E. coli Happens

FOOD SAFETY AND QUALITY

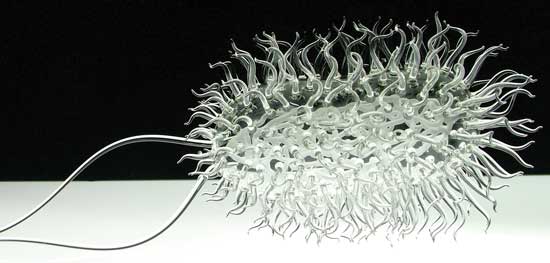

Escherichia coli is a species of bacteria that lives in the intestinal tract of humans and animals and is generally not harmful. It has long been used as an indicator of contamination of food and water by various pathogens, but certain serotypes such as E. coli O157:H7 can cause foodborne illness and even death. E. coli O157:H7 received widespread notoriety as a result of the Jack-in-the-Box foodborne illness outbreak in 1993, and sporadic outbreaks have continued ever since.

Escherichia coli is a species of bacteria that lives in the intestinal tract of humans and animals and is generally not harmful. It has long been used as an indicator of contamination of food and water by various pathogens, but certain serotypes such as E. coli O157:H7 can cause foodborne illness and even death. E. coli O157:H7 received widespread notoriety as a result of the Jack-in-the-Box foodborne illness outbreak in 1993, and sporadic outbreaks have continued ever since.

Most foodborne illness outbreaks have been caused by the O157 serogroup of Shiga toxin–producing E. coli (STEC), but non-O157 strains of E. coli have also been associated with outbreaks. The most common non-O157 serogroups reported to cause foodborne illness in the United States are O26, O111, O103, O121, O45, and O145. The Centers for Disease Control and Prevention (CDC) estimates that 265,000 cases of STEC-based foodborne illness occur in the United States each year; about 36% of these are caused by O157 and the rest by non-O157 STEC.

In 2016 the CDC and the U.S. Food and Drug Administration (FDA) linked a multistate illness outbreak to E. coli O121 and O26 in flour produced by General Mills. The CDC and the Food Safety Inspection Service (FSIS) of the U.S. Dept. of Agriculture (USDA) linked another outbreak to E. coli O157:H7 in beef, veal, and bison products produced by Adams Farm Slaughterhouse. And the CDC and the FDA linked a third outbreak to E. coli O157:H7 in alfalfa sprouts produced by Jack & the Green Sprouts. The STEC strains were identified by DNA fingerprinting by pulsed-field gel electrophoresis and whole genome sequencing.

In 2016 the CDC and the U.S. Food and Drug Administration (FDA) linked a multistate illness outbreak to E. coli O121 and O26 in flour produced by General Mills. The CDC and the Food Safety Inspection Service (FSIS) of the U.S. Dept. of Agriculture (USDA) linked another outbreak to E. coli O157:H7 in beef, veal, and bison products produced by Adams Farm Slaughterhouse. And the CDC and the FDA linked a third outbreak to E. coli O157:H7 in alfalfa sprouts produced by Jack & the Green Sprouts. The STEC strains were identified by DNA fingerprinting by pulsed-field gel electrophoresis and whole genome sequencing.

A number of companies market kits for detecting foodborne pathogens. The FSIS lists test kits that have been validated for detection of E. coli O157:H7 and non-O157 STEC as well as other pathogens. The agency emphasizes that any method a food company chooses should be validated for testing relevant foods. Validation can be 1) by a recognized independent body (AOAC, AFNOR, MicroVal, or NordVal), 2) by inclusion in the FSIS’s Microbiology Laboratory Guidebook or the FDA’s Bacteriological Analytical Manual, or 3) an International Standards Organization method. The FSIS has also published guidance for choosing a microbiological laboratory and guidance on appropriate test portions for E. coli O157:H7 testing and application of non-culture confirmation methods to confirm screening-test results. The FSIS intends to update validated test kit lists on a quarterly basis.

Seed Funding Aids Development

Astrona Biotechnologies Inc., San Francisco, Calif. (astronabio.com), is working to create a handheld device that can be used to detect E. coli and other pathogens, including viruses and fungi, at all stages in the food supply chain. The technology was developed by an interdisciplinary team of faculty members and graduate students from the departments of food science and technology, plant pathology, and electrical and computer engineering at the University of California, Davis. The team received guidance and resources from the university’s Venture Catalyst START program and interdisciplinary research seed-funding program called Research Investments in Science and Engineering (RISE) and formed the company in 2015 with Jeremy Warren as founder and CEO; Marc Pollack as founder scientist; and Maria Marco, Bryce Falk, Paul Feldstein, Andre Knoesen, Josh Hihath, and Erkin Seker as founder advisors.

Warren and Pollack participated in the competitive spring 2016 program run by IndieBio, San Francisco, Calif. (indiebio.com), a biotechnology startup accelerator that provides seed money and an intensive four-month mentoring and networking program for startup companies in exchange for a share of the startup’s equity. IndieBio accepts 30 startups per year, which it divides into two startup cohorts, one in spring and one in fall, to help them turn biotech ideas into prototype products, learn how to run a business, and meet with companies that may be interested in partnering with them for possible commercialization of their projects. Astrona Biotechnologies received $200,000 in cash and $50,000 in program support in exchange for equity in the company.

Warren said that the ultimate goal of the project is to develop compact handheld devices that directly detect genetic information at the molecular level to indicate the presence or absence of E. coli in less than an hour without the need for culturing. The team has initially developed a disposable test kit, using its patent-pending technology to capture and amplify signals from the RNA of pathogens. The company is initially focusing on E. coli O157:H7 and is seeking potential investors to develop a commercial product. The timeline for commercial rollout of the disposable kit, Warren said, would be six to nine months after initial funding. In the meantime, the company is seeking food companies willing to conduct pilot tests with the kit.

The company is developing a fully automated handheld instrument using the advances in biotechnology and electrical engineering developed during the RISE program. The device will feature a simple user interface and provide multiplexed, quantitative detection of a variety of foodborne pathogens. Integrated data-collection software will create a traceable record of safety, recording time, location, user, and results in real time. Warren said that the goal is to have a prototype of the automated device available 12–18 months after funding.

Maria Marco, associate professor in the department of food science and technology and part of the team, said that the technology is based on capturing and amplifying specific nucleic acid sequences of foodborne pathogens. After amplification, the results can be read through any detection method that provides a molecular signal, such as fluorescence, light, and color changes, with electrochemical detection of the products. The technology is based on amplification of RNA rather than DNA, she said, since the pathogen’s chromosome might have only 1–10 copies of the DNA if it is actively dividing but thousands of copies of RNA. Since RNA is a natural amplification of DNA, the method results in a stronger signal and therefore a lower detection threshold. Because viral pathogens also have an RNA genome, viruses are another potential application of the technology, she added.

--- PAGE BREAK ---

USDA Competition Funds Research

USDA Competition Funds Research

A research team from Lincoln University, Jefferson, Mo., was named one of four winners of the first Innovations in Food and Agricultural Science and Technology (I-FAST) competition for its development of a test kit to detect E. coli O157:H7 in food. Sponsored by the USDA’s National Institute of Food and Agriculture (NIFA) and the National Science Foundation (NSF), the competition is designed to help scientists and engineers broaden the impact of their NIFA-funded research by encouraging collaboration between academia and industry to translate fundamental agricultural innovations into the marketplace. Each winning team receives $50,000 to start a business and move their innovation toward commercialization. Team members also participate in NSF’s Innovation Corps (I-Corps), a six-month entrepreneurial immersion course to develop skills that help them commercialize their inventions and discoveries. Teams are also eligible to apply for additional funding through the USDA Small Business Innovation Research Program, administered by NIFA.

Majed Dweik, associate professor and director of Lincoln University’s Center of Nanotechnology, submitted a letter of intent to enter the competition in July 2016. His research team consists of his postdoctoral, graduate, and undergraduate students; Elijah Sharpe, chief executive officer, Nanotechnovate, Jefferson, Mo. (nanotechnovate.com); and Michael Nichols, former vice president, economic development and research, University of Missouri. In his proposal, Dweik said that current pathogen detection methods are expensive, require advanced skill, and are time-consuming processes that can take up to 36 hours but that his rapid detection technique is user-friendly, more accurate in detecting pathogens, affordable, and efficient, providing results in 30 minutes.

Dweik said that the current standard in the food industry for identification of E. coli O157:H7 is polymerase chain reaction (PCR), but food companies, particularly smaller companies, are eager to get a test kit to use in their own facility rather than send samples out to a testing laboratory and receive results back in 48 hours or longer before releasing their product to retail. The team’s vision is to develop a portable device that can be easily placed in a food facility’s quality assurance laboratory and provide results within 18 hours after obtaining a sample. Dweik said that the device uses reactions between antibody and antigens to detect the pathogen within 20 minutes after sample pretreatment, enrichment, and purification. The sample can be solid or liquid, and the instrument can be made specific for other pathogens such as Salmonella and Listeria. Dweik said that the objective is to have a commercial product available by the third quarter of 2017. He is in the process of filing for a patent on the technology.

Nanosensor Combines Two Techniques

Researchers at Pittsburg State University have developed a hybrid nanosensor that can rapidly detect the presence of E. coli O157:H7 in food. Santimukul Santra, assistant professor of chemistry, said that conventional methods to screen food to find pathogens can take as long as 24 hours, which is often too slow to efficiently catch tainted products before they hit store shelves. The required cell count for infection by E. coli O157:H7 is relatively low and efficient diagnostic techniques must be able to quickly detect its presence. The simplest and most conventional bacterial detection technique is culturing on agar with identification of the bacteria accomplished by biochemical tests. This is extremely inefficient with regard to time.

Santra said that a number of more time-efficient methods have been developed for pathogen detection, including nucleic acid amplification (PCR variations) and detection, ELISA, loop-mediated isothermal amplification (a modified version of PCR), immunomagnetic and electrochemical detection via magnetic beads (monitoring the rate of b-D-glucuronidase activity), and nanoparticle-mediated fluorescence identification via targeted nanomaterials. These methods are much faster than culturing, he said, but they still face a number of hurdles, including false positives or negatives, high cost, and complexity. Methods such as magnetic resonance imaging (MRI) and fluorescence also have limitations. MRI can detect extremely low levels of bacteria but loses its effectiveness at higher levels. Fluorescence is the opposite.

Santra and his coworkers developed nanosensors that combine MRI and fluorescence to detect as few as one colony-forming unit of E. coli O157:H7. Fluorescence capability is incorporated by encapsulating a fluorescent dye in nanoparticles. The nanosensors are made with poly(acrylic acid)–coated iron oxide nanoparticles and conjugated with a monoclonal antibody specific for E. coli O157:H7. The nanosensors were tested in lake water and milk solutions (media suitable for bacterial growth) and were able to differentiate between two different strains of E. coli, as well as viable (living) and nonviable (heat-inactivated) E. coli O157:H7 cells. Capable of detecting contamination in less than an hour, the nanosensors were also able to detect the targeted bacteria in the presence of other bacteria. Santra and his coworkers believe that the nanosensors could be customized to detect a wide range of other pathogens.

Research scientist Tuhina Banerjee, one of Santra’s colleagues, said that the research team envisions the nanosensor to be a device like a cell phone that could scan a food and tell whether it is contaminated or okay to eat. She pointed out that development of the device requires active collaboration with other experts, such as microfluidics experts, and that several companies have expressed interest in working with them on commercial development of the nanosensor.

Light Scattering Differentiates Enterobacteriaceae

At Purdue University, food science professor Arun K. Bhunia and coworkers have used a laser scatterometer called BARDOT (bacterial rapid detection using optical light scattering technology) to differentiate the members of the Enterobacteriaceae family. Traditional detection methods rely on bacterial growth on selective media that contain different types of sugars as an energy source, such as glucose for Enterobacteriaceae and lactose for coliforms. However, Bhunia said, differentiation within the family based on biochemical attributes are ambiguous, emphasizing the need for reliable identification techniques.

The laser scatterometer uses a red diode laser beam to generate scatter patterns of colonies directly on a plate. A total of 5,280 scatter images were acquired for the 12 genera on four different growth media from two experimental replicates. The results showed that BARDOT can potentially be used for rapid differentiation and identification of Enterobacteriaceae and coliforms for process verification, hygiene monitoring, and food safety purposes, Bhunia said. The BARDOT system identifies E. coli O157:H7 and the big six serogroups of non-O157 STEC (O26, O111, O103, O121, O45, and O145) and is licensed for commercialization by Andreas Hettich GmbH & Co. KG, Tuttlingen, Germany (hettweb.com).

Neil H. Mermelstein, IFT Fellow, Editor Emeritus of Food Technology

Neil H. Mermelstein, IFT Fellow, Editor Emeritus of Food Technology

[email protected]