Microwave Technology Sterilizes Sweet Potato Puree

North Carolina farmers successfully commercialize aseptic production of non-acidified sweet potato puree using continuous microwave processing.

Several North Carolinian organizations representing industry, academia, and government researchers have collaborated to produce a low-acid, shelf-stable food product using continuous fl ow microwave technology. What they discovered is that the aseptic sweet potato puree product from a newly built facility demonstrated superior quality characteristics when compared with purees processed on other commercially available systems.

Industrial Microwave Systems (IMS), Morrisville, N.C., was formed to develop and commercialize continuous heating and drying of products using microwave energy. To facilitate entry into the food processing industry, IMS teamed up with researchers at the Dept. of Food, Bioprocessing, and Nutritional Sciences at North Carolina State Univ. (NCSU) and the U.S. Dept. of Agriculture, Agricultural Research Service, (USDA/ARS), South Atlantic Area. Together, with these organizations, IMS co-owns process patents for the rapid sterilization of pumpable foods and biomaterials by exposure to electromagnetic energy. These pending patents are the culmination of several years of research on more than 20 fruit and vegetable purees, primarily the North Carolina grown yellow-orange sweet potato (Coronel et. al, 2005).

Industrial Microwave Systems (IMS), Morrisville, N.C., was formed to develop and commercialize continuous heating and drying of products using microwave energy. To facilitate entry into the food processing industry, IMS teamed up with researchers at the Dept. of Food, Bioprocessing, and Nutritional Sciences at North Carolina State Univ. (NCSU) and the U.S. Dept. of Agriculture, Agricultural Research Service, (USDA/ARS), South Atlantic Area. Together, with these organizations, IMS co-owns process patents for the rapid sterilization of pumpable foods and biomaterials by exposure to electromagnetic energy. These pending patents are the culmination of several years of research on more than 20 fruit and vegetable purees, primarily the North Carolina grown yellow-orange sweet potato (Coronel et. al, 2005).

The estimated farm value of the 2008 U.S. sweet potato crop rose 20% to $391 million, the second consecutive record high, according to the USDA Economic Research Service (USDA/ERS, 2009). With higher yields and more harvested acres in 2008, North Carolina maintained its position as the top producer of sweet potatoes. In fact, production in the state jumped 30%, reaching 874 million lb, and the value of the crop rose to $161 million (USDA/ERS, 2009). It is estimated that more than 70% of commercially grown product in North Carolina is sold directly into one of three outlets: chain stores, terminal market facilities, or foodservice providers. The remaining 30% is sold to food processors for canning, flaking, chipping, frying, freezing, or processing as a functional food ingredient for pet food, baby food, baked goods, and nutraceutical beverage products.

From Concept to Commercialization

In 2003, seven agribusiness owners who manage approximately 50% of the North Carolina crop wanted to add value to less-than-perfect-sized sweet potatoes that would otherwise be discarded. They quickly recognized the ability of the continuous fl ow microwave heating system to produce a unique, natural, value-added, shelf-stable puree product, which was currently unavailable in the market. The owners joined together to form a consortium and in 2004 Yamco L.L.C., Snow Hill, N.C, was born. With the assistance of the USDA and various North Carolina state grants, Yamco formed a group to design, build, and operate a state-of-the-art facility devoted to the production of aseptically processed and packaged pumpable vegetable products.

Yamco purchased a manufacturing plant in 2006 and reconfigured it into a modern food production facility with sufficient room for future growth. What differentiates this facility from others is its revolutionary use of microwave heating (Parrott, 2004). Unlike conventional heat exchangers that tend to over-process product to reach required temperatures in the central, coldest part of the material, microwaves heat product volumetrically from the inside out without the need for a hot heating surface.

This is achieved by guiding the microwave energy into a vertical chamber or applicator that is designed to focus it into a compact cylindrical region at its center, similar in concept to a satellite dish. The applicator houses a food-grade product tube located precisely in this cylindrical region. The tube is made of a microwave-invisible ceramic or plastic through which the pumpable sweet potato puree passes from bottom to top. In the Yamco microwave heater, the polar molecules and charged ions of the sweet potato puree are aligned and excited at the rate of 915 million times a second when exposed to the alternating electromagnetic field surrounding the product tube. The friction resulting from this molecular activity immediately creates rapid volumetric heating within the pumpable food product.

--- PAGE BREAK ---

The result is a product exiting the heater with minimal variation in radial temperature profile and cook value. Combined with the rapid heating time and the cool internal tube wall temperature, these attributes render a premium-quality, aseptic product that maintains virtually the same color intensity, textural consistency, flavor profile, and nutritional value as fresh puree.

In order to reduce the microwave power density exposure of the puree and maximize uniformity of heating, the Yamco installation uses a two-stage heater with two applicators connected in series. The system is designed to deliver 50% of the microwave energy to each applicator and product tube.

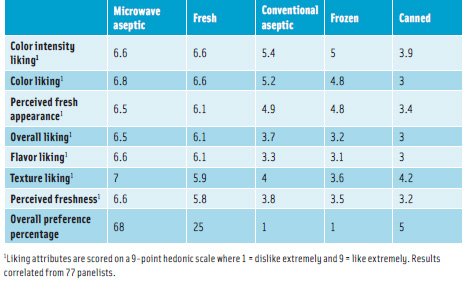

Yamco also funded sensory panel studies in 2006 at NCSU, which demonstrated that sweet potato purees processed in the IMS cylindrical heating system were on par with freshly made purees, and clearly preferred by consumers over conventional tubular aseptic, frozen, and canned purees (Drake and Yates, 2006). A summary of this study is shown in Table 1.

Nutritional Benefits

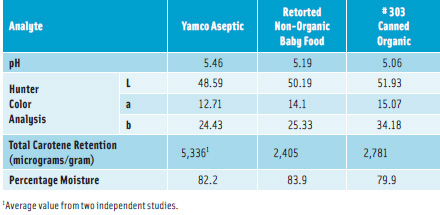

Research by the USDA/ARS found that the microwave technology retained over 94% of the beta carotene in the raw sweet potato samples after processing the puree to a minimum sterilization temperature. Table 2 summarizes an independent study comparing the carotene, color, pH, and moisture values of the various sweet potato puree products that are commercially available. The high value of total carotenes in the shelf-stable Yamco product is higher than the other commercially processed products. This is thought to be due to two effects. First, the yield or extraction of carotenes from the processed matrix of the sweet potato flesh is greatly enhanced when followed by microwave sterilization, known as microwave-assisted extraction or MAE (CRC Press, 2009). Second, the lower overall heat exposure in the microwave minimizes destruction of the heat-sensitive vitamin A or beta carotenes.

These sensory and nutritional advantages would undoubtedly benefit any food processor interested in a cost-effective, high-performance, easy-to-use food ingredient. The possible uses of this sweet potato puree product are manifold. It provides an ideal side dish for meals or frozen dinners and can also be produced in a thicker, more viscous, higher starch version. With its high dietary fiber and naturally enhanced sweetness, the product is an ideal functional food that can replace added sugars in baked goods and snacks, pet and baby foods, as well as nutraceutical beverage formulations. It can also be used as a cost-saving dairy fat replacer in various cheese-based and ice cream products, and as an extender in ground meat and poultry products. Furthermore, replacement fortifies the overall nutritional characteristics of a formulation without adversely affecting its flavor. This is particularly beneficial for companies that strive to comply with the federal FDA labeling guidelines for product nutrition, or those anticipating similar changes in state law, such as those being introduced in California.

The Yamco aseptic process provides a product with an ambient shelf life of at least 18 months and possibly up to 3 years. This is extremely valuable for institutions such as schools, hospitals, prisons, the military, food assistance programs, and export markets because it eliminates the need for cold transportation and storage, and minimizes the costs associated with thawing, opening, and removing product from rigid containers.

--- PAGE BREAK ---

Following the success of the 2006 sensory studies, IMS negotiated an exclusive sublicense agreement with Yamco to use its processing equipment for the manufacture and sale of aseptic sweet potato puree worldwide. Yamco markets aseptic sweet potato puree in three package sizes: 6-gal, 50-lb bag in box; 55-gal, 450-lb bag in fiberboard drum; and 270-gal, 2,250-lb bag in corrugated tote. All products are filled using DuPont Liqui-Box packaging systems.

In 2009, the three joint process patent holders received two awards: the Institute of Food Technologists’ Food Technology Industrial Achievement Award recognizing the commercial success of the first FDA accepted installation to use microwave processing for production of an aseptic low-acid product (Brody, 2009), and the 2009 USDA Agricultural Research Service’s Technology Transfer Award, which recognizes contributions in advancing North American agriculture.

What’s Next?

Yamco’s discoveries have spawned interest in applying microwave technology to other pumpable fruit and vegetable concentrates and purees, as well as particulate food products. Researchers at USDA/ARS and NCSU have run trials with purple sweet potatoes (Steed and Truong, 2008; Steed et. al, 2008), and Yamco has negotiated a nonexclusive license agreement with IMS to use its equipment to process various types of squash puree, including pumpkin. Since some members of the agribusiness consortium already grow butternut squash, the Yamco facility provides a perfect outlet to process product that does not meet the required standards of the fresh squash market. Yamco recently received a letter of non-objection from the FDA to commercially produce and sell their all-natural low-acid squash products.

In order to better understand the processing of fruit and vegetable purees, concentrates, and particulates, IMS has teamed up with the Dept. of Food Science, Purdue University, W. Lafayette, Ind., and installed a state-of-the-art microwave system that is available for customer trials. Current sponsored studies are focused on microwave processing of pumpable high-acid products, such as berry fruit purees and diced and sliced fruits. IMS and Purdue are also conducting detailed studies of changes in product quality when packaged and stored under refrigerated, extended shelf life, and shelf-stable storage conditions. Lastly, upcoming studies are scheduled for low-acid particulate products, such as soups, sauces, and meat- and poultry-based stews, as well as further investigation into the potential benefits of microwave-assisted extraction (MAE).

by David Parrott , Ph.D., a Professional Member of IFT, is General Manager Food Group, Industrial Microwave Systems, L.L.C., 3000 Perimeter Park Dr., Bldg. 1, Morrisville, NC 27560 (dparrott@industrialmicrowave.com).

References

Brody, A. 2009. Aseptic Packaging 2009. Food Technol., 63(7): 71.

Coronel, P., Truong, V.-D., Simunovic, J., Sandeep, K.P., Cartwright, G.D. 2005. Aseptic Processing of Sweet Potato Purees Using a Continuous Flow Microwave System. J. of Food Sci. 70(9) 20: E531-E536.

CRC Press. 2009. “Extracting Bioactive Compounds for Food Products, Theory and Applications.” Edited by M. Angela A. Meireles. pp. 151-155.

Drake, M., Yates, M. 2006. Consumer Sensory Analysis and Descriptive Analysis of Pureed Sweet Potatoes, North Carolina State University, July 12. Private Communication.

Parrott, D.L. 2004. Safe Effective Microwave Cooking. Food Eng.

76(6): 127-128.

Steed, L.E., Truong, V.-D. 2008.Anthocyanin Content, Antioxidant Activity and Selected Physical Properties of Flowable Purple-Fleshed Sweet Potato Purees. J. of Food Sci. 73(5): S215-S221.

Steed, L.E., Truong, V-D.,Simunovic, J., Sandeep, K.P., Kumar, P., Cartwright, G.D., and Swartzel, K.R. 2008. Continuous Flow Microwave-Assisted Processing and Aseptic Packaging of Purple-Fleshed Sweet Potato Purees. J. of Food Sci. 73(9): E455-E462.

U.S. Dept. of Agriculture, Economic Research Service. U.S. sweet potatoes at a glance, 2003-09. www.ers.usda.gov/Briefing/Potatoes/Data/SweetPotatoesAtAGlance.xls. Accessed June 1.