Advances in Meat Processing

PROCESSING

The meat and poultry industries have continued to consolidate, which means that processing plants are larger and more centralized than was previously the case. The industries are still heavily dependent on manual labor, but also suffer from relatively high turnover so they have had to simplify and automate or mechanize tasks so new workers can be quickly and safely trained.

Emerging pathogens, such as Escherichia coli O157:H7, its toxic relatives, and Listeria monocytogenes, have, unfortunately, been too often in the news concerning meat and poultry products. The centralized production of shelf-ready cuts and ground meats has increased the opportunities for cross-contamination and also increased the quantities of product that might be affected.

Emerging pathogens, such as Escherichia coli O157:H7, its toxic relatives, and Listeria monocytogenes, have, unfortunately, been too often in the news concerning meat and poultry products. The centralized production of shelf-ready cuts and ground meats has increased the opportunities for cross-contamination and also increased the quantities of product that might be affected.

The American Meat Institute, Arlington, Va. (phone 703-841-2400), has addressed these issues with a number of programs, including an Equipment Design Task Force (EDTF), which has published 10 principles of sanitary design.

Principles of Sanitary Design

According to the AMI EDTF, the principles are as follows.

1) Cleanable to a microbiological level. “The removal of all food materials is critical. This means preventing bacterial ingress, survival, growth, and reproduction on both product and non-product contact surfaces of the equipment.”

2) Made of compatible materials. “Equipment materials of construction must be inert, corrosion resistant, nonporous, and nonabsorbent.”

3) Accessible for inspection, maintenance, cleaning, and sanitation. “All parts of the equipment shall be accessible … without the use of tools.” This means, in practice, minimization of panels and guards. Those that are necessary are often fastened with wing nuts or similar easy-to-remove devices.

4) No product or liquid collection. “Equipment should be self-draining to assure that food product, water, or product liquid does not accumulate, pool, or condense on the equipment or product zone areas.”

5) Hollow areas should be hermetically sealed. “Bolts, studs, mounting plates, brackets, junction boxes, nameplates, end caps, sleeves, and other such items must be continuously welded to the surface, and not attached via drilled and tapped holes.” Lack of continuous welds and unnecessary openings to hollow areas are two of the most common offenses against this principle.

--- PAGE BREAK ---

6) No niches. “Equipment parts should be free of niches such as pits, cracks, corrosion, recesses, open seams, gaps, lap seams, protruding ledges, inside threads, bolt rivets, and dead ends. All welds must be continuous and fully penetrating.”

7) Sanitary operational performance. “During normal operations, the equipment must perform so it does not contribute to unsanitary conditions or the harborage and growth of bacteria.”

8) Hygienic design of maintenance enclosures. “Maintenance enclosures and human machine interfaces such as push buttons, valve handles, switches, and touchscreens, must be designed, constructed, and maintainable to ensure food product, water, or product liquid does not penetrate into, or accumulate in and on the enclosure and interface. The physical design of the enclosures should be sloped or pitched to avoid use as a storage area."

9) Hygienic compatibility with other plant systems. This refers to such systems as electrical, hydraulics, steam, air, and water.

10) Validate cleaning and sanitizing protocols. “Procedures … must be clearly written, designed, and proven effective and efficient. Chemicals must be compatible with the equipment and the manufacturing environment.”

Listeria monocytogenes is of particular concern in ready-to-eat(RTE) meat and poultry plants because there is no kill step after packaging and the products are vulnerable to contamination before packaging. Most such plants are refrigerated to retard the growth of most microbes, but Listeria grows at low temperatures.

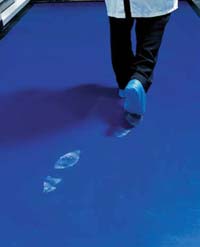

“Clean room” technology may be applied in well-designed packaging areas for RTE foods. This typically means filtering the incoming air; maintaining a positive pressure difference in the room relative to those adjacent; keeping doors closed; using foot baths, sticky pads, or other devices to remove particles from shoes and wheels; and sanitizing tools before bringing them into the room (or having dedicated tools for the room). Cross-contamination by maintenance is often overlooked as a risk.

Dycem Ltd. USA, Warwick R.I. (www.dycem-cc.com, phone 800-458-0060), offers an alternative to baths or sticky pads called CleanZone technology, which uses a smooth polymer pad containing antimicrobial silver. The pads can be easily cleaned to remove the captured particles.

--- PAGE BREAK ---

Upgrading Lower-Value Materials

In a 2005 column (Food Technology 59(7): 80-83), I described Beef Products Inc. (BPI), Dakota Dunes, S.D. (phone 605-217-8000), and its novel process for isolating high protein fractions from fatty trimmings of beef and, potentially, other animals. Because the process relies on delivering a pathogen-free product, the company takes some extraordinary precautions to maintaining sanitary conditions.

The company designs and builds its own very rugged grinders and transfer pumps intended to be low on maintenance requirements. Some models are available for sale to others. Parts of the plant have stainless steel paneled walls and ceilings to make cleaning easier. Drains are stainless steel and are in a clean-in-place (CIP) circuit. Incoming air is washed with a disinfecting solution, and the facility is refrigerated.

The process involves grinding the fatty trim to remove sinews and reduce particle size, then warming to just over 100˚F, where the fat melts but the protein does not cook. The fat and lean are separated by centrifuge.

The fat, which is edible tallow, is vacuum dried and packaged, then cooled so it solidifies. The lean is treated with ammonia, which, by raising the pH, effectively kills all pathogens. This treatment was discovered accidently, when an ammonia release in a cooler resulted in the stored meat becoming nearly sterile. The ammonia is volatile, and so is easily removed.

Quickly, the treated high protein material is spread on a chilled drum, frozen into a sheet, scraped off, ground, and packaged. The whole process is said to take just seven to nine minutes, which is quite short compared to many food processes.

Perhaps more remarkable than its technology, which in some ways is a refinement of edible rendering, is BPI’s guarantee to its customers. The BPI ingredient was new to the industry and required education in its use. It is about 94% protein and is intended to be blended at up to 15% in ground beef formulations for foodservice hamburger patties, chili, and other ground beef-based products. Because of its low-temperature history, the protein is still functional for binding, but its small particle size could detrimentally impact texture.

The economic incentive is to blend the high protein ingredient with less expensive, lower-protein trim to hit desired fat and lean composition while retaining taste and texture. Relatively fatty trim is flavorful and juicy, but consumers are increasingly conscious of calories and saturated fat content. The optimum blend is determined by each user according to its customers’ preferences and costs. BPI guarantees pathogen-free products if their ingredient is used as directed.

There seems to be no obvious reason the process could not be used on other sources of fatty trim, and, in fact, it has been demonstrated on pork.

--- PAGE BREAK ---

Process and Packaging Intersect

Modified atmosphere and vacuum packaging have extended the safe shelf life of fresh and cooked meat products so that more value-added products can be produced in large, central locations. Modified atmosphere (MAP) refers to flushing packages with a mixture of nitrogen, carbon dioxide, and low levels of oxygen before sealing. Some oxygen is necessary to preserve the desirable red color of fresh meat. It also prevents the atmosphere from becoming anaerobic, which would allow formation of botulinum toxin, if the meat were contaminated.

The U.S. Dept. of Agriculture and the meat industry emphasize that fresh or raw meat is not expected to be sterile and that it must be thoroughly cooked before safe consumption. Unfortunately, many of the recalls that the industry has suffered have been triggered by contaminated ground beef. Irradiation of packaged ground beef is a reliable precaution that a few markets are demanding of their meat suppliers. The primary targets are E. coli O157:H7 and Salmonella. In precooked products such as lunch meats and franks, Listeria is the worst hazard. Post-packaging pasteurization with carefully controlled hot water is one possible approach. Another is vacuum steam flushing just before sealing.

Finally, high pressure processing (HPP) is commercially applied to some cooked meat products, such as banquet hams and lunch meats. The products are still refrigerated, but HPP can greatly reduce post-processing contamination.

As previously mentioned, clean room technology may be required if fresh or cooked products are to be packaged for extended shelf life.

The meat industry is a large, sophisticated segment of the food industry, pioneering in such areas as MAP, robotics, HPP, and sanitary design. As other segments evolve toward fresher taste and texture, meaning less severe processing, they could be inspired by and learn from the efforts of the meat industry.

J. Peter Clark, Contributing Editor, Consultant to the Process Industries, Oak Park, Ill.

[email protected]