Rethinking Fats

INGREDIENTS

Rethinking Fats

Today’s fats and oils ingredients category continues to evolve. In recent years, the food industry undertook a large reformulation effort after the U.S. Food and Drug Administration in June 2015 announced that partially hydrogenated oils (PHOs) would lose their generally recognized as safe (GRAS) status. With a requirement to remove PHOs from the food supply by June 2018, manufacturers of fats and oils worked with food developers and foodservice operators to find the optimal alternatives to PHOs that provided acceptable function and nutrition. All involved met the challenge.

Now food manufacturers are addressing the needs of their health-focused consumers who want plant-based products, such as vegan cheese and meat alternatives, or food products that offer nutrient benefits that go beyond the standards, such as protein-fortified bars and bakery and confections with healthier fats. Of course, there are challenges to formulating these kinds of products, too. Read on to learn more about recent ingredient developments in the fats and oils category that offer the functionalities that manufacturers need to successfully launch these types of products and more.

Functional Fats for On-Trend Products

As consumer interest in plant-based food and beverage products and so-called “healthy indulgent” sweets increases, one fats and oils ingredient manufacturer offers up solutions that can help with functionality issues that arise when formulating plant-based products, including dairy and meat alternatives. AAK has created a special team dedicated to developing solutions that address plant-based product formulation challenges, says Vineet Jindal, AAK USA’s global customer innovations manager, plant-based dairy. The team develops specialized fat- and oil-based solutions and creates product concepts such as plant-based cheeses and creamers.

“These prototypes are used to prove successful achievement of functional and sensorial product enhancements, help our customers accelerate new product development, and help build synergies between fats and oils and other ingredients like vegetable protein, starch, fiber, and flavors,” says Jindal.

AAK’s AkoPlanet line of fats and oils are specifically for plant-based ice cream, plant-based dairy (cheese, yogurt, drinks, and spreads), and plant-based meat, where they play major roles in enhancing texture, taste, and flavor carry. This includes creating a creamy, smooth texture in plant-based ice cream, improving the melting of plant-based cheese, and producing the desired bite in plant-based meat.

“The plant-based food industry is being challenged to match or exceed both the sensory and nutritional profile of the animal products they are replacing,” says James S. Jones, AAK’s vice president, customer innovation and plant-based foods. “To do this with a clean label is even more challenging because replacing one highly complex animal ingredient such as milk or meat that contains numerous highly specialized and synergistically functional proteins, fats, emulsifiers, and minerals with isolated plant ingredients necessitates a much more complex ingredient statement.”

Another area of focus for AAK is developing the optimal fats for use in healthy indulgent confections and bakery products, including those formulated with protein or with less sugar. “The trend of improving the nutritional profile of indulgent treats is aimed to respond to a question and a statement: ‘How can I feel better about eating sweets?’ and ‘I wish this nutritional bar/supplement would taste better,’” says Zach Freed, applications specialist, confections, at AAK USA. “The former represents the casual snacker who is also conscious about health; the latter represents those who regularly replace meals with on-the-go nutritional bars and/or daily supplements.”

Some of the ingredients targeted in formulating these products are calcium, protein, and sugar. Freed explains that replacing/reducing sugar can affect the taste and texture of the finished product, and adding calcium, which can be chalky, and protein, which can be sticky and tacky, can contribute off-flavors to the finished product. “This is where specialty vegetable fats and oils play a unique role,” he says. “Fats and oils affect both the structure and flavor delivery for confections. Improved melting properties will allow for better flavor release, and the ability to coat certain ingredients can reduce undesired textures, dryness, and off-flavors. This means that with the right fat or oil—a customized and innovative solution—that once chalky meal replacement bar can taste like a wonderful candy bar.”

Developing a bakery item with added nutrients can be especially challenging. “When enhancing the nutritional profile of a traditional bakery product, whether it be through protein fortification, sugar reduction, or adding more nutritionally dense grains, the texture and flavor profile can be significantly impacted,” says Andrea Weis, applications specialist, bakery, at AAK USA.

Here, the choice of fat affects the organoleptic and textural characteristics of the product, says Larry Marks, customer innovation manager, bakery, at AAK USA. “For example, the oil a doughnut is fried in, the margarine that a cookie is formulated with, or the cube and flake shortening contained in ‘cut and drop’ biscuits will have a huge effect on the baked goods’ eating quality.”

Weis offers up more specifics about the important functional roles that fats have in improving textural attributes of bakery products formulated with added protein. When protein is added to a bakery product that otherwise has a soft and chewy bite, it can transform into one with a dry, dense, and grainy texture, she says. “The proper fat solution and usage level help relieve some textural issues by providing lubricity, resulting in a baked product that has a softer, more moist bite. Selecting a fat with the appropriate solid fat content curve can help with tenderness, freshness, and crispness or reduce crumbliness of the bakery product, as well as help to control flavor release, and provide desirable meltaway characteristics rather than an undesirable waxy mouthfeel.”

New Fats for Bakery

In recent years, finding suitable replacements for PHOs has been an important trend in the fats and oils category. But what’s next for this ingredient category? Well, there are other challenges that food manufacturers face, and the category is evolving to bring improved functionalities to fats and oils.

“Even with PHOs behind us, some of the existing challenges or key needs remain,” says John Satumba, North America R&D director, global edible oil solutions for Cargill. “Bakers still want reliable supply, consistency in the fat system, ease of use, and high stability for long shelf life. Once a shortening is fulfilling its job in a formulation, bakers may look to further improve the Nutrition Facts panel and take first aim at the fat.”

Something else that Satumba says is happening in the industry is the continued push toward healthier food and beverage options. An example of this he cites is reducing overall saturated fat content while maintaining the same functionality that food manufacturers expect.

The Cargill fats and oils experts are also focusing on improving the performance of bakery fats. “In this vein, we recently introduced a new line of high-functionality bakery products under the PalmAgility brand to complement our already diverse portfolio of products available to our customers,” says Satumba. “Our product developers are also ready to collaborate with customers in co-creating value-added solutions for their bakery needs. Along those lines, we are also excited to announce that Cargill is expanding its North American food pilot and processing capabilities to better offer bakery, and other customers, customized solutions on an accelerated timeline.”

Cargill launched four PalmAgility shortenings in early 2019 and four more in late 2019, each designed for various bakery applications, such as icings that need to be stable in temperatures greater than 65°F, creme fillings for sandwich cookies, and Danish doughs that are stored at temperatures less than 65°F.

The PalmAgility shortenings offer additional benefits. “PalmAgility helps to reduce shortening brittleness across a wider temperature range, allowing customers to store it easily without sacrificing workability or texture,” says Satumba. “This also helps address issues that can develop in transportation due to fluctuations in outdoor temperatures, a variable outside of a customer’s control. In addition, PalmAgility provides a smoother, creamier texture than standard palm oil shortenings. This aids in faster mixing time and better incorporation of all ingredients, both of which are easier on baking equipment. A faster crystallization rate also helps improve setting in glazes for doughnuts and fillings for sandwich cookies, for example.”

Among the many product concepts that Cargill has formulated with the PalmAgility shortenings for customers and food shows are doughnuts, biscotti, mini bundt cakes, icings, breakfast bars, cookies, and chocolate cake doughnut holes.

Trait-Modified Oils

The development of trait-modified oils—oils with modified fatty acid compositions—has had a significant impact on the fats and oils industry, according to the authors of Trait-Modified Oils in Foods (Orthoefer and List 2015). “Trait-modified oils owe their existence to the development of new fats and oils through plant breeding biotechnology with the need for more suitable crop varieties to meet the demands of the marketplace,” write the authors. The oilseed plants are modified to produce seeds that create oils with improved functional traits and fatty acid profiles that provide enhanced nutritional profiles. A high-profile example of this is the recent promotion of high oleic soybean oil and shortening for their functional properties that closely match the properties of PHOs, which makes them function well as drop-in replacements for PHOs in most applications. Scientists, plant breeders, and oil manufacturers are working now to bring next-generation trait-modified oils and shortenings to market.

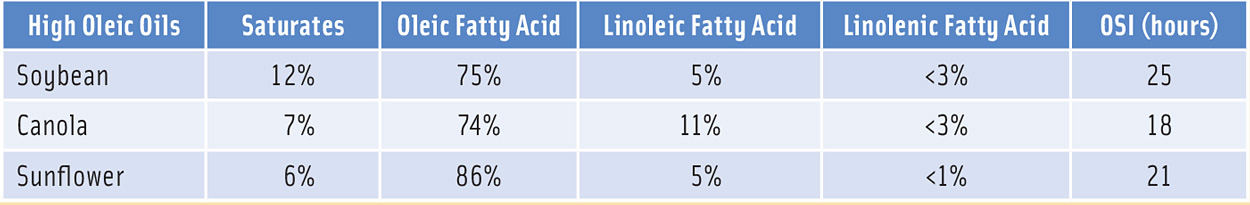

“High oleic sunflower seed oil and canola oil are well-established oils with established demand bases. High oleic soybean oil in its original form also has an established demand base and is currently undergoing the greatest expansion in usage of the high oleic oils,” says Richard Galloway, oil consultant for the United Soybean Board. Both the soy and canola are products of genetic engineering, he says. He points to Calyxt, which “has developed a high oleic soybean through gene editing that is deemed ‘non-GMO,’” and the Missouri Soybean Merchandising Council, which “has developed a high oleic soybean using traditional breeding methods.” While the fatty acid profiles of oils from these soybeans are not publicly available, Galloway says that it seems that the oleic levels fall within those of sunflower, canola, and the current soy product.

The push for having more ingredients that are not genetically modified is driving some of this research. Galloway explains: “While the current demand for ‘non-GMO’ high stability oils is being met with high oleic sunflower, mid-oleic sunflower, and conventional canola, inquiries from food companies for more ‘non-GMO’ high oleic oils are growing.”

Through advanced breeding techniques, Corteva Agriscience has bred both Omega-9 Canola Oil and Plenish high oleic soybean oil seeds to create oil profiles that have increased monounsaturated fat, higher stability, and more functionality than commodity canola and soy, says Tyler Groeneveld, the company’s commercial grains and oils leader for North America. He explains that both Omega-9 Canola Oil and Plenish high oleic soybean oil “were developed to enhance the healthfulness of foods while preserving key function qualities, such as longer, cleaner fry life, clean taste, extended product shelf life, superior versatility, and overall cost effectiveness.” Either of the oils has the advantage of helping packaged foods stay fresh without the use of additives or artificial preservatives, says Groeneveld.

Omega-9 Canola Oil is a naturally stable, healthy oil, according to Groeneveld, who says that the fatty acid profile in it was developed through traditional plant breeding to give food manufacturers an option that is not genetically modified. Plenish high oleic soybean oil has a longer fry life and a healthier nutritional profile (0% trans fat, 20% less saturated fat, and more than 75% oleic) than conventional soybean oil, he adds.

Corteva Agriscience grows high oleic seeds under an “identity preservation” program “that ensures and preserves the quality of the crop and its oil,” and results in seeds that can be connected to specific growers and tracked through the system (from the fields where they are planted to the facilities where the seeds are made into oils), says Groeneveld.

In addition to its work on seed traceability, the company continues to invest in researching oilseed traits and developing trait-modified oils that deliver on sustainability. “Soybean and canola oils are the most widely used oils in the North American food industry. Because of the high stability of the oil, packaged foods last longer, which helps reduce food waste,” says Groeneveld.

“In fact,” he continues, “more than 70% of canola and soybean farmers have adopted sustainable farming practices such as conservation tillage and crop rotation, which support better soil heath. Additionally, the oilseed crops are very well adapted for the environment in which they are grown, requiring little to no irrigation, which reduces water use. By combining conventional and new technologies, Corteva Agriscience is delivering solutions to help meet the needs of a growing population seeking healthier foods and more sustainable options.”

Steps to Sustainable Palm Oil

Sustainability in the food industry—which covers everything from food waste and recyclable/biodegradable packaging to agriculture methods and human and animal welfare—is increasingly becoming more of a concern to consumers. In fact, the topic is one of the top 10 trends for 2020, according to Innova Market Insights (Innova 2019). The company’s research shows that 87% of global consumers in 2019 said that they expect companies to invest in sustainability versus 65% who had that expectation in 2018.

The palm industry is one where the issues of sustainability have been hotly debated, but one company hopes that its initiatives will help address concerns and have a positive impact on both the environment and farmers.

“Palm is the most widely used vegetable oil on the planet, so its various fractions clearly work well for food manufacturers,” says Monique van Wijnbergen, sustainability and corporate communication director for Natural Habitats. As debates about the sustainability of the use of palm oil continue, she says that some consumers are calling for a ban on palm oil without realizing that replacing palm oil has two implications. “Using less efficient oil crops, which demands more land and will have an effect on increased land use change for oil crop production, and using other vegetable oil–based ingredients will have an effect on product quality and performance,” she says. “The latter will bring challenges for food manufacturers and foodservice professionals in their product development and living up to the quality and performance expectations consumers have. Palm oil is an important functional ingredient, giving crispiness to products and lengthening shelf life. People often think it’s easy to replace palm oil with another ingredient, but that’s really not the case, as doing so has quality implications.”

To do its part in making a change in the ways palm is grown and palm oil is produced, Natural Habitats has instituted a number of initiatives that guide the way it operates, starting with its Palm Done Right campaign, which includes four promises to stakeholders. The four promises are “100% organic,” “deforestation-free,” “wildlife friendly,” and “fair and social,” says van Wijnbergen.

To deliver on these promises, van Wijnbergen says Natural Habitats collaborates with all the farmers and plantations in its supply network. “Our palm oil is fully traceable, which means we know all the farmers that deliver the palm fruit that we process in our mill. These were previous conventional farmers that we supported in their transition to organic farming practices.”

Specifically, Natural Habitats provides training and administration as well as certification support, says van Wijnbergen. “All farmers and plantations are audited yearly by independent auditors to ensure they continue to live up to the organic standard. In case noncompliances are found, we support the farmers to correct those noncompliances. This is how we ensure 100% organic farming.”

The company also trains and supports farmers to ensure their oil palm cultivation complies with forest and wildfire protection standards, explains van Wijnbergen. “We performed high carbon value evaluations and land use change analysis and through those analyses know what areas need to be protected and what is allowed and not allowed in their growing practices and land development.” She adds that all the farmers and plantations in Natural Habitats’ supply network are Roundtable on Sustainable Palm Oil certified, which involves independent auditors auditing farmers and plantations annually. Before farmers are added to Natural Habitats’ supply pipeline, they go through what van Wijnbergen says is “a rigorous pre-assessment ... so we will know they will comply to the standards set prior to collaborating with them.”

Protecting farmers and their communities is an integral part of the mission, says van Wijnbergen, and that includes following the Fair for Life/Fair Trade principles of ensuring the rights of farmers and paying them fair prices and wages. “All the farmers and plantations in our supply network are Fair for Life certified,” she says and adds that the company takes other measures to ensure equity in farming. “We operate a strict land use policy that serves to prevent any conflict in relation to land use and preserve the associated rights of the local inhabitants, and we operate a strict forest conservation policy that prohibits the conversion of primary and secondary forests into agricultural production areas, tree plantations, or other degrading land uses.

“Due to the fact that our supply chain is fully traceable and we closely collaborate with all individual farmers and plantations, we can track what is happening in the field and ensure full transparency as to where and how the palm oil is produced.”

A solid at room temperature, palm oil has a functionality that differs from other oils, says van Wijnbergen. It can be fractionated into a liquid and a very hard fat and, she says, “with palm oil you can ‘dial in’ the exact melt point for a recipe.” Other functions of note are that it is shelf stable, stable at high cooking temperatures, neutral in taste and smell, and smooth in texture.

“Palm oil gives an excellent mouthfeel, fulfilling specific characteristics needed in different food products, such as a flaky pie crust, a moist muffin, and a delicate layered pastry—the quality of these products using seed oil is significantly inferior,” says van Wijnbergen. She also notes that palm oil is an alternative to partially hydrogenated fats, which is useful for trans fat-free formulations, and it’s a replacement for dairy and animal fats, making it appealing to consumers who want to avoid animal products.

Next month’s Ingredients section will feature ingredients in the sweeteners category.

REFERENCES

Innova. 2019. “Top Ten Trends 2020.” Webcast, Nov. 7. Innova Market Insights, Arnhem, the Netherlands. foodingredientsfirst.com/webinars/top-ten-trends-2020.html.

Orthoefer, F. T., and G. R. List. 2015. Trait-Modified Oils in Foods. West Sussex, UK: John Wiley & Sons Ltd.