Annual Meeting Papers Address Nonthermal Processing Methods

PROCESSING

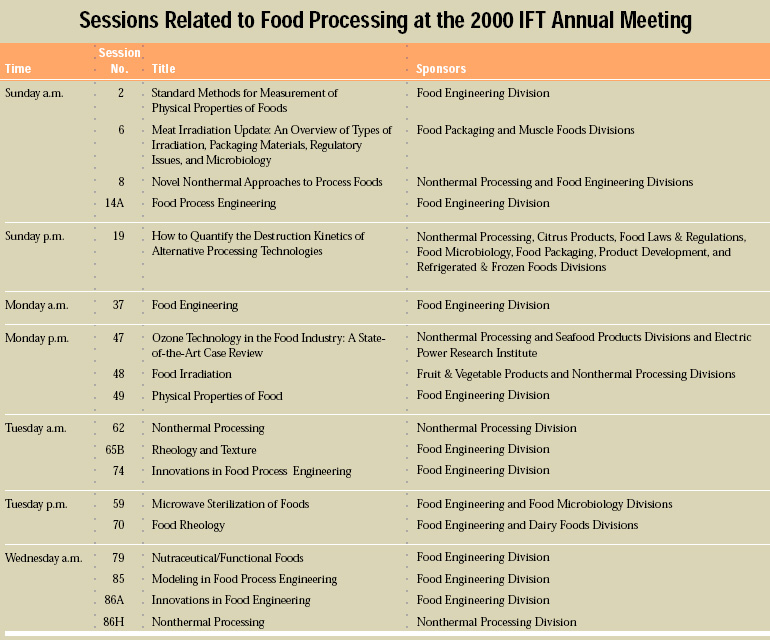

Nonthermal processes continue to be the subject of much research and development. Among them are high pressure, irradiation, pulsed electric fields, pulsed light, ultraviolet light, and ultrasound. The following are brief descriptions of selected papers on these subjects that will be presented at this year’s IFT Annual Meeting.

Overviews

D.F. Farkas of Oregon State University will discuss high-pressure processing (HPP) and ultrasound. Subjecting foods to pressures between 100 and 800 megaPascals, MPa (15,000 to 120,000 psi) inactivates vegetative bacteria, yeasts, molds, and parasites in such products as jams, orange juice, and meat products. Factors that affect the rate of microbial inactivation include pressure magnitude, microbial type and growth stage, temperature, pH, water activity, and food composition. He will discuss microbial inactivation mechanisms of HPP and mathematical models for inactivation kinetics based on these mechanisms, as well as validation of processes. He will also discuss use of ultrasound to evaluate the internal quality and composition of foods. Paper 19-5

D. Knorr of Berlin University of Technology, Germany, will discuss nonthermal technologies for preservation and modification of foods and food constituents, such as high hydrostatic pressure and high-intensity electric field pulses. He will give examples of recent developments in the areas of microbial inactivation, permeabilization of biological membranes, phase transition of water and biopolymers, and process development, and discuss challenges, such as the limited amount of data available on the kinetics of quality and safety changes during and after processing. Paper 62-1

J. Raso-Pueyo of the University of Zaragoza, Spain, will discuss nonthermal methods as hurdles in food preservation. Besides preserving food quality, new nonthermal technologies have to achieve an equivalent or preferably enhanced safety level compared to the procedures that they replace. Most nonthermal preservation techniques are highly effective in inactivating vegetative forms of bacteria, yeast, and molds, but bacterial spores and most enzymes remain difficult to inactivate. Combining nonthermal food processes with traditional or other emerging technologies is known as “hurdle technology.” The most promising combinations include nonthermal methods, such as high hydrostatic pressure, ultrasound, and pulsed electric fields. Paper 8-6

F.F. Busta of the University of Minnesota will discuss IFT’s contract with FDA on how to quantify the destruction kinetics of alternative process technologies, such as thermal, pressure, and electromagnetic processes. Paper 19-6

Q.H. Zhang of Ohio State University will discuss processes developed to sterilize or reduce the microbial population on the surface of packaging materials, including pulsed light, high-intensity x-ray pulses, and oscillating magnetic fields. Paper 19-2

R.P. Singh of the University of California-Davis will discuss the need for standard methods for measurement of physical properties of foods. The literature contains a large amount of data on food properties measured using published methods, but their reliability is often questionable because the methods are not standardized, and slight variations in measurement procedures often lead to errors. He will discuss how IFT’s Food Engineering Division may help steer an effort to develop standard procedures and calibration materials for property measurements. The need for obtaining reliable food property data extends to the emerging areas of high-pressure, pulsed electric field, ohmic heating, and magnetic pulse processing. Paper 2-1

High-Pressure Processing

U. Nienaber of Ohio State University will discuss research on the effects of high-pressure treatments on texture of Cheddar cheese at various stages of ripening. Application of high pressure for short periods early in the ripening process has the potential to shorten ripening time. Applying higher pressures later during ripening may allow cheese manufacturers to arrest ripening at a desired level. Samples were pressure treated in a cold isostatic press initially and at 1 and 3 mo of aging. Applied pressures were 400 and 800 MPa for 5 min at 25°C. The results of evaluations of hardness, cohesiveness, gumminess, and chewiness over time will be presented. Paper 86H-19

L.A. Lucore of Ohio State University will report on the effect of environmental stress on the tolerance of Escherichia coli O157:H7 to high pressure. Cold isostatic HPP can significantly inactivate pathogenic microorganisms in food while maintaining quality. A potential concern is that organisms, particularly pathogenic microorganisms, might develop resistance to HPP when placed under varying stresses, such as exposure to mild acid, heat, salt, and sublethal pressure. Three pressures (300, 500, and 700 MPa) were used. Paper 51H-23

H. He of Oregon State University will report on use of HPP to shuck oysters and extend shelf life. Whole oysters were processed at pressures ranging from 30,000 to 45,000 psi for 0, 1, and 2 min, then stored at <4ºC. Oyster quality was determined by measuring pH, moisture content, microbial counts (including aerobic, anaerobic, and coliforms), and sensory testing. Paper 51A-16

H. Calik of Oregon State University will discuss effect of HPP on Vibrio parahaemolyticus in raw oysters. The study used 35,000 psi for 1–11 min; 40,000 psi for 1–5 min; 45,000 psi for 30–120 sec; and 50,000 psi for 10–60 sec. Paper 51A-17

A.C. Hopper of Ohio State University will report on the effect of HPP on protein dye-binding properties of whey protein isolate. Conformational changes induced by high hydrostatic pressure may dramatically affect the structure and function of protein in food systems; e.g., pressure can induce gelation of protein systems and inactivation of enzymatic activity. The study involved processing at 200, 400, 600, and 800 MPa for 5 min at 30°C and measuring the dye-binding properties. Paper 78A-24

S.Y. Lin of Washington State University will present results of a study on nonthermal attenuation of lactobacilli by HPP or high-intensity pulsed electric fields and the effect of the attenuated lactobacilli on accelerating ripening of Cheddar cheese. The objective was to attenuate lactobacilli with HHP and PEF to retard lactic acid production and retain proteolytic activity of lactobacilli. Paper 78C-35

N.R. Reddy of the National Center for Food Safety and Technology will discuss inactivation of Clostridium botulinum type E spores in a model phosphate buffer and a crabmeat blend by HPP. The samples were subjected to temperatures of 30-75ºC and pressures up to 827 MPa for up to 10 min. Paper 62-2

H. Corwin of Ohio State University will report on using combinations of carbon dioxide and high pressure to inactivate pectin methylesterase in orange juice and polyphenol oxidase in apple juice. HPP can destroy microorganisms and inactivate enzymes, and supercritical carbon dioxide can partially inactivate enzymes in food. Combining the two may improve the effectiveness of the overall process, thereby leading to reduced dwell times and/or decreased pressure levels. The juice was carbonated at 15 psi of CO2 and pressure treated at 500 and 800 MPa for 3 min and 1 min, respectively, at 25 and 50°C using a hydrostatic press. Paper 62-3

H. Ramaswamy of McGill University will report on a study designed to evaluate the development and verification of HPP for treating milk and pork, on the basis of data on pressure destruction kinetics of spoilage and/or pathogenic microorganisms such as Listeria monocytogenes and indigenous microorganisms. Pressure lethality was defined as treatment time at a reference pressure (350 MPa). Paper 62-4

Pulsed Electric Fields and Pulsed Light

G. Barbosa-Cánovas of Washington State University will review pasteurization by pulsed electric fields (PEF), which involves the application of pulses of high voltage to foods placed between electrodes. Microbial inactivation is achieved through dielectric breakdown and electroporation of bacterial membranes. He will discuss advantages of PEF over heat treatment; limitations; and factors that affect the microbial inactivation, including treatment conditions (electric field intensity, treatment time, temperature, and wave shape), microbial entity (type, concentration, and growth stage), and treatment media (pH, ionic strength, and conductivity). Paper 19-1

G.A. Evrendilek of Ohio State University will report results of a study of microbial inactivation and shelf-life extension of chocolate milk processed by a pilot-plant PEF system. Paper 62-5

H.W. Yeom of Ohio State University will present the results of a study to determine the effects of PEF on the activity of microorganisms and pectin methylesterase in orange juice, with the goal of optimizing processing conditions for maximum microbial inactivation in a pilot plant. Paper 62-6

G.A. Evrendilek of Ohio State University will describe the effect of pulse polarity (monopolar and bipolar) on inactivation of E. coli O157:H7 in apple juice treated by PEF, since different PEF systems use different types of electrical pulses and the difference in the pulse shape and polarity changes the treatment effect, so that the same treatment dosage may not result in the same microbial inactivation. Paper 62-7

A. Shuwaish of Mississippi State University will discuss effect of pulsed light on microbial load, appearance, and texture of prepackaged, raw channel catfish fillets. High-energy pulsed light—broad-spectrum white light flashes with intensities as high as 20,000 times that of sunlight—has been shown to be effective in pasteurization and sterilization of packaging and food surfaces. Paper 62-8

J.A. Robbins, Consultant, will describe an electric pulse process for the treatment of fresh citrus juices that is capable of reducing target pathogens without alteration of the juice and was granted an FDA letter of no objection for its use in April 1999. Paper 8-4

Pulsed Magnetic Fields

M.F. San Martin of Washington State University will report on the effects of static and pulsed magnetic fields as an alternative to conventional thermal treatments on the inactivation of Saccharomyces cerevisiae. Paper 86A-23

F.M. Harte of Washington State University will describe results of a study to determine the effect of static and pulsed high-intensity magnetic fields on E. coli. Paper 74-11

G.V. Barbosa-Cánovas of Washington State University will discuss the potential advantages of food preservation by magnetic fields, the proposed interaction mechanisms, and some of the results that have been obtained by exposing living systems to low-and high-frequency, high-intensity magnetic fields. Paper 8-1

F.M. Harte of Washington State Universiy will discuss effect of pulsed magetic fields combined with other technologies on inactivation of E. coli. The other technologies include ultrasound, high hydrostatic pressure, pulsed electric fields, and use of antimicrobials. Paper 86A-24

UltrasoundS.M. Alzamora of the University of Buenos Aires, Argentina, will discuss use of ultrasound as a food preservation method. Ultrasound’s lethal effect on microorganisms has been attributed to cavitation, a phenomenon in which mechanical vibrations of high frequency cause alternate compressions and expansions of millions of microscopic bubbles containing gas and vapor. The bubbles expand, then implode violently, releasing large amounts of energy and generating very high temperatures and pressures within the bubbles. The molecules of the vaporized reaction mixture are fractured, forming highly reactive free radicals. The presentation will focus on application of ultrasound to food processing, alone and in combination with other treatments such as heat, high pressure, heat and high pressure, reduction of pH, and addition of preservatives. Paper 8-2

R.S. Chamul of Mississippi State University will discuss use of continuous and pulsed high-frequency ultrasound as an alternative to the use of chlorination to kill microorganisms in process water. Paper 62-10

Irradiation

G. Deitz of Steris-Isomedix Services will discuss irradiation of meat and other products with gamma rays, a process that has been shown to be safe and effective and is widely used in sterilizing disposable medical devices and for reducing microorganism levels in a large variety of consumer products. Paper 6-4

I.A. Taub of the U.S. Army Natick Soldier Center will review the basic physical, chemical, and biological principles of the use of irradiation to enhance food safety and extend shelf life. Because the chemical changes are comparatively minor, irradiation neither compromises nutrition nor introduces any toxicological hazards, but because the changes that do occur might be discerned in such quality attributes as color, flavor, and texture, the foods to be irradiated and the irradiation conditions to be used need to be judiciously chosen. Paper 48-1

W.W. Nawar of the University of Massachusetts will discuss techniques being developed for detection of irradiation treatment of food. The methods are based on the measurement of chemical, physical, and/or biological changes and must be specific, sensitive, accurate, reproducible, dose dependent, simple, rapid, and economical. Paper 68-1

D.U. Ahn of Iowa State University will report on a study on lipid oxidation, the amount and identity of volatile components, and the sensory characteristics of raw pork subjected to low-dose irradiation. Paper 51C-36

H.G. Schutz of the University of California-Davis will discuss the results of surveys on consumer attitudes regarding food irradiation and research on consumer behavior factors that could influence attitudes toward irradiated foods, including such concepts as values, risk taking, group and individual leaders, attitude formation, and diffusion of innovation models. Paper 48-5

J. Wang of the University of Minnesota will discuss results of a study to determine the acceptability of irradiated ground beef patties and whether the acceptability can be affected by giving consumers information about the benefits of irradiated beef or by identifying whether the samples they tasted had been irradiated. Paper 51C-5

W. Chappas of Damalic Corp. will review the physics of irradiation; the forms of ionizing radiation most practical for the meat-processing industry; the ways in which each interacts with typical foods and their packaging; color and odor changes; how understanding of the fundamental processes can be used to estimate the production of potentially deleterious by-products; and processes that affect quality and dosimetry. Paper 6-1

D.G. Olson of Iowa State University will discuss the different types of irradiation (gamma ray, x-ray, and electron-beam) and the factors that affect their use for food preservation. Paper 6-2

D.W. Thayer of USDA’s Eastern Regional Research Center will discuss the microbiological ecology of irradiated meat products and the characteristic changes in the indigenous microflora of the product that occur during irradiation pasteurization of meat and poultry. Paper 6-3

P. Adams of SteriGenics International Inc., will discuss use of electron-beam and x-ray irradiation to pasteurize fresh and processed meats, fruits, and vegetables, and will describe the activities of the Food Irradiation Coalition, a group of more than 20 food industry trade associations, to increase access to and acceptance of food irradiation. Paper 6-5

C. Barmore of Cryovac Div., Sealed Air Corp., will review the composition of packaging materials that are most applicable for food irradiation; how the food additive regulations affect their use; activities underway by the packaging industry and the National Center for Food Safety and Technology to expand the list of approved polymers and additives; and the relationship between packaging and the organoleptic attributes of irradiated foods. Paper 6-6

P.A. Hansen of the Food and Drug Administration will discuss regulations regarding packaging materials for use during irradiation of prepackaged foods; the impact of recent regulatory changes; and future directions for packaging used during irradiation. Paper 6-7

C. Jo of Iowa State University will report the results of a study to determine the effect of different doses of irradiation on lipid oxidation, odor characteristics, and volatile compound production in aerobic-packaged pork loin patty during refrigerated or frozen storage. Paper 51C-28

W.P. Hanson of Iowa State University will report on the effects of a water-soluble antioxidant (sesamol) and a lipid-soluble antioxidant (alpha-tocopherol) on the volatile compounds resulting from irradiated ground beef that may contribute to irradiation odor. Paper 62-9

G. Gunes of Cornell University will discuss the effect of gamma irradiation, alone or combined with calcium treatment, on the texture of fresh apple slices, since irradiation may result in softening of edible plant tissues. Paper 65A-34

G. Jones of USDA’s Dale Bumpers National Rice Research Center will present results of a study to determine the effects of ultraviolet irradiation on color, tensile strength, elongation at break, water vapor permeability, and water solubility of peanut protein films, with the goal of determining whether UV-induced cross-linking within the film structure could improve the flexibility and moisture barrier properties of the films. Paper 78E-10

Other Nonthermal Methods

R. Ruan of the University of Minnesota will discuss nonthermal plasma technology and its potential applications in the food industry. It relies on electric discharge into air or liquid to produce energetic atoms, highly reactive radicals, ozone, etc., that can kill microbes on contact, with minimal heat-induced damage to food products. Potential applications include pasteurization of liquid food products; produce wash; disinfection of processing equipment, plant floors, and packaging materials; city water and wastewater treatment; and air pollution control. Paper 8-3

M.B. Solomon of USDA’s Meat Science Research Lab will discuss the effect of hydrodynamic shock waves (hydrodynamic pressure processing) on naturally occurring spoilage microorganisms found in ground beef, whole beef muscle, and whole pork muscle and on E. coli O157:H7 B6914-seeded ground beef. Paper 8-5

by NEIL H. MERMELSTEIN

Senior Editor