Packaging for Sweet Treats

PACKAGING

Consumers now enjoy a surfeit of packaged candy choices at candy stores, grocery stores, supermarkets, drug stores, and on the internet. While shelf-life considerations occupy the center stage in packaging material selection, production efficiencies, convenience, and the drive for brand presence via packaging define package design. The nature of candy as a unique treat is communicated via the expressive aspects of candy packaging design.

Chocolate Bar Packaging Evolves

After chocolate bars were first created with the Fry’s Chocolate Cream bar in the 1860s, rapid developments led to Nestlé, Lindt, Cadbury, and Toblerone establishing packaged chocolate brands in Europe by 1910. The HERSHEY’S 5-cent chocolate bar in coated paper wrap was the first mass-produced bar in the United States in the early 1900s. Interestingly, chocolate shelf life is terminated primarily due to temperature abuse or inappropriate processing resulting in blooming. Because of the high fat content of chocolate, however, the coatings on paper and glassine packaging structures are readily plasticized and more prone to absorb flavors and odors, resulting in a deleterious effect on sensory properties.

The initial HERSHEY’S chocolate bar packaging evolved in the 1980s from coated paper to a two-layer package with an inner foil wrap covered by an overwrap. Additional 5-cent packaged chocolate bars employed single layers of glassine, foil, or paper.

“During the Depression years, BabyRuth, the Clark bar, MilkyWay, CHARLESTON CHEW, SNICKERS, and PAYDAY provided energy and nutrients from caramel, egg whites, and nuts and thus gained popularity,” shares Beth Kimmerle, confectionery historian and owner of Attribute Analytics. In these bars, chocolate provided the edible barrier protecting the added ingredients from moisture loss or gain as well as oxidation. In the 1940s, the bar size of HERSHEY’S was doubled, and a switch was made to an inner glassine wrap while maintaining the iconic block lettering on the dark paper background of the outer wrap of the new 10-cent chocolate bar.

The tactile aspect of unwrapping a candy bar shifted as brands began to use higher-efficiency packaging machines. Since early 2002, HERSHEY’S bars have been flow-wrapped in a single oriented polypropylene-based barrier, which allows for increased production efficiency and less flavor and odor adsorption than glassine wrap or paper-coated foil. The packaging of the iconic brands of Nestlé, Lindt, and Cadbury has also migrated from paper-based to polymers and back. For example, Nestlé employs recyclable paper-based packaging for its chocolate, fruit, and nut Yes! branded bar. Notably, the 10 g of protein within each bar is protected by the traditional package as well as edible coatings, including a chocolate coating, for a 9 mo shelf life. Altering from the most common material structure, nonmetallized or metallized polypropylene, involved production adjustments to compensate for the lower tensile strength and tear resistance of the paper-based packaging. These adjustments included modifying the former on the horizontal form-fill-seal machine to more gently form a tube into which the bar was inserted at a rate of 300 chocolate bars per minute. After sealing, cartoning operations inhibited the tearing commonly associated with paper-based packaging. While the majority of chocolate bars are rectangular prisms, the TOBLERONE triangular product and prism-shaped packaging defines the brand and is reminiscent of Mount Toblerone in Switzerland.

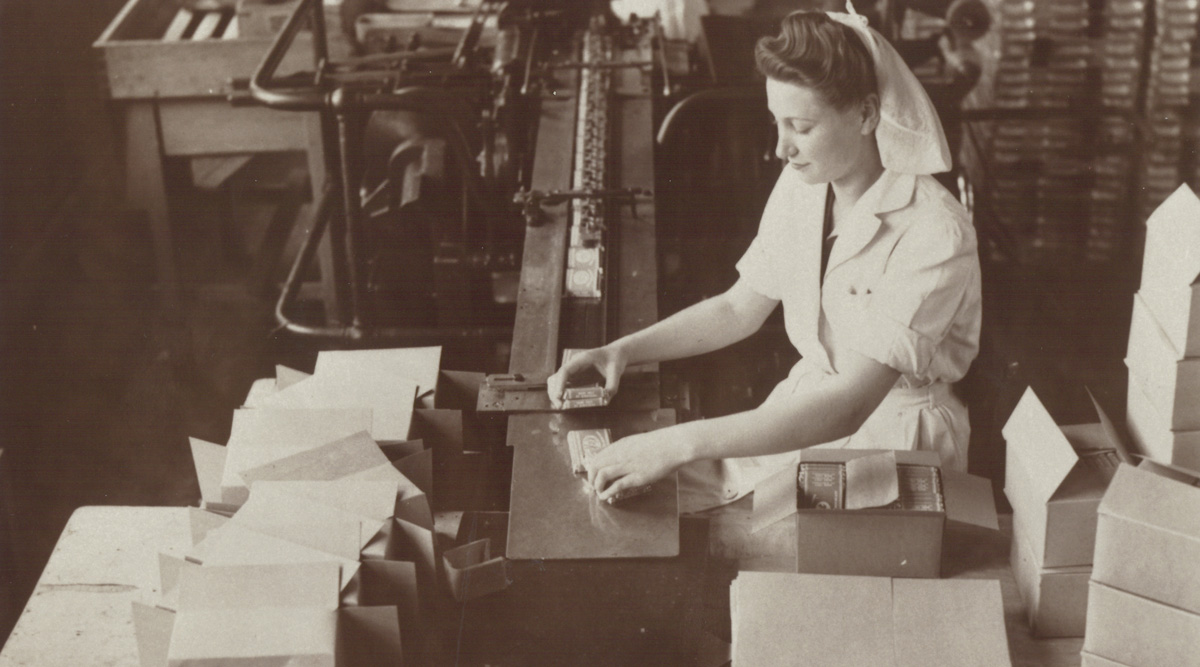

The rapid advance of chocolate bars suitable for individual retail sale from 1900 to 1920, as well as brand retention, mirrored the other packaged confections at the time. Much like with chocolate, advances in production and packaging machinery of other candy products led to increased sales in the 1920s. Since then, further advances created and retained iconic brands via packaging. For example, Just Born Quality Confections retained its iconic brand presence while adding automation and expanding product offerings with packaging. Just Born’s recent investment in further automation was made to increase efficiency and provide the agility to employ different packaging types.

Senior Packaging Engineer Charlotte Edwards shares a recent innovation in the automation of PEEPS packaging: “The Just Born automated system begins with tray erectors and handling of the PEEPS soft marshmallows using Soft Robotics grippers, and ends with a flow wrapper and case packing station using an array of spiral, S-curve, and lug conveyors. Packaging changes made to accommodate this automated packaging ensured that consumers experienced the same strong brand image.” Providing product protection for iconic brands such as PEEPS is also paramount. Edwards expanded: “The soft and warm PEEPS coming off the production belt must be shipped flat on their “back” to avoid damage. However, the retail case needs to showcase the PEEPS face-first for consumers. To do this, we designed the corrugated case to ship one way and then be displayed at retail from another side. This solution led to cost-effective results and improved retail display.”

One of Just Born’s target markets for MIKE AND IKE and HOT TAMALES is the gaming and theater industry. With these products, consumers push in a perforated tab on the side of the box and then control product dispensing with a shake of the hand while they are busy gaming or watching a movie. This package dispensing feature is intuitive and allows for the “safe sharing” of the candy without the risk of product contamination. Recent additions such as heat-sealable oriented polypropylene and polyethylene stand-up pouches that contain MIKE AND IKE, HOT TAMALES, and individually wrapped Egg Hunt PEEPS retain a strong brand presence as well. Likewise, the GOLDENBERG’S PEANUT CHEWS candy is now available in a stand-up pouch, and graphics have remained consistent since their development as high-energy, high-protein food for World War I soldiers. As with other mentioned candy brands, WHITE RABBIT has a strong brand image linked to its unique packaging. Edible rice paper is used as the inner packaging for this creamy, sweet candy.

Gum and Mints Mix It Up

Unlike candy bar packaging, chewing gum and mints packaging has deviated in recent years from a standard package shape. From the Neolithic period to the 1960s, chewing gum was derived from various types of tree bark. The inherent stickiness of gum has proved a packaging challenge. In the early 1900s, wrapping machinery innovations enabled the mass packaging of gum. To provide shelf life and convenience, gum is now also packaged in laminated foil and coated paper, sealed polyethylene terephthalate thermoformed trays, resealable stand-up pouches, and lidded, rigid polypropylene cups that fit within car cup holders.

Many brands use multiple packaging formats with unique brand-focused package design. For example, Dentyne ICE is offered to consumers packaged in a wide variety of packaging types and sizes, including a shrink-wrap labeled, resealable, rigid hourglass-shaped canister containing 60 pieces, a sealed thermoform tray containing 10–16 pieces within a paperboard sleeve, as well as a resealable stand-up pouch containing 110 pieces. Similarly, mints employ packaging material and shape to create a brand image. For example, ALTOIDS and NEWMAN’S OWN mints are packaged within a recyclable or reusable short, steel cuboid-shaped reclosable container; and Tic Tac employs a rigid, clear cuboid with a dispensing system that consumers identify with the brand.

Packaging to Meet Emotional Needs

To enable consumers to enjoy the product presentation and unwrapping experience, specialty candy lacks the convenience features associated with other types of candy. An iconic specialty candy box is part of the gift. The process of unwrapping the packaging is connected more with meeting emotional needs than the rationale for consumers’ convenience. For example, a gift of a Valentine’s Day heart-shaped box of candy is a message from the giver to the receiver.

The formerly torpid and solely regional sales of specialty candy have expanded with the increase in e-commerce. And while the packaging of specialty candy is designed for gift giving and special occasions, it is also designed to reduce damage during shipping. For example, the redesign of Ethel M Chocolates allows for hand packing of each piece of candy into thermoformed trays within a two-piece interlocking rigid paperboard box. The packaging features the color palettes of the Mojave Desert, where the company is based, in order to give consumers a sense of the location. Cold packs are used to ensure that the chocolate is protected against the heat.

The high degree of specificity in specialty chocolate demands adjustable and agile packaging systems. For example, packaging for the Mr. B’s Chocolates seasonal hand-painted corn, pumpkins, and fall leaves candy requires flexible bags with inner padding; and the unique shapes of roosters, tractors, and bison require further specialized hand-packable package designs. Notably Mr. B’s Chocolates employed an inner foil-based wrap with a coated, printed paper-based overwrap suggestive of early candy bar packaging. Likewise, since 1920 Hammond’s of Denver has produced innovative flavor combinations for packaged candy and has expanded beyond regional sales via the internet.

The packaging of a wide variety of holiday-specific candy is accomplished by using common paper-based bags with windows to showcase the differences between the shapes and colors. Similarly, the use of creative packaging annually transforms quotidian candy into seasonal candy using shaped windows, glow-in-the-dark packaging, and eye-catching retail display cases.