Quinoa Germ: A Nutrition Powerhouse

Ingredients | APPLIED SCIENCE

Quinoa (Chenopodium quinoa) is a superfood that has gained widespread popularity worldwide in recent years. This ancient pseudo-grain from the Andean region in South America is renowned for its rich nutrient composition and bioactive components, including high-quality proteins, fiber, phytochemicals, and essential amino acids. In fact, quinoa is rich in lysine and threonine, which are limiting amino acids in cereals. Quinoa also contains nutritionally favorable lipids, polyunsaturated fatty acids, and phenolics.

Due to its chemical constituents and therapeutic properties, quinoa is increasingly considered an important ingredient in the development of functional foods for human health. Clinical studies have shown that quinoa in the diet results in highly positive effects on metabolic, cardiovascular, and gastrointestinal health in humans. For example, since it is naturally gluten-free, quinoa serves as a nutritious component of celiac disease diets, and the high-quality protein and fat in the edible seed has been shown to help manage cardiovascular and diabetic conditions in humans.

Quinoa also offers opportunities to address food security issues around the globe. It grows in drought-prone, high salinity soil, and agriculturally marginal areas. As such, quinoa could serve as a sustainable crop due to its ability to adapt to unfavorable environmental conditions, spurring the stress-tolerant crop’s evolution as a potential ingredient in the development of foods that meet the challenges of future global food and nutrition security issues.

Quinoa is primarily processed to produce whole grain flour and used to fortify products in different food formulations, ranging from baked goods, pizza crusts, and plant-based burgers, to beer, breakfast bars, stews, and soups. Quinoa also is processed as an ingredient to produce value-added food products such as protein isolates, oil, starch, malt, and more. There is growing interest in applying quinoa as a functional ingredient in plant-based alternative protein sources due to its exceptional nutritional quality, high protein, and outstanding fat and mineral content.

Although quinoa is highly versatile and used in a wide variety of applications, the biggest challenge for product developers is finding practical separation methods to effectively free the nutrient-dense germ from the seed’s outer covering to unleash its full nutritional power. The germ can be considered the nutritive capsule of quinoa due to the high quality of the protein present in this part of the grain, its perfect amino acid balance that fulfills daily dietary intake recommendations for adults, and the presence of good fat (88% unsaturated fatty acids), including polyunsaturated (60%), monounsaturated (30%), and a unique ratio of omega-6 and omega-3 fatty acids (Nowak et al. 2016). In addition, minerals and total phenolic content along with antioxidant activity is mostly concentrated in the germ, making it the most sought-after component of the grain.

Challenges of Germ Separation

Quinoa fruit differs from other cereal grains in terms of its structure and location of the storage reserve for the developing embryo. In quinoa, the reserve store is perisperm instead of endosperm. Perisperm mainly consists of starch grains that are angular in shape. Quinoa grain has a peripheral embryo consisting of a hypocotyl-radicle axis with two cotyledons. Cotyledons have a complex structure with lipid and protein bodies, nucleus, and other necessary organelles for carrying out degradative and synthetic functions for the seed to transform into a plant. The embryo stores protein and lipids of the grain. The outer covering of quinoa consists of three layers of cell, beginning with perianth and pericarp and followed by a seed coat as the outermost layer. Unlike conventional cereals, in which the germ constitutes only 1%–3% of the grain, quinoa germ accounts for almost 30%. The germ, which contains the highest amount of protein and fat than any other part of quinoa, is the most nutrient-dense functional component.

Examining the grain structure reveals that the germ in quinoa is peripheral, surrounding the peri-sperm at the core and forming a ring-like structure beneath the bran layer (Prego et al. 1998). While quinoa is commonly consumed as a whole grain, there is enormous potential for the germ, the most nutritious part of the grain, to be used as an individual nutrient-dense component. While researchers worldwide are interested in exploring the nutritional and health benefits of this exceptional grain, one area that lacks extensive study is its processing for separation of different components. Germ separation from quinoa grain is challenging due to its very small, sometimes tiny, grain size. Due to the seed’s small size, even gentle pressure can pulverize it into a fine mass, making it difficult to differentiate the fractions. The grain’s complex structure makes it further difficult to achieve separation.

A Novel Process to the Rescue

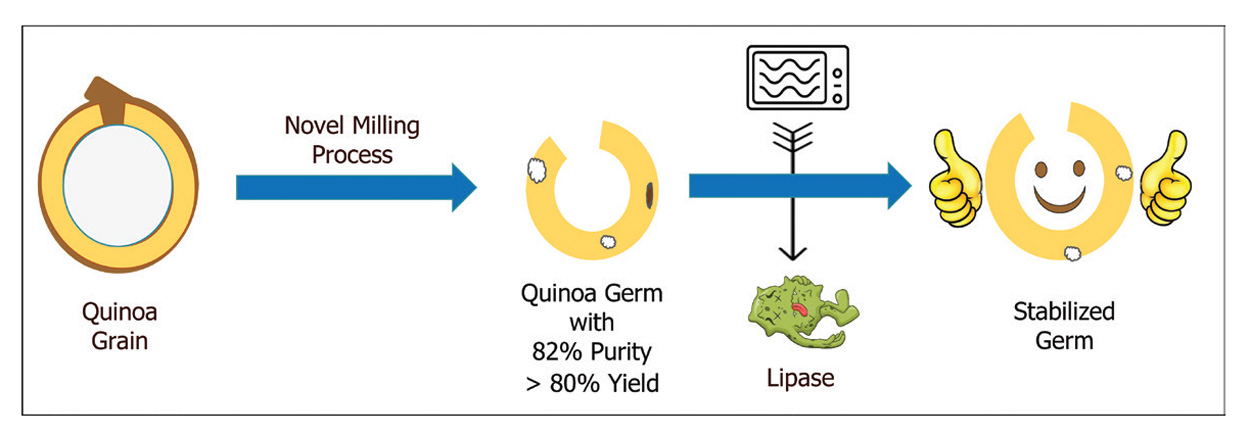

Unique physical characteristics are explored through gradual roller milling, a process known for its efficient fractionation of grain components based on their structures. A dry milling process has been developed that is industrially scalable and eco-friendly compared to the conventional wet method of milling, particularly for the separation of bran, germ, and perisperm from quinoa as potential functional ingredients in food (Ray et al. 2021).

This novel fractionation process involves conditioning quinoa grains, gradual dry milling, aspiration, and sieving operations. First, grains are cleaned to remove any foreign impurities, followed by a pretreatment to modify the physical properties of different components to facilitate clean separation during the process. Grain tempering or conditioning for a short period allows the bran to absorb moisture, rendering it leathery in texture and easier to separate. Simultaneously, the germ becomes pliable and the perisperm softens. These modifications aid in breaking open the grain while ensuring clean separation of its components. Tempering moisture content and time influence the extent of the physical modification of grain components and their separation during process. According to research, milling at medium moisture content (14%–16%) looks promising to achieve the clean separation of different components.

During the milling operation, germ separation from other components is performed in a gradual and controlled manner to achieve the higher purity and yield of fractions. At the first stage, the grain breaks down, releasing germ and perisperm from the outer bran. The second stage is used to remove the remaining perisperm sticking to the bran and germ. A high amount of pure germ is released during these two stages, while at third stage, perisperm is scraped to get cleaner bran. The released germ is further separated by sieving and aspiration.

Research findings show that this novel process enables quinoa germ separation with a recovery of more than 82% yield and purity. Germ produced by this process shows high protein (34.78%) and fat (21.62%) content, along with good mineral content (4.75%). In addition, the germ alone accounts for almost twice the protein and minerals and three times the fat as compared to the whole quinoa seed. The outer bran produced also doubles the amount of dietary fiber compared to the whole quinoa grain. In addition, the perisperm fraction recovered in the form of flour contains less than 1% mineral content with a higher color brightness value that is similar to wheat flour. Such characteristics of perisperm flour could find application in the development of bakery products.

What’s Next for Quinoa R&D?

Quinoa germ has the potential to be the functional ingredient elixir of this century. The prospects for its use are numerous due to its high nutritional quality coupled with its adaptability to growing in adverse environmental conditions. However, it is important to note that it will take time to research, fully realize, and explore the potential of this grain for future practical applications. But strides are being made and many technological innovations are rapidly being put forward by the food science and technology research community. For example, high fat content in the presence of lipase enzyme poses a great challenge for shelf stability of ingredients, including quinoa. New research has shown that a short period of microwave treatment addresses this challenge and favorably enhances the shelf life of quinoa germ (Ray et al. 2023).

As described here, the breakthrough dry milling process that can effectively separate nutrient-dense components of quinoa is another step forward in meeting the important challenge of germ separation. The technology is economically viable, making quinoa germ more commercially attractive to the food product development and pharmaceutical industries. Also, the process results in separated fractions of bran, germ, and perisperm that are highly specific in their nutritional composition and functionality, which promises opportunities for a wide range of varied practical applications in the food industry for product development. Ultimately, this innovation holds great promise to unlock the potential of quinoa as a valuable crop and functional food ingredient across the globe.

LEARNING OBJECTIVES

- Review the major nutritional, physiochemical, and functional components of quinoa.

- Understand the challenges of formulating quinoa into food products.

- Learn about a novel processing method developed to separate the nutrient-rich germ.