Cleanroom Technologies in Food Processing and Packaging

PACKAGING

What is a cleanroom and why should any of us care about applying such technologies for food processing and/or packaging? What are the benefits of a cleanroom?

The answer, my friends, is almost literally driven on the wind (to cite Bob Dylan) from one of our stellar University of Georgia online Master’s Degree in Food Technology graduate students, Paul Rockwell, who recently addressed those questions brilliantly in one of his term projects. Rockwell ([email protected]) is R&D Chef for Diversified Foods and Seasonings in Madisonville, La. Information from his great report is extracted and presented here for Food Technology readers.

The answer, my friends, is almost literally driven on the wind (to cite Bob Dylan) from one of our stellar University of Georgia online Master’s Degree in Food Technology graduate students, Paul Rockwell, who recently addressed those questions brilliantly in one of his term projects. Rockwell ([email protected]) is R&D Chef for Diversified Foods and Seasonings in Madisonville, La. Information from his great report is extracted and presented here for Food Technology readers.

An Introduction to Cleanroom Technologies

Cleanroom technologies significantly reduce the contamination of foods and their interior primary packaging by the use of reduced air and waterborne dust and microorganisms, plus a hygienic environment in which the low level of pollutants or particulates is controlled through the implementation of very specific design. Cleanrooms are engineered to minimize food and beverage contamination by application of positive filtered or incinerated air pressure and a tightly controlled environment. Long used in hospital operating rooms and for pharmaceutical packaging, cleanrooms help to extend shelf life and deliver a safer food/beverage product for the consumer. We shall explore cleanroom basics, the steps of designing a cleanroom for food and food packaging industry applications, common uses, and the assets and liabilities inherent to technologies of today and for the future.

Applied in industries that require an environment free of dirt, dust, and ubiquitous microorganisms for processing, cleanrooms have entered into the food and food packaging industries. The roots of cleanrooms can be traced back to Swiss watchmakers who covered their work to prevent dust from falling on their timepieces. Various other attempts were made to control particulates throughout history, but the big strides in the technology came during and after World War II with the need to control particulates for nuclear and aerospace testing and production. Today’s cleanrooms need not be rooms with four walls, a floor, and a ceiling. Rather they are controlled three-dimensional space with, for example, barriers from air curtains.

Food and Food Packaging Applications

Today, food and food packaging industries apply cleanrooms to retard airborne microbes from entering foodstuffs. This reduction can help extend shelf life, retain freshness, increase yield, and reduce product recalls. Consumers’ preferences today are for minimally processed products with few articulated additives. Therefore, producing and packaging food products in a cleaner environment are important challenges for food manufacturers/packagers.

--- PAGE BREAK ---

Cleanroom technology can be utilized in the food and packaging operations within processes that cannot be performed in a closed machine such as aseptic processing or packaging. Microorganisms can attach to airborne particles, and thus, when foodstuffs are exposed to air, there is opportunity for airborne contamination.

As part of the hurdle technology approach, many processors are using elements of cleanroom technology in the design of production facilities. With newly published international standards for cleanrooms, there are more uniform guidelines as to what constitutes a cleanroom, and, with this, possibly more food and beverage companies are becoming aware of how others are benefiting.

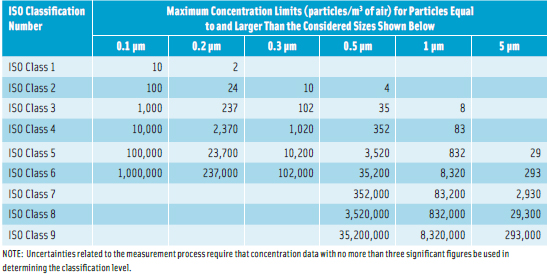

ISO Classification of Cleanrooms

ISO 14644-1 states that a cleanroom is “a room in which the concentration of airborne particles is controlled, and which is constructed and used in a manner to minimize the introduction, generation, and retention of particles and microbes inside the room and in which other relevant parameters, e.g., temperature, humidity, and pressure, are controlled as necessary,” according to the National Science Foundation. Cleanrooms are classified according to the cleanliness needed for the product. Classifications are determined by the maximum number of particulates for each particle size found in a cubic meter of air. Table 1 shows the classifications of clean room as determined by ISO 14644-1.

ISO 14644-1 states that a cleanroom is “a room in which the concentration of airborne particles is controlled, and which is constructed and used in a manner to minimize the introduction, generation, and retention of particles and microbes inside the room and in which other relevant parameters, e.g., temperature, humidity, and pressure, are controlled as necessary,” according to the National Science Foundation. Cleanrooms are classified according to the cleanliness needed for the product. Classifications are determined by the maximum number of particulates for each particle size found in a cubic meter of air. Table 1 shows the classifications of clean room as determined by ISO 14644-1.

Air Filtration

A critical part of the cleanroom’s operation is air filtration. High efficiency particulate air (HEPA) filters, which can remove 99.99% of particles (typically 0.3 μm), are often used. Generally in a cleanroom environment, supply air enters from overhead in a laminar flow pattern, meaning that the air will flow in parallel layers with a uniform velocity. This allows for a non-turbulent airflow, helping to reduce the number of particles in the air, eventually scrubbing the floor with air as it comes down from the top entry level.

Air change rate, another important concept, is the number of volumes of air, equivalent to the cleanroom’s air volume capacity, that enter and exit the three-dimensional space. The FDA specifies 20 air changes per hour, but some plants have cleanroom enclosed fillers that provide 40 complete air changes an hour.

--- PAGE BREAK ---

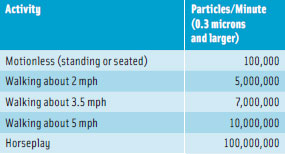

Contamination Sources  Contamination comes from many sources—the facility itself (walls, floors, ceilings, paint, coatings); construction material (sheet rock, sawdust, etc.); air conditioning debris and equipment; and supplies (particles from friction and wear, lubricants and emissions, vibrations, brooms, mops, items brought into the cleanroom, debris, corrugated fiberboard case dust). But the biggest source of contamination is from people (skin flakes, oil, hair, spittle, and particles attached to clothes). Table 2 shows particle generation from various human activities.

Contamination comes from many sources—the facility itself (walls, floors, ceilings, paint, coatings); construction material (sheet rock, sawdust, etc.); air conditioning debris and equipment; and supplies (particles from friction and wear, lubricants and emissions, vibrations, brooms, mops, items brought into the cleanroom, debris, corrugated fiberboard case dust). But the biggest source of contamination is from people (skin flakes, oil, hair, spittle, and particles attached to clothes). Table 2 shows particle generation from various human activities.

Appropriate employee training and effective cleanroom design can help to ensure proper cleanroom protocol with acceptably reduced contaminant introduction.

Cleanroom Construction and Materials

The construction of cleanrooms and the materials used are imperative to the lasting success of their operation. Panels should be easy to clean and provide a sanitary surface in the processing/packaging environment. Careful attention should be paid to the joints for the panels (areas where the panels meet the floor, ceiling, or each other). Proper installation and using the correct materials can help prevent water migration, which will lead to mold and bacterial growth. Ceiling lights should be enclosed to help minimize contamination. Doors and windows are often custom made to fit the specifications for the cleanroom.

Steps in Engineering a Cleanroom

1) The first step in designing a cleanroom is to consider the flow of materials and people. The workers in a cleanroom are the largest source of contamination. Therefore, all of the critical processes (i.e., packaging) should be isolated from the worker access points. Employees must be trained and follow cleanroom protocol. The appearance of the cleanroom itself should set it apart from the rest of the facility, in that it looks like an area where special attention needs to be paid and a natural tendency toward discipline occurs. The cleanroom will most likely contain several areas such as gowning/ungowning rooms, but the most critical processes should be performed in an area that has only a single access.

2) The next step is determining the classification of the clean room. It is important when engineering to take into account that there can be no more than two differences in classifications between physical spaces. For example, you cannot have a Class 10,000 room connect to a Class 10 area, but it is acceptable to have a Class 1,000 connect to a Class 100. The more critical processes will occur in higher class clean spaces. Class 100 clean rooms are suggested for aseptic processes while Class 100,000 should be used for sterile packaging.

--- PAGE BREAK ---

3) The next step in the designing process is to determine the space pressurization. Part of the technology of the cleanroom is to maintain a positive air pressure to minimize the introduction of particles. It is advised to have a positive pressure going from a clean area to a less clean area. A pressure differential of 0.03–0.05 inches of water has been found to be successful in helping reduce the introduction of contaminants. Drawbacks of high pressure differential include a higher cost and more difficulty in controlling.

4) Determining the air change range per room is the next step. The clean room classification, the occupancy rate, and the anticipated activity all need to be taken into consideration. Each classification has a suggested range, and a rate should be chosen within the range based on these considerations.

5) Next, the air exfiltration needs to be determined. Generally cleanrooms are under positive pressure but not hermetically sealed. There will be exfiltration into adjoining spaces and usually leakage of 1% to 2% due to electrical outlets, window frames, door frames, light fixtures, ceiling/wall/floor joints, etc. Leakage is not necessarily a problem, but needs to be accounted for.

6) The next step is space/air balance determination. Basically, all the air coming in (supply/infiltration) needs to be balanced with all the air going out (exhaust/exfiltration). Final adjustments need to be made once the cleanroom is up and running due to unplanned leakage.

7) Environmental conditions are an important aspect of cleanroom design. Temperature is one of the main items to be addressed. Comfort of the workers needs to be taken into consideration as they may be wearing suits over their regular clothes. Typical temperatures for cleanrooms tend to be 66°F to 70°F, but they may be much cooler for safe food production in chilled meat, seafood, produce, salad, and ready meal, etc., plants.

--- PAGE BREAK ---

Relative humidity is an important consideration. Cleanrooms develop a large electrostatic charge due to the high airflow. The relative humidity must be high enough (between 40% and 50% relative humidity) to reduce an electrostatic charge buildup. If the humidity is low and the walls and ceilings have a high electrostatic charge, particulates will adhere and then be released when the charge is discharged, sending them out into the air. Noise and vibration may cause more particulate disruption.

Issues and Solutions with Cleanrooms in Food Processing

Cleanrooms provide excellent environments for contaminant-sensitive products, but there are several problems with utilizing cleanrooms in the food industry. There are high production rates, and, therefore, personnel traffic that can disrupt the ventilation. Air locks and air showers can help to minimize this problem. There are also potential problems with the operating staff not respecting the cleanroom’s strict procedures. Proper staff training, cleanroom design, and management presence is key for personnel understanding and respecting the cleanroom procedures and protocols.

Food processing and packaging, and the subsequent cleaning that takes place in the facility can cause the relative humidity to fluctuate greatly, thus causing damage to the cleanroom equipment and environment. Proper design, appropriate monitoring, and adequate equipment are necessary to keep the cleanroom environment in compliance.

More Application Opportunities Ahead

Having found its way into the food and food packaging industries after being developed and effectively utilized in other industries, cleanroom technology offers many benefits for food manufacturers now and in the future. With the benefits of safer products and extended shelf life, cleanroom technologies must be more widely applied. Proper design, training, and monitoring, along with developing technologies, can help food manufacturers to continue to successfully move forward with cleanroom technology.

To prolong the safe, quality shelf-life extension, drill down into the entire distribution system for total control of the environment. Cleanroom is as much an effective elemental component for chilled foods as are hurdle technologies, oxygen reduction, ingredients, formulation, and intelligence—another yellow brick on our road to a great new food category.

Aaron L. Brody, Ph.D.,

Contributing Editor

President and CEO, Packaging/Brody Inc., Duluth, Ga., and Adjunct Professor, University of Georgia

[email protected]