GRAS) and exempt from the food additive tolerance requirements of the Federal Food, Drug, and Cosmetic Act. In addition, glass is nonporous and impermeable for the typical time period of use within the food and beverage industries, so migration testing associated with other packaging materials is not required for glass packaging. However, Current Good Manufacturing Practices, Hazard Analysis, and Risk-Based Preventive Controls for Human Food in title 21 of the Code of Federal Regulations applies to glass. Glass containers are used to avoid flavor and odor scalping with high flavor–profile foods such as vanilla, peppermint, and saffron as well as with products that are oxygen sensitive. This is because the chemical interaction between glass and foods and water vapor and oxygen barrier properties are considered to be zero for the life of most food products. Glass is also readily sterilizable when reused or recycled.

The Image of Glass Design

Scott DeFife, president of the Glass Packaging Institute, shares what he sees as renewed interest in glass packaging: “The consumer connection between packaging and food is advancing rapidly. This represents an opportunity for brands to more clearly employ packaging that more closely aligns with the brand of the food within the package. Furthermore, increasingly, brand owners are using glass to convey a healthy, sustainable, and premium product image. There is much inertia fueling creative glass design.” For example, Oui yogurt by General Mills uses a distinctive glass container to set it apart from other yogurt products.

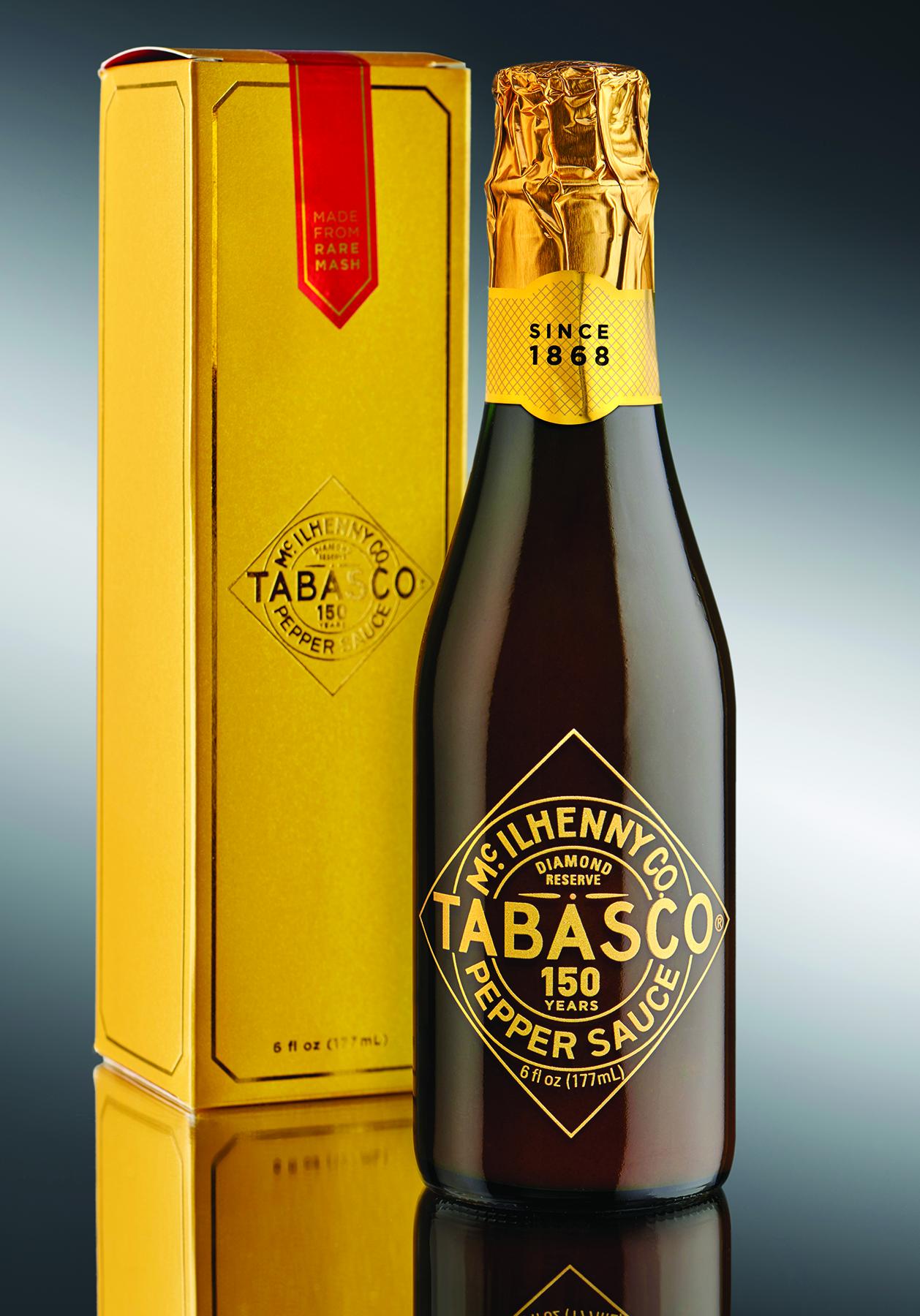

The Clear Choice Awards recognize the abundance of creative design options for glass. TABASCO Diamond Reserve Pepper Sauce by McIlhenny Co. won a Clear Choice Award in the food category in 2018. For McIlhenny’s award-winning product, glass supplier Ardagh Group developed a complementary unique glass bottle highlighted with a gold label and foil seal. Recent innovations such as charcoal- colored glass, raised images, and embossing create a distinctive look. For example, Gruppo Campari and the Owens-Illinois (O-I) glass company employed raised print on the Wild Turkey Longbranch glass bottle, and the O-I EXPRESSIONS RELIEF facilitates digitally embossing of designs and personalization.

To reduce the incidence of glass breakage during distribution and bottle filling, various design tactics are integral. The low-impact strength and thermal shock resistance of glass containers can be mitigated with proper design of the glass container, secondary and tertiary packaging, and management of bottle-filling operations. The inherent low-impact strength of glass requires secondary and tertiary packaging to protect the glass from impact-related distribution hazards such as forklifts and high drop heights. Despite their low-impact strength, glass containers have high compression strength, which means that glass supports the weight of a product and secondary packaging. Optimal container design focuses on many areas such as the shoulder, the area between the top of the bottle and the bottle sidewalls, and the radius (which is maximized to dissipate the stress). Glass corrugated cases serve to reduce impact strength but provide limited support for the actual glass. It is not uncommon to see glass pallets stacked up to five levels high in warehouses with lower cases of glass supporting the entire load.

When glass is a primary package, the need for secondary packaging and tertiary packaging is often less than with other packaging materials. For example, when food in glass is shipped by the pallet load, outer corrugated cases are replaced by dividers between the body contact areas of glass bottles and chipboard sheets between the layers of glass. Alternatively, trays ready for on-shelf display at grocery stores have replaced many of the corrugated cases that entirely enrobe glass containers. This package system relies on the compressive strength of glass and accommodates the low-impact strength of glass while providing storage flexibility and added capacity. Preheating, uniform wall thickness, and large radii of glass containers reduce thermal shock associated with hot-filling glass containers. The abrasion of high-speed filling operations is reduced by having specific container contact points, lubricating coatings, and knurling ridges at the container base.

Glass Recycling Is Essential

About 70% of glass is 0% silica, and 15% of glass is stabilizing oxides of calcium and aluminum oxide and sodium and potassium oxide. Material costs represent 50% of the cost of glass manufacturing. Each glass container is made from about 30% recycled glass that is called cullet, which is required to seed the formation of the chemical structure of glass and reduces carbon dioxide emission by about 15% and reduces material costs. Because of its high recycled content, glass is often used as a means to achieve sustainability goals related to recycling. Notably, Vetropack glass company has used 83% cullet in glass containers, which is a record amount. Obtaining cullet is a challenge, but it can be addressed with improved collection and sorting and attaching economic value to used glass containers. The glass recycling rate in the European Union is 75%, with Sweden at 95%, while recycling rates in China and the United States are highly variable and low with an average of about 33%. The variation in recycling rates is primarily due to factors relating to the contamination of recyclables

during collection and the economic incentives to recycle. Commingling recyclable glass bottles and jars with other packaging enables a high degree of contamination just as it does for other recyclable packaging. For example, in commingled recycling collection systems, broken glass frequently is embedded within corrugated board. This process contaminates the board as well as reduces the likelihood of the glass being recycled. For curbside pickup, collecting, sorting, and subsequent handling by material recovery centers results in 15% less packaging being recycled than if consumers sort recyclable packaging. In areas where recycling is not commingled and sorted before collection, glass recycling rates are close to 90%. “We want that glass back [in] our glass plants rather than glass needlessly ending up in the landfills!” DeFife exclaims. “Because of this, the Glass Packaging Institute is working to reduce contamination issues that will benefit paperboard, polymer, and metal recycling as well as glass.” Another means to increase recycling is to attach economic value to postconsumer glass, which has worked in the past. Deposits for glass containers increase recycling rates, reduce contamination, and fund glass-handling. For example, 75% of the funds gathered in the Michigan Beverage Container Act of 1976 fund the State Cleanup and Redevelopment Trust Fund, and 25% of that fund is used to compensate retailers who handle bottle returns.

Returnable Glass Is Back

Global legislation to ban single-use packaging and the increased urbanization and satellite processing of finished goods are factors that are increasing the feasibility of refillable glass containers for food. Recently proposed bottle bills have incorporated guidelines for returnable glass packaging. Refilling glass containers avoids energy costs associated with glass manufacturing. To manufacture a glass container, blended ingredients are melted at about 2900°F, then conditioned at 2300°F, and formed; finished containers are cooled to facilitate annealing. Refilling glass containers saves the energy of remaking glass containers with recycled glass. Refillable glass containers were once more common for beverages. In urban environments that may not have glass manufacturing facilities nearby, refilling glass within a short distance has a more favorable life cycle analysis than shipping glass far away for recycling after each use. Likewise, refilling stations near major urban areas reduce the energy impact associated with transit from food manufacturers to consumers. Products are increasingly finetuned and tailored at satellite processing facilities. This provides an avenue for glass containers to be sterilized and refilled. DeFife sees several states and municipalities studying reuse and refillable models to increase the use of glass. For example, the Oregon Beverage Recycling Cooperative and O-I created the BottleDrop refillable glass bottle that seven Oregon breweries now use; the glass bottle is in compliance with the first statewide refillable bottle system. Notably, the words “refillable, please return” are on the shoulder and base of the BottleDrop glass bottle to increase consumer awareness and facilitate more rapid sorting. The bottle can be used 25 times and then recycled.