Seeking a Sustainable Supply Chain

With customer demand for transparent and responsibly produced products gaining momentum, food and beverage companies are asking how they can operate in more sustainable ways. They’re taking a closer look at their environmental impact—and turning to their suppliers for solutions.

Article Content

What is a sustainable food? According to The Nature Conservancy, “a sustainable food system is achieved when every part of the production chain—from the farm to the supermarket shelf—is working to meet the challenge of producing enough food for a rapidly growing world, while conserving our lands and waters, tackling climate change and biodiversity loss, and improving the ability of future generations to meet their own needs.” In short, it requires a 360 view of the supply chain and demands that standards and practices be put in place by all players, from farmers to agents to subcontractors to suppliers, all the way to the consumer.

With both businesses and individuals facing the reality that we are dependent upon our natural resources for a sustainable supply of nourishment, food and beverage companies are increasingly seeking out more traceable and transparent supply chains. But adhering to non-negotiable sourcing standards can present real day-to-day challenges when it comes to sourcing ingredients for products, regardless of whether the product is a long-established brand or a new offering in the early stages of development.

Companies large and small are providing leadership by setting sustainable sourcing goals, initiating collaborations and partnerships, aligning carbon emissions with science-based targets, reducing packaging, exploring zero waste initiatives, and much more. Suppliers with global reach, like Barry Callebaut, say the pressure to reduce environmental impact is coming from all angles.

“Consumers are saying loud and clear that they believe the ingredients in their products should be better for them and the people who make them, that they want to see less packaging, and that companies, as well as governments, have a responsibility to address climate change,” says Peter Boone, CEO and president Americas, Barry Callebaut Group. In the case of this global cocoa producer, that means getting everyone on board with an ambitious goal of making sustainable chocolate the norm. “In the cocoa sector, farmer poverty, deforestation, and child labor are the most crucial issues. … These issues are complex, interrelated, and they are all crucial to sustainability.”

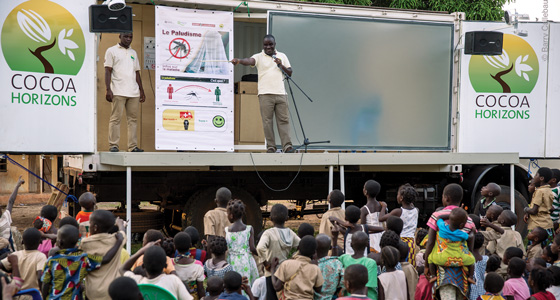

The company’s research shows that consumers prefer sustainably marketed cocoa and chocolate concepts three to one over conventional ones, so it created the Cocoa Horizons Foundation as a means to drive on-the-ground change in cocoa-growing communities. Brands using Cocoa Horizons chocolate can market their use of sustainable cocoa to consumers, allowing them to shine as a responsible manufacturer while funding programs like agroforestry training for women in the Ivory Coast. Brach’s Double Dipped Hazelnuts from Ferrara Candy Co., for example, are made with the chocolate and feature the Cocoa Horizons stamp on packaging, and Edward Marc Brands, a family-owned business since 1914, now uses only certified sustainable cocoa through Cocoa Horizons to promote its present-day focus on sustainable innovation.

This is just one of many ways that a global company like Barry Callebaut acts on sustainability initiatives, but it points to a growing set of out-of-the-ordinary tools that are increasingly available to food and beverage companies seeking more sustainable solutions that will get consumers’ attention.

Partnering to Meet Customer Demands

Certainly, the race to sustainability can’t be achieved by any one company alone. Supplier-manufacturer relationships are just as important, as are collaborative efforts that bring together corporate and nonprofit entities.

Mission-driven food companies like Justin’s have been focused on sustainability from the start, and now larger consumer packaged goods (CPG) companies are leading the way on a larger scale. “The power of collective sharing and uniting with others in the industry to drive a larger-scale impact is exciting,” says Justin Gold, the nut butter and snack company’s founder.

Two years ago, the company upgraded all sub-ingredients in nut butters to be organic and relied on suppliers to achieve its sustainability goals. More recently, Justin’s partnered with a supplier to launch a 25% post-consumer recycled content bag for a non-GMO Project Verified and USDA-organic product—tuning in to the Mintel statistic that 56% of consumers believe packaging manufacturers are responsible for environmentally friendly food and beverage choices. Additionally, the company joined forces with a number of pollinator organizations to raise awareness because, as Gold observes, “without bees, there’d be no Justin’s.”

Justin’s parent company, Hormel Foods, has established companywide goals and initiatives as well. It requires all suppliers to follow its Supplier Responsibility Principles to ensure all purchases are compliant with the company’s sourcing policy. Kelly Braaten, Hormel Foods’ manager of external communications and corporate responsibility, says, “We strictly enforce suspension of any supplier not in accordance with such policies.” Hormel Foods meets regularly with key suppliers to discuss initiatives and expectations. The company also publishes results in its annual Corporate Responsibility Report and established a public palm oil sourcing policy to address the unique environmental and social risks associated with the ingredient.

Diana Visser, Corbion’s senior director of sustainability, also says collaboration is the way to progress. “It really is important to work together with stakeholders,” she says, noting that even investors are looking to build their “impact investing” portfolios, while banks are now offering companies like Corbion discounts on loan interest tied to annual sustainability targets.

Corbion, a Dutch food and biochemicals company, encourages joint assessments with some customers during product development to show the impact that can be made with sustainable ingredients, while other customers may ask them to participate in audits by companies like EcoVadis, a sustainability ratings service for global supply chains. “It is important for our customers to see that we have these practices in place,” says Visser. “With palm oil and sugar cane, we use certification schemes to provide the evidence that certain criteria are met.”

The company has a global presence, especially in bakery and meat ingredients, though a new product offers a fresh a spin on the sustainability angle. AlgaPrime DHA, a traceable, algae alternative to marine-based omega-3s used in aquaculture feed, was developed to reduce dependency on marine fisheries. In turn, salmon brands that feed their fish with the product, like Ventisqueros’ Silverside Premium Pacific Salmon, market an improved sustainability and nutritional profile to their consumers.

Challenging Ingredients

When it comes to sustainability, some ingredients pose larger obstacles than others. Palm oil, soy, and cocoa, for example, are known challenges in the agricultural supply chain. To navigate the complex web of sourcing, food companies can begin by asking suppliers the right questions, like which organizations they belong to and work with, who advises them, how they use data and research, how they analyze and report progress, and whether they have been certified against any sustainability measures. Palm oil suppliers, for example, are likely focused on deforestation and may be a member of the Roundtable on Sustainable Palm Oil (RSPO) or even carry an orangutan-friendly certification.

“Transparency is essential in ensuring sustainable supply chains,” says a Nestlé spokesperson. The food giant works with over 700,000 farmers directly around the world, and with many others through its supply chain. “All these farmers and workers are crucial to our company, but it can be difficult to fully understand the complex supply chains that connect us.”

In addition to Nestlé’s Responsible Sourcing Standard, a guide to supplier requirements, the company has initiatives in place for its 15 most important raw materials, which include palm oil and coffee. Its Palm Oil Transparency Dashboard uses Starling data to monitor deforestation trends observed near the mills it sources from. This year, it announced that 77% of its agricultural commodities are verified as deforestation-free, a key milestone in the company’s efforts to achieve its zero-deforestation commitment.

For coffee sourcing, the company launched the Nescafé Plan nearly 10 years ago to bring together its global commitments on farming, production, and consumption. Last year, the company launched its Grown Respectfully program to communicate Nescafé’s efforts to consumers. Using various channels, including branded product packaging featuring the Grown Respectfully stamp, the program helps to illustrate the breadth of the Nescafé Plan’s sustainability program to a broader audience.

For coffee sourcing, the company launched the Nescafé Plan nearly 10 years ago to bring together its global commitments on farming, production, and consumption. Last year, the company launched its Grown Respectfully program to communicate Nescafé’s efforts to consumers. Using various channels, including branded product packaging featuring the Grown Respectfully stamp, the program helps to illustrate the breadth of the Nescafé Plan’s sustainability program to a broader audience.

Water Resources Top of Mind

A top sustainability challenge, according to The Nature Conservancy’s head of corporate engagement for agriculture and food, Stewart Lindsay, includes water quality and efficiency. “The agriculture and food sector have to deliver significant environmental improvement for its own resilience and to help meet global goals,” says Lindsay. “The good news is that we are seeing positive change, and the opportunities are manifest. More companies are engaged, more market-based solutions are being tested, more technology and data are being brought to bear, and more collaborative efforts are creating workable standards.” The conservation group works with many industry leaders to advance sustainability, including Cargill and General Mills.

Cargill says transparency, traceability, and transformation are the three words dominating discussions lately. Although most of what the agricultural producer offers isn’t sold directly to the consumer, Cargill’s sustainable ingredients can help food companies address

consumers’ demands for more information about where their food is grown, and how it’s produced. “Providing traceable food to consumers builds trust and increases transparency in the food supply chain and gives them confidence in the food they purchase and eat,” the company says.

Along with greenhouse gas and land use, water resources are top of mind for Cargill. In developing countries, the company may look at it more around supplying access to safe drinking water, while in other agricultural communities, irrigation practices are the priority. As a founding member of the Midwest Row Crop Collaborative (MRCC), Cargill supports the efficient and sustainable production of row crops in the U.S. Midwest. Understanding why companies like Cargill are making investments like these is key for food and beverage companies wanting to capitalize on sustainable ingredients.

It’s important for Cargill to engage in groups like the MRCC because of the significant role we play in the U.S. beef supply chain. More than 50% of the water used in U.S. beef production is dedicated to irrigating the row crops that become feed for cattle. … By putting first-of-its-kind, cost-effective irrigation technology in the hands of farmers, the amount of water needed for row crop irrigation is greatly reduced, as is the environmental impact of the beef supply chain.”

CPG companies seeking sustainable ingredients should ask suppliers about commodity groups they work with that provide tools for improving sustainability. The Almond Board of California (ABC), for example, offers growers and suppliers opportunities for education and assessment on sustainability best practices and initiatives. Its California Almond Sustainability Program is one way that the almond community measures progress against goals, helping farmers to see how they are tracking, while providing a road map to identify areas for improvement in their operations.

Recently, the ABC announced the Almond Orchard 2025 Goals, to focus on higher impacts across the key areas that define the California almond industry’s sustainability roadmap. These goals include two key areas of focus for CPG companies: sustainable water use and reducing food waste, according to Harbinder Maan, the ABC’s associate director, trade marketing, and stewardship.

Addressing Food Waste: Upcycling Trends

Kara Nielsen, trendologist and vice president of trends and marketing for CCD Innovation, says the startup/entrepreneurial market is leading change when it comes to sustainability. “They have their work cut out for them to harness a new supply chain, make products, and then communicate their benefit,” she says. “These products need to really stand out and connect with consumers in more ways than sourcing.”

Products made from upcycled ingredients, she says, continue to appear in the marketplace. “Thus, we are learning about a variety of former waste stream ingredients that are being transformed into edible products,” Nielsen says. She cites several companies in this space: Grain Elevator and Brewer’s Crackers are finding new uses for spent grains; Barnana taps into high-fiber flour from green bananas; Renewal Mill uses soybean waste from tofu to make flour; Planetarians makes an edible fiber from defatted sunflower seeds; and several others that are finding new uses for unusual ingredients such as salmon skin, cacao fruit, and more.

Companies like Comet Bio, a manufacturer that upcycles crop leftovers into healthy, sustainable ingredients for use in supplements, foods, and beverages, say their ingredients are better for the planet because they reduce greenhouse gases and help farmers take advantage of their whole harvest. “Food and beverage producers have set ambitious sustainability goals, involving targets to make every aspect of their supply chain as environmentally friendly as possible,” says Rich Troyer, chief executive officer of Comet Bio.

“This has frequently involved R&D projects to find new ways to produce the most sustainable products possible, which has led to analyzing things all the way down to the individual ingredient.” Products like Comet Bio’s Sweeterra syrups, he says, can help get companies to the next level of environmental impact.

Even organizations like the Almond Board of California are embracing a zero-waste approach through “co-product utilization,” with research investments on emerging new uses for almond shells. Almond Board–funded research shows that needs across multiple industries could be addressed with innovation of almond co-products, including using almond hull and shell components in beer brewing and mushroom cultivation or as feed sources for poultry and aquaculture.

The trend often highlights a brand’s culinary expertise in food products, as is the case with Render Foods’ two beverages, Weyla, a sparkling drink made from upcycled whey, fruit, herbs, and botanicals, and Bryner, a vegetable drink made from upcycled pickle brine. “Being thoughtful and crafty about ways to minimize waste at scale is just an extension of the chef world that [our] team comes from,” explains Dana Peck, chief executive officer and a cofounder of Render. Weyla is crafted through a collaboration with James Beard Award–winning chef Cortney Burns and Bryner with fellow James Beard Award–winning chef and author Nicolaus Balla. “People love that there is a sustainability story intertwined into our beverages, and we’re thrilled that these are products that people would love even if that narrative wasn’t there.

“The biggest hurdle with scaling a truly upcycled product is consistency,” Peck says. “We built flexibility into our products to help account for the natural variability in real food.”

Of this growing trend, Nielsen adds, “Consumers readily understand this topic and may be willing to pay a premium to support upcycled products.” She says that other emerging topics in sustainability include regenerative agriculture, soil health, and other “beyond organic” terms like biodynamic agriculture.

Developing a Shared Vision

Now that “CSR” (corporate social responsibility) practices and “ESG” (environmental, social, and governance) criteria are commonplace initiatives in the food arena, it’s easier than ever before for food and beverage manufacturers to learn more about what their suppliers are doing to tackle sustainability issues. But that’s just the start.

A sustainable supply chain is one that continuously looks at the products being sold in order to minimize, if not completely eliminate, the specific impacts those products drive, explains Jenny Ahlen, director of supply chain for the Environmental Defense Fund. “You don’t become a completely sustainable supply chain overnight. Rather, it’s a journey—a continuous process of improvement. Every company can and should always be doing more, no matter how sophisticated they are in terms of sustainability.”

Ahlen says topics grab the public’s attention periodically. “Right now, those words are ‘soil health’ and ‘regenerative agriculture,’ which are topics about the ability of well-managed soil to provide resiliency to farms and to potentially sequester greenhouse gasses. Deforestation also continues to be an issue,” she says. In the agricultural space, she sees an increasing number of companies prioritizing farm impacts and piloting innovative ways to provide farmers with information, tools, and resources to increase resiliency in the supply chain.

Ahlen adds, “To legitimately address consumer demands, a company cannot just examine their own operations that are easy to control—they must also examine all the way up the supply chain to the companies and farmers they source from.”

Anna Klainbaum, a member of IFT, is an independent writer and consultant ([email protected]).

Many agree: the coffee we drink is important. But what does sustainable coffee really look like?

Many agree: the coffee we drink is important. But what does sustainable coffee really look like? General Mills’ supplier base is large, complex, and global, with thousands of suppliers in more than 25 countries. Its Supplier Code of Conduct serves as the backbone of its sustainability program, but it’s the company’s Triple Bottom Line Operating Unit that is grabbing consumer attention with its focus on brands such as Annie’s, Cascadian Farm, Epic, and Muir Glen.

General Mills’ supplier base is large, complex, and global, with thousands of suppliers in more than 25 countries. Its Supplier Code of Conduct serves as the backbone of its sustainability program, but it’s the company’s Triple Bottom Line Operating Unit that is grabbing consumer attention with its focus on brands such as Annie’s, Cascadian Farm, Epic, and Muir Glen.