A Random Walk Through Research Spending

An informal survey of major food companies indicates that spending on research fits more of a statistical random walk than a trend

In an effort to determine research spending trends, I conducted a telephone survey of the spending habits of companies that do research, develop new products, and improve food safety. I spoke with representatives of about 50 companies selected from a list of the top 150 food companies.

While it is perfectly possible to torture the resulting data into some kind of trend line, I recognized that it would be inaccurate to do so. The spending ranged from a negative single-digit percentage to an increase of about 400%. This suggests that there is something going on, but tracking the data produces something much more like a random walk than a trend. Now, we could harden the categories of spending and maybe come up with some trends, but the information is too good to stuff into a graph and swallow whole. So I looked deeper. Here’s what I found.

While it is perfectly possible to torture the resulting data into some kind of trend line, I recognized that it would be inaccurate to do so. The spending ranged from a negative single-digit percentage to an increase of about 400%. This suggests that there is something going on, but tracking the data produces something much more like a random walk than a trend. Now, we could harden the categories of spending and maybe come up with some trends, but the information is too good to stuff into a graph and swallow whole. So I looked deeper. Here’s what I found.

Research Spending in General

Categories of spending for food science should include food safety, food processing, and research into structure–function activities, not all of which are located in a traditional research budget. Product development activities may be partly charged to marketing or market development in some companies.

Spending trends are much as other reports have stated: the increase in spending is generally somewhere around the cost of living increase, and there are about equal numbers of companies that increase spending and companies that decrease spending slightly or keep it at about the same level.

There are important increases in research spending for specific projects resulting from new understanding of the role of novel ingredients in consumer health, specifically in preventing chronic or catastrophic disease. These projects gain from government spending, university spending, and other research, and these inputs are not readily assigned to specific food projects.

Much of the initial work on these novel ingredients is being done outside the United States, and is either used by U.S. subsidiaries or licensed to companies for development. Capturing the license fees as part of research spending is difficult, but this spending should be considered a research expense. Capturing these expenses as a business expense skews the understanding of research costs.

More spending is being used for clinical studies, and development of novel ingredients and specialty items as new product lines.

Growth in number of new products is down in most product categories across the board (1997–98), continuing a 5-year trend. This trend may be deceptive, as it may be difficult to capture innovation in sectors such as foodservice.

Spending for food safety should be factored into the overall picture, despite the fact that these funds may be accounted for in quality control or quality assurance or manufacturing budgets in companies.

So, research spending is up. But it isn’t all traditional research nor product development. A considerable amount of the food science being developed in companies, universities, and other organizations is on methodologies for assuring food safety. Some of it is being funded as quality control or quality assurance, some as basic research into food systems, and some as process development. With the increased attention to food safety and concern about ensuring that food is safe when it leaves the production area, reaches its marketing point, and is served to the consumer, it appears that a great deal of research is being done. But is it being counted as part of the research budget?

--- PAGE BREAK ---

Spending on Food Science for Safety

Much of the research into improved means of assuring food safety is done at the university level, and much more at the federal level. This year, appropriations for food safety are up—the U.S. Dept. of Agriculture’s Food Safety and Inspection Service is slated to receive $616,986,000, and the Food and Drug Administration’s Center for Food Safety and Applied Nutrition is to receive $230,830,000. The Food Safety Initiative gains $25 million for FDA, $16.5 million for FSIS, and $2 million for USDA’s Food and Nutrition Service. USDA’s Cooperative State Research, Education, and Extension Service will get $16 million. The effect of this funding on industry depends to a great degree on how the information resulting from funding is used, and specifically on which projects are funded.

Spending for GRAS affirmation and food additive approval can be prodigious. The Flavor and Extract Manufacturers’ Association, representing the flavor industry, spends a major portion of its $2 million per year on evaluation of the safety of food flavors and their components. This is in addition to the original work of testing these compounds in multiple animal studies. Minimum costs for studies to reach the FEMA GRAS status are thought to be $1–2 million for relatively simple compounds.

Spending for clinical studies, part of food safety that often falls into the product development category, is growing, as companies that are accustomed to doing clinical studies enter the food arena. How these expenses are sorted out—either as food safety or basic science—makes a difference in determining what the actual cost of research is. Doing clinical studies is one expense, but understanding the results of studies, both internal and by others, is also time consuming and costly. As foods for special medical effects are introduced, the cost of clinical trials should be taken into account if they are used for marketing advantage.

Spending on New Product Development

Food companies competing in hot areas are spending more to get their new ideas on the shelf. The range of increase in spending is very wide—from about 6% to over 400%. It is apparent that companies that are gaining market share in a category will spend more to provide a complete line of products (the picket-fence approach) than those with only one or two products, unless two companies are both starting fresh in a category and must keep pace with the other.

Hot new products this year came from both groups: General Mills’ new Go-Gurt (yogurt for the younger set) plugged a hole in the company’s product line and helped maintain market share for its combined Yoplait and Colombo yogurt business. Go-Gurt, packaged in a tube, with kid-type flavors such as watermelon, has an extra wrinkle: a freeze–thaw-stable system allows the product to be frozen in the tube, and thaw in time for a young person to consume it at noon, when the product is carried in a brown bag or lunch box. Research spending for the yogurt group at General Mills is up a little higher than the cost of living, and stands a little above the 0.8% of sales that is considered average for the food industry. Yoplait and Colombo yogurts make up a significant contribution to General Mills’ sales.

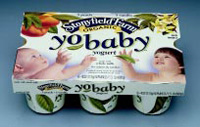

Yogurt for the whole family is hot in Europe, with Nestlé’s products winning a large share of the market. But in the U.S., yogurt for kids is starting to build. Stonyfield Farms has added its contribution to kids’ products with an organic yogurt version called yo baby, made from whole milk and natural fruits, plus agave nectar used as a sweetener. Stonyfield Farms’ Vice President of R&D, Kasi Reddy, noted that the firm is the only U.S. licensee of Bio-Gaia A.S.’s probiotic culture Lactobacillus reuterii, and that the exclusive license for the material, which would be considered a research cost if done in-house, dwarfs his budget. Still, the company has increased its use of resources for both R&D and quality assurance by about 25% since the addition of this 6th live culture to its product, and Reddi sees this as a long-term commitment. A major portion of this increased budget is for research into quality assurance methods and testing.

--- PAGE BREAK ---

Dannon has been developing yogurt for the young set for a few years, packaged in six-pack cups featuring pictures of endangered species. The company also recently started test markets in Phoenix and Denver to evaluate U.S. acceptance of Actimel, a 3.3-oz container of a probiotic diary-based product that contains three cultures. Already on the market in parts of Europe, the yogurt drink is offered in additional flavors, including orange, red berry, and apple. The Danone Group’s research focuses on five priority themes: molecular biology and biotechnology; process engineering; food safety and quality; taste, texture and sensory perception; and nutrition and health. Total spending on R&D is slightly less than 1% of sales.

Danone is involved with a significant amount of nutrition research, and works with experts to understand the physiological mechanisms of digestion, eating behavior patterns, metabolism, and varying nutritional needs of different age groups of consumers. Worldwide, Danone’s sales are 43% from fresh dairy products, which returns an 11% margin worldwide, and an 11.6% margin in France. Much of the research that goes into Danone’s new products comes from the Centre International de Recherche Daniel Carasso in Paris, which serves as a resource center for consumer and regulatory questions, and as a source of expertise for all of Danone’s companies that make yogurt or other milk-based products.

Other new products are in the emerging category of fat-based products that contain plant sterols and stanols, such as Raisio’s Benecol® and Unilever’s Take Control ™ margarines, salad dressings, and similar products. Benecol, marketed in the U.S. and elsewhere by McNeill Specialty Products, has been on the market for less than a year, after introduction in Finland in the earlier 1990s. The cost to develop the concept and the stanol esters used as the fat source was borne by Raisio, and is not public information. After licensing the intellectual property, McNeill incurred substantial additional costs in funding several additional clinical studies, and developing the products that would fit American palates. Gilbert A. Leveille, who heads the development of the project, notes that McNeill will increase spending by “about an order of magnitude” as they continue the development of new products containing the stanol esters. To date, development has been sustained by reassigning personnel from the over-the-counter product category. Because McNeill had no significant food development group, the expenditures started from about ground zero.

The other major product containing fats configured to reduce cholesterol is Take Control, marketed in the U.S. by T.J. Lipton, a division of Unilever. Spending at Unilever’s multiple research sites amounts to about a half-billion pounds Sterling, and much of this spending is concentrated into one of five product groups—tea, ice cream, yellow fats, culinary, and frozen foods. Yellow fats, including margarine, were the basis for the early growth of Unilever, and member companies, including Lipton, can use the massive amounts of basic research from Unilever research centers that specialize in yellow fats.

William Franke, Vice President of Scientific and Regulatory Affairs for Unilever United States Inc.’s Lipton, estimates that total budget for recent years has been and will continue to be up about 5% to accommodate the increased work on the plant sterols and total formulations for Take Control. This doesn’t include expenditures that were the result of careful prioritization to put more emphasis on the new products. Much of the original work on phytosterols was done at Unilever’s Vlaardingen, Netherlands, laboratories, but the formulations and GRAS affirmation work was done in the U.S.

Spending on Science Can Change the Market

Research budgets are usually slightly under 1% of sales for most companies, and larger expenses, such as licensing basic research, frequently fall into categories other than the research budget. Companies that are involved with basic research often prioritize expenditures in such a way that the basic work can be charged to several different projects to defray heavy costs. Increases and decreases in research budgets may represent new ways of thinking about research as much as actual budgetary changes. There will be increases in research budgets and in supporting spending, and these budgets will normally be expressed as increments.

Market share of products can be profoundly affected by the appearance of major innovation, the kind that comes from real knowledge about the use and efficacy of products with compelling advantages. The compelling advantage resulting from health-related foods that also taste as good as conventional products, are as convenient as possible, and are not prohibitive in price changes the orderliness of the marketplace, and can eliminate competitors. But this only happens when a company that has access to this new knowledge is capable of fully developing it through investment in formulation, process, quality control and assurance, food safety in its larger meaning, and market research. These may all be research dollars, and should be counted as such when evaluating the changes in research spending.

by FRAN KATZ

Editor