Food Technology Magazine | Applied Science

How to Formulate for Food Intolerances

In this column, the author describes the global prevalence of food intolerances and provides insight into state-of-science ingredient replacement and removal methods when formulating gluten-free and lactose-free foods.

© Daisy-Daisy/iStock/Getty Images Plus

In recent years, there have been an increasing number of medical diagnoses associated with food intolerances and allergies, making it a major public health concern around the globe. Food intolerances are food-related diseases caused by certain food components that produce a hypersensitive reaction in the body either due to malabsorption or non-recognition by the immune system. In 2009, researchers estimated that 20% of the population in industrialized countries had been medically diagnosed with at least one food intolerance or allergy (Zopf et al. 2009). The study found a prevalence of 2%–5% immunological hypersensitivity in the adult population and 5%–10% in young children. In a 2023 review article, clinicians referenced updated prevalence rates, which estimated that today, food allergies affect about 8% of children and 10% of adults worldwide (Bartha et al. 2023).

The rising prevalence of food intolerance not only presents a significant global public health issue but also presents significant challenges for food product developers. A better understanding of the food components at the root of intolerance and the methods available to deliver products that are free from these components will help ensure that formulations provide safe, nutritious foods that all consumers can enjoy.

Cause and Effect

There are three food intolerance types ranked by the severity of the impact on the human body. They are as follows:

Type 1 involves food components that are not tolerated or not recognized by the human immune system and cause quick allergenic reactions such as inflammation, irritation, vasodilation, or diarrhea as the body tries to protect itself.

Pseudo-allergies, also known as food idiosyncrasies, are categorized as Type 2 food intolerances, which are caused by food additives. In Type 2 cases, food additives such as flavors, sulfites, benzoate, and even vitamins trigger protection reactions in the body, including atopic dermatitis herpetiformis (a chronic blistering rash caused by gluten and commonly affecting individuals with celiac disease), chronic urticaria (an allergic skin condition), and eye inflammation.

The causes of Type 3 food intolerances are either organic dysfunctions in the body in which there is a lack or reduction in the secretion of certain metabolic enzymes (i.e., enzymopathies) or organic malabsorption due to anatomical or morphological alteration of the gastrointestinal tract. Type 3 intolerance can induce discomfort in the body such as flatulence, abdominal pain, and diarrhea approximately one to three hours after ingestion of an allergen-containing food.

The top food components responsible for the most frequently diagnosed intolerances are lactose, gluten, caffeine, salicylates, histamines, fructose, and sulfites. Of those, the three most common food intolerances arise from the consumption of lactose, a sugar found in milk; casein, a protein found in milk; and gluten, a protein found in grains such as wheat, rye, and barley. Here, we’ll explore two of the top three—gluten and lactose—and define considerations for product developers in making these “free-from” products.

Developing Gluten-Free Products

In the case of gluten intolerance, the two primary components of the cereal-based protein are gliadin and glutenin, which when not tolerated, metabolized, or absorbed by the body can trigger an immune reaction that can induce the onset of celiac disease. Due to the potential severity of resulting health issues for consumers, it is important that gluten-free products comply with the U.S. Food and Drug Administration’s (FDA) labeling rule that specifies any foods labeled with a “gluten-free” or similar claim must contain less than 20 ppm of gluten (FDA 2013).

Among technological solutions available to developers creating gluten-free products are several involving the use of modified or replacement ingredients for gluten-containing cereals, including:

- Genetically modified wheat varieties with gluten-free characteristics.

- Biotechnologically modified gluten via complete proteolysis during dough fermentation, which creates gluten/gliadin-free products.

- Technologically modified food formulas by substituting or replacing gluten cereals with pseudo-cereals such as quinoa, amaranth, millet, chickpeas, buckwheat, rice, tapioca, sago, or sorghum, and/or replacing with legumes such as peas, potatoes, beans, lentils, or lupines.

- Removal and replacement of gluten-containing ingredients with dietary powders such as starch, polenta, sorghum flour, soya, and buckwheat, pre-fermented or cooked paste (e.g., rice, buckwheat, peas), corn flakes, expanded cereals, sauces/milks (soya), tofu, or oilseeds (e.g., soybean, flaxseed, sunflower, or pumpkin) to create functional gluten-free foods.

Of these, legumes and pseudo-cereals are the principal protein replacement ingredients in gluten-free formulations, whether used in their natural state or technologically transformed through germination, fermentation, malting, gelatinization, or granulation. Other common replacement ingredient solutions include combining cereals with pseudo-cereals or legumes. Another gluten replacement approach is to use additives for improving water- and gas-binding during dough formation, including methylcellulose cellulose, xanthan, and guar gum, or enzymes such as transglutaminase, proteases, glucose oxidase, or laccase. Similarly, using protein fortification agents in gluten-free formulations, including animal proteins such as milk (caseinate), egg (albumin), or dietary fiber supplements such as Psyllium fiber, β-glucan, and locust bean gum, enhances the protein content of finished bakery products (Vintilă 2021).

Food companies, including key market players in the gluten-free space such as Conagra Brands, Hain Celestial, General Mills, Kellogg, and Kraft Heinz, employ formulations that use more than 400 different ingredients with gluten-replacing abilities. This includes bakery and convenience commercial formulations, typically maize starch and flour, rice flour, potato starch, guar gum, eggs, sugar, and sunflower oil and butter. Some companies also utilize processing technologies to produce products with the gluten-free claim, including thermal treatment with microwave or infrared radiation of dry dough ingredients, nonthermal high pressure processing treatment of dough, and vacuum baking to reduce the temperature of starch gelatinization and promote the cross-linking of proteins in gluten-free formulations (Šmídová and Rysová 2022).

Developing Lactose-Free Products

About 75% of the world’s adult population is lactose intolerant, which has created new market opportunities for the development of lactose-free or lactose-reduced dairy products (Silanikove et al. 2015). According to a 2018 survey conducted by Cargill, 61% of consumers in the United States avoided dairy products due to lactose intolerance or milk protein allergies.

With such a high percentage of affected people, food companies have long worked on ways to remove or replace this component from dairy products and ingredients. It can be a significant challenge for product developers since FDA and some other international food regulatory agencies do not define the terms “lactose-free” or “lactose-reduced” since lactose intolerance, which does not involve the immune system, is not considered a dairy allergy. FDA states that products with a lactose-free claim must not contain any lactose at all. In addition, reduced-lactose products must not be labeled lactose-free. Of course, even when lactose is removed from a product, the milk protein is still present. According to a paper published in Foods in 2023, “although there are no common standards on allowable lactose threshold, in most countries, lactose content of low-lactose and lactose-free products are within 1 g/100 g and 10 mg/100 g, respectively” (Li et al. 2023).

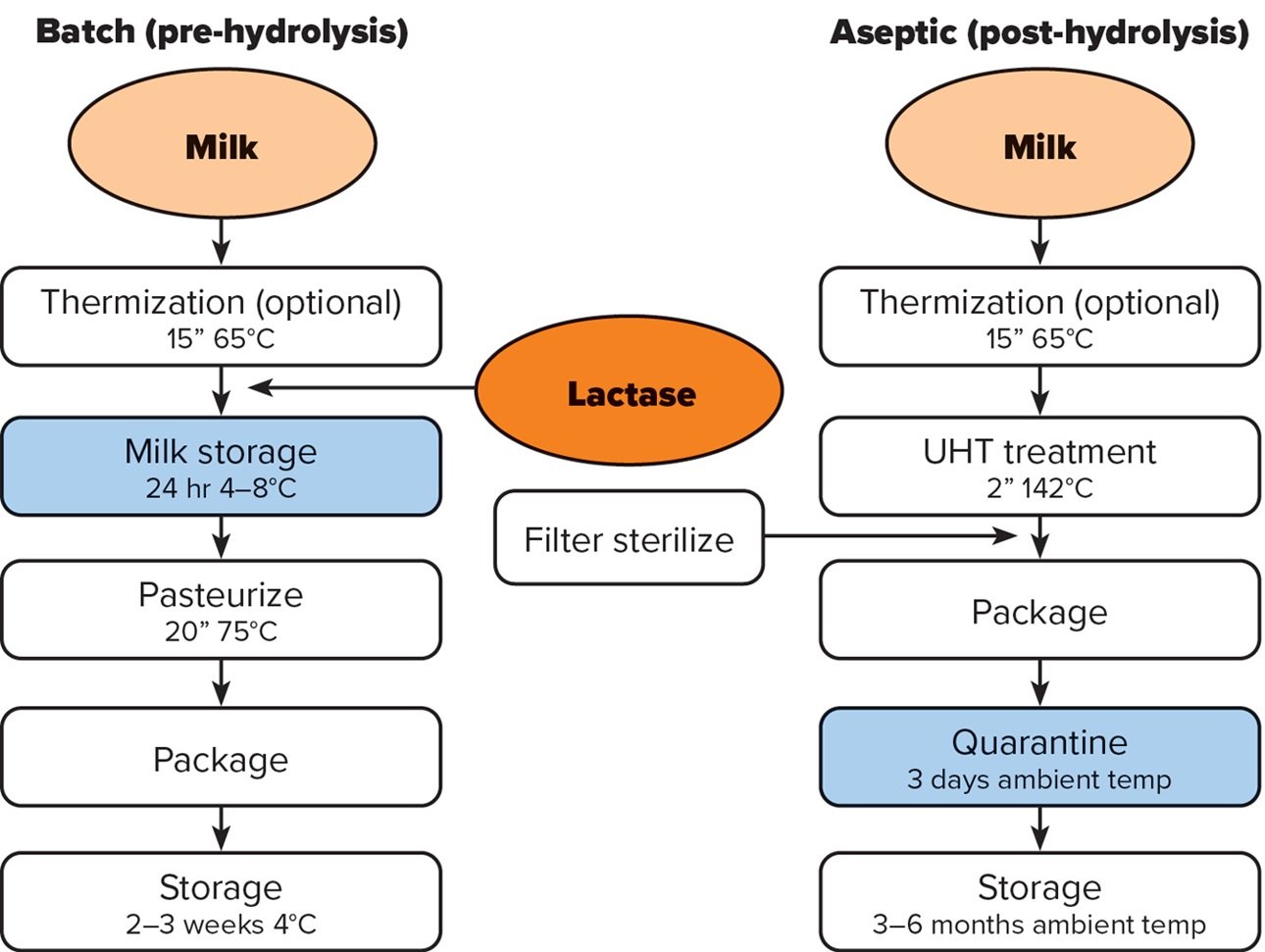

There are several ways to reduce the lactose content from dairy products, from fluid milk to cheese and yogurt. The industry’s principal solution is enzymatic hydrolysis, in which lactose is hydrolyzed into glucose and galactose by the enzyme β-galactosidase (lactase). This can be done in a batch (pre-hydrolysis) or aseptic (post-hydrolysis) process (Figure 1). When the milk is made using the batch system, the enzyme is inactivated during the pasteurization step and there is no residual enzyme activity in the final product (Dekker et al. 2019). There are also several commercially available enzymes, including β-galactosidase enzymes derived from dairy yeast and genetically modified lactase enzymes that are certified kosher/halal.

Other methods used to reduce or remove lactose from milk products include milk fractionation by membrane separation, microfiltration, ultrafiltration, nanofiltration, fermentation, and reverse osmosis. In addition, alternative ingredient sources can be used to replace milk in lactose-free formulations, including coconut, oat, almond, rice, or soy milks. Since lactose-free milk is the basic component for all milk-derived formulations such as milk powder, condensed milk, yogurt, cheese, ice cream, and butter, product developers may need to fortify these products with calcium, vitamins D and E, zinc, copper, and magnesium to increase the food’s nutritional quality.

Free-From Opportunities

Consumers with food intolerances, allergies, and related immune system diseases like celiac continue to seek out food products that are safe and wholesome to eat, spurring a growing market for free-from products. For example, the market size for global lactose-free dairy products was valued at nearly $11.5 billion in 2021 and is projected to reach nearly $24.4 billion by 2031, according to Allied Market Research. And Fortune Business Insights forecasts that the global gluten-free market, driven by rising incidences of celiac disease and gluten intolerance, will grow to a value of nearly $10 billion by 2028, up from about $5.3 billion in 2020.

As the market grows, so do the opportunities for product developers to design new innovative and functional products for consumers with food intolerances. However, many formulation challenges remain, including fine-tuning ways to improve sensory characteristics and nutritional values of these free-from products while reducing or removing the components that cause food intolerance and disease. As food science and technologies advance, developers will find next-level methods to ensure that products formulated with food intolerance in mind will be nutritious and delicious for consumers everywhere.ft