Software Automates Nutrition Labeling & More

LABORATORY

An increasing number of databases and software packages are becoming available to help food processors and others provide accurate, up-to-date information about the nutritional value of the foods and beverages they are producing or providing. They range from databases of nutrient values of foods to software packages that simplify their use. Here’s a brief introduction to some of the databases and software packages available.

• International Nutrient Database Directory. The National Nutrient Databank Conference recently released its updated International Nutrient Database Directory (www.medicine.uiowa.edu/gcrc/nndc/survey.html), a compilation of software applications and their accompanying food composition databases, as well as reference databases that are sources of the food composition values and supporting information.

"This directory is intended to assist potential users in determining which combination of program and database might best meet their needs," says Phyllis Stumbo ([email protected]), Nutrition Manager for the General Clinical Research Center at the University of Iowa, Iowa City, and Past Chair of the National Nutrient Databank Conference Steering Committee.

• National Nutrient Database. The Nutrient Data Laboratory (NDL) (www.ars.usda.gov/nutrientdata), part of the U.S. Dept. of Agriculture’s Agricultural Research Service, Beltsville, Md., develops the National Nutrient Database for Standard Reference, the foundation of most U.S. food and nutrition databases used in food policy, research, and nutrition monitoring.

NDL maintains an electronic database of 7,200 foods and 128 dietary components and includes estimates for agricultural commodities, processed and prepared fruits, vegetables, meats, poultry, and grains as well as brand-name and generic estimates for breakfast cereals, selected fast foods, candies, and beverages, according to NDL Research Leader Joanne Holden ([email protected]). The database contains data from government contracts, the food industry, trade associations, and scientific literature and is available at no charge to the public and scientific community, she says.

• ProductVision®. Advanced Software Designs (ASD), Chesterfield, Mo. (www.asdsoftware.com), provides product development software solutions for the formula-based process industries, including food and beverages, paint, ink, chemicals, and personal care products. The company’s ProductVision software automates calculation of all nutritional property and costing information, says Ted Pliakos, Vice President of Sales ([email protected]). "Query features allow easy access to existing recipes that may meet new requirements."

The software provides full tracking of a product from inception through production and eventual retirement, Pliakos points out. "The status control feature allows approved formulas and raw materials to be locked to prevent accidental changes, and historical formulas may be archived to separate them from production recipes."

--- PAGE BREAK ---

The Formula Management module is the base module. All other modules, such as Projects, Workflow, and Regulatory Compliance, integrate into it, so the user only works with one database of information, Pliakos says.

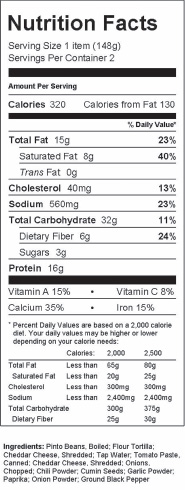

The Nutrition Labeling module automatically creates Nutrition Facts panels and ingredient declarations that comply with the Nutrition Labeling and Education Act (NLEA) regulations as well as current and pending regulations for Canadian and European Union labels.

The Nutrition Labeling module automatically creates Nutrition Facts panels and ingredient declarations that comply with the Nutrition Labeling and Education Act (NLEA) regulations as well as current and pending regulations for Canadian and European Union labels.

"This greatly reduces the time required to create the product label and guarantees consistency with the recipe," Pliakos says. "The label is based on the most current composition of the recipe, with all government regulations and rounding rules built in."

Detailed change tracking is available using the Audit Module, which provides a complete history of changes made to an item in ProductVision, Pliakos explains. "The date, time, and user are recorded, along with the specific details of the change, so one never has to wonder when a change was made or by whom. This functionality greatly reduces the need to maintain hard-copy records of historical raw material and formula information, as all revision information is available online."

• Nutritionist Pro™. Axxya Systems, Stafford, Tex. (www.axxya.com), offers the Nutritionist Pro™ line of software products and a comprehensive, accurate, and up-to-date nutrition knowledge base, according to Shazia Nathoo, Lead Registered Dietitian ([email protected]).

"Our user-friendly Nutritionist Pro Nutrition Analysis software includes an extensive food database and provides thorough nutrient analysis of diets, recipes, and menus," Nathoo says.

--- PAGE BREAK ---

Nutritionist Pro Food Labeling software enables users to create and design camera-ready Nutrition Facts panels that comply with NLEA regulations. It offers 17 different Nutrition Facts panels for various package sizes as required by the Food and Drug Administration. Labels include vertical, dual declarations, tabular, and bilingual (French and Spanish), as well as panels for infants and children. Food labels can also be extracted into various graphics file formats such as jpg or pdf for easy formatting.

Moreover, users can display nutrient content claims for foods and recipes, create ingredient and allergen statements, or incorporate Hazard Analysis Critical Control Points (HACCP) into a recipe or formulation.

"With Nutritionist Pro software, users can search for nutrients in our database of over 27,000 foods representing 400 brands and then display food information such as portions, nutrients, diabetic exchanges, My Pyramid servings, and food categories," Nathoo adds.

The company’s knowledge base includes data from manufacturers, Nutrition Facts panels, and generic food resources such as USDA’s Standard References, Food Consumption Survey Database, and Canadian Nutrient Files, which are updated by the company’s staff of registered dietitians, she points out.

"Our software is designed to create food labels and nutrient claims that allow the user to promote their formula or recipe as high-fiber, high-calcium, or low-fat, etc.," Nathoo says. "In addition, food manufacturers use our software to modify recipes to meet specific FDA guidelines."

The feature most utilized is the ability to customize the software by adding ingredients and recipes to create graphics files for food labels, Nathoo mentions.

Restaurants also use Axxya’s software and services to provide recipe analysis for consumers on their Web sites and menus.

"Companies have an option to either purchase our software for nutrient analysis or use our services whereby we can work with their team and create the analysis for them," Nathoo says.

--- PAGE BREAK ---

• Genesis R&D SQL. This product development and labeling software by ESHA Research, Inc., Salem, Ore. (www.esha.com), is used by more than 90% of the leading U.S. food producers and developers, according to Layne Westover, Vice President of Marketing and Business Development ([email protected]).

The newest generation of this software offers NLEA-compliant labels with automatically generated ingredient statements and the option to include allergen statements and nutrient content claims on the labels. In addition, Canadian and Spanish labeling modules are available.

Nutrient analyses may also be displayed in a wide variety of graphic reports: as a spreadsheet, protein quality analysis, bar graph comparison, single nutrient, and others. "Genesis R&D SQL provides many tools to aid in the creation and modification of nutrition labels and ingredient statements," Westover says. "The software acts as a time- and cost-saver in the creation of new food products and reformulation of existing items by calculating the nutritional content of products and simplifying regulatory compliance."

The software’s Fat Formulator™ feature allows users to create customized meat formulations with a specified fat content; bilingual, aggregate, and dual declaration labels; global recipe moisture and fat adjustments with instant, on-screen results; and food-specific yield data to determine precise processing and cooking losses.

The nutrient database consists of more than 27,000 foods and ingredients that are collected from more than 1,500 sources, including USDA, Health Canada, suppliers, food associations, companies, and independent research organizations, Westover says. "The database includes whole foods, raw materials, chemicals and additives, combination foods, brand-name items, fast foods, and baby foods. Plus, users can add an unlimited number of their own ingredients."

The ESHA nutrient database is available for licensing, allowing integration with a food manufacturer’s own software or Web site applications.

• TechWizard™. This software package from Owl Software, Columbia, Mo. (www.owlsoft.com), offers product development, nutrition labeling, least-cost food formulation, and batching. It is used by small operations as well as large ingredient and product manufacturers, consultants, and universities for package and point-of-sale Nutrition Facts panels, recipe development, batching, and recipe costing, says Ann Roland, Vice President ([email protected]).

--- PAGE BREAK ---

It not only evaluates recipes but also creates them and has the capability to formulate amounts and totals to a user-specified final composition. It will also determine a formulation that meets those specifications, and if prices are entered, it can compute a least-cost formulation. In making ice cream, for example, there can be multiple sources of fat, Roland points out. If on a given day fat from cream is cheaper than fat from milk, the software can take that into account to produce a formula that will meet a manufacturer’s specs at the least cost. The software can be used to determine if a specific nutrition profile is possible from a combination of candidate ingredients.

"Our main concern," Roland adds, "is that the database information accurately reflects the actual information a manufacturer is using. While the USDA food composition database is included with TechWizard, we emphasize that the user is responsible for their ingredient information, which can vary. With this in mind, the client has total control over the ingredient information used in the program to ensure this information is as accurate as possible."

• Production Wizard™. This software, also from Owl Software, takes TechWizard to the plant floor for day-to-day batching, including features that complement existing enterprise resource planning and laboratory information management systems.

"When creating a nutrition label and ingredient statement, it is a company’s mandate to ensure this is consistently manufactured by the plant, especially if the ingredients vary or the particular product is being reformulated," Roland emphasizes. "Production Wizard was designed to meet this need. When plants make an effort to recycle product that is left over during manufacturing, it is crucial to do this in a controlled fashion to ensure that only ingredients allowed in a formula are actually used in that formula.

The software is a powerful tool for least-cost formulation and fast, day-to-day reformulation, Roland says. It provides real-time ingredient updates, specialized calculations for particular situations, and special features to control product loss and handle rework or salvage. Dispensing error determination/"smart" batching, as well as control of unwanted ingredient contamination and allergenicity are also part of the software’s capabilities.

by Linda L. Leake,

Contributing Editor,Food Safety Consultant,

Wilmington, N.C.

[email protected]