Retaining Ingredient Functionality in Clean Label Products

FOOD SAFETY AND QUALITY

Like “natural,” the term “clean label” is consumer driven with no official definition, regulations, or guidelines from the Food and Drug Administration (FDA) or the U.S. Department of Agriculture. Data from numerous market research surveys indicate that to most consumers, clean label means foods with a short list of ingredients that are natural, organic, and free from preservatives and functional additives, with no chemical or unrecognizable components.

Despite the added expense of producing products that can meet consumers’ definitions of clean label or better-for-you ingredients, shoppers have made it clear that they expect to see no price impact. That expectation can create hurdles for formulating these foods and beverages.

“Each product line faces its own set of challenges, whether it is a regulatory issue, availability, flavor, or overall functionality in application,” says Melissa Riddell, head of innovation and technical services at Batory Foods. “There is also the acceptability by the consumer that still needs to be heavily considered when offering better-for-you ingredients.”

Growing Demand

The clean label ingredients market was valued at $38.8 billion in 2018 and is projected to reach $64.1 billion by 2026, according to a 2019 Allied Market Research report. Major multinational companies are participating in the development of clean label ingredients, including Cargill, Archer Daniels Midland, Corbion, Kerry, Ingredion, Tate & Lyle, Sensient Technologies, Frutarom, Koninklijke DSM, Chr. Hansen, and DuPont (Allied Market Research 2019). Many smaller companies also are approaching this burgeoning market with new ingredient offerings. Colors, flavors, sweeteners, starches, preservatives, emulsifiers and other functional ingredients, and shelf-life enhancers make up the key market segments for clean label ingredients.

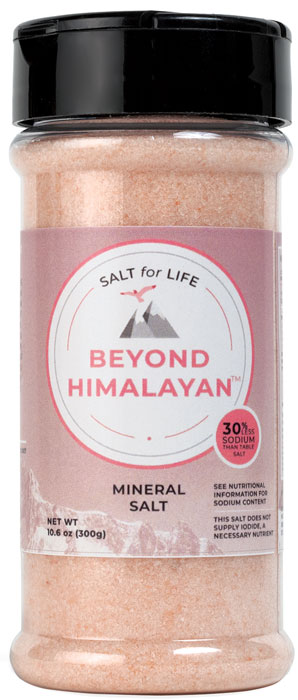

Sodium Reduction

Global overconsumption of sodium chloride, an essential nutrient, is the leading cause of hypertension. In a 2013 study by the Hartman Group, 50% of the participants cited sodium salt as an ingredient to avoid (Phillips 2014). At NuTek Natural Ingredients, senior scientist and project manager Krishnamoorthy Pitchai is working with his team to develop several clean label ingredients, and a proprietary salt solution is at the top of the list.

NuTek has developed a patented process for potassium salt that does not have the bitterness normally associated with potassium chloride and packs a double health whammy by reducing sodium and supplying needed potassium in the diet. Reducing salt alone can impact saltiness, functionality, and food safety. Replacing some salt with potassium salt, however, retains saltiness, functionality, and food safety, and increases daily values of potassium, an underconsumed and much needed nutrient. The FDA now recommends 4,700 mg potassium per day for adults (FDA 2020), which is reflected in the new potassium requirement on the nutritional label. But it is difficult to get this amount of potassium just by consuming foods that are rich in the mineral. For example, someone would have to eat more than 11 bananas a day, with approximately 422 mg potassium per banana (USDA 2019). NuTek’s potassium salt solution has 470 mg of potassium (10% Daily Value) per 1/4 tsp.

The FDA has OK’d the listing of potassium chloride as potassium salt for ingredient labels, which should not ring as chemical or unnatural to consumers looking for clean labels.

Preservative Replacement

Kerry and other suppliers are building portfolios of fermentates, organic acids, and live culture extracts for the clean label market. Several plant-derived extracts and parabens are currently being evaluated by Batory Foods for their preservation efficacy, including plum, rosemary, and moringa. They are not readily used in products today, however, because further research is needed.

Sugar Replacement

According to Kerry market research, 68% of consumers who read the nutritional label focus on overall sugar content. Many consumers are eager to lower their intake of calories from refined sugar, but reduction or substitution of sugar is problematic for product formulations. Granulated sugar is not only a sweetener, enhancing palatability and certain flavors and masking undesirable flavors, but a functional ingredient (Goldfein and Slavin 2015). It lowers the water activity of a product, which helps preservation, reduces microbial growth, and increases shelf life. As part of the Maillard reaction, sugar combines with amino acids to give baked goods, chocolate, coffee, and meat desirable browning and caramel flavors. Adding bulk, sugar provides texture and mouthfeel as well as a unique sensory profile on the tongue. And compared with other sweeteners, sugar is inexpensive and readily available.

How can product formulations reduce sugar but maintain its functionality? “The answer is often found through the use of other humectants such as glycerin, salts, or other types of sugars,” says Batory Foods’ Riddell. “Humectants lower the water activity of a product because water preferentially binds to them. Each humectant has its own unique ability to lower water activity, depending on its chemical makeup.

“[One humectant] example is crystalline fructose,” she says. “Even though crystalline fructose is a ‘sugar,’ it has a sweetness equivalence approximately 14% higher than sugar, allowing for less sweetener solids to be used while achieving the same desired sweetness. This results in a sugar and calorie reduction. It also contributes to shelf stability due to the very hygroscopic nature of this monosaccharide, which reduces the water activity. The same phenomenon is seen with allulose, which [reduces the sugar concentration and lowers the weight of sugar on] the ‘No Sugar Added’ label now regulated by the FDA.”

Otis Curtis, global portfolio director for Kerry, suggests reducing sugar by adopting a hurdle approach: “Osmolytes, including sugar, acid, and salt, are used to reduce water activity, reduce pH, and typically prevent all microbial growth. A good example is ketchup, which is high in both sugar and salt. As consumers become more conscious of nutritional composition, there is an interest in lowering or eliminating such components that both contribute to the familiar great taste and provide some preservation properties.”

Curtis recommends replacing sugar by:

• increasing product stability through thermal processing, high pressure processing, and advancements in aseptic packaging

• using natural preservatives such as fermentates, vinegar-based antimicrobials, natural cures, and live culture extracts

• introducing other osmolytes, such as polyols or nonsodium salts, to contribute to desired organoleptic properties

• developing new products to replace traditional osmolytes. Kerry’s TasteSense product has been reported to reduce sugar or salt by at least 30% with no effect on organoleptic properties

Functional Ingredients

Another way to achieve a clean or better-for-you label is to cite an ingredient’s function on the label, such as “citric acid for color retention,” “sodium sorbate for shelf stability,” and “guar gum for texture.”

Other functional ingredients do not need to be listed on the label at all, such as enzymes, which are used in food manufacturing as processing aids. “… Amylase enzymes can release sugars from the starch in flour to generate sugars [which] the yeast can then utilize to optimize bread volume. Similarly, lipase enzymes can modify fats and lipids to form emulsifiers that help dough handling and bread texture,” says Liz Lalor, assistant marketing manager (enzymes) for Kerry. “Maltogenic amylase is used to slow the loss of moisture and the recrystallization of starches in bread, slowing down the staling process. Kerry’s Biobake enzyme system can double the textural shelf life of fried baked goods such as doughnuts, while maintaining softness and texture. Production costs and waste can be cut with no change to the label or nutritional profile of the product.”

Another clean label alternative is chickpea broth, a nonallergenic, non-GMO, gluten-free ingredient developed by Ingredion as an emulsifier in dressings, sauces, and ready meal applications. It can also be used as an egg replacement, making it suitable for vegan offerings. In addition, pectin, cellulose gel, milk proteins, tapioca, citrus fiber, and rice starch all can be used as clean label ingredients (Anonymous 2017).

Colors and Flavors

Artificial colors and flavors are no-nos on a clean label. Natural colors derived from vegetable sources such as carrot and beet have been used successfully in bakery items, which have short shelf lives. But many natural colors quickly lose their pigment over time.

Kerry has developed a proprietary fruit and vegetable crystalline product as a longer-lasting clean label alternative to FD&C colors. Suppliers also are using browning technology and smoke as coloring agents in meat, sauce, and snack applications, while fermentation products can serve as flavor enhancers.

Fewer Ingredients

Sinplicity, in the form of fewer ingredients, creates a clean label halo for foods. In addition to using ingredients denoted as processing aids, which are not required on the ingredient list, food companies can combine aseptic packaging with microwave technologies to reduce the number of ingredients needed to ensure quality, safety, and shelf life by decreasing thermal processing times and providing a sterile package.

Future Trends

The COVID-19 pandemic has influenced consumer perceptions of healthy, clean label, and better for you foods. Immunity-boosting and gut health or microbiome-supporting ingredients are now in demand, and shelf life and sustainability are in the spotlight due to less frequent trips to the grocery store.

“The onset of the COVID-19 pandemic has significantly impacted the functional ingredients market in the positive direction,” says Riddell. “Ingredients such as ashwagandha, elderberry, lavender, chamomile, and CBD are not only used in the dietary supplement space for mood relaxing, anti-anxiety, stress relief, improved sleep, and improved immunity claims, but are quickly finding their way into the food and beverage space. Other ingredients like proteins, dietary fibers, probiotics, and omega fatty acids are continuing to grow in the functional ingredient space as they contribute to muscle growth, digestive health, heart health, and other health-related label claims.”

But just because a product is clean label doesn’t necessarily mean it is a true sustainable solution, cautions Christina O’Keefe, manager of sustainability and assurance systems at Kerry. “Typically, moving to fewer natural ingredients does not change the major components of manufacturing,” she says. “The raw materials still need to be sourced, heated, cooled, dried, shaped, packaged, and shipped. For a true holistic sustainable solution, all parts of the product life cycle need to be reviewed.”

REFERENCES

Allied Market Research. 2019. Clean Label Ingredients Market by Type (Natural Color, Natural Flavor, Starch & Sweetener, Natural Preservative, and Others), Application (Beverage, Bakery & Confectionary, Sauce & Condiment, Dairy & Frozen Dessert, and Other Processed Foods), and Form (Powder and Liquid): Global Opportunity Analysis and Industry Forecast 2019–2026. Allied Market Research, Portland, Ore. alliedmarketresearch.com.

Anonymous. 2017. “Clean Label Options in Stabilizers, Texturizers, Emulsifiers.” Dairy Foods, March. https://www.dairyfoods.com/ext/resources/DF/2017/February/showcase/Showcase-Emulsifiers.pdf.

FDA. 2020. “Daily Value on the New Nutrition and Supplement Facts Labels.” https://www.fda.gov/food/new-nutrition-facts-label/daily-value-new-nutrition-and-supplement-facts-labels.

Goldfein, K. R. and J. L. Slavin 2015. “Why Sugar Is Added to Food: Food Science 101.” Compr. Rev. Food Sci. Food Saf. 14(5): 644–656. doi: 10.1111/1541-4337.12151.

Phillips, D. 2014. “Label It Clean.” Food Process., Oct. 3. https://www.foodprocessing.com/articles/2014/label-it-clean/.

USDA, Agricultural Research Service. Food Data Central, 2019. https://fdc.nal.usda.gov/.