Packaging Strategies to Stall Lipid Oxidation

PACKAGING

Off-flavors and odors that decrease shelf life can result from the lipid oxidation of unsaturated fats and oils in foods, including beef jerky, crackers, chips, nuts, and bakery goods. Recent trends in using more unsaturated than saturated lipids mean more foods are now prone to lipid oxidation.

Packaging, however, can help combat these issues by stalling the origination and propagation of oxidation. Inhibiting oxidation origination can be accomplished by removing the O2 within the package headspace and using superior O2 barriers, machinery, and oxygen scavengers. The propagation of the oxidation reaction can be stalled by using antioxidants that prevent free radicals produced from the initiation phase from breaking down into secondary reaction byproducts that produce off-flavors and odors. Antioxidants have been in use for many years, but the use of naturally derived antioxidants is increasing.

Packaging Machinery Strategies

Employing packaging machinery to reduce initial O2 and using high-barrier packaging to impede permeation of O2 into the package can inhibit or stall oxidation. This is a specific area of modified atmosphere packaging (MAP) within the field of active packaging. An abundance of packaging machines can be used to reduce or remove oxygen within packaging.

Bags formed via vertical and horizontal form-fill-seal machinery, or premade bags, can be used to gas flush packaging and reduce and eliminate O2 inside the package. For example, BW Flexible Systems’ ISB family of vertical form-fill-seal machines reduces O2 to levels ranging from 1% to 2% for foods prone to oxidation.

“The packaging environment we create is a function of the product needs,” says Jim Kolmus, mechanical engineering lead at BW Flexible Systems. “For example, our horizontal flow wrapper machines use CO2 to flush packaging, enrobing a 1-pound cheese chunk. After the cheese absorbs the CO2, a low O2 package is similar to a vacuum package in appearance. This creates a 0% 02 package inhibiting oxidation. In contrast, the BW Flexible Systems vertical form-fill-seal machines for shredded cheese replace some O2 with N2, and this creates an inflated bag which also serves to protect the product during distribution.”

Although gas flushing technology is a critical part of achieving low or no O2 within the packaging, BW Flexible Systems says other factors also come into play to ensure the machines enable safe and consistent low or no O2.

“[Food and Drug Administration]-compliant gas flushing mechanisms, intuitive human machine interfaces (HMI), and flexibility are critical,” says Kolmus. “Advanced HMIs and associated ease of use help to compensate for high employee turnover experienced in food packaging operations, operator error, and the need for rapid changeovers. For example, our machines have recipes—including seal pressure, seal jaw temperature, line speeds—stored so that line operators may rapidly select the product and package size to dictate proper settings. These recipes ensure that proper settings are always used, and seal integrity is consistently at peak performance.”

Proper machine settings are especially critical because these parameters define the elastomers’ behavior that must flow to caulk potential channels within the seal area to maintain a low O2 environment within the package. Many shelf-life issues with low O2 packaging can be traced back to production-induced inconsistent seals.

“Brands also increasingly desire flexibility in achieving low O2 packaging,” Kolmus continues. “For example, BW’s machines now have 50% higher seal pressure capability. This allows the same seal integrity and production line speeds when using alternative or more sustainable packaging, including recyclable, recycled content, and thinner gauge package materials. This gives brands much needed flexibility to convert to more sustainable low and no O2 packaging operations.”

Reiser also supplies a range of packaging machinery to remove or reduce oxygen from the package headspace, including Ross tray sealing lines, Repak and Variovac horizontal form-fill-seal packaging machinery, and Supervac vacuum chamber packaging machines. “The pulsing evacuation sequence allows the product to equilibrate and release the O2 in stages for much reduced O2 levels in bakery and wet foods,” says Mike McCann, packaging specialist at Reiser.

Ensuring the proper seal also demands machinery finesse. “Reiser packaging specialists fine-tune machinery specifications such as seal area design and gaskets,” says McCann. “For low and no O2 packaging, sealing gaskets that connect two package components are very critical. We fine-tune our wide array of sealing gasket designs, including parabolic-shape for some wetter foods, double bead for other applications, to make sure the seal is robust.”

Although reducing or eliminating O2 within the package headspace is the primary goal of MAP machinery, food safety is also center stage. The unique headspace evacuation system allows for enhanced food safety, McCann explains. “We have separate pins for evacuation and gassing. O2 is evacuated through one set of pins while the proper gas mixture is added through a second set of pins to ensure that the gas entering the system remains uncontaminated,” he says.

Oxygen Scavengers

Evacuating O2 from foods such as bakery products, with an inherent amount of air channels, and foods with intercellular oxygen presents a particular challenge. O2 levels remain higher than desired when air is not quickly released from these channels and intercellular regions in the degassing and gassing operations and before sealing.

Often oxygen scavengers are used in combination with barrier packaging and packaging machinery that creates a vacuum and low O2 environment. Oxygen absorbers and scavengers are incorporated into the package structure or added as sachets within the package headspace. For example, beef jerky brands Jack Link’s, Great Value, Wild West, and Cattleman’s Cut contain oxygen scavengers within their high-barrier packaging to inhibit oxidation and microbial growth. Sachet components commonly include iron powder and enzymes, ascorbic acid, unsaturated fatty acids, photosensitive dyes, immobilized yeast, or palladium.

Introducing Antioxidants

Synthetic and edible packaging imparts antioxidants, which stall oxidation. Butylated hydroxyanisole (BHA) and butylated hydroxytoluene (BHT) and tert-butylhydroquinone (TBHQ) are commonly used synthetic antioxidants that are incorporated into packaging. These antioxidants diffuse from the package material into the package headspace and foods, inhibiting further oxidation by impeding the formation of secondary reaction byproducts.

The use of natural antioxidants within bioderived and edible packaging (packaging that humans can consume), however, is rapidly replacing or complementing the use of these synthetic antioxidants. This conversion is the result of interest in clean labels, cost reduction, and more focused solutions with intimate food contact. Common bioderived and edible packaging substrates include polysaccharides and proteins such as hydroxypropyl methylcellulose, chitosan, sodium alginate, and whey and soy proteins. Antioxidants incorporated into edible packaging include alpha-tocopherols, phenolics, ginger, rosemary, oregano, and thyme essential oils; green, oolong, and black tea; and cypress and grape seed extracts.

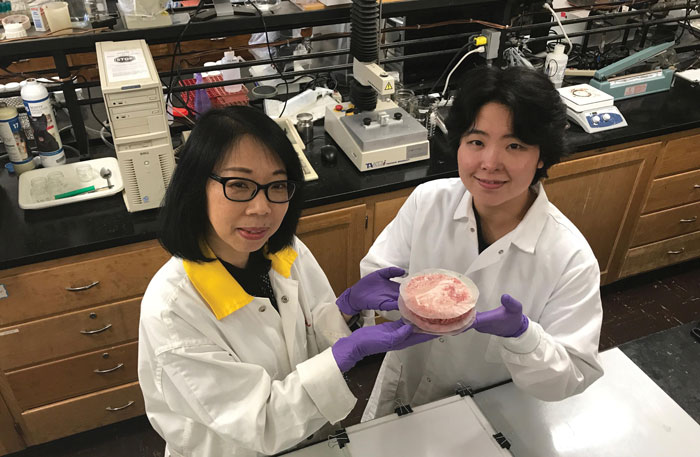

Yanyun Zhao, professor in the Department of Food Science and Technology at Oregon State University and an IFT Fellow, has researched bioderived and edible packaging for more than 20 years. “When I began research in bioderived and edible packaging, I considered edible packaging substrates as an excellent carrier for nutrients such as vitamin E and calcium onto carrots, strawberries, and other fruit that lack these nutrients,” she says. “Since then, we have expanded this capability to carry not only nutrients but also antioxidant and antimicrobial agents. Specifically, to stall lipid oxidation in the packaging used for high-fat food items, such as fish fillets, meat, tree nuts, and cheese, we have enabled the use of antioxidants such as vitamin E and phenolics.”

Vitamin E (alpha-tocopherol) is a natural, free radical scavenger that stops oxidation reactions specifically within cell membranes by donating a hydrogen atom to a peroxyl radical. Phenolics are free radical acceptors and prevent the formation of other radicals.

In addition, “we have advanced the use of other substrates such as chitosan as a film-forming (matrix) material,” says Zhao. “Chitosan has great antioxidant activity due to several mechanisms, including the donation of hydrogen or lone pairs of electrons from positively charged amino groups and hydroxyl groups in chitosan for scavenging free radicals and chelating metal ions. We have interest in chitosan because of its unique antioxidant and antimicrobial functions.”

The Zhao laboratory has also produced beta-chitosan from squid pens with fewer extraction steps than shrimp and crab shells. “We also have advanced edible packaging production and can produce monolayer films and multilayer coatings and laminates. This last area, laminates, has much promise,” she says. “The ability to create laminations has allowed my laboratory to refine edible packaging to have mechanical—tensile strength, elongation, seal strength—and barrier and chemical—permeability and water and oil resistance—properties that closely match the capabilities of nonedible films to release antioxidants and antimicrobials.

“For example, to create edible packaging effective against gram+ and gram- bacteria, suitable for cheese and other food items, we combine layers composed of chitosan and lysozyme with other layers with higher mechanical and chemical strength. This same approach is used to create a combination antioxidant and antimicrobial film,” she says.

Zhao says several of her research areas have implications relating to bioderived and edible packaging that inhibits oxidation. “One area is how the properties of food waste can be harnessed to extend the shelf life of food. For example, we have employed the natural antioxidant capability of phenolics extracted from upcycled fruit and wine grape pomace in edible film formulations to reduce lipid oxidation,” she explains. “A second area is laminating our bioderived packaging onto synthetic films such as Saranex to significantly decrease lipid oxidation. The third area defines the use of cellulose microfibrils and cellulose microcrystals within edible packaging, and our recent patents—US10334863B2, US9826750B2, US10400128B2—on this area are a glimpse into how fast this area is developing. The incorporation of alpha-tocopherol into nanoparticle-loaded films for the controlled release of antioxidants is of particular interest.”

The contributions of Rachel Rosenbloom, former research assistant in Yanyun Zhao’s laboratory, are appreciated.