Reducing Food Waste via Active Packaging

Waste from packaged food exacts a substantial environmental toll, but turning to sustainable new technologies has the potential to lessen its carbon footprint.

Article Content

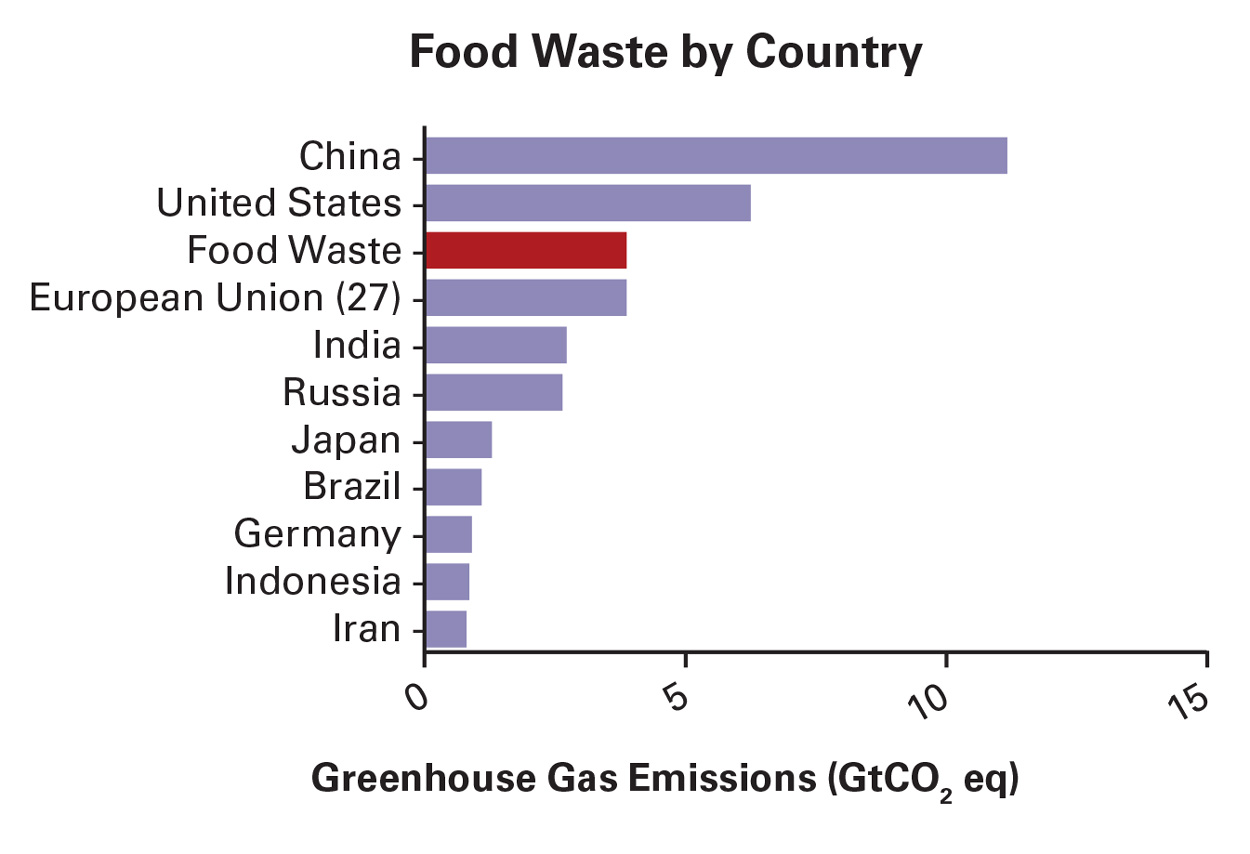

According to the Food and Agriculture Organization (FAO) of the United Nations, “[i]f food waste were a country, it would be the third largest emitting country in the world” behind only China and the United States (FAO 2015, Figure 1). Although consumers are increasingly aware of the environmental damage from polymeric (plastic) packaging, there remains a substantial, yet less visible, ecological impact of wasted food inside the packaging. Most recent estimates of global annual greenhouse gas emissions caused by food waste (4.4 GtCO2 eq) are greater than emissions from the transportation (1.9 GtCO2 eq) and electricity (1.8 GtCO2 eq) sectors combined in the United States alone (EPA 2020). Greenhouse gas emissions for food waste are estimated through life cycle assessment, which considers emissions at all stages of food production in proportion to global food waste.

Globally, about 1.3 billion metric tons of food is wasted annually along the farm to fork continuum, from agricultural production to consumer consumption (FAO 2013). Despite higher proportions of food waste occurring at both agricultural production and postharvest stages, consumer food waste accounts for almost 40% of the food system’s carbon footprint while contributing only 22% to the proportion of food wastage (FAO 2015). This discrepancy can be attributed to the compounding of greenhouse gas emissions from each of the previous processing stages (inclusive of transportation) into the final product. Therefore, food waste occurring during the processing, distribution, and consumption stages proves proportionally most costly in its effect on greenhouse gas production.

Mechanisms of Food Spoilage

Product formulations (including incorporation of additives) and unit operations in food processing (e.g., thermal or high-pressure treatment) are designed by food manufacturers not only for product flavor and texture, but importantly, to extend product and in turn reduce consumer-level food waste. When a food product is no longer fit for consumption due to changes in appearance or flavor, it is considered spoiled (Odeyemi et al. 2020). Degradation mechanisms of food spoilage often fit into three main categories: microbial, chemical, and physical, according to the primary mechanism of degradation.

Microbial spoilage occurs through the unintentional contamination and subsequent in-package growth of spoilage microorganisms, and the microbial breakdown of food components (e.g., by proteolytic or lipolytic enzymes). Unanticipated microbial growth can result in product flavor changes, off-putting aromas, and degradation of quality, leading to food waste (Blackburn 2006).

Unlike microbial spoilage, chemical and physical deterioration mechanisms are generally related to intrinsic factors that impact food quality. In even the simplest of foods, there is an intricate interplay between components and environments working with one another to influence final product characteristics. From extreme pH environments (citrus juices and fermented foods) to low water activity (breads and powders), as well as other influencers such as emulsifiers (soy lecithin), charged compounds (acids and bases, many emulsifiers), and bioactive agents (antioxidants and antimicrobials), the inherent complexity of food and beverage systems renders them in constant chemical flux, and they are thus in a state of constant instability, even in final packaged formulations. This instability causes chemical cascades where food components undergo a series of chemical reactions, including oxidation, hydrolysis, and enzymatic and nonenzymatic chemical changes, impacting food quality and shelf life. These deteriorative mechanisms can result in off-odors, nutritive loss, color changes, and textural changes that influence food waste (Subramaniam 2016).

Similarly, physical instability during harvesting or component phase changes upon storage, such as staling, moisture migration, or freezer damage, can lead to reduced quality and increased food waste. Manufacturers design processing operations to control food stability and extend preservation. Using unit operations like thermal preservation, chilling, microwave heating, high pressure processing, and ultraviolet treatments, food manufacturers aim to control degradation of crucial food components and prevent subsequent degradation and ultimate spoilage. In addition, and frequently in tandem, food formulations often include natural and/or synthetic food additives such as antioxidants, antimicrobials, and salts to act as preservation aids (Subramaniam 2016). Yet increasing consumer demand for “less processed” foods and reduced additive use demands a shift in the traditional “food preservation paradigm” to maintain shelf life, quality, and convenience, leaving manufacturers in search of innovative solutions for managing food spoilage and subsequent waste.

Packaging’s Role in Food Preservation

Another aspect of food preservation (arguably the final unit operation in food manufacturing) is food packaging. Whether using glass, metal, paper, plastic, or a combination of materials, the design of primary packaging (i.e., that which contacts the food/beverage) considers the protective, informative, and marketing needs of specific food products to limit food waste (Robertson 2006). At the distribution level, secondary packaging materials are designed to protect products during transport from manufacturers to consumers and allow for efficient product distribution. Inefficient transportation systems can lead to increased losses and inflation of the product’s carbon footprint. Packaging systems also prevent spoilage by acting as a barrier between outside influences—including environmental effects such as light, oxygen, temperature, humidity, and mechanical damage—during product movement while limiting intrinsic deterioration factors. Furthermore, packaging provides information to consumers about product contents, nutrition, and handling to ensure informed use by consumers, thereby decreasing food spoilage. Due to the increased globalization of the food supply, food and beverage products are traveling farther distances and being stored for longer amounts of time at varying (often extreme) temperatures, adding further demands on food packaging.

Active packaging has been defined as packaging that can “extend shelf life or improve safety or sensory properties while maintaining the quality of the food” (Vermeiren et al. 1999), a definition that can be extended beyond food and beverage packaging to other consumer goods as well. This emerging technology builds upon the concept of traditional packaging by introducing additional functionality to packaged products, tailoring its method of action in accordance to its protective function and product needs beyond simply containment, protection, and communication to limit deteriorative processes. Active packaging thus offers a new approach to reducing food waste and loss in an era of reduced processing, reduced additives, and increasing supply chain demands, while maintaining current manufacturing schemes (Sand 2020).

One category of active packaging technology focuses on the removal of oxygen in the final product through the incorporation of oxidizable iron powder or oxygen-reducing enzymes as additives to base materials or included as sachets. Limiting oxygen can help slow the deterioration and extend the usability of the final product by decreasing the growth of aerobic spoilage microorganisms, restricting the oxygenic breakdown of nutrients and color, and controlling the onset of oxidation. Oxygen-scavenging packaging provides an economical alternative to vacuum or modified atmosphere packaging and can thus improve product profitability.

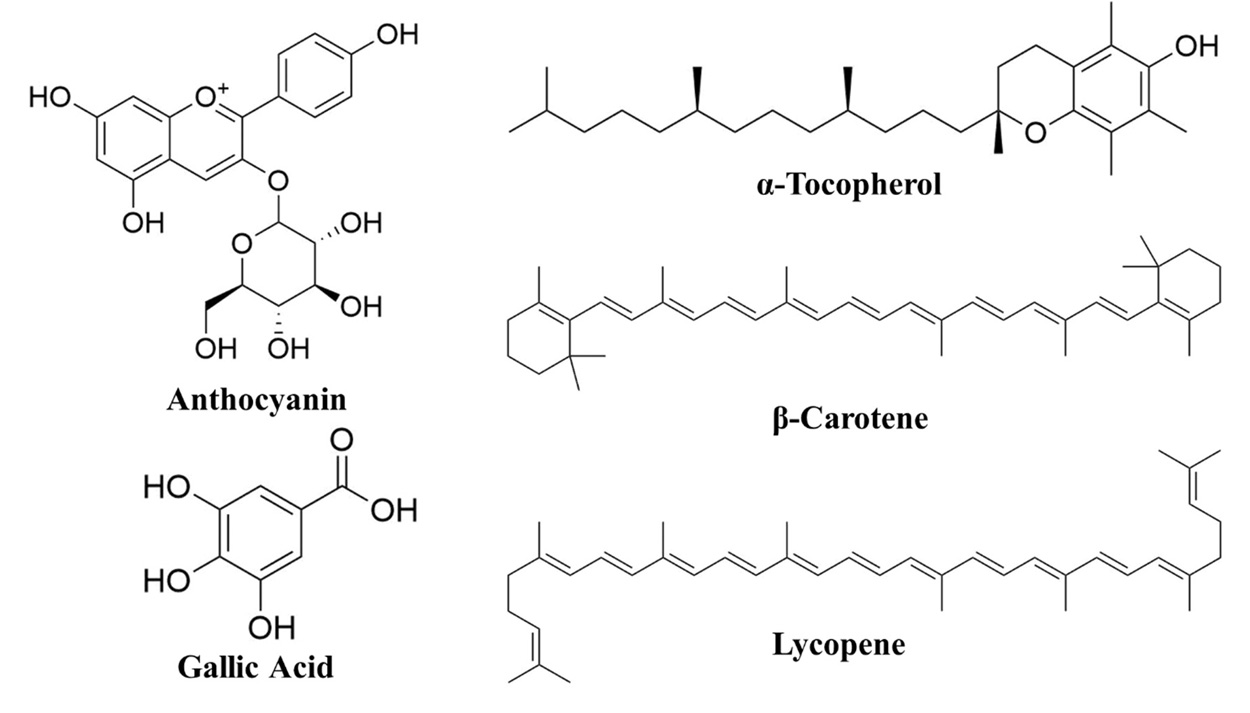

Another active packaging approach to limiting oxidation is through the inclusion of natural and synthetic antioxidants in base materials. Antioxidants are used to inhibit the oxidation of fats, nutrients, and color compounds in foods through the termination of degradative radicals formed under oxidative conditions or the removal of radical-forming (prooxidant) compounds. Natural antioxidants are largely found in fruits, vegetables, and herbs as electron-rich vitamins (vitamin C and vitamin E), coloring agents (carotenoids, flavonoids, and anthocyanins), as well as natural phenolic compounds (catechins and phenolic acids) that readily accept and stabilize free radicals (Figure 2). Similarly, artificial antioxidants such as BHA (butylated hydroxyanisole), BHT (butylated hydroxytoluene), and TBHQ (tert-butylhydroxyquinone) also inhibit oxidative degradation through phenolic radical quenching. Metal chelators are another class of antioxidants more recently explored for use in active packaging that prevent radical formation at the source by binding prooxidant metal species and eliminating radical development prior to oxidative degradation (Herskovitz and Goddard 2020, Tian et al. 2013). The inclusion of antioxidant and oxygen-scavenging compounds in active packaging, along with the elimination of oxygen in packaged products, helps to mitigate the effects of oxidation on the final product and prevent food spoilage.

The oxidation of food components is the second-largest contributor to food spoilage behind only microbial degradation, which accounted for about 25% of food spoilage postharvest and post-slaughter (Gram et al. 2002). Antimicrobial active packaging approaches have been researched, including the inclusion of sachets, blending of antimicrobial agents in the packaging material, internal coating of packaging materials, or the production of volatile antimicrobial agents within the package. Numerous antimicrobial compounds have been explored, including organic acids, parabens, natural antimicrobial polymers, antimicrobial proteins and enzymes, metals, fungicides, essential oils, and plant extracts, with the common goal of delaying or reducing the growth of spoilage microbes. Investigation into volatile antimicrobial packaging is limited, with major efforts focused on sulfur dioxide (for grapes), carbon dioxide, and volatile plant extracts, with specific emphasis on allyl isothiocyanate, the pungent compound found in mustard and horseradish.

A Novel Approach to ‘Cleaner Label’ Food Preservation

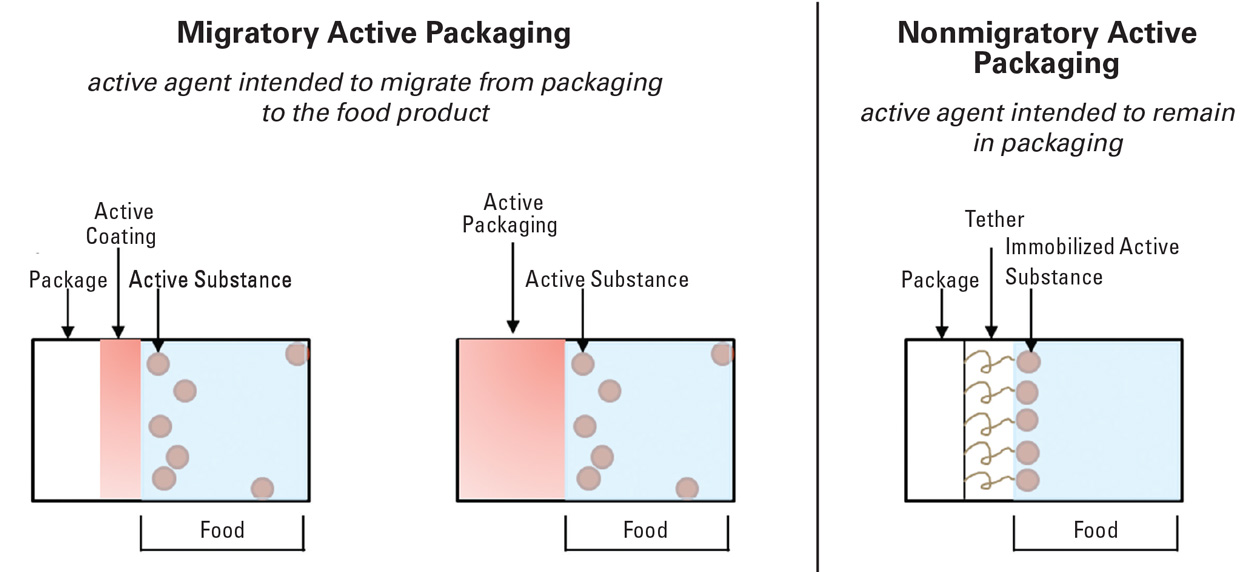

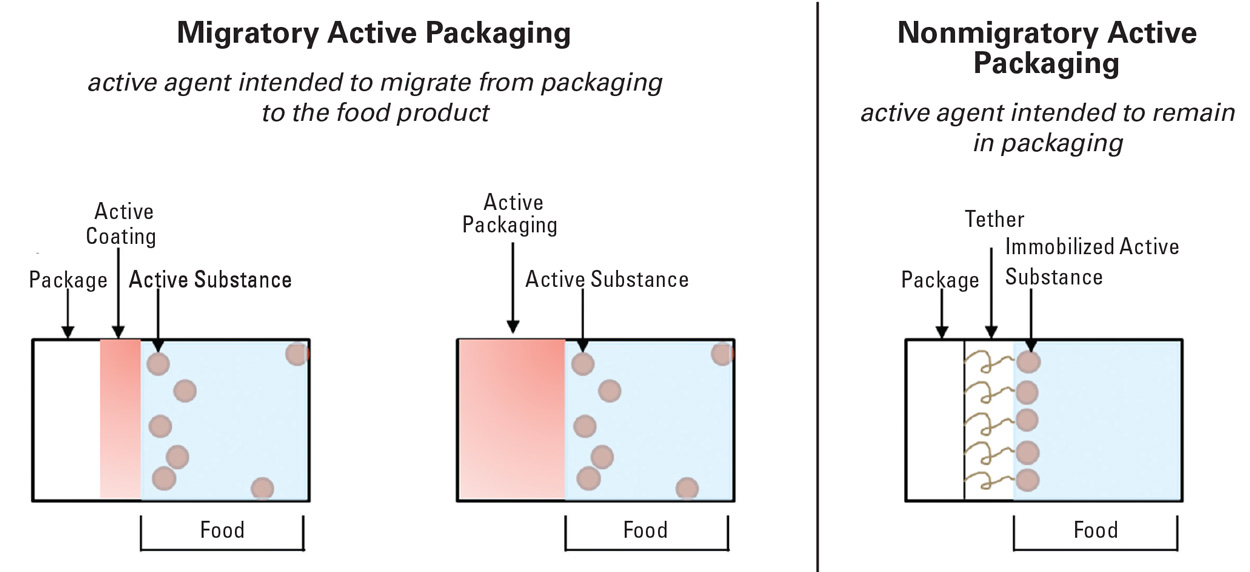

Other active packaging interventions exist focusing on limiting overripening of produce (ethylene scavenging), delaying staling in baked products (moisture migration), and reducing flavor scalping or loss. Whether the target application is antioxidant, antimicrobial, or other active packaging modalities, most active packaging approaches rely on the migration of incorporated additives to food products, necessitating their regulation as direct additives, a hefty hurdle for new compounds and contrary to the goal of “clean label” products. Nonmigratory active packaging seeks to overcome this hurdle through the covalent immobilization of active agents, retaining functionality without necessity of additive migration to the food product, meaning it would fall under the indirect additive classification and thus be regulated as a food contact material (Figure 3).

Research in nonmigratory active packaging has largely focused on the covalent immobilization of active agents onto material surfaces, either through multi-step (e.g., surface functionalization, linker attachment, and active agent immobilization) or single-step (e.g., application of prepared active copolymer coating) approaches on petroleum-based packaging materials. Many of these proof-of-principle technologies have shown success in retaining activity of active compounds after immobilization despite only interacting with food products at the food-surface interface (Lin and Goddard 2018, Roman et al. 2014).

Nevertheless, the current state-of-the-art in nonmigratory (and many migratory) active packaging technologies still presents technical hurdles that prevent widespread industrial adoption due to its technically complicated, time-consuming, and expensive method of preparation. More recently, nonmigratory active packaging technologies such as reactive extrusion and emulsion polymerization have been explored in an attempt for further widespread adoption and greener chemistry (Herskovitz and Goddard 2020).

Indeed, there exist a range of innovative active packaging technologies at varying stages of development that can potentially address converging challenges of reducing food waste and addressing demands for reduced additive use. Yet food waste is only part of the equation for improving sustainability in the packaged food system. In the United States, the two highest factors to landfilled waste are food (22%) and plastic (19%), respectively, meaning both the wasted food and also the plastic packaging that contains the food contribute to a significant environmental burden (EPA 2019)

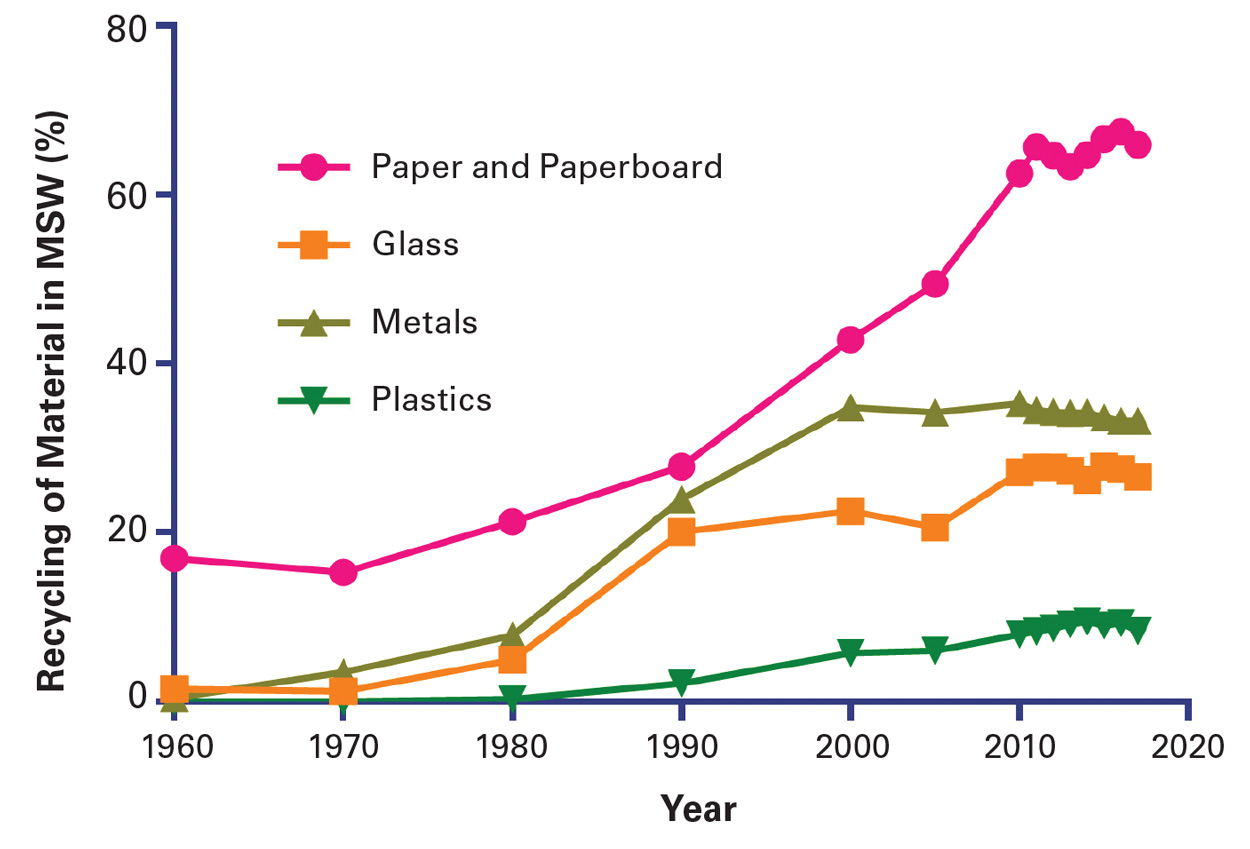

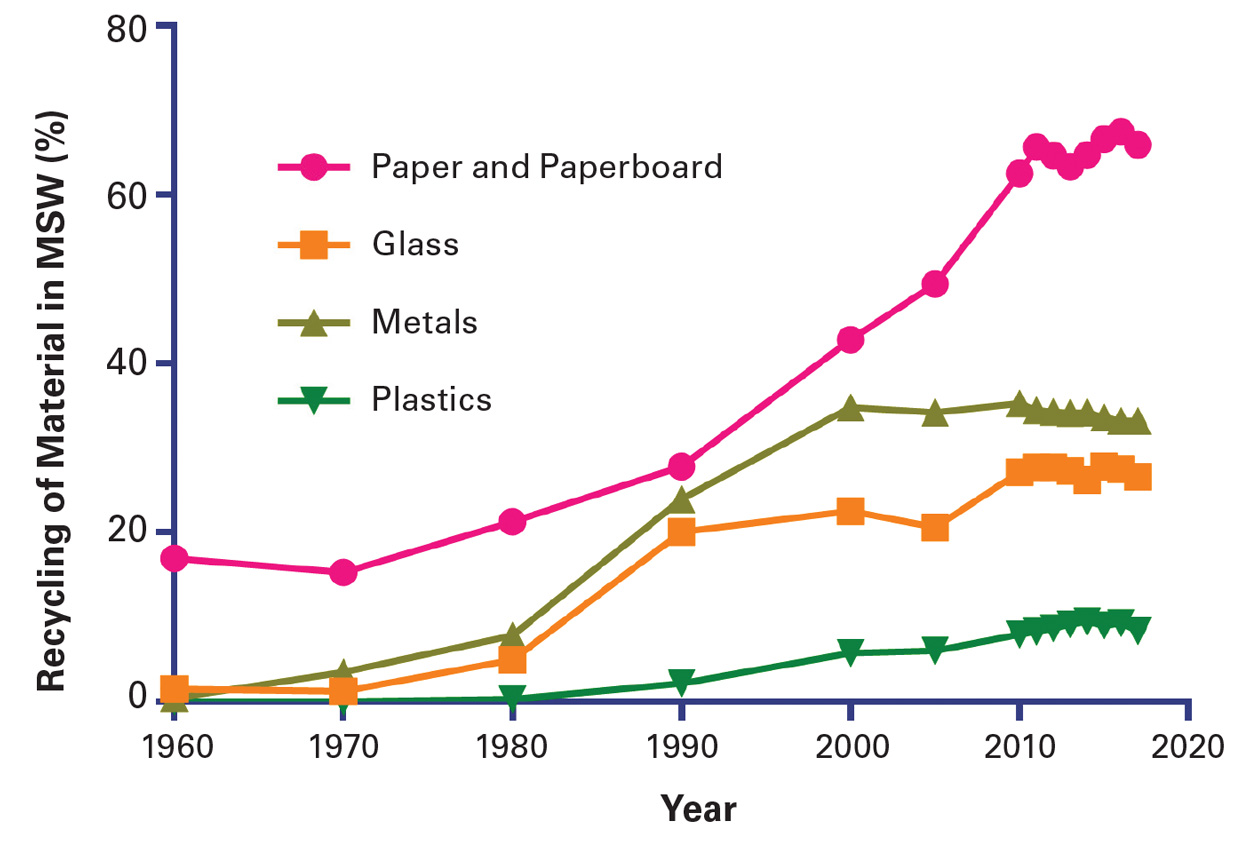

Some of the same reasons that make many petroleum-derived polymeric materials ideal for food packaging are the ones that make it problematic. Polymeric packaging materials are chosen for their inert nature (unlikely to interact with food components) and ability to keep structural integrity until disposal, but these characteristics also cause them either to be resistant to most degradation mechanisms or to require significant energy inputs to break them down (Geyer et al. 2017). This problem is only exacerbated by the many different polymer architectures of (often incompatible) plastic packaging materials used in the food packaging system, which, in concert with recent reports on the disruption of the plastics recycling market, often means it is more economically advantageous to landfill plastics than to recycle them (Hopewell et al. 2009, Figure 4).

Active Packaging Using Biomaterials

Expanding the use of biomaterials in packaging is one way in which product manufacturers attempt to overcome the increasing amount of petroleum-based polymeric packaging in our environment. Biomaterials are differentiated based on starting material (bio-based or petroleum-based) and end-of-life waste stream (biodegradable, recyclable, or strictly landfilled). Bio-based materials come from renewable feedstocks that can be utilized to make traditional polymers with recycling waste streams or biodegradable materials. Biodegradable packaging materials can be produced using either petroleum-based starting materials or bio-based feedstocks. In either case, advancements in bio-based and/or biodegradable materials technology are necessary as there currently exist no direct replacements for traditional petroleum-based packaging materials with sufficient properties (e.g., mechanical properties, gas transmission rates, processability). Examples of research approaches to improve these properties include adding processing aids (e.g., gums, starches, and nanoparticles) to biomaterials or blending multiple compatible biomaterials together with the goal of creating advantageous compatibilized blends, similar to plant genetic crossing, where beneficial properties are retained and deleterious ones are lost.

Nonmigratory active packaging technology produced using these enhanced bio-based biodegradable materials and using technologies scalable to industrially employed production lines represents the ultimate opportunity to improve the environmental impact of our packaged food and beverage system. Such an approach could help reduce global food waste, improve food delivery efficiency, lower greenhouse gas emissions, curb reliance on additives, and limit the environmental price of wasted packaging materials. Overall, developing a sustainable active packaging technology can reduce the growing environmental strain of packaged food products. Doing so would enable a more sustainable and closed-loop food system in which packaging provides more than traditional containment, protection, information, and convenience, but rather is an integral facet of a food’s safety, security, and sustainability from its manufacture to consumption.

REFERENCES

Blackburn, C. D. 2006. “Microbial Food Spoilage and Safety.” In Food Spoilage Microorganisms. Cambridge, England: Woodhead Publishing.

ClimateWatch. 2015. “Global Historical Emissions.” climatewatchdata.org.

EPA. 2019. Sustainable Materials Management (SMM)—Materials and Waste Management in the United States Key Facts and Figures.

EPA. 2019. Advancing Sustainable Materials Management: 2017 Fact Sheet.

EPA. 2020. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2018.

FAO. 2013. Food Wastage Footprint—Impacts on Natural Resources—Summary Report.

FAO. 2015. “Food Wastage Footprint & Climate Change.” Food Waste Footprint, 1–4.

Geyer, R., J. R. Jambeck, and K. L. Law. 2017. “Production, use, and fate of all plastics ever made.” Sci. Adv. 3(7).

Gram, L., L. Ravn, M. Rasch, et al. 2002. “Food spoilage—interactions between food spoilage bacteria.” Int. J. Food Microbiol. 78(1): 79–97.

Herskovitz, J. E. and J. M. Goddard. 2020. “Reactive Extrusion of Nonmigratory Antioxidant Poly(Iactic acid) Packaging.” J. Ag. Food Chem. 68(7): 2, 164–2, 173.

Hopewell, J., R. Dvorak and E. Kosior. 2009. “Plastics recycling: challenges and opportunities.” Philos. Trans. R. Soc. Lond. B. Biol. Sci. 364(1,526): 2, 115–2, 126.

Lin, Z. S. and J. Goddard. 2018. “Photo-Curable Metal-Chelating Coatings Offer a Scalable Approach to Production of Antioxidant Active Packaging.” J. Food Sci. 83(2): 367–376.

Odeyemi, O. A., O. O. Alegbeleye, M. Strateva, et al. 2020. “Understanding spoilage microbial community and spoilage mechanisms in foods of animal origin.” Comp. Rev. Food Sci. Food Saf. 19(2): 311–331.

Robertson, G. L. 2006. Food Packaging: Principles and Practice. New York: CRC Press.

Roman, M. J., F. Tian, E. A. Decker, et al. 2014. “Iron Chelating Polypropylene Films: Manipulating Photoinitiated Graft Polymerization to Tailor Chelating Activity.” J. Appl. Polym. Sci. 131(4).

Sand, C. K. 2020. “Active and Intelligent Packaging = Longer Shelf Life.” Food Technol. 74(4): 128–130.

Subramaniam, P. 2016. Stability and Shelf Life of Food, 2nd ed. Amsterdam: Woodhead Publishing.

Tian, F., E. A. Decker, and J. M. Goddard. 2013. “Controlling lipid oxidation of food by active packaging technologies.” Food Funct. 4(5): 669–680.

Vermeiren, L., F. Devlieghere, M. van Beest, et al. 1999. “Developments in the active packaging of foods.” Trends Food Sci. Technol. 10(3): 77–86.