Understanding the Chemistry and Evolution of Chocolate Flavor

With a growing market for high-end chocolates with complex flavors, understanding the chemistry of cocoa from the time of bean harvest through processing and the impact of other ingredients in chocolate on taste perception is essential to formulating successful new products.

Article Content

Similar to our penchant for wine and coffee, there exists a rapidly growing consumer demand for craft chocolates that elicit complex flavor profiles and are composed of either estate or single origin cocoa beans. “We’ve definitely gotten some attention for our Porcelana and CSB [Criollo Santa Bárbara] Chama beans. A few International Chocolate Awards helped that along. These are precious beans from a country with a lot of amazing cacao—Venezuela,” says David Castellan, owner of SOMA Chocolatemaker in Toronto, Canada. “When we first started, our Madagascar origin also received a lot of love. We used to call Madagascar the ‘gateway’ chocolate. It is much further on the fruity acidic spectrum than most consumers are used to and opens them up to the flavor possibilities of origin chocolate. We are currently working with some beans from Haiti and Fiji that look very promising.”

While complex flavors composed of “fruity”, “caramel”, and “malted” notes are often indicators of a high-quality chocolate, poor chocolate comes off as dilute, one-dimensional, and over-compensated by cloying sweetness. Furthermore, the inferior product is exceedingly bitter and astringent compared to chocolate made from much sought-after beans. In addition to the hundreds of aroma compounds that food scientists have identified, cocoa also possesses an appreciable number of polyphenols—with total levels surpassing both tea and red wine—that are responsible for giving chocolate its distinct bitterness. For us to understand and truly appreciate the artistry and precision that goes into chocolate treats, we must first explore where its flavors originate and how other ingredients and processes may play a role.

Cocoa Bean Quality at Harvest

The final flavor profile of chocolate is largely influenced by the quality of the cocoa bean during the time of harvest. While botanically seeds, cocoa beans grow within the pods of cacao trees (Theobroma cacao) on plantations situated within 20 degrees North and South of the equator. Extreme care is taken during cultivation to protect the beans and their contents from various environmental factors such as rainfall, high winds, and temperature. “The climate could have an influence on the physical and chemical characteristics of cocoa butter,” says Koen Dewettinck, professor at Ghent University in Ghent, Belgium. “Low temperatures change cocoa butter, which becomes more soft and contains high diunsaturated triacylglycerols and high unsaturated fatty acids, for example, oleic and linoleic acid.” Botanically, this ability to alter cocoa butter composition is a response to maintain proper fluidity and biochemistry within the bean. However, the melting profile of chocolate made from these beans may be altered as well.

Cocoa beans may also produce more carbonyl compounds in response to high levels of rainfall and incomplete drying, which can result in “hammy” off-notes (Afoakwa et al. 2008). To offer some protection from the environment such as direct sunlight and harsh winds, cacao trees, particularly young ones (< 1 year of age), have traditionally been cultivated beneath the canopy of larger trees throughout Latin America and West Africa (Rice and Greenberg 2000). Products such as Pyramide des Tropiques from French chocolatier François Pralus, which offers chocolate squares differing solely in bean origin, perform an exceptional job at highlighting the range of chocolate flavors based on source of harvest.

The harvesting window for cocoa beans is rather long—lasting up to nine months—which may permit the opportunity for significant differences in bean quality to exist from batch-to-batch and month-to-month if care is not taken. Beans that suffer from a poor harvest are at risk of adulteration using bulk varieties (e.g., CCN-51) that are high yielding and robust against environmental conditions and disease but inferior in taste. “Sourcing beans was very difficult when we first started in 2003. When we were contacting brokers, there were only 11 companies in North America that were processing cacao beans,” explains Castellan. “Things have become progressively better and there are many reputable bean suppliers. They supply a wealth of information on each origin and, in this way, have gone down the coffee route. Sometimes we receive info sheets that list what type of animals live in the region of the farms! We’ve had more direct contact with growers and this has been the most rewarding.”

The harvesting window for cocoa beans is rather long—lasting up to nine months—which may permit the opportunity for significant differences in bean quality to exist from batch-to-batch and month-to-month if care is not taken. Beans that suffer from a poor harvest are at risk of adulteration using bulk varieties (e.g., CCN-51) that are high yielding and robust against environmental conditions and disease but inferior in taste. “Sourcing beans was very difficult when we first started in 2003. When we were contacting brokers, there were only 11 companies in North America that were processing cacao beans,” explains Castellan. “Things have become progressively better and there are many reputable bean suppliers. They supply a wealth of information on each origin and, in this way, have gone down the coffee route. Sometimes we receive info sheets that list what type of animals live in the region of the farms! We’ve had more direct contact with growers and this has been the most rewarding.”

During reproduction, ovules located within cacao flowers become pollinated and eventually develop into the coat that surrounds the cocoa bean. Genetic fingerprints from the DNA that is extracted from this coat can be generated through single nucleotide polymorphism (SNP) markers to authenticate genetic origin and verify if the bean has been adulterated. SNPs are relatively simple to use in comparison to other DNA-based techniques and have been developed by Fang et al. (2014) for the authentication of cocoa beans.

Formation of Aroma Precursors Through Fermentation

Many people may not realize that chocolate is a fermented product. In its raw state, cocoa beans do not possess any of the flavors associated with chocolate. The beans must undergo fermentation following harvest, where bacteria and natural yeast metabolize sugars and proteins within the bean and generate chemical precursors that are important to aroma compound formation. This process usually takes place over 4 to 6 days and can result in temperatures that exceed 50° C.

The cocoa beans along with their surrounding pulp are removed from the pods and piled to begin this fermentation. Sugars within the pulp are broken down into organic acids such as acetic acid that lower the pH from 6.5 to 4.8. It has been shown that this pH is correlated to flavor intensity in chocolate. This is due to the activity of enzymes responsible for producing these aroma precursors. Activity is dependent on pH and is suppressed if acid levels increase too rapidly due to over-fermentation (Camu et al. 2008).

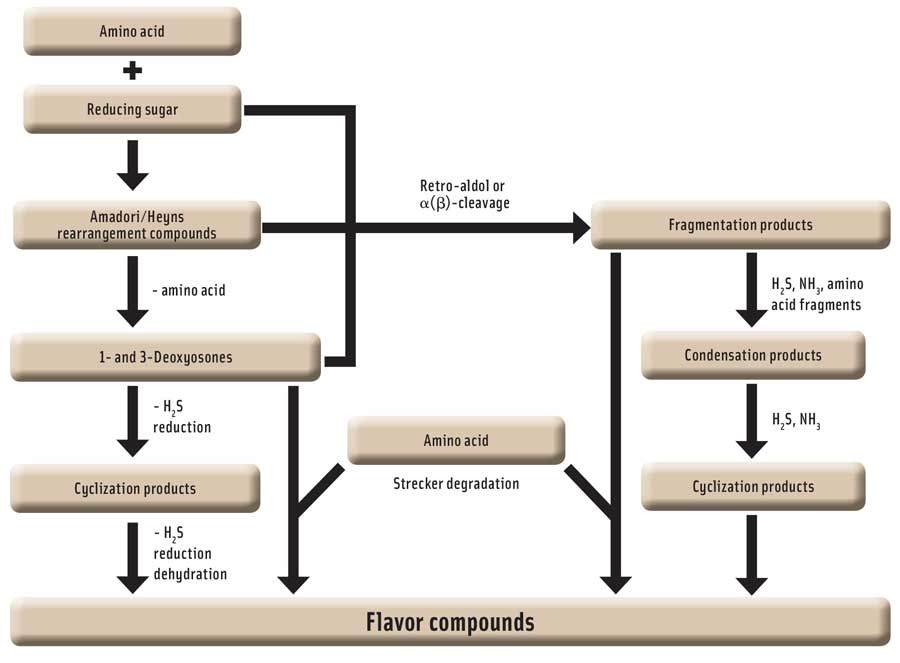

Proteins found within the cocoa beans undergo proteolysis during fermentation, where they are converted into oligopeptides and essential amino acids that will undergo reactions with sugars later in processing to generate aroma compounds (Buyukpamukcu et al. 2001). This mixture of amino acids is completely dependent on the proteins that formed during growth and harvesting and dictates what aroma compounds can be produced. Without fermentation, the beans do not undergo the necessary change in pH nor are the proper amino acids formed and, as a result, key aroma compounds that contribute to chocolate flavor cannot be formed. Other products of fermentation include alcohols, esters, ketone, and free fatty acids.

Drying and Roasting of the Beans

Once fermentation is complete, the beans are dried to reduce water content from 60% to 8% by weight. This enables the beans to be transported from the plantation to roasters without spoilage. Furthermore, the acids that are produced from fermentation volatilize during this process, which reduces the astringency and acidity of the beans.

In West Africa (e.g., Ivory Coast, Ghana, etc.) where the climate is dry, the fermented beans are raked over banana leaves and allowed to dry under direct sunlight. In regions that are humid, such as Latin America or Southeast Asia, drying by sunlight cannot be achieved and instead the fermented beans are dried using smokehouses. What is quite interesting about this method of drying is that a smokiness may be imparted into the bean and becomes part of the chocolate’s flavor profile.

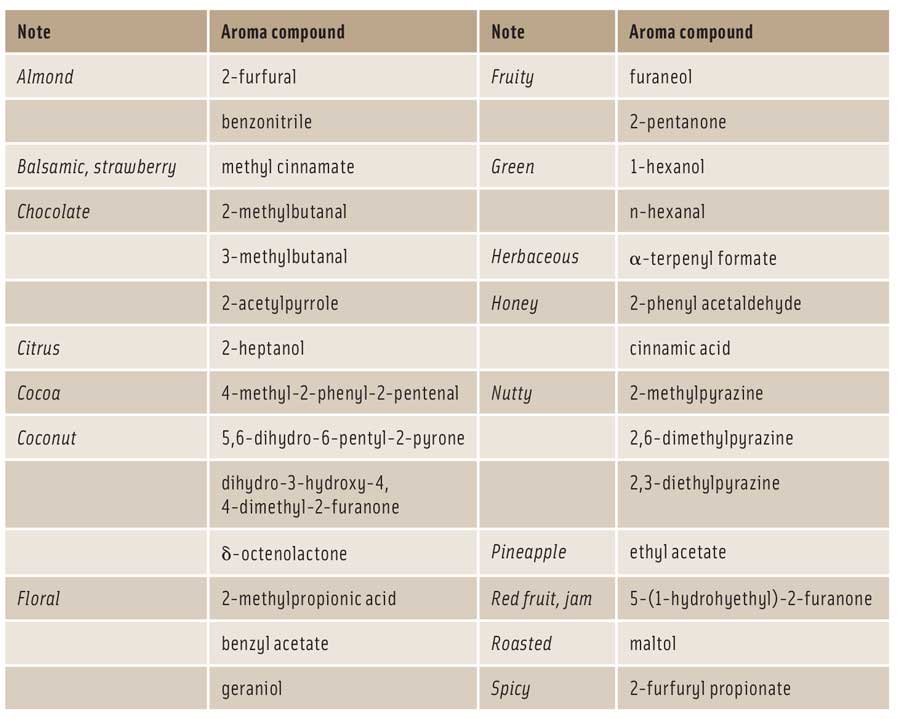

The cocoa beans leave the plantation following drying, where they are exposed to high temperatures in drum roasters. These temperatures not only further reduce the water content to 2% by weight and remove unwanted odors but they also facilitate Maillard chemistry, where sugars react with critical amino acids that are formed during fermentation to produce the aroma compounds. Such compounds include Strecker aldehydes and pyrazines, both of which are aromatic classes contributing to chocolate flavor. Key aroma compounds and their associated notes are listed in Table 1 (Aprotosoaie et al. 2016).

Refining the Bean through Conching

To finish the production of chocolate, the beans are deshelled and ground into a fine mass. This mass is further refined with added sugar, cocoa butter, and emulsifier, where the particle size of both cocoa mass and sugar is reduced through a process called conching. The size of dry mass particles can impact the release of certain aroma compounds and, ultimately, the flavor profile of the chocolate. For example, the intensities of “praline”, “caramel”, and “honey” notes have been shown to increase with a particle size reduction to 18–25 microns, which is attributed to the presence of such aroma compounds as 3-methybutanal, trimethylpyrazine, 2-phenyl acetaldehyde, and furfurol (Afoakwa et al. 2009).

The molten chocolate is heated to 80° C while conching, which may last 72 hr. Certain aroma compounds may be formed at this stage depending on conching temperature while unwanted compounds may evaporate. Too high of temperatures during conching can result in the formation of aroma compounds such as dimethyl trisulfide, which can contribute to “onion” and “cabbage” off-notes (Counet et al. 2002). Without control during conching, it is possible to lose desirable aroma compounds through evaporation and destroy the chocolate’s flavor. “Over-conched chocolate tastes flat and uninteresting. You can taste this in some mostly older European chocolates. In general, the trend in craft chocolate is to gently conche as the whole point is to discover those flavors locked within the cacao bean,” says Castellan.

The Role of Other Ingredients on Flavor

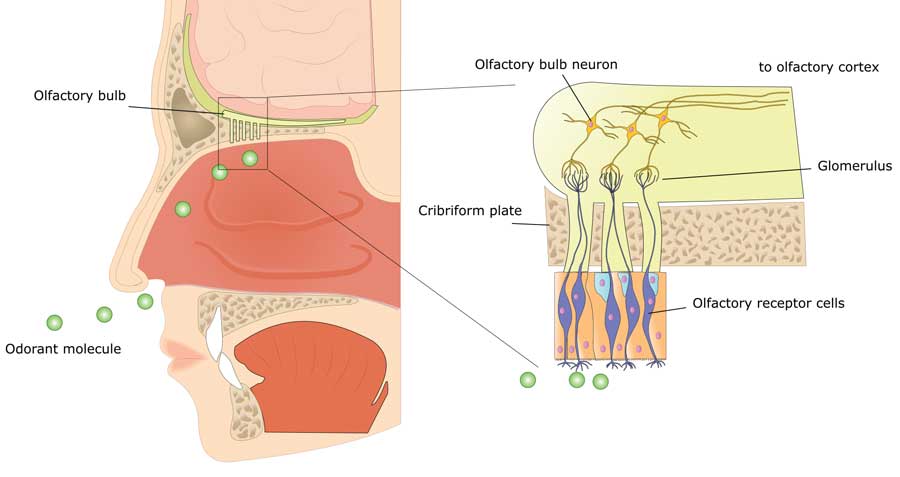

Cocoa butter is by and large a functional ingredient in chocolate and not known much for its significant imposition on chocolate flavor itself. With proper tempering, cocoa butter achieves the proper texture, gloss, and stability that any high-quality chocolate should have. This ingredient is essentially a physical barrier between the aroma compounds in the cocoa mass and our olfactory receptor cells. Only when cocoa butter melts are these compounds released and able to volatilize. “Indeed, further study is needed to get a better understanding to these interactions. Fat is important in foods for sensory qualities such as flavor, color, texture, and mouthfeel,” explains Dewettinck. “In the context of flavor, fat plays a significant role as the precursor, carrier, and modifier of many flavor components in addition to their effects on flavor stability and flavor generation.”

Taking this into consideration, the physical properties of cocoa butter, such as its melting point and crystallinity, should be just as important as the aroma compounds when it comes to flavor perception. Some factors that can influence a compound’s volatility includes temperature, solubility, and molecular interactions with other ingredients. “Fat can entrap lipophilic volatile compounds. The solubility of flavor compounds in the fat phase depends on their hydrophobicity [ability to dissolve in fat]. Vanillin is an example of a flavor compound that can be entrapped in the fat phase,” adds Dewettinck. This was confirmed in a study by Li et al. (1997) using liquid chromatography, where the aroma compound vanillin had decreased in concentration within the fat phase of vanilla ice cream as total fat content had been reduced.

“In the final product, cocoa butter in theory should reduce or thin out the flavor, but at the right amount, the cocoa butter can contribute to distributing the flavor rapidly around the mouth and therefore enhancing flavor release,” says Castellan. “Sugar particle size can contribute to feeling immediate sweetness (and overwhelming the initial flavor release) or persistent long-lasting full sweetness, which can control or subdue inherent bitterness.”

Influence of Shelf Life on Flavor

Chocolate consumers should be aware of how to properly store and maintain the quality of their chocolate. While a common indicator that limits chocolate’s shelf life is fat bloom, which is the greyish dulling of its surface, flavor may also be impacted. Aroma compounds may either oxidize or be lost through evaporation if the chocolate is stored at elevated temperatures or under high humidity. In a storage study by Nightingale et al. (2012), the concentration of aroma compounds 2-methylpentanal, 2-methylbutanal, and 3-methylbutanal were found to significantly increase if chocolates were stored at 30.5° C. To preserve the chocolate’s flavor profile at the time of purchase, it is best to keep it stored at temperatures between 18° and 21° C and away from either moisture or light.

Significant efforts to widen the repertoire of chocolate flavor profiles have been firmly entrenched by chocolatiers, especially those involved in the production of craft chocolates. Understanding how origin and quality of the bean during harvest as well as how processing is used to generate different aroma compounds is essential to meet the growing demand of flavors with greater complexities. Beyond the small operations growing in number and scope, it is also important to fully realize and appreciate this chemistry as well as the impact of other ingredients that ultimately contribute to our enjoyment of chocolate.

Ryan West, a student member of IFT, is a doctoral candidate at Ryerson University ([email protected]). Dérick Rousseau is a professor at Ryerson University ([email protected]).

The authors would like to thank David Castellan of SOMA Chocolatemaker and Koen Dewettinck of Ghent University for their knowledge and insight.