Growing food from plant cells; Boosting soybean yield; Food tracking in China

CUTTING EDGE TECHNOLOGY

Researchers create appliance to grow food from plant cells

Researchers create appliance to grow food from plant cells

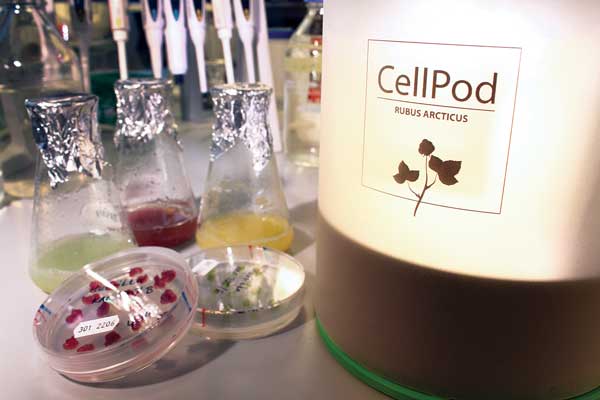

Researchers at the VTT Technical Research Centre of Finland Ltd. are working to develop an appliance for the home kitchen that can grow food within a week from plant cells. The first prototype machine or bioreactor—called CellPod—resembles a design lamp and is already producing harvests.

The idea of the CellPod concept is based on growing the undifferentiated cells of a plant rather than a whole plant. In other words, only the best parts of a plant are cultivated. These cells contain the plant’s entire genetic potential, so they are capable of producing the same healthy compounds—such as antioxidants and vitamins—as the whole plant. The nutritional value of a cloudberry cell culture, for example, is similar to or even better than that of the berry itself. But the taste still needs work—it is very mild and neutral.

“Urbanization and the environmental burden caused by agriculture are creating the need to develop new ways of producing food—CellPod is one of them. It may soon offer consumers a new and exciting way of producing local food in their own homes,” says Lauri Reuter, VTT research scientist.

To date, VTT has used cells from its own culture collection to grow Arctic bramble cells, cloudberry cells, and stone bramble cells in the CellPod. The bioreactor also enables the production of healthy food from plants other than traditional food crops, such as birch.

Nitrogen enhancement increases soybean yield

Biologists at Washington State University (WSU) have genetically modified a soybean plant to better utilize nitrogen, resulting in increased yield and quality of soybeans. “The biggest implication of our research is that by ramping up the natural nitrogen allocation process we can increase the amount of food we produce without contributing to further agricultural pollution,” said WSU biologist Mechthild Tegeder. “Eventually we would like to transfer what we have learned to other legumes and plants that humans grow for food.”

Tegeder inserted a gene from a bean into the soybean plant to increase the flow of nitrogen, an essential nutrient, from specialized bacteria in soybean root nodules to the seed-producing organs. She and Amanda Carter, a biological sciences graduate student, found the increased rate of nitrogen transport kicked the plants into overdrive.

For years, scientists have tried to increase the rate of nitrogen fixation in legumes by altering rhizobia bacterioid function or interactions that take place between the bacterioid and the root nodule cells. Tegeder, however, took a different approach. She increased the number of proteins that help move nitrogen from the rhizobia bacteria to the plant’s leaves, seed-producing organs, and other areas where it is needed. The additional transport proteins sped up the overall export of nitrogen from the root nodules. This initiated a feedback loop that caused the rhizobia to start fixing more atmospheric nitrogen, which the plant then used to produce more seeds.

“They are bigger, grow faster, and generally look better than natural soybean plants. Some evidence we have suggests they might also be highly efficient under stressful conditions like drought,” noted Tegeder.

Improving food safety through blockchain

During the recent opening of the Walmart Food Safety Collaboration Center in Beijing, Walmart, IBM, and Tsinghua University announced a collaboration to improve the way food is tracked, transported, and sold to consumers across China. The first product to be tracked in the pilot program is pork.

Food authentication and supply chain tracking are crucial to quickly find and address sources of contamination around the world. Blockchain ledger technology provides a permanent record of transactions which are then grouped in blocks that cannot be altered. It could serve as an alternative to traditional paper tracking and manual inspection systems, which can leave supply chains vulnerable to inaccuracies.

With blockchain, food products can be digitally tracked from an ecosystem of suppliers to store shelves and ultimately to consumers. When applied to the oftentimes complex food supply chain, digital product information such as farm origination details, batch numbers, factory and processing data, expiration dates, storage temperatures, and shipping data are digitally connected to food items and the information is entered into the blockchain along every step of the process. Each piece of information provides critical data points that could potentially reveal food safety issues with the product.

If you are working on or know of some cutting edge technology that you would like to be featured in this column, please send an email to [email protected].