Top Packaging Challenges: Getting It and Making It Count

Packaging | APPLIED SCIENCE

An array of challenges exists in the field of food packaging. Two—procurement and alignment with consumer needs—are top of mind. Procuring packaging that is required for food and environmental safety has become more complex due to supply chain disruption. As packaging costs continue to rise, packaging must make a valued connection to consumers. Solutions to both challenges demand more creative problem solving, increased agility, and cultivated expertise.

Getting It: Procurement

One of the impacts of stressed supply chains is the extended wait time in procuring packaging. This extended time impacts delivery dates of standard packaging and research and development (R&D) of packaging for new food product launches. For routine packaging procurement, developing a robust and resilient supply chain insulates the food business from volatility due to natural disasters, human strife, and dynamics such as power grid fluctuations. While working with trusted suppliers limits this risk, this is not always possible.

Due to supply chain disruptions, substitute packaging sources often are needed to procure packaging. These substitutions—in the form of coatings, adhesives, and thicknesses of layers—may occur throughout the supply chain of manufacturers and converters. In the past, qualifying multiple packaging suppliers for a package material allowed for resiliency in sourcing. However, it is imperative to ensure that final packaging converters and their converters have qualified substitutions and that these substitutions do not impact product attributes.

Tracking the chain of custody for all the materials used in the packaging, including additives, inks, and coatings, allows all supply chain risks to be more wholly determined. Another way to manage and assess risk is to perform stress tests within the entire packaging supply chain. This defines nodes in the supply chain that are at risk. For example, the loss of an adhesive source may prevent required lamination processes and result in substitution to meet timelines. Planning for this substitution reduces risk.

Increasingly, brands need to switch packaging materials and formats due to sourcing issues. Predicting shelf life and measuring shelf life in accelerated conditions, coupled with experiential knowledge—benchmarking competitors’ current product barriers, temperature, and humidity conditions and additional shelf life or product differences—allows for more rapid switching. In addition, package parameters and a solid knowledge of the mode of product deterioration need to be known. Packaging barriers to water and oxygen are needed to defend against the four modes of deterioration—water vapor loss/gain, lipid oxidation, microbial growth, and browning—in addition to flavor loss.

Package fraud also is a result of packaging procurement challenges. As with food fraud, economics drive package fraud, which threatens a food package’s primary function: to protect food. Fraudulent packaging can provide different migration rates, use of unapproved chemicals, and processing aids, all of which can affect shelf life and seal integrity. Package fraud can be deterred by developing a chain of custody for packaging components, for which the economics driving packaging fraud are high. For example, the substitution of virgin material for recycled or bioderived polymers happens when their prices exceed virgin polymers. Extra effort in confirming this supply minimizes the risk of package fraud occurring.

Known or unknown (fraudulent) switching of package materials also exposes another area—that of chemicals of concern (COCs). Chemicals such as inks and coatings on paperboard can migrate into food, hampering recycling, reuse, and composting efforts. More than 10,000 chemicals are approved for direct food contact based on a defined condition of use. So, a package suitable for food contact for one product type, such as hard candy, will not be acceptable for salad dressing. Packaging suppliers supply information based on approved use. It is best practice to verify that migration is not an issue for each product, especially if the package source is new and the chain of custody is not tight. Food-simulating liquids measure migration when packaging is in contact with the food.

Package Development Delays

Prototype and production tooling for new packaging are experiencing longer wait times. However, product launch deadlines are often not extended. Instead, creative problem-solving, adopting refined expertise in developing package options, and communicating added risks are used to meet launch timelines.

To meet R&D timelines, one solution is to employ a nonsequential research and development process. For example, R&D trials and factory acceptance tests (FATs) now provide the ability to assess numerous package options in a single trial versus allowing time to refine packaging between successive trials. This demands expertise in defining what options should be trialed versus relying on a sequence of trial results to fine-tune and define all package options in a single trial. Managing the risk of a suboptimal option is critical. To manage this, a phased-in approach is used to fine-tune packaging immediately after less-than-perfect packaging at launch.

Making It Count: Meeting Consumer Needs

The rising cost of packaging and the increased cost of food means that packaging must work harder to add brand and consumer value and maintain food safety. Adding value with a packaging investment needs to connect in a meaningful way with consumers and retailers to drive sales and pay off on the investment. For example, front-of-house (FOH) packaging that extends the shelf life of food in a display case reduces out-of-stocks (OOS), the economic loss of food waste, and labor in rotating and checking on products. In this scenario, a packaging solution needs to increase product shelf life for a meaningful amount of time. This varies by product and venue. A 20-minute extension is worthy of additional packaging investment for hamburgers at a QSR but not for a fruit salad sold in a grocery store. With this time parameter firmly established by product type, packaging solutions that meet this need are developed and weighed against the economics of OOS, food waste, and labor.

Likewise, for retailers and brands, packaging has intense value if it resonates with consumers. The process of price-pack architecture involves a rational conjoint analysis to define what package elements drive consumer purchase intent. Essentially, the connection between packaging investment and consumer needs is critical. In many cases, packaging options are assessed before evaluating whether the solutions the options provide have meaning to consumers. For example, in a recent survey, consumers ranked closure solutions and liked the flip top closure used by the category leader best. However, when asked in the qualitative section of the research it became apparent that switching to a flip top closure will not drive more consumers to purchase the product or in greater frequency than the current closure. Instead, consumers explained they needed additional shelf life after opening.

This led to a more thoughtful approach designed to connect with consumers. The final solution was visible to consumers on the label claim, which communicated the product would continue to be fresh 25% longer after opening. Yet, the double shelf life after opening the solution—an oxygen-absorbing layer in the bottle and the closure liner—was invisible to consumers. Identifying what is critical to consumers is vital in determining where package investment dollars should be spent. In this case, the addition of an innovative flip closure was well-ranked but did not reduce consumer food waste and did not connect with consumers.

As consumer food prices increase, brands that meet the consumer need for packaging that allows for less food waste are imprinting on consumers. Implementing food waste reduction packaging solutions allows brands to connect with consumers in a meaningful manner. The outdated reasoning was that food sales decline if consumers waste less food. The new approach is that consumers value brands that result in their wasting less food. Further, for brands and retailers to meet food waste reduction targets, consumer-derived food waste must be addressed with packaging. In terms of food waste, packaging solutions that increase food shelf life are best valorized and then ranked.

Slack-Fill Frustration

The presence of slack-fill continues to cause consumer frustration. As the wave of anti-packaging continues to crest, communicating the functions of packaging to consumers aligns with nonfunctional slack-fill legislation and builds trust with consumers. Importantly, minimizing packaging saves money and reduces environmental impact, so a reduction in slack-fill has advantages beyond pleasing consumers. Recent court cases that highlight the required use of slack-fill regulations designed to protect consumers and remove empty package space as unfair have cited the section on misleading containers in the U.S. FDA Code of Federal Regulations (21 CFR Part 100.100) and the California Fair Packaging and Labeling Act (12606 for non-food and 12606.2 for food).

Slack-fill can be functional. However, communicating to consumers the function of “empty space,” whether it’s dispensing, filling and manufacturing processes, product protection during distribution, or pilfer prevention, and showing actual fill levels represents a real challenge to the food industry.

In package testing, functional prototypes are essential for accurate consumer testing and refining packaging to meet consumer and retail needs. In the steps to commercialize a genuinely innovative package design, many iterations are needed to make sure details resonate with consumers, ensure an ideal retail fit in the planogram, and ensure production tooling is efficient.

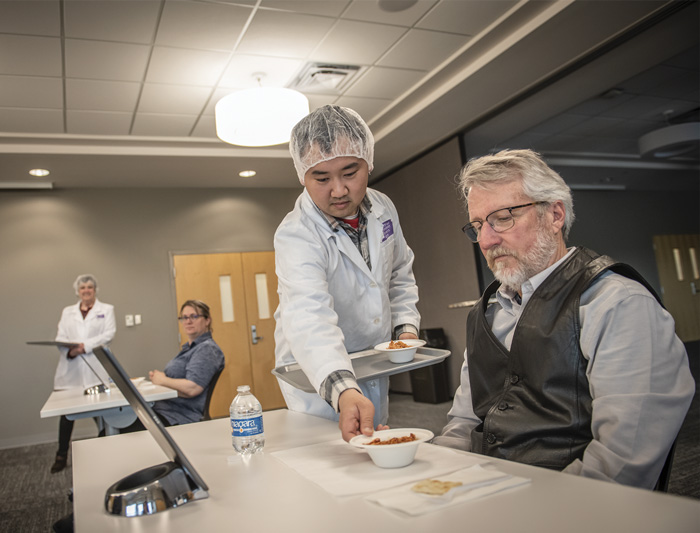

Use of a facility familiar with package testing is critical. Martin Talavera, assistant professor, Department of Food, Nutrition, Dietetics and Health at Kansas State University - Olathe Campus, notes that K-State’s Sensory and Consumer Research Center conducts “Quant + Qual” sessions to help industry design functional packaging with consumer appeal. Talavera explains that these involve first conducting large quantitative sessions from which three to four groups of approximately six respondents each are selected to participate in follow-up qualitative sessions, which can be live streamed with high-quality video and sound.

“The benefit of this combination,” he notes, “is that it provides fast, in-depth exploration of quantitative results while allowing off-site teams live access to the sessions for instant feedback and interaction with staff and moderators.

“The right packaging is a key factor for product success,” Talavera adds. “Packaging will not only help maximize product stability, but it serves as a ‘door’ to the product. It can help consumers interact with the product starting from the shelf and provide a sense of quality, convenience, and sustainability. This is why getting an early read of consumer perceptions of packaging design is paramount to match their expectations.”

Optimal Outcomes

Procurement and aligning with consumer needs will continue to challenge the food packaging industry. Investment in proactive solutions such as stress testing and the valorization of packaging innovation options will guide rational decision-making and ensure food safety remains center stage.

Learning Objectives

- Understand two different challenges facing food packaging.

- Define solutions that are used to address these challenges.

- Gauge how to connect with packaging functions in a meaningful way.